Professional Documents

Culture Documents

Mhdp-08-Rsdll Report Issue 6.0

Mhdp-08-Rsdll Report Issue 6.0

Uploaded by

billCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mhdp-08-Rsdll Report Issue 6.0

Mhdp-08-Rsdll Report Issue 6.0

Uploaded by

billCopyright:

Available Formats

Document No: MHDP-08-R-01

Issue: 6.0

Date: 4th January 2017

Stage 1 & 2

Building Risk

Assessment

Report

Yanbu Distribution Hub

Prepared for:

Mustang-HDP

Prepared by:

© 2017 Risktec Solutions DMCC

This document has been prepared by Risktec Solutions DMCC.

Subject to any contractual terms between Risktec Solutions

DMCC and its client to the contrary, it is the property of Risktec

Solutions DMCC. It shall not be reproduced in whole or part, nor

Cleopatra Ong, Senior Engineer disclosed to a third party without the express written permission

of the owner. This document has been specifically prepared for

Reviewed by: the client of Risktec Solutions DMCC and no responsibility to third

parties is accepted unless expressly agreed in writing.

Office 3004 Liwa Heights

Jumeirah Lakes Towers

PO Box 450113

Sophia Chua, Senior Engineer Dubai

Approved by: United Arab Emirates

www.risktec.com

Mike Bates, Principal Consultant

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

EXECUTIVE SUMMARY

The purpose of the Yanbu Distribution Hub (YDH) Project (which is currently in the design stage) is to efficiently

meet the Kingdom’s refined product demands in Makkah province. The YDH will aggregate refined product from

the three local refineries (SAMREF, YASREF and Yanbu) and act as the origin pump station for at least two

connecting pipelines, i.e. the Yanbu to Jiddah pipeline and the Yanbu to Central Region pipeline.

Mustang-HDP (MHDP) is currently undertaking the YDH Project (BI-10-02399) for Saudi Aramco. MHDP has

contracted Risktec Solutions DMCC (Risktec) to conduct a Stage 1 and 2 Building Risk Assessment (BRA) for YDH

(including associated pipelines).

This report presents the results of the Stage 1 and Stage 2 BRA, whereby the worst case credible hazard

consequences (fire, explosion, and flammable vapour clouds) are identified, and their impact on plant buildings

evaluated.

Stage 1 BRA Results Summary

A total of 9 buildings have been assessed as occupied, and 5 buildings have been assessed as functionally

significant.

Stage 2 BRA Results Summary

Jet Fire

The following buildings will be subjected to direct flame impingement and exposed to heat radiation flux above

35kW/m2:

B-01 SS-XXX1 Receiving Substation Transformer Yard (the maximum heat radiation flux is calculated as

171kW/m2);

B-02 SS-XXX2 Utility Power Substation Transformer Yard (the maximum heat radiation flux is calculated

as 142kW/m2);

B-04 RIB-XXX2 Remote I/O Building (the maximum heat radiation flux is calculated as 154kW/m2);

B-15 Operation Shelter-1 (the maximum heat radiation flux is calculated as 138kW/m2);

B-20 Custody Metering Shelter (Vendor Package) (the maximum heat radiation flux is calculated as

240kW/m2; and

B-22 Operation Shelter-2 (the maximum heat radiation flux is calculated as 137kW/m2);

Although the jet fires will not impinge the B-03 RIB XXX1 Remote I/O Building, it is potentially exposed to heat

radiation flux above 35kW/m2 (the maximum heat radiation flux is calculated as 98kW/m2). The B-21 Oily Water

Metering Shelter -Marafiq is potentially exposed to heat radiation flux between 12.5kW/m2 and 35kW/m2 due to

YNJ-1 scraper launcher.

All other buildings are potentially exposed to heat radiation flux below 4.7kW/m2.

Pool Fire

The B-20 Custody Metering Shelter (Vendor Package) is potentially exposed to heat radiation flux between

12.5kW/m2 and 35kW/m2 due to release from SAM-30 and YR-22 pipelines.

The B-21 Oily Water Metering Shelter -Marafiq) is potentially exposed to heat radiation flux between 12.5kW/m2

and 35kW/m2 due to release from the YNJ-2 pipeline.

The B-22 Operation Shelter-2 is potentially exposed to heat radiation flux between 12.5kW/m2 and 35kW/m2 due

to release from YNJ-1 and YNJ-2 pipelines.

The following buildings will be subjected to heat radiation flux between 4.7kW/m2 and 12.5kW/m2 due to bund

fires within the Yanbu Distribution Hub:

B-01 SS-XXX1 Receiving Substation Transformer Yard;

B-02 SS-XXX2 Utility Power Substation Transformer Yard;

B-03 RIB-XXX1 Remote I/O Building;

Risktec Solutions DMCC Page 2 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

B-04 RIB-XXX2 Remote I/O Building;

B-07 Security Guard House (B);

B-08 X-Ray Building;

B-10 Security Support Building (B);

B-12 Operation Building;

B-16 IDAS Shelter-001; and

B-17 IDAS Shelter-002.

Flammable Vapour Dispersion

The flammable vapour dispersions will reach all of the buildings being assessed. All building assessed are exposed

to flammable vapour concentrations above ½ LFL with the exception of the following which are exposed to

flammable vapour concentrations below ½ LFL:

B-05 FSF Building;

B-06 Security Guard House (A);

B-09 Security Support Building (A);

B-21 Sanitary Metering Shelter – Marafiq; and

B-19 Utility Water Metering Shelter – Marafiq.

Therefore, a flammable atmosphere could be expected in each building.

Vapour Cloud Explosions (VCE)

All buildings are only expected to suffer minor damage, which is below the SAES-B-014 damage criteria, and no

further assessment is required.

Recommendations

Building Specific Recommendations

Based on the Stage 2 BRA results summary, building specific risk mitigation measures have been developed for

each building and are presented in Table 1.

Table 1: Proposed Building Specific Risk Mitigation Measures

Occupied/

Name of Functionally

Proposed Risk Mitigation Measures

Building Significant

Building

Review functionality of the building. Based on review of potential business

interruption impact, consider rating the external walls to withstand direct

jet fire flame impingement (the maximum heat radiation flux is calculated

as 171kW/m2).

B-01 SS-XXX1 Also, consider relocating the building outside the flame impingement

Receiving radius of 121m from the Scraper-YNJ-1 (G) (for the scenario description

Functionally

Substation refer to Assumption A03, Appendix A).

Significant

Transformer

Yard Note: Further risk mitigation measures may not be required if the impact

of losing the buildings function does not have a catastrophic impact on

the continued operation of the plant.

Hydrocarbon gas detectors should be installed at the building to provide an

audible and visual alarm.

Risktec Solutions DMCC Page 3 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

Occupied/

Name of Functionally

Proposed Risk Mitigation Measures

Building Significant

Building

Review functionality of the building. Based on review of potential business

interruption impact, consider rating the external walls to withstand direct

jet fire flame impingement (the maximum heat radiation flux is calculated

as 142kW/m2).

B-02 SS-XXX2

Utility Power Also, consider relocating the building outside the flame impingement radius

Functionally of 60m from the PG 95 Storage Tanks outlet header.

Substation

Significant

Transformer Note: Further risk mitigation measures may not be required if the impact of

Yard losing the buildings function does not have a catastrophic impact on the

continued operation of the plant.

Hydrocarbon gas detectors should be installed at the building to provide an

audible and visual alarm.

B-03 RIB-XXX1

Functionally Hydrocarbon gas detectors should be installed at the building to provide an

Remote I/O

Significant audible and visual alarm.

Building

B-04 RIB-XXX2

Functionally Hydrocarbon gas detectors should be installed at the building to provide an

Remote I/O

Significant audible and visual alarm.

Building

If building occupants are required to stay in the building in the event of an

incident on the plant, hydrocarbon gas detectors should be installed in

HVAC inlets, which automatically shutdown the HVAC system (close the fire

dampers and put the HVAC system into re-circulation mode). Hydrocarbon

gas detectors should initiate an audible and visual alarm and all external

B-05 FSF doors should be fitted with gas-tight seals and equipped with quick acting,

Occupied adjustable door closing mechanism. Windows should be eliminated,

Building

minimised or designed to prevent flammable gas ingress. The HVAC system

installed should comply with the requirements of SAES-K-022.

