Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

10 viewsRefrigeration Definitions

Refrigeration Definitions

Uploaded by

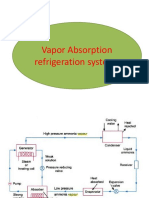

Ashish AnandAn absorption refrigeration system uses a vapor absorption process rather than mechanical compression to provide cooling. It consists of an evaporator, absorber, pump, and generator. In the absorber, a refrigerant such as ammonia is absorbed by a liquid absorbent like water, reducing pressure. The pump increases the pressure of this solution. In the generator, heat vaporizes the refrigerant from the solution. The refrigerant then enters the condenser and evaporator to produce cooling before being absorbed again. The absorption process replaces the function of the compressor in a traditional vapor compression system.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Mineral Processing CalculationDocument119 pagesMineral Processing CalculationAbinya Alfatih100% (1)

- OpenFOAM WingmotionDocument81 pagesOpenFOAM WingmotionMason925No ratings yet

- Absorption Refrigeration SystemDocument4 pagesAbsorption Refrigeration SystemFrancisco ValdezNo ratings yet

- Report On Vapor Absorption Refrigeration System: Ubmited by Sourav Mondal B. E. Power Engg. Jadavpur UniversityDocument14 pagesReport On Vapor Absorption Refrigeration System: Ubmited by Sourav Mondal B. E. Power Engg. Jadavpur UniversitysouravNo ratings yet

- RACDocument3 pagesRACneerajbhayal3456No ratings yet

- Vapour AbsererDocument3 pagesVapour AbsererVijay GunasekaranNo ratings yet

- Different Refrigeration CyclesDocument11 pagesDifferent Refrigeration CyclesLester AngelesNo ratings yet

- Notes - VAPOUR-ABSORPTION-SYSTEMDocument9 pagesNotes - VAPOUR-ABSORPTION-SYSTEMpiyush palNo ratings yet

- ELECTROLUX REFRIGERATOR (The Fluid Refrigerator)Document2 pagesELECTROLUX REFRIGERATOR (The Fluid Refrigerator)Anonymous pKd6ekNo ratings yet

- Vapor Absorption Refrigeration CycleDocument11 pagesVapor Absorption Refrigeration CycleUSHA PAWARNo ratings yet

- How Absorption Cooling WorksDocument2 pagesHow Absorption Cooling WorksvicksksNo ratings yet

- Vapour Absorption SystemDocument5 pagesVapour Absorption Systemhwaj100% (1)

- What Is Vapour Absorption Refrigeration System Working of Vapour Absorption Refrigeration System Components in Vapour AbsorDocument1 pageWhat Is Vapour Absorption Refrigeration System Working of Vapour Absorption Refrigeration System Components in Vapour Absordhoom 760No ratings yet

- Banana Cold Storage: Chapter 2: Related LiteratureDocument8 pagesBanana Cold Storage: Chapter 2: Related LiteratureVelaNo ratings yet

- Refrigeration and Air-Conditioning: Unit - 3Document30 pagesRefrigeration and Air-Conditioning: Unit - 3SAATVIK JAINNo ratings yet

- BUILDING UTILITIES 2 Building HVAC SystemsDocument142 pagesBUILDING UTILITIES 2 Building HVAC Systemsjona serranoNo ratings yet

- Thermal Engineering Unit 5Document23 pagesThermal Engineering Unit 5MohanCool100% (1)

- Submitted By: Hans Wilson C Mechanical Dept ME03913Document12 pagesSubmitted By: Hans Wilson C Mechanical Dept ME03913Hans wilsonNo ratings yet

- Vapor Absorption SystemsDocument17 pagesVapor Absorption SystemsTalibHussainNo ratings yet

- Absorption Refrigeration SystemsDocument4 pagesAbsorption Refrigeration SystemspraneshNo ratings yet

- VarsDocument25 pagesVarsRuturaj UmaranikarNo ratings yet

- Ammonia - Water Vapour Absorption Refrigeration SystemDocument19 pagesAmmonia - Water Vapour Absorption Refrigeration SystemAarjab GhimireNo ratings yet

