Professional Documents

Culture Documents

Steel Studs Fabrication System 1

Steel Studs Fabrication System 1

Uploaded by

Canada Job DepotCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Studs Fabrication System 1

Steel Studs Fabrication System 1

Uploaded by

Canada Job DepotCopyright:

Available Formats

Truss Rollformers

ScotTruss combines next‐genera on rollforming technology, sophis cated ScotSteel design engineering so ware, and innova ve assembly

processes into one integrated solu on. ScotTruss is the most advanced and complete light gauge steel truss system available today. Each

rollformer is supplied with a powered decoiler, Sco sdale’s ScotRF ‐ Truss CNC so ware and powerful truss engineering so ware.

The Series 600 Rollformer is the heart of the ScotTruss. With state

Truss Rollformers

of the art ScotSteel design engineering so ware as the beginning

Models point for this remarkable truss system, ScotTruss brings you just‐in‐

RF6‐050 51mm high Patented Hat Profile me rollforming to revolu onise an industry.

RF6‐075 77mm high Patented Hat Profile

There is no scrap, or wasted mo on, the ScotTruss rollformer

RF6‐038 40mm open box sec on (for

produces truss components directly from the coil to assembly. All

webs)

func ons necessary are performed within the ScotTruss rollformer.

Standard Opera ons The computer controlled servo driven machine precisely rolls the

Cut‐Off Tool chord/web profile through 9 progressive sta ons. As the steel exits

Cope Punch the roll cage and enters the toolhead, the full power and efficiency

Notch Tool

of the ScotTruss equipment is realised. Five specific func ons are

Connec on Hole (2 sets)

hydraulically per‐formed within the toolhead and remove all but

Roller sta ons geared & driven

assembly from the equa on.

Computer Communica ons Elements are cut exactly to length, coped, notched and bolt holes

Ethernet punched producing components that are assembled into a finished

truss.

Power Supply

Voltage Three Phase 380 ‐ 400V U lising a patented profile that forms the truss chord and web as

Frequency, standard 50Hz well as the holes for the bolted connec on, ScotTruss equipment

Frequency, op onal 60Hz delivers an easy to operate, simple to adjust, low maintenance

solu on. Built on a rugged frame, this rollformer is at home in a

For full technical specifica ons and a comparison high volume fabrica on facility or on the job‐site, the choice is

chart, please review the document tled yours.

Systems Comparison Chart

SCOTTSDALE CONSTRUCTION SYSTEMS

Phone: +64 6 843 6276, 17 Cadbury Street, Onekawa, Napier 4110, New Zealand

Email: sales@scottsdalesteelframes.com www.scottsdalesteelframes.com

ScotTruss System ScotSteel Design

Engineering Software

Features

Powerful so ware creates the truss and

Fully Automa c Truss Produc on communicates directly with the Rollformer

so ware

No inventory or random lengths

No culling of materials

No cu ng

Integrated RF Software

No measuring ScotTruss so ware interprets all commands

No layout & drives the state‐of‐the‐art Rollformer,

providing all func ons to create complicated

No jigs required truss components ready for assembly

Virtually no scrap

Low produc on cost

From Coil to Fabrication

ScotTruss System Just in me Rollforming virtually

eliminates waste, requires no cu ng,

coping, punching or addi onal manual

Powerful engineering and layout labour

so ware

Integrated produc on so ware

Low cost, portable Rollformer

Powered automa c decoiler

On‐site machine commissioning and

operator training

Opera ons and technical manuals

High quality, high strength steel

One Way Truss Assembly

No jigs or layout tables required as the

truss can only go together one way, the

RIGHT way

The Industry Exclusive Bolted

Connection

The industry exclusive BOLTED CONNECTION drama cally

increases produc vity and eliminates any fastener concerns

that may occur with vibra on during delivery and installa on

SCOTTSDALE CONSTRUCTION SYSTEMS

Phone: +64 6 843 6276, 17 Cadbury Street, Onekawa, Napier 4110, New Zealand

Email: sales@scottsdalesteelframes.com www.scottsdalesteelframes.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- VMC Series Vertical Machining Centers: Operator'S ManualDocument176 pagesVMC Series Vertical Machining Centers: Operator'S Manualcafetux100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 902, 906, & 908 Compact Wheel Loader Electrical System: Machine Harness Connector and Component LocationsDocument2 pages902, 906, & 908 Compact Wheel Loader Electrical System: Machine Harness Connector and Component Locationsait mimouneNo ratings yet

- I Disagree - How These Two Words Are The Secret To Thinking Differently and Taking Control of Your Health by Patrick Flynn (2019)Document184 pagesI Disagree - How These Two Words Are The Secret To Thinking Differently and Taking Control of Your Health by Patrick Flynn (2019)Canada Job DepotNo ratings yet

- Monism: The MonistDocument1 pageMonism: The MonistCanada Job DepotNo ratings yet

- Quiet EgoDocument13 pagesQuiet EgoCanada Job DepotNo ratings yet

- Om (Disambiguation) Aum (Disambiguation)Document1 pageOm (Disambiguation) Aum (Disambiguation)Canada Job DepotNo ratings yet