If building occupants are not required to stay in the building in the event of

an incident on the plant, hydrocarbon gas detectors should be installed at

the building to provide an audible and visual alarm.

If building occupants are required to stay in the building in the event of an

incident on the plant, hydrocarbon gas detectors should be installed in

HVAC inlets, which automatically shutdown the HVAC system (close the fire

dampers and put the HVAC system into re-circulation mode). Hydrocarbon

gas detectors should initiate an audible and visual alarm and all external

B-06 Security doors should be fitted with gas-tight seals and equipped with quick acting,

Guard House Occupied adjustable door closing mechanism. Windows should be eliminated,

(A) minimised or designed to prevent flammable gas ingress. The HVAC system

installed should comply with the requirements of SAES-K-022.

If building occupants are not required to stay in the building in the event of

an incident on the plant, hydrocarbon gas detectors should be installed at

the building to provide an audible and visual alarm.

Risktec Solutions DMCC Page 4 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

Occupied/

Name of Functionally

Proposed Risk Mitigation Measures

Building Significant

Building

Ensure that emergency escape and evacuation procedures for the building

consider potential sources of thermal radiation, ensuring escape routes and

mustering areas are outside the >4.7kW/m2 thermal radiation zone.

If building occupants are required to stay in the building in the event of an

incident on the plant, hydrocarbon gas detectors should be installed in

HVAC inlets, which automatically shutdown the HVAC system (close the fire

B-07 Security dampers and put the HVAC system into re-circulation mode). Hydrocarbon

Guard House Occupied gas detectors should initiate an audible and visual alarm and all external

(B) doors should be fitted with gas-tight seals and equipped with quick acting,

adjustable door closing mechanism. Windows should be eliminated,

minimised or designed to prevent flammable gas ingress. The HVAC system

installed should comply with the requirements of SAES-K-022.

If building occupants are not required to stay in the building in the event of

an incident on the plant, hydrocarbon gas detectors should be installed at

the building to provide an audible and visual alarm.

B-08 X-Ray Functionally Hydrocarbon gas detectors should be installed at the building to provide an

Building Significant note audible and visual alarm.

If building occupants are required to stay in the building in the event of an

incident on the plant, hydrocarbon gas detectors should be installed in

HVAC inlets, which automatically shutdown the HVAC system (close the fire

dampers and put the HVAC system into re-circulation mode). Hydrocarbon

gas detectors should initiate an audible and visual alarm and all external

B-09 Security doors should be fitted with gas-tight seals and equipped with quick acting,

Support Building Occupied adjustable door closing mechanism. Windows should be eliminated,

(A) minimised or designed to prevent flammable gas ingress. The HVAC system

installed should comply with the requirements of SAES-K-022.

If building occupants are not required to stay in the building in the event

of an incident on the plant, hydrocarbon gas detectors should be installed

at the building to provide an audible and visual alarm.

Ensure that emergency escape and evacuation procedures for the building

consider potential sources of thermal radiation, ensuring escape routes and

mustering areas are outside the >4.7kW/m2 thermal radiation zone.

If building occupants are required to stay in the building in the event of an

incident on the plant, hydrocarbon gas detectors should be installed in

HVAC inlets, which automatically shutdown the HVAC system (close the fire

B-10 Security dampers and put the HVAC system into re-circulation mode). Hydrocarbon

Support Building Occupied gas detectors should initiate an audible and visual alarm and all external

(B) doors should be fitted with gas-tight seals and equipped with quick acting,

adjustable door closing mechanism. Windows should be eliminated,

minimised or designed to prevent flammable gas ingress. The HVAC system

installed should comply with the requirements of SAES-K-022.

If building occupants are not required to stay in the building in the event

of an incident on the plant, hydrocarbon gas detectors should be installed

at the building to provide an audible and visual alarm.

Risktec Solutions DMCC Page 5 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

Occupied/

Name of Functionally

Proposed Risk Mitigation Measures

Building Significant

Building

If building occupants are required to stay in the building in the event of an

incident on the plant, hydrocarbon gas detectors should be installed in

HVAC inlets, which automatically shutdown the HVAC system (close the fire

dampers and put the HVAC system into re-circulation mode). Hydrocarbon

gas detectors should initiate an audible and visual alarm and all external

B-11 OME doors should be fitted with gas-tight seals and equipped with quick acting,

Occupied adjustable door closing mechanism. Windows should be eliminated,

Building

minimised or designed to prevent flammable gas ingress. The HVAC system

installed should comply with the requirements of SAES-K-022.

If building occupants are not required to stay in the building in the event of

an incident on the plant, hydrocarbon gas detectors should be installed at

the building to provide an audible and visual alarm.

Ensure that emergency escape and evacuation procedures for the building

consider potential sources of thermal radiation, ensuring escape routes and

mustering areas are outside the >4.7kW/m2 thermal radiation zone.

If building occupants are required to stay in the building in the event of an

incident on the plant, hydrocarbon gas detectors should be installed in

HVAC inlets, which automatically shutdown the HVAC system (close the fire

dampers and put the HVAC system into re-circulation mode). Hydrocarbon

B-12 Operation

Occupied gas detectors should initiate an audible and visual alarm and all external

Building

doors should be fitted with gas-tight seals and equipped with quick acting,

adjustable door closing mechanism. Windows should be eliminated,

minimised or designed to prevent flammable gas ingress. The HVAC system

installed should comply with the requirements of SAES-K-022.

If building occupants are not required to stay in the building in the event of

an incident on the plant, hydrocarbon gas detectors should be installed at

the building to provide an audible and visual alarm.

If building occupants are required to stay in the building in the event of an

incident on the plant, hydrocarbon gas detectors should be installed in

HVAC inlets, which automatically shutdown the HVAC system (close the fire

dampers and put the HVAC system into re-circulation mode). Hydrocarbon

gas detectors should initiate an audible and visual alarm and all external

doors should be fitted with gas-tight seals and equipped with quick acting,

B-13 Musalla Occupied adjustable door closing mechanism. Windows should be eliminated,

minimised or designed to prevent flammable gas ingress. The HVAC system

installed should comply with the requirements of SAES-K-022.

If building occupants are not required to stay in the building in the event

of an incident on the plant, hydrocarbon gas detectors should be installed

at the building to provide an audible and visual alarm.

B-14 Chemical Functionally Hydrocarbon gas detectors should be installed at the building to provide

Shelter Significant note an audible and visual alarm.

Risktec Solutions DMCC Page 6 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

Occupied/

Name of Functionally

Proposed Risk Mitigation Measures

Building Significant

Building

Ensure that emergency escape and evacuation procedures for the building

consider potential sources of thermal radiation, ensuring escape routes and

mustering areas are outside the >4.7kW/m2 thermal radiation zone.

If building occupants are required to stay in the building in the event of an

incident on the plant, hydrocarbon gas detectors should be installed in

HVAC inlets, which automatically shutdown the HVAC system (close the fire

dampers and put the HVAC system into re-circulation mode). Hydrocarbon

B-15 Operation

Occupied gas detectors should initiate an audible and visual alarm and all external

Shelter-1

doors should be fitted with gas-tight seals and equipped with quick acting,

adjustable door closing mechanism. Windows should be eliminated,

minimised or designed to prevent flammable gas ingress. The HVAC system

installed should comply with the requirements of SAES-K-022.

If building occupants are not required to stay in the building in the event of

an incident on the plant, hydrocarbon gas detectors should be installed at

the building to provide an audible and visual alarm.

B-16 IDAS Functionally Hydrocarbon gas detectors should be installed at the building to provide an

Shelter-001 Significant note audible and visual alarm.

B-17 IDAS Functionally Hydrocarbon gas detectors should be installed at the building to provide an

Shelter-002 Significant note audible and visual alarm.

B-18 Sanitary

Functionally Hydrocarbon gas detectors should be installed at the building to provide an

Metering

Significant note audible and visual alarm.

Shelter-Marafiq

B-19 Utility

Functionally Hydrocarbon gas detectors should be installed at the building to provide an

Water Metering

Significant audible and visual alarm.