- Steam CondenserDocument6 pagesSteam CondenserAnonymous Xc8C1hNo ratings yet

- 8 Vapor Absorption RCDocument3 pages8 Vapor Absorption RCSanidhya PainuliNo ratings yet

- Absorption Refrigeration SystemDocument8 pagesAbsorption Refrigeration SystemSajjadullah BaigNo ratings yet

- Rac, Module 3-NoteDocument81 pagesRac, Module 3-NoteShan Mathews VettikuzhiyilNo ratings yet

- Vapour Absorption RefrigerationDocument3 pagesVapour Absorption RefrigerationErGiteshAroraNo ratings yet

- Vapour Absorption Refrigeration Test RigDocument7 pagesVapour Absorption Refrigeration Test RigSwapnil DeyNo ratings yet

- PP Ws CondenserDocument14 pagesPP Ws CondenserBhaskar AnupamNo ratings yet

- SolarDocument6 pagesSolarMuneeb YounisNo ratings yet

- Section B PDFDocument20 pagesSection B PDFKamal YadavNo ratings yet

- Literature Review of Vapour Absorption Refrigeration SystemDocument7 pagesLiterature Review of Vapour Absorption Refrigeration SystemnqdpuhxgfNo ratings yet

- Solar Automobile FridgeDocument4 pagesSolar Automobile FridgeRahul SinghNo ratings yet

- Steam CondenserDocument20 pagesSteam CondensernitinNo ratings yet

- Unit 5.1 RefrigrationDocument11 pagesUnit 5.1 RefrigrationPalanichamy MuruganNo ratings yet

- Vapour Compression CycleDocument5 pagesVapour Compression CycleNimra EhsanNo ratings yet

- Vapour Absorption System NotesDocument12 pagesVapour Absorption System NotesManik SharmaNo ratings yet

- Non-Conventional Refrigeration SystemsDocument21 pagesNon-Conventional Refrigeration SystemsNishit ParmarNo ratings yet

- The Refrigeration CycleDocument2 pagesThe Refrigeration CycleIvy Pearl TabagNo ratings yet

- WATER COOLER 9235074-F935-49bc-90cc-08ed4ab8014dDocument3 pagesWATER COOLER 9235074-F935-49bc-90cc-08ed4ab8014dAmbika prasadNo ratings yet

- Unit 4 - The Heat PumpDocument25 pagesUnit 4 - The Heat PumpShyam WanaskarNo ratings yet

- Vapour Absorption Refrigeration SystemDocument12 pagesVapour Absorption Refrigeration SystemHarshNo ratings yet

- How Does Air Condition WorksDocument6 pagesHow Does Air Condition Worksnguyen van ANNo ratings yet

- Unit 2 RacDocument40 pagesUnit 2 Racozair arshadNo ratings yet

- Refrigeration Using Waste Heat in Cars: AbstractDocument2 pagesRefrigeration Using Waste Heat in Cars: AbstractManishGuptaNo ratings yet

- Refrigeration & Air Conditioning: Arun Jose Tom, Rac, CcetDocument340 pagesRefrigeration & Air Conditioning: Arun Jose Tom, Rac, CcetRubin JosephNo ratings yet

- Rac VarcDocument8 pagesRac VarcAmit singhNo ratings yet

- Ac Compressor OperationDocument3 pagesAc Compressor OperationshalabyahmedNo ratings yet

- Refrigeration and Air ConditioningDocument9 pagesRefrigeration and Air ConditioningLuis Enrique Cervantes DominguezNo ratings yet

- Heat ExchangersDocument29 pagesHeat ExchangerscooLkiD1412No ratings yet

- TesfayDocument29 pagesTesfayfisahabirhane16No ratings yet

- Chapter 3 RACDocument26 pagesChapter 3 RACSameer AhmadNo ratings yet

- Major Elements of Refrigeration System and Their FunctionsDocument8 pagesMajor Elements of Refrigeration System and Their FunctionsXahid HasanNo ratings yet