- BrahmanDocument2 pagesBrahmanCanada Job DepotNo ratings yet

- Mantra: Om Shanti (Film) Mantra (Disambiguation)Document2 pagesMantra: Om Shanti (Film) Mantra (Disambiguation)Canada Job DepotNo ratings yet

- FCE First Certificate 001Document52 pagesFCE First Certificate 001Canada Job DepotNo ratings yet

- FCE First Certificate 001Document52 pagesFCE First Certificate 001Canada Job DepotNo ratings yet

- MemoryDocument21 pagesMemoryCanada Job DepotNo ratings yet

- Cambridge Preliminary English Test 004Document13 pagesCambridge Preliminary English Test 004Canada Job DepotNo ratings yet

- Cambridge Preliminary English Test 004Document13 pagesCambridge Preliminary English Test 004Canada Job DepotNo ratings yet

- Definitive Guide Robot Welding Torches v1.0Document50 pagesDefinitive Guide Robot Welding Torches v1.0AlexgriNo ratings yet

- Zeiss Erosion ModuleDocument13 pagesZeiss Erosion ModulepakhiddeyasNo ratings yet

- Operating Manual Parts List: 1500VMC (FANUC 0iMD)Document261 pagesOperating Manual Parts List: 1500VMC (FANUC 0iMD)apodsh100% (1)

- Generalbio2 StecDocument105 pagesGeneralbio2 StecJohn V. LabradorNo ratings yet

- Department of Education: Republic of The PhilippinesDocument3 pagesDepartment of Education: Republic of The PhilippinesRhenalyn Rose Obligar PasaholNo ratings yet

- Singer 291U1, U3Document46 pagesSinger 291U1, U3Datum VivelacriqueNo ratings yet

- Mathematics ECAT (Sir Nasim Zulfiqar) - 1Document134 pagesMathematics ECAT (Sir Nasim Zulfiqar) - 1AYESH qureshiNo ratings yet

- JNTUH R09 Percentage & Credits Calculator-1Document16 pagesJNTUH R09 Percentage & Credits Calculator-1msg2dpNo ratings yet

- Physics ProjectDocument8 pagesPhysics Projectmitra28shyamalNo ratings yet

- The Blessed TrinityDocument2 pagesThe Blessed TrinityPatNo ratings yet

- Manual Spare Parts DB540!72!07Document124 pagesManual Spare Parts DB540!72!07Gustavo CarvalhoNo ratings yet

- Brown Et Al. 2009 Tribolium A Model For Developmental and Pest BiologyDocument9 pagesBrown Et Al. 2009 Tribolium A Model For Developmental and Pest BiologyAneel Nizar AliNo ratings yet

- Crabs Hell Ms DsDocument1 pageCrabs Hell Ms DsRega Wahyu AnggrainiNo ratings yet

- Pathophysiology Cardiac ArrestDocument1 pagePathophysiology Cardiac ArrestPATHOSHOPPE100% (2)

- Banco Preguntas Prueba SaberDocument21 pagesBanco Preguntas Prueba SaberYulieth Valeria Sanchez CortesNo ratings yet

- Dialysis - Purpose, Types, Risks, and MoreDocument13 pagesDialysis - Purpose, Types, Risks, and MoreTino HelaNo ratings yet

- FarmMachineryEquipment I ManualDocument51 pagesFarmMachineryEquipment I ManualBea SmithNo ratings yet

- Texi Post DD ErsatzteillisteDocument52 pagesTexi Post DD ErsatzteillisteJozsef TomoriNo ratings yet

- Selwood EngineDocument5 pagesSelwood EngineramjoceNo ratings yet

- Carlos Xuma - Dating Dynamics - Getting Men More Success With Women (2005)Document47 pagesCarlos Xuma - Dating Dynamics - Getting Men More Success With Women (2005)Retaliator StrikesbackNo ratings yet

- Total Width of The ACP PanelDocument8 pagesTotal Width of The ACP PanelARYA100% (1)

- Msds UreaDocument5 pagesMsds UreaHunterlan Register FilanNo ratings yet

- Brenes 2006Document6 pagesBrenes 2006Alfonso CáceresNo ratings yet

- 33 1rv18cv119 Umar BashirDocument10 pages33 1rv18cv119 Umar BashirUMARNo ratings yet

- FINAL Ulster Combined Report From STONE 12-15Document104 pagesFINAL Ulster Combined Report From STONE 12-15Watershed PostNo ratings yet

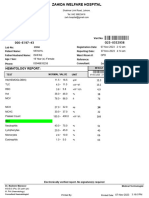

- Hematology Report:: MRN: Visit NoDocument1 pageHematology Report:: MRN: Visit Nojuniadsheikh6No ratings yet

- Case Study TPM Jet AirwaysDocument15 pagesCase Study TPM Jet AirwaysSanjay Domdiya100% (1)

- Blockk PDFDocument5 pagesBlockk PDFIsaias Bartolomeu SambgaNo ratings yet