Shelter-Marafiq

The functionality of the building should be reviewed and the impact of losing

the function of the building determined. If loss of the building function can

have catastrophic impact on continued safe operation of the facility, the

following risk reduction measures should be considered.

Either design the external walls of the building to withstand direct jet fire

flame impingement (the maximum heat radiation flux is calculated as

240kW/m2) or relocate the building outside the flame impingement radius

B-20 Custody

of:

Metering Shelter Functionally

(Vendor Significant note 184m from the Gasoline Custody Metering Skid (X40-U-0014A);

Package) 170m from the Gasoline Meter Prover Skid (X40-U-0014D);

213m from the from gasoline receiving manifold outlet headers

(for PG 91 and PG 95); and

30m from the diesel pipelines from Yasref/Samref and gasoline

pipeline from Yasref.

Hydrocarbon gas detectors should be installed at the building to provide

an audible and visual alarm.

B-21 Oily Water

Functionally Hydrocarbon gas detectors should be installed at the building to provide an

Metering Shelter

Significant note audible and visual alarm.

-Marafiq

Risktec Solutions DMCC Page 7 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

Occupied/

Name of Functionally

Proposed Risk Mitigation Measures

Building Significant

Building

Ensure that emergency escape and evacuation procedures for the building

consider potential sources of thermal radiation, ensuring escape routes and

mustering areas are outside the >4.7kW/m2 thermal radiation zone.

If building occupants are required to stay in the building in the event of an

incident on the plant, hydrocarbon gas detectors should be installed in

HVAC inlets, which automatically shutdown the HVAC system (close the fire

dampers and put the HVAC system into re-circulation mode). Hydrocarbon

B-22 Operation

Occupied gas detectors should initiate an audible and visual alarm and all external

Shelter-2

doors should be fitted with gas-tight seals and equipped with quick acting,

adjustable door closing mechanism. Windows should be eliminated,

minimised or designed to prevent flammable gas ingress. The HVAC system

installed should comply with the requirements of SAES-K-022.

If building occupants are not required to stay in the building in the event of

an incident on the plant, hydrocarbon gas detectors should be installed at

the building to provide an audible and visual alarm.

Note: The B-03 RIB-XXX1 Remote I/O Building, B-04 RIB-XXX2 Remote I/O Building, B-08 X-Ray Building, B-14 Chemical Shelter,

B-16 IDAS Shelter-001, B-17 IDAS Shelter-002, B-18 Sanitary Metering Shelter-Marafiq, B-20 Custody Metering Shelter (Vendor

Package) and B-21 Oily Water Metering Shelter -Marafiq are not occupied nor functionally significant as per the requirement of

SAES-B-014. These buildings have been included for completeness and are assessed under the functional building criteria.

General Recommendations

As well as the building specific mitigation measures detailed in Table 1, the following general mitigation measures

should be considered:

All buildings in YDH should comply with the requirements of SAES-B-055 for spacing between buildings,

and process plant, and with SAES-B-014 for fire and water system requirements. In addition, all buildings

covered by SSD-9 and SSD-26 must comply with the requirements of these directives.

It is generally recommended, in process industries, that in-plant buildings do not have windows. This is

supported by SAES-B-014. However, Clause 5.8, Exception B of SAES-B-014 states that windows are

allowed for ‘Operator shelters that are specifically designed for personnel protection and for monitoring of

a process facility or bulk plant operation such as truck loading. Personnel protection against any

overpressures anticipated by the risk assessment shall be included in the sizing and design of the windows’.

SAES-B-014 also states that as a minimum, these windows should be double glazed with tempered glass,

internal lamination, a catch system for the glass using anchored cables or wrap bars. The glass used in

the windows will be a minimum of 6 mm (¼ in) thick and is either wired, tempered or laminated safety

glass. The glass shall meet all fire-resistive regulations and safety performance requirements of SAES-M-

100 and ASME Z97.1 and shall be labelled as such by the supplier.

Should the design of these buildings contain windows, the design details shall be provided to the company

representative for approval by the Supervisor, Civil Engineering Unit, Consulting Services Department

(CSD), Dhahran, and by the Chief Fire Prevention Engineer or his representative.

A qualified structural engineer should review the estimated VCE overpressures and impulses and ensure

that the building is designed to withstand the predicted results.

The site ERP should include any of the new buildings which are designed to act as safe refuges in the

event of an emergency. Additional potential risk mitigation measures may be required for these buildings.

Additionally, the site ERP, drills and escape routes should take into account the identified fire hazard

scenarios on each building.

Where adequate mitigations cannot be implemented, or where the cost of the mitigations is deemed

excessive, a Stage 3 BRA should be conducted to determine the risk to personnel and building functionality.

Risktec Solutions DMCC Page 8 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

The escape arrangements (e.g. escape route, access, egress) for the following buildings could be

(depending on the direction of the release) impaired by jet/pool fire events from one or more hazard

sources:

o B-01 SS-XXX1 Receiving Substation Transformer Yard;

o B-02 SS-XXX2 Utility Power Substation Transformer Yard;

o B-03 RIB-XXX1 Remote I/O Building;

o B-04 RIB-XXX2 Remote I/O Building; and

o B-20 Custody Metering Shelter (Vendor Package).

It is recommended that a formal Escape, Evacuation and Rescue Assessment (EERA) is performed and

further risk mitigation measures identified (if required).

Risktec Solutions DMCC Page 9 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

ISSUE RECORD

Issue Date Author Reviewer Approver Revision History

Initials Initials Initials

1.0 12-Jun-16 CO MJB MJB Draft Report for Review and Approval

2.0 26-Jun-16 CO MJB MJB Draft Report updated for Review and Approval

3.0 07-Jul-16 CO MJB MJB Report issued incorporating client comments

4.0 06-Sep-16 AA MJB MJB Report issued incorporating client comments

5.0 25-Oct-16 AA MJB MJB Report issued incorporating client comments

6.0 04-Jan-17 CO SC MJB Final report incorporating client comments

DISTRIBUTION

Ahmed AlHatem Mustang-HDP, Saudi Arabia

File Risktec Solutions Limited, Dubai, UAE

Risktec Solutions DMCC Page 10 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

CONTENTS

EXECUTIVE SUMMARY................................................................................................................................ 2

ISSUE RECORD ......................................................................................................................................... 10

DISTRIBUTION ......................................................................................................................................... 10

1 INTRODUCTION ...................................................................................................................... 13

1.1 Overview .......................................................................................................................................................... 13

1.2 Objectives ........................................................................................................................................................ 13

1.3 Scope .............................................................................................................................................................. 13

2 FACILITY OVERVIEW .............................................................................................................. 14

2.1 General ............................................................................................................................................................ 14

3 BRA METHODOLOGY ............................................................................................................... 15

3.1 Approach to Building Risk Assessment ............................................................................................................... 15

3.2 Stage 2 BRA Consequence Modelling ................................................................................................................. 16

3.3 Jet Fire ............................................................................................................................................................ 17

3.4 Pool Fire (including Bund Fire) ........................................................................................................................... 17

3.5 Tank Fires ........................................................................................................................................................ 17

3.6 Flammable Dispersion ....................................................................................................................................... 17

3.7 Building Types .................................................................................................................................................. 18

3.8 Damage Level Thresholds ................................................................................................................................. 18

4 STAGE 1 BRA ........................................................................................................................... 21

5 STAGE 2 BRA ........................................................................................................................... 23

5.1 Consequence Analysis ....................................................................................................................................... 23

5.2 Separation Distances......................................................................................................................................... 23

5.3 Stage 2 BRA Results ......................................................................................................................................... 23

6 CONCLUSIONS ........................................................................................................................ 31

6.1 Stage 1 BRA ..................................................................................................................................................... 31

6.2 Stage 2 BRA ..................................................................................................................................................... 31

7 RECOMMENDATIONS .............................................................................................................. 33

7.1 Building Specific Recommendations ................................................................................................................... 33

7.2 General Recommendations ................................................................................................................................ 38

8 REFERENCES ........................................................................................................................... 39

APPENDIX A ASSUMPTIONS REGISTER ................................................................................................ A.1

APPENDIX B SEPARATION DISTANCES ..................................................................................................B.1