- 18-Tugas 1-Prak. Perawatan Mesin Konversi Energi 1Document5 pages18-Tugas 1-Prak. Perawatan Mesin Konversi Energi 1Oh WiwinNo ratings yet

- Air Condition How Does It Works?Document10 pagesAir Condition How Does It Works?Gwapong CrisNo ratings yet

- What Is The Basic Principle of Refrigeration and What Do You Understand by Refrigeration Cycle?Document3 pagesWhat Is The Basic Principle of Refrigeration and What Do You Understand by Refrigeration Cycle?a4104165No ratings yet

- Refrigeration Systems: Ruiz Delgado Luis Fernando 17151402Document10 pagesRefrigeration Systems: Ruiz Delgado Luis Fernando 17151402Anonymous UXZdef7JNo ratings yet

- Absorption RefrigerationDocument40 pagesAbsorption RefrigerationAniket MitraNo ratings yet

- Group 5 Melab3Document14 pagesGroup 5 Melab3Gigi SalesNo ratings yet

- Jet CondenserDocument3 pagesJet CondenserMLNDG boysNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Candidate Marks Report: Series: May-July 2019Document42 pagesCandidate Marks Report: Series: May-July 2019Ashish AnandNo ratings yet

- Ap Motronix Private Limited: SynchroDocument4 pagesAp Motronix Private Limited: SynchroAshish AnandNo ratings yet

- Environmental Impacts of Energy Utilization and Renewable Energy Sources in TurkeyDocument13 pagesEnvironmental Impacts of Energy Utilization and Renewable Energy Sources in TurkeyAshish AnandNo ratings yet

- Cryogenic TechnologyDocument2 pagesCryogenic TechnologyAshish AnandNo ratings yet

- Refrigeration: Units of Refrigeration CapacityDocument5 pagesRefrigeration: Units of Refrigeration CapacityAshish AnandNo ratings yet

- Thermodynamic & Thermo-Physical PropertiesDocument8 pagesThermodynamic & Thermo-Physical PropertiesAshish AnandNo ratings yet

- Cryogenic TechnologyDocument2 pagesCryogenic TechnologyAshish AnandNo ratings yet

- BEST Series Build-Up Evaluation Shut-In Tool: A New Level of Accuracy in Dynamic Reservoir EvaluationDocument2 pagesBEST Series Build-Up Evaluation Shut-In Tool: A New Level of Accuracy in Dynamic Reservoir EvaluationFabio ParceroNo ratings yet

- SQL 1Document108 pagesSQL 1prkshjsNo ratings yet

- Design of DC MachinesDocument60 pagesDesign of DC Machinesmanu eNo ratings yet

- Boiler Comp. For 250bhpDocument2 pagesBoiler Comp. For 250bhpNewaz KabirNo ratings yet

- Chapter Three EarthingDocument33 pagesChapter Three EarthingKorsa Korsa100% (1)

- Summary Report 323GC FJM10738 - Nabire BaruDocument8 pagesSummary Report 323GC FJM10738 - Nabire Baruzjmjcndhs7No ratings yet

- Thumbwheel 175dtDocument7 pagesThumbwheel 175dtmoyali25176750No ratings yet

- Datasheet PDFDocument5 pagesDatasheet PDFadminNo ratings yet

- Controlling (MCQ'S)Document4 pagesControlling (MCQ'S)KOMAL AGGARWALNo ratings yet

- Calculating Freight Charges As A Percentage of Order Amount in Oracle Advanced PricingDocument9 pagesCalculating Freight Charges As A Percentage of Order Amount in Oracle Advanced Pricingmks210No ratings yet

- Bullet Train 3-3Document4 pagesBullet Train 3-3Pradumna KasaudhanNo ratings yet

- RS 485Document3 pagesRS 485marcos_visNo ratings yet

- Manual 005Document50 pagesManual 005Anonymous B7pghh0% (1)

- Daaf006099 000Document2 pagesDaaf006099 000apsNo ratings yet

- Vortex Breakers in Practice - 201606Document2 pagesVortex Breakers in Practice - 201606JQuest229100% (4)

