Professional Documents

Culture Documents

Wigva BGTM15 PDF

Wigva BGTM15 PDF

Uploaded by

Goutham KSCopyright:

Available Formats

You might also like

- EDUC5711 Week 8 Discussion Assignment Unit 8Document3 pagesEDUC5711 Week 8 Discussion Assignment Unit 8Meleisa WrayNo ratings yet

- Brand AuditDocument17 pagesBrand AuditAVINASH TOPNONo ratings yet

- TC FLS Sihi Akhx enDocument12 pagesTC FLS Sihi Akhx enandrescaligoNo ratings yet

- Turbogenerator ConceptDocument10 pagesTurbogenerator ConceptJorge MontalvoNo ratings yet

- 06 Casquillos de Agujas Sin Fondo Clutch SimilarDocument98 pages06 Casquillos de Agujas Sin Fondo Clutch SimilarSara Sarmiento EcheverryNo ratings yet

- WILO SCP RangeDocument48 pagesWILO SCP RangeSaikat PurkaitNo ratings yet

- Catalogo Colheitadeira Case 2388-2399aDocument2,384 pagesCatalogo Colheitadeira Case 2388-2399aThiago RomeroNo ratings yet

- C Series: Cutter ImpellerDocument6 pagesC Series: Cutter ImpellerNichamon NNo ratings yet

- Enerpac WHC WHR Series CatalogDocument1 pageEnerpac WHC WHR Series CatalogTitanplyNo ratings yet

- Bomba Agua dulceTC - FLS - SIHI - AKHA - ENDocument18 pagesBomba Agua dulceTC - FLS - SIHI - AKHA - ENOscar CaviedesNo ratings yet

- FICHA - ARMSTRONG Recirculadores Series S y H EspecificacionesDocument4 pagesFICHA - ARMSTRONG Recirculadores Series S y H EspecificacionesSalvador RiveraNo ratings yet

- Jl. Perak Timur 102 Surabaya: Weight SummaryDocument74 pagesJl. Perak Timur 102 Surabaya: Weight SummaryhajarNo ratings yet

- Katalog POMPA ARITA 2022Document30 pagesKatalog POMPA ARITA 2022Washiul RizkiNo ratings yet

- Katalog Produk PompaDocument35 pagesKatalog Produk PompaRiyan SiregarNo ratings yet

- MD-500 Torque SpecDocument7 pagesMD-500 Torque SpecBiswanath LenkaNo ratings yet

- Configuration: Price Lead TimeDocument2 pagesConfiguration: Price Lead TimeiudexisNo ratings yet

- Warren ValvesDocument1 pageWarren ValvesNebstereNo ratings yet

- Pumpworks 610-BB3Document6 pagesPumpworks 610-BB3Padmanabhan VenkateshNo ratings yet

- WEG Part Number Configuration Weg Motors Usapnconf Quick Guide EnglishDocument1 pageWEG Part Number Configuration Weg Motors Usapnconf Quick Guide EnglishGustavo Gaibar0% (1)

- PumpWorks 610 PWD Brochure1Document6 pagesPumpWorks 610 PWD Brochure1Octa RioNo ratings yet

- HT Cable ScheduleDocument2 pagesHT Cable ScheduletceterexNo ratings yet

- Planetary Gearbox For Servo Motor 2014Document40 pagesPlanetary Gearbox For Servo Motor 2014Blaze123xNo ratings yet

- D00 RSRT STD EN ED01 REV03 WebDocument68 pagesD00 RSRT STD EN ED01 REV03 WebRedOne KhasmiNo ratings yet

- 15W (150HP) BLHSeriesBrushlessDCMotorSpeedControlSystemsDocument3 pages15W (150HP) BLHSeriesBrushlessDCMotorSpeedControlSystemsHậu Trần TrọngNo ratings yet

- Teaching Modules For Steel Instruction: Developed by Scott Civjan University of Massachusetts, AmherstDocument28 pagesTeaching Modules For Steel Instruction: Developed by Scott Civjan University of Massachusetts, AmherstkiranNo ratings yet

- Chelsea 880 - PTODocument2 pagesChelsea 880 - PTOkaabach80No ratings yet

- Project Data: DesignDocument18 pagesProject Data: DesignMarco ZanellaNo ratings yet

- Part List Ebara 3MDocument2 pagesPart List Ebara 3MEddie GuillénNo ratings yet

- NC Rotary Tables: Standard TypeDocument2 pagesNC Rotary Tables: Standard TypeNathan ChenNo ratings yet

- Brochure FSA, 60 HZDocument6 pagesBrochure FSA, 60 HZIbrahim SanusiNo ratings yet