APPENDIX C CONSEQUENCE RESULTS ................................................................................................. C.1

APPENDIX D STAGE 2 BRA RESULTS .................................................................................................... D.1

APPENDIX E STAGE 1 SCREENING ........................................................................................................ E.1

Risktec Solutions DMCC Page 11 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

TABLES

Table 1: Proposed Building Specific Risk Mitigation Measures ............................................................................................. 3

Table 2: Building Types .................................................................................................................................................. 18

Table 3: Thermal Radiation Damage ............................................................................................................................... 18

Table 4: Flammable Vapour Damage............................................................................................................................... 19

Table 5: Explosion Overpressure Damage........................................................................................................................ 19

Table 6: Building Damage Categories .............................................................................................................................. 19

Table 7: Stage 1 BRA Results Summary .......................................................................................................................... 21

Table 8: Stage 2 BRA Results Summary .......................................................................................................................... 24

Table 9: Hazard Source for Building Impairment Exceeding Assessment Criteria ................................................................ 26

Table 10: Proposed Building Specific Risk Mitigation Measures .......................................................................................... 33

FIGURES

Figure 1: Yanbu Distribution Hub Plot Plan & Building Locations ....................................................................................... 14

Figure 2: BRA Methodology ............................................................................................................................................ 15

Risktec Solutions DMCC Page 12 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

1 INTRODUCTION

1.1 Overview

The purpose of the Yanbu Distribution Hub (YDH) Project (which is currently in the design stage) is to

efficiently meet the Kingdom’s refined product demands in Makkah province. The YDH will aggregate

refined product from the three local refineries (SAMREF, YASREF and Yanbu) and act as the origin pump

station for at least two connecting pipelines, i.e. the Yanbu to Jiddah pipeline and the Yanbu to Central

Region pipeline.

Mustang-HDP (MHDP) is currently undertaking the YDH Project (BI-10-02399) for Saudi Aramco. MHDP

has contracted Risktec Solutions DMCC (Risktec) to conduct a Stage 1 and 2 Building Risk Assessment

(BRA) for YDH (including associated pipelines).

The BRA is implemented in accordance with the Saudi Aramco Engineering Standard, SAES-B-014

(Reference 1) and the American Petroleum Institute guidance document, API RP 752 (Reference 2). The

BRA provides information on the risks to personnel located inside plant buildings and building functionality

and identifies potential risk mitigation measures to ensure these risks are reduced to a level which can be

considered As Low As Reasonably Practicable (ALARP).

This report presents the results of the Stage 1 and Stage 2 BRA, whereby the worst case credible hazard

consequences (fire, explosion, and flammable vapour clouds) are identified, and their impact on plant

buildings evaluated.

Recommendations are made for those buildings where the consequences exceed the assessment criteria.

However, where the potential worst credible impact to building occupants and/or functionality cannot be

mitigated / protected against, a recommendation is made to consider the hazards and buildings in more

detail as part of a Stage 3 BRA, which is outside of the scope of this report.

1.2 Objectives

The objectives of the BRA are to:

Identify the various hazard sources and associated sources within the YDH (including associated

pipelines) through a desktop Hazard Identification (HAZID);

Carry out consequence modelling using Shell FRED software package v6.1 to determine the extent of

the different hazards identified;

Evaluate the impact of the different hazards on the occupancy and structure of the buildings;

Where the impacts on the buildings are outside the Saudi Aramco tolerability criteria, recommend

mitigation measures to reduce the impact of the different hazards on the buildings to an acceptable

level; and

Document the results of Stage 1 and Stage 2 BRA.

1.3 Scope

The scope for the YDH BRA is limited to the following:

Yanbu Distribution Hub (YDH) facility;

Yanbu to Jiddah pipeline up to 200m from the YDH fence;

Yanbu to Central Region pipeline up to 200m from the YDH fence; and

Tie-ins to existing refineries up to 200m from the YDH fence (SAMREF, YASREF and Yanbu refineries).

The YDH BRA will exclude the following:

On-site facilities at SAMREF, YASREF and Yanbu refineries;

Refinery tie-in pipelines outside of 200m from the YDH fence; and

Export pipelines outside of 200m from the YDH fence.

Risktec Solutions DMCC Page 13 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

2 FACILITY OVERVIEW

2.1 General

The YDH is located near the city of Yanbu on the coast of the Red Sea in the Western Province of Saudi

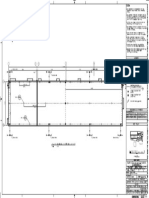

Arabia. The overall plot plan, showing the buildings to be assessed, is presented in Figure 1.

Figure 1: Yanbu Distribution Hub Plot Plan & Building Locations

Risktec Solutions DMCC Page 14 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

3 BRA METHODOLOGY

3.1 Approach to Building Risk Assessment

The BRA has been conducted in accordance with Saudi Aramco Engineering Standard SAES-B-014 ‘Safety

Requirements for Plant Operations and Support Buildings’ (Reference 1), which requires a systematic 3-

stage approach. This approach is illustrated in Figure 2.

Figure 2: BRA Methodology

SAES-B-014 requires an assessment of the hazards associated with the siting, design and construction of

buildings for each of the three stages shown in Figure 2. Each stage represents an increasingly detailed

level of analysis to define the minimum requirements for siting, design and construction for the following

buildings:

Onshore in-plant buildings;

Out-of-plant (offsite) buildings within 500 m of a plant perimeter fence; and

Service buildings, whether inside or outside of plants, that directly support in-plant operations such

as; communications facilities, centralized computer facilities and electrical substations.

The intent of the assessment process is to screen out buildings at the earliest stage in order to provide an

efficient, yet comprehensive, analysis with the main objective of ensuring that people in plant buildings

are not exposed to unacceptable levels of risk in the event of any accidental release of hydrocarbons,

which would commonly require emergency response.

3.1.1 Stage 1 BRA – Building Occupancy & Functionality Identification

In the Stage 1 BRA, the building is assessed in terms of occupancy and functionality. Buildings considered

to be occupied and/or functionally significant are identified at this stage for consideration in the Stage 2

BRA.

Risktec Solutions DMCC Page 15 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

3.1.1.1 Occupancy Screening

As per SAES-B-014 (Reference 1, Section A.4.1.1), a building is considered to be occupied, for the purposes

of occupancy screening, if:

the building occupancy load is 300 or more man-hours per week; or

during peak occupancy, 5 people or more are routinely expected in the building for at least one hour.

3.1.1.2 Functionality Screening

As per SAES-B-014 (Reference 1, Section A.4.1.2), a building is defined as functionally significant, if:

people are expected to remain or take refuge in the building during an emergency. Possible reasons

for people to remain in a building include a lack of suitable evacuation options or the need for

occupants to perform emergency shutdown procedures;

the building is required for emergency response, such as fire stations or clinic; or

the building is necessary for continued operation or the safe shutdown of plant units that may be able

to continue to operate or may be unaffected by an incident in another area or the economic impact

on operation of loss of the building is significant. This includes operations and control centre, or

substations that control or provide power to multiple process units.

3.1.2 Stage 2 BRA – Building Hazard Evaluation

In Stage 2 of the BRA process, all buildings carried forward from Stage 1 are assessed against the worst

case credible consequences of fire, explosions and flammable vapour releases to determine the potential

impact on the buildings considered. This includes assessment of the potential harm to a building’s

occupants and/or the potential loss of a building’s functionality.

Hazards are selected based on the results of a desktop HAZID study, conducted to define the discrete

accident scenarios that could results in fire, explosion, or flammable vapour hazards.

The outcome of the Stage 2 BRA is to identify which buildings suffer harm above the tolerability criteria

defined by Saudi Aramco and to provide mitigation measures which can be put in place to reduce the

consequence to the buildings. If the mitigation measures identified are cost prohibitive then the buildings

will require further assessment in a Stage 3 BRA, which is outside of the scope of this report.

3.1.3 Stage 3 BRA – Risk Management

Based on the assessment of buildings, the frequency and consequences of the discrete accident scenarios

defined from the hazard sources are evaluated to quantitatively determine the risk to building occupants

and functionality.

The stage of the BRA can be used to focus consideration of remedial optioneering, to further prevent or

mitigate the hazards defined.