- PetDocument12 pagesPetRoxana LazarNo ratings yet

- ABB ACS850 Drive ModulesDocument125 pagesABB ACS850 Drive ModulesNeeraj RaushanNo ratings yet

- Chapter - 11: Access Layer: Object Storage and Object InteroperabilityDocument8 pagesChapter - 11: Access Layer: Object Storage and Object Interoperabilitydeeparanjini100% (1)

- AG 807-1992 Approval Requirements For Natural Gas Flexible Hose and Hose Assemblies For Pressures Above 2.6 MDocument7 pagesAG 807-1992 Approval Requirements For Natural Gas Flexible Hose and Hose Assemblies For Pressures Above 2.6 MSAI Global - APACNo ratings yet

- VMCE95 Textbook 20180914 PDFDocument281 pagesVMCE95 Textbook 20180914 PDFIvo MayerNo ratings yet

- Ultramat SiemensDocument39 pagesUltramat Siemensafi1belleNo ratings yet

- Lavatory ServicingDocument2 pagesLavatory ServicingAhmad Yani S NoorNo ratings yet

- Additive MAnufacturing ExplainDocument19 pagesAdditive MAnufacturing ExplainHoracioGutierrezNo ratings yet

- MY CV Margana Sakti3Document6 pagesMY CV Margana Sakti3Margana SaktiNo ratings yet

- John Deere Serial Number Range GuideDocument6 pagesJohn Deere Serial Number Range GuideMohamed ZakiNo ratings yet

- TMS374 PDFDocument6 pagesTMS374 PDFZoltán BodócsNo ratings yet

- Business Objects: Designer Desktop Intelligence (Reporting) Info View/web Intelligence CMCDocument67 pagesBusiness Objects: Designer Desktop Intelligence (Reporting) Info View/web Intelligence CMCsravan001No ratings yet

- Ficha Tecnica E70 enDocument23 pagesFicha Tecnica E70 enAyan MajiNo ratings yet

Refrigeration Definitions

Refrigeration Definitions

Uploaded by

Ashish Anand0 ratings0% found this document useful (0 votes)

10 views3 pagesAn absorption refrigeration system uses a vapor absorption process rather than mechanical compression to provide cooling. It consists of an evaporator, absorber, pump, and generator. In the absorber, a refrigerant such as ammonia is absorbed by a liquid absorbent like water, reducing pressure. The pump increases the pressure of this solution. In the generator, heat vaporizes the refrigerant from the solution. The refrigerant then enters the condenser and evaporator to produce cooling before being absorbed again. The absorption process replaces the function of the compressor in a traditional vapor compression system.

Original Description:

Definite vapor

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAn absorption refrigeration system uses a vapor absorption process rather than mechanical compression to provide cooling. It consists of an evaporator, absorber, pump, and generator. In the absorber, a refrigerant such as ammonia is absorbed by a liquid absorbent like water, reducing pressure. The pump increases the pressure of this solution. In the generator, heat vaporizes the refrigerant from the solution. The refrigerant then enters the condenser and evaporator to produce cooling before being absorbed again. The absorption process replaces the function of the compressor in a traditional vapor compression system.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

10 views3 pagesRefrigeration Definitions

Refrigeration Definitions

Uploaded by

Ashish AnandAn absorption refrigeration system uses a vapor absorption process rather than mechanical compression to provide cooling. It consists of an evaporator, absorber, pump, and generator. In the absorber, a refrigerant such as ammonia is absorbed by a liquid absorbent like water, reducing pressure. The pump increases the pressure of this solution. In the generator, heat vaporizes the refrigerant from the solution. The refrigerant then enters the condenser and evaporator to produce cooling before being absorbed again. The absorption process replaces the function of the compressor in a traditional vapor compression system.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

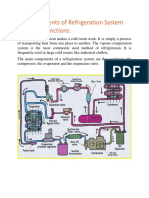

VAPOUR ABSORPTION SYSTEM

How Absorption Refrigeration System Works?

CONDENSER: Just like in the traditional condenser of the vapor compression

cycle, the refrigerant enters the condenser at high pressure and temperature and

gets condensed. The condenser is of water cooled type.

