Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

20 viewsConstruction Estimating RCONSTRUCTION ESTIMATING REFERENCE DATA 5 METALS SECTIONeference Data 5 Metals Section PDF

Construction Estimating RCONSTRUCTION ESTIMATING REFERENCE DATA 5 METALS SECTIONeference Data 5 Metals Section PDF

Uploaded by

Muhammad Salman RaufCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Procurement & Supply Cycle: Gateway Review: Stop, Think, CheckDocument1 pageProcurement & Supply Cycle: Gateway Review: Stop, Think, CheckMuhammad Salman RaufNo ratings yet

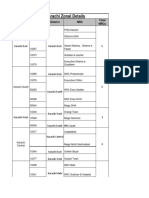

- RHO Karachi Zonal Details: Zone Loccode District NRC Total NrcsDocument3 pagesRHO Karachi Zonal Details: Zone Loccode District NRC Total NrcsMuhammad Salman RaufNo ratings yet

- Letter To Earnest Money HolderDocument1 pageLetter To Earnest Money HolderMuhammad Salman RaufNo ratings yet

- Procurement of Health Sector Goods: Trial EditionDocument26 pagesProcurement of Health Sector Goods: Trial EditionMuhammad Salman RaufNo ratings yet

- Dha Development of Dha City Karachi. M&C Dha Development of Dha City Karachi. M&CDocument1 pageDha Development of Dha City Karachi. M&C Dha Development of Dha City Karachi. M&CMuhammad Salman RaufNo ratings yet

- Application For The Purchase of Tender Document: Section V: Sample FormDocument1 pageApplication For The Purchase of Tender Document: Section V: Sample FormMuhammad Salman RaufNo ratings yet

- Activities For Plumbing Network PDFDocument2 pagesActivities For Plumbing Network PDFMuhammad Salman RaufNo ratings yet

- Development of Dha City Karachi. MC Classic WBS Layout Dec-18-16 05:00Document2 pagesDevelopment of Dha City Karachi. MC Classic WBS Layout Dec-18-16 05:00Muhammad Salman RaufNo ratings yet

- Dha Development of Dha City Karachi. Dha Development of Dha City KarachiDocument4 pagesDha Development of Dha City Karachi. Dha Development of Dha City KarachiMuhammad Salman RaufNo ratings yet

- Basf Masterseal 707st TdsDocument2 pagesBasf Masterseal 707st TdsMuhammad Salman RaufNo ratings yet

- Example Tender Package: Solar Heating Systems For Single Family HousesDocument19 pagesExample Tender Package: Solar Heating Systems For Single Family HousesMuhammad Salman RaufNo ratings yet

- Isl Hot Dipped Galvanized SteelpdfDocument16 pagesIsl Hot Dipped Galvanized SteelpdfMuhammad Salman Rauf100% (1)

- IC SEO Dashboard1Document11 pagesIC SEO Dashboard1Muhammad Salman RaufNo ratings yet

Construction Estimating RCONSTRUCTION ESTIMATING REFERENCE DATA 5 METALS SECTIONeference Data 5 Metals Section PDF

Construction Estimating RCONSTRUCTION ESTIMATING REFERENCE DATA 5 METALS SECTIONeference Data 5 Metals Section PDF

Uploaded by

Muhammad Salman Rauf0 ratings0% found this document useful (0 votes)

20 views12 pagesOriginal Title

297728543-Construction-Estimating-RCONSTRUCTION-ESTIMATING-REFERENCE-DATA-5-METALS-SECTIONeference-Data-5-Metals-Section.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

20 views12 pagesConstruction Estimating RCONSTRUCTION ESTIMATING REFERENCE DATA 5 METALS SECTIONeference Data 5 Metals Section PDF

Construction Estimating RCONSTRUCTION ESTIMATING REFERENCE DATA 5 METALS SECTIONeference Data 5 Metals Section PDF

Uploaded by

Muhammad Salman RaufCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 12

metals

section

contents

Structural Steel

Structural Stee! Fabrication

Structural Steel Erection

Steel Items.