- HY25-0152-B1 - US870 Series Chelsea PTODocument2 pagesHY25-0152-B1 - US870 Series Chelsea PTORobbie GlezNo ratings yet

- Fsa - Ebara End Suction Volute PumpDocument6 pagesFsa - Ebara End Suction Volute PumpkhristprasatyaNo ratings yet

- 4A Reg-Da Panel Existing Control PanelDocument2 pages4A Reg-Da Panel Existing Control Panelangga wira pramanaNo ratings yet

- MIT Screws and Gears GWDocument37 pagesMIT Screws and Gears GWmohanavenkateshNo ratings yet

- Screw ForcesDocument10 pagesScrew ForceskasreedharNo ratings yet

- Pumps Spec Series2400 8 09Document8 pagesPumps Spec Series2400 8 09Hamatouty TottiNo ratings yet

- Output Shaft Lube Nozzle Bearings Bolts RCM Face-Gear PMC Face-GearsDocument9 pagesOutput Shaft Lube Nozzle Bearings Bolts RCM Face-Gear PMC Face-GearsMichael KinneyNo ratings yet

- Caseih Staiger PBDocument1,366 pagesCaseih Staiger PBFernando SabinoNo ratings yet

- DanlyIEM PunchCalcPrefPress 0903Document2 pagesDanlyIEM PunchCalcPrefPress 0903salvador hernandezNo ratings yet

- LP1 TK 10HSD M M8 Deg 1001 C PDFDocument13 pagesLP1 TK 10HSD M M8 Deg 1001 C PDFnguyenanhtuanbNo ratings yet

- LP1 TK 10HSD M M8 Deg 1001 CDocument13 pagesLP1 TK 10HSD M M8 Deg 1001 CnguyenanhtuanbNo ratings yet

- Brochure FSA, 50 Hz1-Dikonversi - Pdf. TerbaruDocument6 pagesBrochure FSA, 50 Hz1-Dikonversi - Pdf. TerbaruDt BarusNo ratings yet

- Ball Valve Full PortDocument2 pagesBall Valve Full PortHardik ShahNo ratings yet

- 735fe, 735xm, 834xm CatlougeDocument143 pages735fe, 735xm, 834xm Catlougedadu tractor83% (30)

- Series1 Steel Bandejas B LineDocument26 pagesSeries1 Steel Bandejas B LineJorge ChavezNo ratings yet

- Hendrix Sole Source LetterDocument9 pagesHendrix Sole Source Lettersaeid.power63No ratings yet

- 12-1/4" Hole Drilling Performance - S-927, Jan 2013: 0 15 Wob (Kdan)Document1 page12-1/4" Hole Drilling Performance - S-927, Jan 2013: 0 15 Wob (Kdan)Balkis FatihaNo ratings yet

- Fire Pump 50HZ-2016 PDFDocument12 pagesFire Pump 50HZ-2016 PDFSinggih MechanicNo ratings yet

- PDF Katalog BallscrewsDocument32 pagesPDF Katalog BallscrewsSaka WahyuNo ratings yet

- Materials: For A Ins MusDocument7 pagesMaterials: For A Ins MusSoumya SameerNo ratings yet

- Technical Specifications Premium 5-1/2" OD Heavy-Weight Drill Pipe, 1340, TT-550 Conn's. NewDocument2 pagesTechnical Specifications Premium 5-1/2" OD Heavy-Weight Drill Pipe, 1340, TT-550 Conn's. NewbkprodhNo ratings yet

- Sihi Aeh enDocument12 pagesSihi Aeh enIrvan NouriNo ratings yet

- Spindle Ball Bearings (HY) KH 6005 E: Precision Class P4 / ABEC7Document1 pageSpindle Ball Bearings (HY) KH 6005 E: Precision Class P4 / ABEC7skohhcslzypqtdhkvaNo ratings yet

- A2-Pile Calculation - BH M1Document90 pagesA2-Pile Calculation - BH M1Priya GopalNo ratings yet

- U18sl 900 6TDocument3 pagesU18sl 900 6TLuis fernando100% (1)

- Engine Differences 1 1Document1 pageEngine Differences 1 1Jamal ShaikhNo ratings yet

- Crane GirderDocument55 pagesCrane GirderRaveendra Babu Cherukuri100% (1)

- Mel346 16Document33 pagesMel346 16ch301202jdocsNo ratings yet

- Thrust Block Design - Presentationhanson PDFDocument10 pagesThrust Block Design - Presentationhanson PDFSaravanan MuthuramanNo ratings yet