EXPANSION VALVE OR RESTRICTION: When the refrigerant passes

through the expansion valve, its pressure and temperature reduces suddenly. This

refrigerant (ammonia in this case) then enters the evaporator.

EVAPORATOR: The refrigerant at very low pressure and temperature enters

the evaporator and produces the cooling effect. In the vapor compression cycle

this refrigerant is sucked by the compressor, but in the vapor absorption cycle,

this refrigerant flows to the absorber that acts as the suction part of the

refrigeration cycle.

ABSORBER: The absorber is a sort of vessel consisting of water that acts as the

absorbent, and the previous absorbed refrigerant. Thus the absorber consists of

the weak solution of the refrigerant (ammonia in this case) and absorbent (water

in this case). When ammonia from the evaporator enters the absorber, it is

absorbed by the absorbent due to which the pressure inside the absorber reduces

further leading to more flow of the refrigerant from the evaporator to the

absorber. At high temperature water absorbs lesser ammonia, hence it is cooled

by the external coolant to increase it ammonia absorption capacity.

The initial flow of the refrigerant from the evaporator to the absorber occurs

because the vapor pressure of the refrigerant-absorbent in the absorber is lower

than the vapor pressure of the refrigerant in the evaporator. The vapor pressure of

the refrigerant-absorbent inside the absorbent determines the pressure on low-

pressure side of the system and also the vaporizing temperature of the refrigerant

inside the evaporator. The vapor pressure of the refrigerant-absorbent solution

depends on the nature of the absorbent, its temperature and concentration.

When the refrigerant entering in the absorber is absorbed by the absorbent its

volume decreases, thus the compression of the refrigerant occurs. Thus absorber

acts as the suction part of the compressor. The heat of absorption is also released

in the absorber, which is removed by the external coolant.

PUMP: When the absorbent absorbs the refrigerant strong solution of

refrigerant-absorbent (ammonia-water) is formed. This solution is pumped by the

pump at high pressure to the generator. Thus pump increases the pressure of the

solution to about 10bar.

GENERATOR: The refrigerant-ammonia solution in the generator is heated by

the external source of heat. This is can be steam, hot water or any other suitable

source. Due to heating the temperature of the solution increases. The refrigerant

in the solution gets vaporized and it leaves the solution at high pressure. The high

pressure and the high temperature refrigerant then enters the condenser, where it

is cooled by the coolant, and it then enters the expansion valve and then finally

into the evaporator where it produces the cooling effect. This refrigerant is then

again absorbed by the weak solution in the absorber.

When the vaporized refrigerant leaves the generator weak solution is left in it.

This solution enters the pressure reducing valve and then back to the absorber,

where it is ready to absorb fresh refrigerant. In this way, the refrigerant keeps on

repeating the cycle.

The pressure of the refrigerant is increased in the generator, hence it is considered

to be equivalent to the compression part of the compressor.

You might also like

- Mineral Processing CalculationDocument119 pagesMineral Processing CalculationAbinya Alfatih100% (1)

- OpenFOAM WingmotionDocument81 pagesOpenFOAM WingmotionMason925No ratings yet

- Absorption Refrigeration SystemDocument4 pagesAbsorption Refrigeration SystemFrancisco ValdezNo ratings yet

- Report On Vapor Absorption Refrigeration System: Ubmited by Sourav Mondal B. E. Power Engg. Jadavpur UniversityDocument14 pagesReport On Vapor Absorption Refrigeration System: Ubmited by Sourav Mondal B. E. Power Engg. Jadavpur UniversitysouravNo ratings yet

- RACDocument3 pagesRACneerajbhayal3456No ratings yet

- Vapour AbsererDocument3 pagesVapour AbsererVijay GunasekaranNo ratings yet

- Different Refrigeration CyclesDocument11 pagesDifferent Refrigeration CyclesLester AngelesNo ratings yet

- Notes - VAPOUR-ABSORPTION-SYSTEMDocument9 pagesNotes - VAPOUR-ABSORPTION-SYSTEMpiyush palNo ratings yet