Painting Erected Structural

Steel.

Specialized Painting on Stee!

and Iron

Structural Aluminum

Construction Casting

Expansion Joints .

Bird and Squirrel Screens

Wrought Iron , —

Open-Web Stee! Joists .

Metal Decking. .

Diaphragms.

Corrugated Metal Decking ....

Steel Stairs and Stairways

Floor Gratings. .... .

Steel Stair Rail -

Fire Escapes

124

124

- 125

126

~ 126

«126

127

127

127

127

. 127

128

~ 130

131

132

133

123

134

134

Structural Steel

Structural steel used in bullding construction is presently manufactured

‘in approximately thirteen different grades. Most steel structures use A36

Stee! which has a yield strength of 36,000 pounds per square inch. This

‘steel is duetile and can be either welded, Bolted, or cold-worked. ASTM

Aah stool hes teplaced AT and ANTE mooie aa wn allgurpoee carbon

sf

Where lighter members are required and local buckling or high deflection

are nol objectionable, the high-strength steels are an economical choice.

Most of the high-alloy steols ere weldable except steel manutactured

under ASTM Specification A440,

Welding electrodes are furnished either bare or coat

match the parent metal and weld process to be used.

Welding Society standard AWS D1.! lists the

rods used for each weld,

Processes and types of

High-strength oits for structural applications are furnished in two

Grades; ASTM 325 and ASTM 490, ASTM 490 boils offer one-third greater

shear capacity in friction-type connects. All high-strength baits require

Hghvatrengih nuts and hardened washers. Hloh-atrengih bots can be

‘distinguished from common mild-siee! bolts by three raised

Tadial nes on the bolt head 120 degrees apart, The nutp.are identified by

three circumferential lines 120. degrees apart. Hardened washers have no

identification markings, but can usually be identified by a scratch test.

‘Assembly of Structural Stee!

Most structural steo! is assembled with either bolted or welded connec:

tons. Both shop welding and field bolting can be used. improvements in

flekd-welding methods allow structural engineers to use field-weided

connections for major structures rather than high-strength bolts. Where

fiekd-welding is permitted for major connections and splices, sirict com-

pliance with project specifications is essential.

‘The practice of the majority of the structural engincors In far west states

[5 to detail all major connections in ihe project plans and specifications,

‘The fabricator merely prepares his shop drawings {rom the project plans

and bids the structural stes! accordingly. On the east coast and in the

midwest, many designers da not fully datall major connections. Far ex-

ample, on a truss design, a stress diagram with members adequately siz-

‘ed will be shown on the plans. The contractor must then hire a structural

engineer to furnish dasign calculations and datalls. This may cause

‘delays and differences in interpreting the intent of tha design. Where

project plans and specifications use contractorfurnished design, a

‘meeting between the owner's engineer, the contractor and the design

tngineer should be held immediately afterward to deta the atructual

st

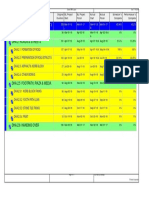

Labor for Structural Steel Fabrication

Man-Hours

Work Element Unit Per Unit

‘Structural frames: Ton

Columns Ton

Girders Ton

Beams Ton

‘Trusses ‘Ton

Purlins, girts and struts Ton

Frames for openings Ton

Cutting (gas) 100 LF.

Welding (arc) 100 LF.

Stairs Ton

Platforms Ton

Fabrication of structural steel includes cutting, riveting, burning,

Grilling, milting, fitti assembling, welding, bolting, storing,

loading, and hauting to the job si

Man-hour units are based on bolted connections. If sectians are to

be welded add 25% for welded joint preparation.

For multiple pass welds, use the total linear feet of all weld

passes.