Stage 3 BRA of the BRA process is outside of the scope of this report, and therefore, excluded from the

study.

3.2 Stage 2 BRA Consequence Modelling

Consequence analysis was conducted using Shell’s FRED software v.67 and DNV Phast v6.7 (Reference 3).

The modelling assumptions are presented in Appendix A. The consequence analysis considered the

following events:

Jet Fire: High momentum fires resulting from pressurised flammable vapour or liquid jet fire from

liquid release due to flashing;

Pool Fire: Fires resulting from the delayed ignition of a pool of hydrocarbon liquid formed after the

release;

Tank Top Fires: Fires resulting from the ignition of a pool of hydrocarbon liquid at the top of a tank;

Flammable Dispersion: The release of flammable vapours measured to hazardous concentrations (i.e.

¼ of the Lower Flammable Limit (LFL) and ½ LFL) will result in a flammable cloud being formed. The

Risktec Solutions DMCC Page 16 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

flammable cloud by itself does not pose any significant threat, however, if the cloud finds an ignition

source then this can lead to either of the following consequences:

- Flash Fire: A slow deflagration of a vapour cloud with no overpressure effects; and

- Vapour Cloud Explosion (VCE): Explosion resulting from the late ignition of flammable vapour

contained within an area of congestion or confinement with associated overpressures.

The consequence results are presented in Appendix C.

3.3 Jet Fire

Reference 5 suggests that non-volatile liquids (e.g. diesel and gasoline) are unlikely to sustain a two-phase

jet fire, unless permanently piloted by an adjacent fire; however some liquid drop-out is likely including

the formation of a pool. As such, jet fires can be discounted from the assessment. However, as a

conservative approach, jet fires from gasoline releases (≤ 100 mm) have been included as the flow rates

are relatively low and less energy is required to sustain ignition (Reference 6).

Immediate ignition of a leak is assumed to result in a steady state jet fire except for the low pressure

systems where a jet fire is unlikely to be sustained for any length of time. The magnitude/impact of a jet

fire is governed by the fluid and process conditions of that fluid.

3.4 Pool Fire (including Bund Fire)

Delayed ignition of a liquid leak is assumed to result in a pool fire. The terms that define the size of the

pool fire are:

The size of the leak;

The total released volume (which limits the maximum size of the pool); and

The containment features available (tank bunds, drainage pits, topography, etc.).

Bunds are assumed to be adequately sized and sufficient to contain the maximum liquid spill from the

combined volume of tanks within each bund. Kerb areas around pumps and loading bays are expected to

cope with the spillages to the extent of the kerb assuming that the drain system is not compromised at

the time.

For unconfined liquid releases, the maximum pool diameter is assumed not to exceed 25m taking into

account the topography of the site (Assumption A02, Appendix A).

3.5 Tank Fires

The releases of hydrocarbon at the top of a floating roof tank will lead to a pool being formed at the tank

top. Two scenarios are considered with respect to pools at the tank top:

Spill on Roof Fire: Any ignited spill on a roof leading to partial covering of the roof. This assessment

assumes 25% coverage of the roof surface from events such as rim seal failure, jamming of the roof,

tilting the roof, etc.; and

Full Surface Fire: Any ignited event which causes the full surface of the roof to be covered by

hydrocarbons such as a sunken roof. In this case, the pool size is limited by the tank diameter.

3.6 Flammable Dispersion

Flammable dispersion from a release of flammable vapours will result in a flammable cloud being formed.

Flammable dispersion are modelled in order to assess flash fire and VCE consequences. As the evolution

of large quantities of flammable vapour from diesel or kerosene is very unlikely, flammable vapour

consequences are only considered for gasoline releases.

The size and shape of this cloud is dependent upon the release itself (including the size of any associated

pool) and the weather conditions at the time. Two ignited release scenarios are considered as shown in

Section 3.6.1 and Section 3.6.2.

.

Risktec Solutions DMCC Page 17 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

3.6.1 Flash Fire

The delayed ignition of a flammable vapour cloud in open areas is assumed to result in a flash fire.

3.6.2 Vapour Cloud Explosion (VCE)

The delayed ignition of a flammable vapour cloud in a confined or congested area is assumed to result in

an explosion and associated overpressures. The explosion assessment concentrates on outdoor explosions

and uses the CAM2 model in FRED. The CAM parameters used for this project are presented in Assumption

A04. The equivalent fuel assumed in the CAM model is Propane.

3.7 Building Types

The proposed building types utilised in the BRA follows the guidance set out in SAES-B-014 (Reference 1)

and API RP752 (Reference 2) and are presented in Table 2.

These building types provide a basis for quantifying the potential building damage for the maximum

credible explosion overpressures observed.

Table 2: Building Types

Construction

Description

Type

B1 Wood, temporary buildings, trailers

B2 Steel frame with metal siding

B3 Brick/un-reinforced masonry (load bearing wall)

B4 Steel or concrete frame with masonry fill or cladding

B5 Blast resistant (reinforced concrete)

B6 Brick/moderately reinforced masonry – load bearing

B7 Steel frame building with pre-cast walls and concrete roof

3.8 Damage Level Thresholds

The consequences of the worst credible releases defined have been presented at various thresholds (end

points) which can be correlated to a level of building damage. The effects on buildings for fires, flammable

vapour and overpressure have been specified in the following tables (References 3 and 4).

Table 3: Thermal Radiation Damage

Radiation

Effect on Buildings

Level

The thermal radiation level at which glass windows would be

4.7kW/m2

expected to break.

The thermal radiation level which general/process buildings

12.5kW/m2

would be expected to withstand.

The thermal radiation level at which damage to process

35kW/m2

plant and building may be expected to occur.

Direct Flame

Process plant and buildings may fail within minutes.

Impingement

Table 3 shows that significant building damage is expected to occur when the thermal radiation exceeds

35kW/m2. This has therefore been selected as the defining criteria for building damage.

Risktec Solutions DMCC Page 18 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

Table 4: Flammable Vapour Damage

LFL Level Effect on Buildings

Stage 2 BRA criteria for the flammable end point inside buildings

¼ LFL (based on expected air infiltration rates and the effects of any air

handling systems).

½ LFL Stage 2 BRA criteria for flammable end point outside buildings.

The criteria in Table 4 are based on the BRA criteria presented in SAES-B-014 (Reference 1). The table

shows that based on 2 air changes per hour and the likely effects of air handling systems, a flammable

vapour mixture may exist inside a building, where a flammable vapour concentration exceeds ¼ LFL

outside the building. This has therefore been selected as the defining criteria for the onset of building

damage.

The damage interface value from a given overpressure varies depending on the building construction type.

This is presented in Table 5.

Table 5: Explosion Overpressure Damage

Pressure (psi)

Vulnerability 1 0.6 0.3 0.05 0

Damage

4/5 3/4 2B/3 2A/2B 1/2A

Interface

B1 8.01 3.00 2.10 1.31 0.59

Proposed Building Type

B2 8.01 4.00 2.49 1.49 0.59

B3 4.80 1.31 1.00 0.75 0.49

B4 8.01 3.80 2.49 1.25 0.59

B5 15.00 8.01 6.00 4.50 3.00

B6 7.01 1.49 1.00 0.75 0.49

B7 8.01 5.11 4.10 2.80 1.31

The resultant building damage (by building type) for each damage interface level is presented in Table 6.

Table 6: Building Damage Categories

Discrete

Brief

Damage Full Description

Description

Level

Onset of visible damage. Repairs are only needed for

1 Minor damage

cosmetic reasons. Building is reusable following an explosion.

Localised building damage. Building performs function and

Moderate can be used; however, major repairs are required to restore

2A

damage integrity of structural envelope. Total cost of repairs is

moderate.

Widespread building damage. Building cannot be used until

Significant

2B major repairs are completed. Total cost of repairs is

damage

significant, approaching replacement cost of building.

Risktec Solutions DMCC Page 19 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

Discrete

Brief

Damage Full Description

Description

Level

Building has lost structural integrity and may collapse due to

3 Major damage environmental conditions (i.e. wind, snow, rain). Total cost

of repairs exceeds replacement cost of building.