- ELECTROLUX REFRIGERATOR (The Fluid Refrigerator)Document2 pagesELECTROLUX REFRIGERATOR (The Fluid Refrigerator)Anonymous pKd6ekNo ratings yet

- Vapor Absorption Refrigeration CycleDocument11 pagesVapor Absorption Refrigeration CycleUSHA PAWARNo ratings yet

- How Absorption Cooling WorksDocument2 pagesHow Absorption Cooling WorksvicksksNo ratings yet

- Vapour Absorption SystemDocument5 pagesVapour Absorption Systemhwaj100% (1)

- What Is Vapour Absorption Refrigeration System Working of Vapour Absorption Refrigeration System Components in Vapour AbsorDocument1 pageWhat Is Vapour Absorption Refrigeration System Working of Vapour Absorption Refrigeration System Components in Vapour Absordhoom 760No ratings yet

- Banana Cold Storage: Chapter 2: Related LiteratureDocument8 pagesBanana Cold Storage: Chapter 2: Related LiteratureVelaNo ratings yet

- Refrigeration and Air-Conditioning: Unit - 3Document30 pagesRefrigeration and Air-Conditioning: Unit - 3SAATVIK JAINNo ratings yet

- BUILDING UTILITIES 2 Building HVAC SystemsDocument142 pagesBUILDING UTILITIES 2 Building HVAC Systemsjona serranoNo ratings yet

- Thermal Engineering Unit 5Document23 pagesThermal Engineering Unit 5MohanCool100% (1)

- Submitted By: Hans Wilson C Mechanical Dept ME03913Document12 pagesSubmitted By: Hans Wilson C Mechanical Dept ME03913Hans wilsonNo ratings yet

- Vapor Absorption SystemsDocument17 pagesVapor Absorption SystemsTalibHussainNo ratings yet

- Absorption Refrigeration SystemsDocument4 pagesAbsorption Refrigeration SystemspraneshNo ratings yet

- VarsDocument25 pagesVarsRuturaj UmaranikarNo ratings yet

- Ammonia - Water Vapour Absorption Refrigeration SystemDocument19 pagesAmmonia - Water Vapour Absorption Refrigeration SystemAarjab GhimireNo ratings yet

- Steam CondenserDocument6 pagesSteam CondenserAnonymous Xc8C1hNo ratings yet

- 8 Vapor Absorption RCDocument3 pages8 Vapor Absorption RCSanidhya PainuliNo ratings yet

- Absorption Refrigeration SystemDocument8 pagesAbsorption Refrigeration SystemSajjadullah BaigNo ratings yet

- Rac, Module 3-NoteDocument81 pagesRac, Module 3-NoteShan Mathews VettikuzhiyilNo ratings yet

- Vapour Absorption RefrigerationDocument3 pagesVapour Absorption RefrigerationErGiteshAroraNo ratings yet

- Vapour Absorption Refrigeration Test RigDocument7 pagesVapour Absorption Refrigeration Test RigSwapnil DeyNo ratings yet

- PP Ws CondenserDocument14 pagesPP Ws CondenserBhaskar AnupamNo ratings yet

- SolarDocument6 pagesSolarMuneeb YounisNo ratings yet

- Section B PDFDocument20 pagesSection B PDFKamal YadavNo ratings yet

- Literature Review of Vapour Absorption Refrigeration SystemDocument7 pagesLiterature Review of Vapour Absorption Refrigeration SystemnqdpuhxgfNo ratings yet

- Solar Automobile FridgeDocument4 pagesSolar Automobile FridgeRahul SinghNo ratings yet

- Steam CondenserDocument20 pagesSteam CondensernitinNo ratings yet

- Unit 5.1 RefrigrationDocument11 pagesUnit 5.1 RefrigrationPalanichamy MuruganNo ratings yet

- Vapour Compression CycleDocument5 pagesVapour Compression CycleNimra EhsanNo ratings yet

- Vapour Absorption System NotesDocument12 pagesVapour Absorption System NotesManik SharmaNo ratings yet