Suggested Crew: two to six steel workers depending on the weight

and length of the materials,

Labor for Structural Ste

Work Element

Handling (unloading steel from truck to

‘ground location at erection site)

Erection of steel (erect, bolt, and plumb

only)"

Foundation work

Columns and struts

Beams and channels

ate girders

Crane rails

Knee braces

Floor plates

ittings bolts, rods, and anchor plates

Grits, angles, angle braces, purlins

Skylight frames and curbs

Monitor frames

Dormers

Door frames

Roof trusses

Transmission towers

Light stee! trest

‘Steel mill buildings

Steel frame multistoried buildings

‘Temporary bolting? (3 to 10 balts/ton)

Boiting, high-strength (15 to 30 high-

strength bolts/ten)

Riveting, air driven™

(On ground, easy work

Trusses

‘Steel office buildings

‘Stee! mill buildings

Light trestles and towers

Riveting, hand driven

Easy work

ifficult work

Welding* (5-10 feet of % weld/ton)

Ton

Ton

Ton

Ton

Ton

Ton

Ton

Ton

Ton

Ton

Ton

Ten

Ton

Ton

Ton

Ton

Ten

Ton

Ton

100 botts

100 bolts

100 rivers

100 rivets

100 rivets

100 rivets

100 rivets

100 rivets

100 rivets

100 LF.

a

Voveougnue

Notes for Structural Stee! Erection

* For steel erection in this table, the crew consists of one foreman,

‘one crane operator, and tour ironwarkers. Crew size can vary

considerably with each job:

?For bolting, the crew in this table consists of four bolters and one

helper.

The riveting crew size in this table Is five men: one helper, one

catcher, twa riveters, and one helper to handle air compressor

and hoses.

“Welding crew is two welders and one helper.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Procurement & Supply Cycle: Gateway Review: Stop, Think, CheckDocument1 pageProcurement & Supply Cycle: Gateway Review: Stop, Think, CheckMuhammad Salman RaufNo ratings yet

- RHO Karachi Zonal Details: Zone Loccode District NRC Total NrcsDocument3 pagesRHO Karachi Zonal Details: Zone Loccode District NRC Total NrcsMuhammad Salman RaufNo ratings yet

- Letter To Earnest Money HolderDocument1 pageLetter To Earnest Money HolderMuhammad Salman RaufNo ratings yet

- Procurement of Health Sector Goods: Trial EditionDocument26 pagesProcurement of Health Sector Goods: Trial EditionMuhammad Salman RaufNo ratings yet

- Dha Development of Dha City Karachi. M&C Dha Development of Dha City Karachi. M&CDocument1 pageDha Development of Dha City Karachi. M&C Dha Development of Dha City Karachi. M&CMuhammad Salman RaufNo ratings yet

- Application For The Purchase of Tender Document: Section V: Sample FormDocument1 pageApplication For The Purchase of Tender Document: Section V: Sample FormMuhammad Salman RaufNo ratings yet

- Activities For Plumbing Network PDFDocument2 pagesActivities For Plumbing Network PDFMuhammad Salman RaufNo ratings yet

- Development of Dha City Karachi. MC Classic WBS Layout Dec-18-16 05:00Document2 pagesDevelopment of Dha City Karachi. MC Classic WBS Layout Dec-18-16 05:00Muhammad Salman RaufNo ratings yet

- Dha Development of Dha City Karachi. Dha Development of Dha City KarachiDocument4 pagesDha Development of Dha City Karachi. Dha Development of Dha City KarachiMuhammad Salman RaufNo ratings yet

- Basf Masterseal 707st TdsDocument2 pagesBasf Masterseal 707st TdsMuhammad Salman RaufNo ratings yet

- Example Tender Package: Solar Heating Systems For Single Family HousesDocument19 pagesExample Tender Package: Solar Heating Systems For Single Family HousesMuhammad Salman RaufNo ratings yet

- Isl Hot Dipped Galvanized SteelpdfDocument16 pagesIsl Hot Dipped Galvanized SteelpdfMuhammad Salman Rauf100% (1)

- IC SEO Dashboard1Document11 pagesIC SEO Dashboard1Muhammad Salman RaufNo ratings yet