4 Collapse Building fails completely. Repair not feasible.

5 Annihilation Occupant survival is not possible.

Risktec Solutions DMCC Page 20 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

4 STAGE 1 BRA

The results of the Stage 1 BRA are presented in Table 7 (the Stage 1 screening process is presented in

Appendix E).

The building types have been determined from the information provided and previous experience of similar

Saudi Aramco facilities.

Table 7: Stage 1 BRA Results Summary

Building Occupied /Functionally Stage 2

Building Name

Type Significant? Required?

B-01 SS-XXX1 Receiving Substation

B3 Functionally Significant Yes

Transformer Yard

B-02 SS-XXX2 Utility Power Substation

B3 Functionally Significant Yes

Transformer Yard

B-03 RIB-XXX1 Remote I/O Building B4 Functionally Significant Yes

B-04 RIB-XXX2 Remote I/O Building B4 Functionally Significant Yes

B-05 FSF Building B3 Occupied Yes

B-06 Security Guard House (A) B3 Occupied Yes

B-07 Security Guard House (B) B3 Occupied Yes

B-08 X-Ray Building B3 Not any Yes

B-09 Security Support Building (A) B4 Occupied Yes

B-10 Security Support Building (B) B4 Occupied Yes

B-11 OME Building B4 Occupied Yes

B-12 Operation Building B5 Occupied Yes

B-13 Musalla B3 Occupied Yes

B-14 Chemical Shelter B3 Not any Yes

B-15 Operation Shelter-1 B4 Occupied Yes

B-16 IDAS Shelter-001 B3 Not any Yes

B-17 IDAS Shelter-002 B3 Not any Yes

B-18 Sanitary Metering Shelter-Marafiq B3 Not any Yes

B-19 Utility Water Metering Shelter-

B3 Functionally Significant Yes

Marafiq

B-20 Custody Metering Shelter (Vendor

B3 Not any Yes

Package)

B-21 Oily Water Metering Shelter -

B3 Not any Yes

Marafiq

B-22 Operation Shelter-2 B4 Occupied Yes

It can be seen from Table 7 that a total of 9 buildings have been assessed as occupied, and 5 buildings

have been assessed as functionally significant.

The B-03 RIB-XXX1 Remote I/O Building, B-04 RIB-XXX2 Remote I/O Building, B-08 X-Ray Building, B-14

Chemical Shelter, B-16 IDAS Shelter-001, B-17 IDAS Shelter-002, B-18 Sanitary Metering Shelter-Marafiq,

B-20 Custody Metering Shelter (Vendor Package) and B-21 Oily Water Metering Shelter -Marafiq are not

occupied nor functionally significant as per the requirement of SAES-B-014. These buildings have been

Risktec Solutions DMCC Page 21 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

included in the Stage 2 assessment for completeness, and are assessed under the functional building

criteria.

Risktec Solutions DMCC Page 22 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

5 STAGE 2 BRA

The hazard consequences associated with each release source has been determined for the discrete hazard

threshold levels (end points) specified in Assumption A03 of Appendix A. The distance to each threshold

has been compared against the (point-to-point) separation distance between the release source and the

building with the worst-case hazard level and associated building damage defined.

Results are presented separately for each of the following hazards:

Jet Fire;

Pool Fire;

Flammable Vapour Dispersion; and

Vapour Cloud Explosion (VCEs).

It should be noted that there are no toxic components in the fluids at YDH and as such no toxic modelling

has been performed. In addition, the software is not able to define complex compositions for the explosion

analysis and therefore, an equivalent fuel type has been determined. For gasoline this has been defined

as Propane.

5.1 Consequence Analysis

Shell’s FRED consequence modelling software v6.1 and DNV Phast v6.7 have been used to determine the

impact of each of the flammable hazard sources. The full consequence modelling results are presented in

Appendix C.

5.2 Separation Distances

The separation distances from each hazard source to the building are presented in Appendix B. This data

has been utilised to determine the worst case hazard impact for each building and whether the building

resides within the range of the lowest threshold modelled. The results from this comparison are presented

in the following sections.

5.3 Stage 2 BRA Results

Table 8 summarises the results of the Stage 2 BRA, while a summary of process units leading to impairment

to the buildings exceeding the assessment criteria are presented in Table 9. The full Stage 2 BRA results

are presented in Appendix D.

Risktec Solutions DMCC Page 23 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

Table 8: Stage 2 BRA Results Summary

Maximum Credible Explosion Hazard Maximum Credible Fire Hazard

Building Can building

Building Name Maximum heat Can gas Can gas

Type Overpressure Overpressure Worst Damage be subjected

flux at building concentration concentration

(mbar) (psi) Level to flame

(kW/m2) exceed ¼ LFL? exceed ½ LFL?

impingement?

B-01 SS-XXX1 Receiving > 35 (calculated

B3 7 0.102 Minor Y Y Y

Substation Transformer Yard as 171)

B-02 SS-XXX2 Utility Power > 35 (calculated

B3 32 0.464 Minor Y Y Y

Substation Transformer Yard as 142)

B-03 RIB-XXX1 Remote I/O > 35 (calculated

B4 25 0.363 Minor N Y Y

Building as 98)

B-04 RIB-XXX2 Remote I/O > 35 (calculated

B3 26 0.377 Minor Y Y Y

Building as 154)

B-05 FSF Building B3 15 0.218 Minor N < 4.7 Y N

B-06 Security Guard House (A) B3 29 0.421 Minor N < 4.7 Y N

B-07 Security Guard House (B) B3 24 0.348 Minor N 4.7 – 12.5 Y Y

B-08 X-Ray Building B3 22 0.319 Minor N 4.7 – 12.5 Y Y

B-09 Security Support Building

B4 21 0.305 Minor N < 4.7 Y N

(A)

B-10 Security Support Building

B4 19 0.276 Minor N 4.7 – 12.5 Y Y

(B)

B-11 OME Building B4 23 0.334 Minor N < 4.7 Y Y

B-12 Operation Building B5 17 0.247 Minor N 4.7 – 12.5 Y Y

B-13 Musalla B3 16 0.232 Minor N < 4.7 Y Y

B-14 Chemical Shelter B3 27 0.392 Minor N < 4.7 Y Y

B-15 Operation Shelter B4 34 0.493 Minor Y >35 Y Y

B-16 IDAS Shelter-001 B3 4 0.044 Minor N 4.7 – 12.5 Y Y

Risktec Solutions DMCC Page 24 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

Maximum Credible Explosion Hazard Maximum Credible Fire Hazard

Building Can building

Building Name Maximum heat Can gas Can gas

Type Overpressure Overpressure Worst Damage be subjected

flux at building concentration concentration

(mbar) (psi) Level to flame

(kW/m2) exceed ¼ LFL? exceed ½ LFL?

impingement?

B-17 IDAS Shelter-002 B3 3 0.044 Minor N 4.7 – 12.5 Y Y

B-18 Sanitary Metering

B3 30 0.435 Minor N < 4.7 Y Y

Shelter-Marafiq

B-19 Utility Water Metering

B3 30 0.435 Minor N < 4.7 Y N

Shelter-Marafiq

B-20 Custody Metering Shelter > 35 (calculated

B3 27 0.392 Minor Y Y Y

(Vendor Package) as 240)

B-21 Oily Water Metering

B3 2 0.029 Minor N 12.5 - 35 Y Y

Shelter -Marafiq

B-22 Operation Shelter-2 B4 7 0.102 Minor Y >35 Y Y

Risktec Solutions DMCC Page 25 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

Table 9: Hazard Source for Building Impairment Exceeding Assessment Criteria

Vapour Cloud Explosions Jet/Pool Fire Hazards Flammable Gas Dispersion Hazards

Building Pool Fire Maximum Worst

Building Name Jet Flame Jet Fire Heat

Type Explosion Worst Damage Heat heat flux at Flammable Vapour Flammable

Hazard Radiation

Source Level Radiation building Hazard Source Vapour

Source Source

Source (kW/m2) Concentration

B-01 SS-XXX1 Receiving X40-D-0104/0204

Scraper-YNJ- > 35 (calculated

Substation Transformer B3 CA-12AB Minor Scraper-YNJ-1 - X40-D-XXX1 LFL

1 as 171)