- Non-Conventional Refrigeration SystemsDocument21 pagesNon-Conventional Refrigeration SystemsNishit ParmarNo ratings yet

- The Refrigeration CycleDocument2 pagesThe Refrigeration CycleIvy Pearl TabagNo ratings yet

- WATER COOLER 9235074-F935-49bc-90cc-08ed4ab8014dDocument3 pagesWATER COOLER 9235074-F935-49bc-90cc-08ed4ab8014dAmbika prasadNo ratings yet

- Unit 4 - The Heat PumpDocument25 pagesUnit 4 - The Heat PumpShyam WanaskarNo ratings yet

- Vapour Absorption Refrigeration SystemDocument12 pagesVapour Absorption Refrigeration SystemHarshNo ratings yet

- How Does Air Condition WorksDocument6 pagesHow Does Air Condition Worksnguyen van ANNo ratings yet

- Unit 2 RacDocument40 pagesUnit 2 Racozair arshadNo ratings yet

- Refrigeration Using Waste Heat in Cars: AbstractDocument2 pagesRefrigeration Using Waste Heat in Cars: AbstractManishGuptaNo ratings yet

- Refrigeration & Air Conditioning: Arun Jose Tom, Rac, CcetDocument340 pagesRefrigeration & Air Conditioning: Arun Jose Tom, Rac, CcetRubin JosephNo ratings yet

- Rac VarcDocument8 pagesRac VarcAmit singhNo ratings yet

- Ac Compressor OperationDocument3 pagesAc Compressor OperationshalabyahmedNo ratings yet

- Refrigeration and Air ConditioningDocument9 pagesRefrigeration and Air ConditioningLuis Enrique Cervantes DominguezNo ratings yet

- Heat ExchangersDocument29 pagesHeat ExchangerscooLkiD1412No ratings yet

- TesfayDocument29 pagesTesfayfisahabirhane16No ratings yet

- Chapter 3 RACDocument26 pagesChapter 3 RACSameer AhmadNo ratings yet

- Major Elements of Refrigeration System and Their FunctionsDocument8 pagesMajor Elements of Refrigeration System and Their FunctionsXahid HasanNo ratings yet

- 18-Tugas 1-Prak. Perawatan Mesin Konversi Energi 1Document5 pages18-Tugas 1-Prak. Perawatan Mesin Konversi Energi 1Oh WiwinNo ratings yet

- Air Condition How Does It Works?Document10 pagesAir Condition How Does It Works?Gwapong CrisNo ratings yet

- What Is The Basic Principle of Refrigeration and What Do You Understand by Refrigeration Cycle?Document3 pagesWhat Is The Basic Principle of Refrigeration and What Do You Understand by Refrigeration Cycle?a4104165No ratings yet

- Refrigeration Systems: Ruiz Delgado Luis Fernando 17151402Document10 pagesRefrigeration Systems: Ruiz Delgado Luis Fernando 17151402Anonymous UXZdef7JNo ratings yet

- Absorption RefrigerationDocument40 pagesAbsorption RefrigerationAniket MitraNo ratings yet

- Group 5 Melab3Document14 pagesGroup 5 Melab3Gigi SalesNo ratings yet

- Jet CondenserDocument3 pagesJet CondenserMLNDG boysNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Candidate Marks Report: Series: May-July 2019Document42 pagesCandidate Marks Report: Series: May-July 2019Ashish AnandNo ratings yet

- Ap Motronix Private Limited: SynchroDocument4 pagesAp Motronix Private Limited: SynchroAshish AnandNo ratings yet

- Environmental Impacts of Energy Utilization and Renewable Energy Sources in TurkeyDocument13 pagesEnvironmental Impacts of Energy Utilization and Renewable Energy Sources in TurkeyAshish AnandNo ratings yet

- Cryogenic TechnologyDocument2 pagesCryogenic TechnologyAshish AnandNo ratings yet

- Refrigeration: Units of Refrigeration CapacityDocument5 pagesRefrigeration: Units of Refrigeration CapacityAshish AnandNo ratings yet

- Thermodynamic & Thermo-Physical PropertiesDocument8 pagesThermodynamic & Thermo-Physical PropertiesAshish AnandNo ratings yet