Yard YNJ-1

X40-D-0016A/B/C

B-02 SS-XXX2 Utility Power X40-D-0104/0204

> 35 (calculated

Substation Transformer B3 CA-12I Minor L6-42 L6-42 - X40-D-0002A/C(G) LFL

as 142)

Yard X40-D-0501

L6-42

X40-D-0016A/B/C

X40-D-0104/0204

B-03 RIB-XXX1 Remote I/O > 35 (calculated

B4 CA-12J Minor - L6-42 - X40-D-0002A/C LFL

Building as 98)

X40-D-0501

L6-42

X40-D-0016A/B/C

X40-D-0104/0204

B-04 RIB-XXX2 Remote I/O X40-G- X40-G- > 35 (calculated X40-D-0205

B3 CA-12T Minor - LFL

Building XXX3A/B/C XXX3A/B/C as 154) X40-D-0501

X40-D-XXX1

X40-G-XXX3 A/C

X40-D-0016A/B/C

X40-D-0104/0204

B-05 FSF Building B3 CA-10 Minor - - - < 4.7 X40-D-0205 1/4LFL-1/2LFL

X40-D-0002A/B/C

X40-D-0501

Risktec Solutions DMCC Page 26 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

Vapour Cloud Explosions Jet/Pool Fire Hazards Flammable Gas Dispersion Hazards

Building Pool Fire Maximum Worst

Building Name Jet Flame Jet Fire Heat

Type Explosion Worst Damage Heat heat flux at Flammable Vapour Flammable

Hazard Radiation

Source Level Radiation building Hazard Source Vapour

Source Source

Source (kW/m2) Concentration

X40-D-0016A/B/C

X40-D-0104/0204

B-06 Security Guard House

B3 CA-10 Minor - - - < 4.7 X40-D-0205 1/4LFL-1/2LFL

(A)

X40-D-0002A/B/C

X40-D-0501

X40-D-0016C

B-07 Security Guard House X40-D-0006A

B3 CA-10 Minor - - 4.7 – 12.5 X40-D-0002C 1/2LFL-LFL

(B) X40-D-0009

X40-D-0501

X40-D-0016C

X40-D-0006A

B-08 X-Ray Building B3 CA-10 Minor - - 4.7 – 12.5 X40-D-0002C 1/2LFL-LFL

X40-D-0009

X40-D-0501

X40-D-0016A/B/C

X40-D-0104/0204

B-09 Security Support

B4 CA-09 Minor - - - < 4.7 X40-D-0205 1/4LFL-1/2LFL

Building (A)

X40-D-0002A/B/C

X40-D-0501

X40-D-0016C

B-10 Security Support X40-D-0006A

B4 CA-10 Minor - - 4.7 – 12.5 X40-D-0002C 1/2LFL-LFL

Building (B) X40-D-0009

X40-D-0501

B-11 OME Building B4 CA-10 Minor - - - < 4.7 X40-D-0501 1/2LFL-LFL

X40-D-0016C

X40-D-0006A

B-12 Operation Building B5 CA-12AC Minor - - 4.7 – 12.5 X40-D-0002C 1/2LFL-LFL

X40-D-0009

X40-D-0501

B-13 Musalla B3 CA-10 Minor - - - < 4.7 X40-D-0501 1/2LFL-LFL

B-14 Chemical Shelter B3 CA-10 Minor - - - < 4.7 X40-D-0501 1/2LFL-LFL

Risktec Solutions DMCC Page 27 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

Vapour Cloud Explosions Jet/Pool Fire Hazards Flammable Gas Dispersion Hazards

Building Pool Fire Maximum Worst

Building Name Jet Flame Jet Fire Heat

Type Explosion Worst Damage Heat heat flux at Flammable Vapour Flammable

Hazard Radiation

Source Level Radiation building Hazard Source Vapour

Source Source

Source (kW/m2) Concentration

B-15 Operation Shelter B4 CA-12I Minor - L6-42 L6-42 > 35 L6-42 LFL

X40-D-0016A/C

X40-D-0405

B-16 IDAS Shelter-001 B3 CA-23 Minor - - 4.7 – 12.5 X40-D-0104/0204 LFL

X40-D-0501

X40-D-0002C

X40-D-0205

B-17 IDAS Shelter-002 B3 CA-23 Minor - - X40-D-XXX2 4.7 – 12.5 X40-D-0204 LFL

X40-D-XXX1

B-18 Sanitary Metering

B3 CA-10 Minor - - < 4.7 X40-D-0501 <1/4LFL

Shelter-Marafiq

B-19 Utility Water Metering

B3 CA-10 Minor - - - < 4.7 X40-D-0501 <1/4LFL

Shelter-Marafiq

X40-D-0016C

X40-U- X40-U- X40-D-0002A/B/C

0014A/D 0014A/D X40-D-0204

L1-30 L1-30 X40-U-0014A/C

B-20 Custody Metering L5-30 L5-30 > 35 (calculated

B3 CA-13A Minor - L1-30 LFL

Shelter (Vendor Package) as 240)

YAS-30 YAS-30 L5-30

SAM-30 SAM-30 YAS-30

YR-24 YR-24 SAM-30

YR-24

B-21 Oily Water Metering

B3 CA-12V Minor Scraper-YNJ-1 YNJ-2 12.5 – 35 YNJ-1 1/2LFL-LFL

Shelter -Marafiq

YNJ-1 YNJ-1

B-22 Operation Shelter-2 B4 CA-12AB Minor Scraper-YNJ-1 Scraper-YNJ-1 > 35 LFL

YNJ-2 X40-D-0015B

Risktec Solutions DMCC Page 28 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

It can be seen from Table 8 that all buildings are impacted by consequences above the Stage 2 BRA

criteria. As such, mitigations will need to be implemented as part of the building design. Where the

adequate mitigations cannot be implemented, or where the cost of the mitigations is deemed excessive,

a Stage 3 BRA can be conducted to determine the risk to personnel within the buildings.

The following sections present the Stage 2 BRA results for each hazard effects.

5.3.1 Jet fire

It can be seen from Table 8 that the following buildings will be subjected to direct flame impingement and

exposed to heat radiation flux above 35kW/m2:

B-01 SS-XXX1 Receiving Substation Transformer Yard (the maximum heat radiation flux is

calculated as 171kW/m2);

B-02 SS-XXX2 Utility Power Substation Transformer Yard (the maximum heat radiation flux is

calculated as 142kW/m2);

B-04 RIB-XXX2 Remote I/O Building (the maximum heat radiation flux is calculated as 154kW/m2);

B-15 Operation Shelter-1 (the maximum heat radiation flux is calculated as 138kW/m2);

B-20 Custody Metering Shelter (Vendor Package) (the maximum heat radiation flux is calculated

as 240kW/m2; and

B-22 Operation Shelter-2 (the maximum heat radiation flux is calculated as 137kW/m2);

Although the jet fires will not impinge the B-03 RIB XXX1 Remote I/O Building, it is potentially exposed to

heat radiation flux above 35kW/m2 (calculated as 98kW/m2). The B-21 Oily Water Metering Shelter -

Marafiq is potentially exposed to heat radiation flux between 12.5kW/m2 and 35kW/m2 due to YNJ-1

scraper launcher.

All other buildings are potentially exposed to heat radiation flux below 4.7kW/m2.

5.3.2 Pool Fire

The B-20 Custody Metering Shelter (Vendor Package) is potentially exposed to heat radiation flux between

12.5kW/m2 and 35kW/m2 due to release from SAM-30 and YR-22 pipelines.

The B-21 Oily Water Metering Shelter -Marafiq) is potentially exposed to heat radiation flux between

12.5kW/m2 and 35kW/m2 due to release from YNJ-2 pipeline.

The B-22 Operation Shelter-2 is potentially exposed to heat radiation flux between 12.5kW/m2 and

35kW/m2 due to release from YNJ-1 and YNJ-2 pipelines.

The following buildings will be subjected to heat radiation flux between 4.7kW/m2 and 12.5kW/m2 due to

bund fires within the YDH:

B-01 SS-XXX1 Receiving Substation Transformer Yard;

B-02 SS-XXX2 Utility Power Substation Transformer Yard;

B-03 RIB-XXX1 Remote I/O Building;

B-04 RIB-XXX2 Remote I/O Building;

B-07 Security Guard House (B);

B-08 X-Ray Building;

B-10 Security Support Building (B);

B-12 Operation Building;

B-16 IDAS Shelter-001; and

B-17 IDAS Shelter-002.