- Cryogenic TechnologyDocument2 pagesCryogenic TechnologyAshish AnandNo ratings yet

- BEST Series Build-Up Evaluation Shut-In Tool: A New Level of Accuracy in Dynamic Reservoir EvaluationDocument2 pagesBEST Series Build-Up Evaluation Shut-In Tool: A New Level of Accuracy in Dynamic Reservoir EvaluationFabio ParceroNo ratings yet

- SQL 1Document108 pagesSQL 1prkshjsNo ratings yet

- Design of DC MachinesDocument60 pagesDesign of DC Machinesmanu eNo ratings yet

- Boiler Comp. For 250bhpDocument2 pagesBoiler Comp. For 250bhpNewaz KabirNo ratings yet

- Chapter Three EarthingDocument33 pagesChapter Three EarthingKorsa Korsa100% (1)

- Summary Report 323GC FJM10738 - Nabire BaruDocument8 pagesSummary Report 323GC FJM10738 - Nabire Baruzjmjcndhs7No ratings yet

- Thumbwheel 175dtDocument7 pagesThumbwheel 175dtmoyali25176750No ratings yet

- Datasheet PDFDocument5 pagesDatasheet PDFadminNo ratings yet

- Controlling (MCQ'S)Document4 pagesControlling (MCQ'S)KOMAL AGGARWALNo ratings yet

- Calculating Freight Charges As A Percentage of Order Amount in Oracle Advanced PricingDocument9 pagesCalculating Freight Charges As A Percentage of Order Amount in Oracle Advanced Pricingmks210No ratings yet

- Bullet Train 3-3Document4 pagesBullet Train 3-3Pradumna KasaudhanNo ratings yet

- RS 485Document3 pagesRS 485marcos_visNo ratings yet

- Manual 005Document50 pagesManual 005Anonymous B7pghh0% (1)

- Daaf006099 000Document2 pagesDaaf006099 000apsNo ratings yet

- Vortex Breakers in Practice - 201606Document2 pagesVortex Breakers in Practice - 201606JQuest229100% (4)

- PetDocument12 pagesPetRoxana LazarNo ratings yet

- ABB ACS850 Drive ModulesDocument125 pagesABB ACS850 Drive ModulesNeeraj RaushanNo ratings yet

- Chapter - 11: Access Layer: Object Storage and Object InteroperabilityDocument8 pagesChapter - 11: Access Layer: Object Storage and Object Interoperabilitydeeparanjini100% (1)

- AG 807-1992 Approval Requirements For Natural Gas Flexible Hose and Hose Assemblies For Pressures Above 2.6 MDocument7 pagesAG 807-1992 Approval Requirements For Natural Gas Flexible Hose and Hose Assemblies For Pressures Above 2.6 MSAI Global - APACNo ratings yet

- VMCE95 Textbook 20180914 PDFDocument281 pagesVMCE95 Textbook 20180914 PDFIvo MayerNo ratings yet

- Ultramat SiemensDocument39 pagesUltramat Siemensafi1belleNo ratings yet

- Lavatory ServicingDocument2 pagesLavatory ServicingAhmad Yani S NoorNo ratings yet

- Additive MAnufacturing ExplainDocument19 pagesAdditive MAnufacturing ExplainHoracioGutierrezNo ratings yet

- MY CV Margana Sakti3Document6 pagesMY CV Margana Sakti3Margana SaktiNo ratings yet

- John Deere Serial Number Range GuideDocument6 pagesJohn Deere Serial Number Range GuideMohamed ZakiNo ratings yet

- TMS374 PDFDocument6 pagesTMS374 PDFZoltán BodócsNo ratings yet

- Business Objects: Designer Desktop Intelligence (Reporting) Info View/web Intelligence CMCDocument67 pagesBusiness Objects: Designer Desktop Intelligence (Reporting) Info View/web Intelligence CMCsravan001No ratings yet

- Ficha Tecnica E70 enDocument23 pagesFicha Tecnica E70 enAyan MajiNo ratings yet