Risktec Solutions DMCC Page 29 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

5.3.3 Flammable Vapour Dispersion

It can be seen from Table 8 that the flammable vapour dispersions will reach all of the buildings being

assessed. All building assessed are exposed to flammable vapour concentrations above ½ LFL with the

exception of the following which are exposed to flammable vapour concentrations below ½ LFL:

B-05 FSF Building;

B-06 Security Guard House (A);

B-09 Security Support Building (A);

B-18 Sanitary Metering Shelter – Marafiq; and

B-19 Utility Water Metering Shelter – Marafiq.

Therefore, a flammable atmosphere could be expected in each building.

5.3.4 Vapour Cloud Explosions (VCE)

It can be seen from Table 8 that all buildings are only expected to suffer minor damage, which is below

the SAES-B-014 damage criteria, and no further assessment is required.

Risktec Solutions DMCC Page 30 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

6 CONCLUSIONS

This report presents the results of the Stage 1 and Stage 2 BRA, whereby the worst case credible hazard

consequences (fire, explosion, and flammable vapour clouds) are identified, and their impact on plant

buildings evaluated. The results of the Stage 2 assessment are summarised in Table 8, from which the

following findings and conclusions are made:

6.1 Stage 1 BRA

A total of 9 buildings have been assessed as occupied, and 5 buildings have been assessed as functionally

significant.

6.2 Stage 2 BRA

6.2.1 Jet fire

The following buildings will be subjected to direct flame impingement and exposed to heat radiation flux

above 35kW/m2:

B-01 SS-XXX1 Receiving Substation Transformer Yard (the maximum heat radiation flux is

calculated as 171kW/m2);

B-02 SS-XXX2 Utility Power Substation Transformer Yard (the maximum heat radiation flux is

calculated as 142kW/m2);

B-04 RIB-XXX2 Remote I/O Building (the maximum heat radiation flux is calculated as 154kW/m2);

B-15 Operation Shelter-1 (the maximum heat radiation flux is calculated as 138kW/m2);

B-20 Custody Metering Shelter (Vendor Package) (the maximum heat radiation flux is calculated

as 240kW/m2; and

B-22 Operation Shelter-2 (the maximum heat radiation flux is calculated as 137kW/m2);

Although jet fires will not impinge the B-03 RIB XXX1 Remote I/O Building, it is potentially exposed to heat

radiation flux above 35kW/m2 (calculated as 98kW/m2). The B-21 Oily Water Metering Shelter -Marafiq is

potentially exposed to heat radiation flux between 12.5kW/m2 and 35kW/m2 due to YNJ-1 scraper

launcher.

All other buildings are potentially exposed to heat radiation flux below 4.7kW/m2.

6.2.2 Pool fire

The B-20 Custody Metering Shelter (Vendor Package) is potentially exposed to heat radiation flux between

12.5kW/m2 and 35kW/m2 due to release from SAM-30 and YR-22 pipelines.

The B-21 Oily Water Metering Shelter -Marafiq) is potentially exposed to heat radiation flux between

12.5kW/m2 and 35kW/m2 due to release from YNJ-2 pipeline.

The B-22 Operation Shelter-2 is potentially exposed to heat radiation flux between 12.5kW/m2 and

35kW/m2 due to release from YNJ-1 and YNJ-2 pipelines.

The following buildings will be subjected to heat radiation flux between 4.7kW/m2 and 12.5kW/m2 due to

bund fires within the YDH:

B-01 SS-XXX1 Receiving Substation Transformer Yard;

B-02 SS-XXX2 Utility Power Substation Transformer Yard;

B-03 RIB-XXX1 Remote I/O Building;

B-04 RIB-XXX2 Remote I/O Building;

B-07 Security Guard House (B);

B-08 X-Ray Building;

B-10 Security Support Building (B);

B-12 Operation Building;

Risktec Solutions DMCC Page 31 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

B-16 IDAS Shelter-001; and

B-17 IDAS Shelter-002.

6.2.3 Flammable vapour dispersion

The flammable vapour dispersions will reach all of the buildings being assessed. All building assessed are

exposed to flammable vapour concentrations above ½ LFL with the exception of the following which are

exposed to flammable vapour concentrations below ½ LFL:

B-05 FSF Building;

B-06 Security Guard House (A);

B-09 Security Support Building (A);

B-18 Sanitary Metering Shelter – Marafiq; and

B-19 Utility Water Metering Room – Marafiq.

Therefore, a flammable atmosphere could be expected in each building.

6.2.4 Vapour cloud explosions

All buildings are only expected to suffer minor damage, which is below the SAES-B-014 damage criteria,

and no further assessment is required.

Risktec Solutions DMCC Page 32 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

7 RECOMMENDATIONS

7.1 Building Specific Recommendations

Based on the Stage 2 BRA results summary, building specific risk mitigation measures have been developed

for each building and are presented in Table 10.

Table 10: Proposed Building Specific Risk Mitigation Measures

Occupied/

Name of Functionally

Proposed Risk Mitigation Measures

Building Significant

Building

Review functionality of the building. Based on review of potential business

interruption impact, consider rating the external walls to withstand direct jet

fire flame impingement (the maximum heat radiation flux is calculated

as 171kW/m2).

B-01 SS-XXX1

Also, consider relocating the building outside the flame impingement radius

Receiving

Functionally of 121m from the Scraper-YNJ-1 (G) (for the scenario description refer to

Substation

Significant Assumption A03, Appendix A).

Transformer

Yard Note: Further risk mitigation measures may not be required if the impact of

losing the buildings function does not have a catastrophic impact on the

continued operation of the plant.

Hydrocarbon gas detectors should be installed at the building to provide an

audible and visual alarm.

Review functionality of the building. Based on review of potential business

interruption impact, consider rating the external walls to withstand direct jet

fire flame impingement (the maximum heat radiation flux is calculated

B-02 SS-XXX2 as 142kW/m2).

Utility Power Also, consider relocating the building outside the flame impingement radius

Functionally

Substation of 60m from the PG 95 Storage Tanks outlet header.

Significant

Transformer Note: Further risk mitigation measures may not be required if the impact of

Yard losing the buildings function does not have a catastrophic impact on the

continued operation of the plant.

Hydrocarbon gas detectors should be installed at the building to provide an

audible and visual alarm.

B-03 RIB-XXX1

Functionally Hydrocarbon gas detectors should be installed at the building to provide an

Remote I/O

Significant audible and visual alarm.

Building

B-04 RIB-XXX2

Functionally Hydrocarbon gas detectors should be installed at the building to provide an

Remote I/O

Significant audible and visual alarm.

Building

If building occupants are required to stay in the building in the event of an

incident on the plant, hydrocarbon gas detectors should be installed in HVAC

inlets, which automatically shutdown the HVAC system (close the fire

dampers and put the HVAC system into re-circulation mode). Hydrocarbon

gas detectors should initiate an audible and visual alarm and all external doors

B-05 FSF should be fitted with gas-tight seals and equipped with quick acting,

Occupied adjustable door closing mechanism. Windows should be eliminated,

Building

minimised or designed to prevent flammable gas ingress. The HVAC system

installed should comply with the requirements of SAES-K-022.

If building occupants are not required to stay in the building in the event of

an incident on the plant, hydrocarbon gas detectors should be installed at the

building to provide an audible and visual alarm.

Risktec Solutions DMCC Page 33 of 39

Stage 1 & 2 BRA for Yanbu Distribution Hub Document No: MHDP-08-R-01

Mustang-HDP Issue: 6.0

Occupied/

Name of Functionally

Proposed Risk Mitigation Measures

Building Significant

Building

If building occupants are required to stay in the building in the event of an

incident on the plant, hydrocarbon gas detectors should be installed in HVAC

inlets, which automatically shutdown the HVAC system (close the fire

dampers and put the HVAC system into re-circulation mode). Hydrocarbon

gas detectors should initiate an audible and visual alarm and all external doors

B-06 Security should be fitted with gas-tight seals and equipped with quick acting,