- Fv-Kupplung: Couplings General Catalogue - 2015Document28 pagesFv-Kupplung: Couplings General Catalogue - 2015Ivano VerbiNo ratings yet

- Catalog Varvel RS RTDocument60 pagesCatalog Varvel RS RTNikola VojisavljevicNo ratings yet

- Biffi 4Document1 pageBiffi 4Goutham KSNo ratings yet

- Biffi 8Document1 pageBiffi 8Goutham KSNo ratings yet

- GeM Bidding 6498355Document86 pagesGeM Bidding 6498355Goutham KSNo ratings yet

- Mean Well 03252021 NTS 250P Spec-2238450Document7 pagesMean Well 03252021 NTS 250P Spec-2238450Goutham KSNo ratings yet

- ABB Scoop Reference PricingDocument1 pageABB Scoop Reference PricingGoutham KSNo ratings yet

- Biffi 1Document4 pagesBiffi 1Goutham KSNo ratings yet

- Biffi 2Document6 pagesBiffi 2Goutham KSNo ratings yet

- Roots OCRDocument556 pagesRoots OCRGoutham KSNo ratings yet

- Valintec VAEngineering Manejo VaporDocument8 pagesValintec VAEngineering Manejo VaporGoutham KSNo ratings yet

- Psa in Pol LocationsDocument47 pagesPsa in Pol LocationsGoutham KSNo ratings yet

- Hipps Interactive Solutions Tool en Us 176516 PDFDocument62 pagesHipps Interactive Solutions Tool en Us 176516 PDFGoutham KSNo ratings yet

- Discover Valve Automation: Cover Graphic Should Fill and Not Exceed The Defined Grey BoxDocument17 pagesDiscover Valve Automation: Cover Graphic Should Fill and Not Exceed The Defined Grey BoxGoutham KS0% (1)

- MIL 41000 New - Heavy Duty Cage Guided Control ValvesDocument36 pagesMIL 41000 New - Heavy Duty Cage Guided Control ValvesGovarthanan GopalanNo ratings yet

- E SeriesBrochure 000Document6 pagesE SeriesBrochure 000Goutham KSNo ratings yet

- Control ValvesDocument20 pagesControl ValvesGoutham KSNo ratings yet

- Electric Actuators For Use in Nuclear Power Plants: by Michael Herbstritt, Auma Riester GMBH & Co. KG, GermanyDocument5 pagesElectric Actuators For Use in Nuclear Power Plants: by Michael Herbstritt, Auma Riester GMBH & Co. KG, GermanyGoutham KSNo ratings yet

- Electric Actuation - Bernard ControlsDocument4 pagesElectric Actuation - Bernard ControlsGoutham KSNo ratings yet

- New Doc 2019-10-15 21.46.56Document17 pagesNew Doc 2019-10-15 21.46.56Goutham KSNo ratings yet

- Brochure Bettis m2cp Electric Valve Actuators en 86630Document16 pagesBrochure Bettis m2cp Electric Valve Actuators en 86630Goutham KSNo ratings yet

- Waterman CastGate SpecBooklet 4-24-17Document24 pagesWaterman CastGate SpecBooklet 4-24-17Goutham KSNo ratings yet

- Barauni Kanpur Pipeline, Barauni: Indian Oil Corporation LimitedDocument3 pagesBarauni Kanpur Pipeline, Barauni: Indian Oil Corporation LimitedGoutham KSNo ratings yet

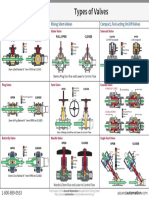

- Types of Valves PDFDocument1 pageTypes of Valves PDFGoutham KSNo ratings yet

- Base WorksheetDocument4 pagesBase WorksheetNicola StephensNo ratings yet

- ISR4321-V/K9 Datasheet: Quick SpecsDocument6 pagesISR4321-V/K9 Datasheet: Quick SpecsDjibril FayeNo ratings yet

- 4.202324 Module Handbook PPDDocument15 pages4.202324 Module Handbook PPDAyesha IrumNo ratings yet

- The Management of Foreign Exchange RiskDocument97 pagesThe Management of Foreign Exchange RiskVajira Weerasena100% (1)

- Merged E-Portfolio HRM 2021-1-286-2Document16 pagesMerged E-Portfolio HRM 2021-1-286-2DrKomal KhalidNo ratings yet

- Case Study TipsDocument4 pagesCase Study TipsUjjawal PandeyNo ratings yet

- C. Health Problems Common in ToddlerDocument72 pagesC. Health Problems Common in ToddlerRika MaeNo ratings yet

- 13 Electrical Pole's TrasverseDocument7 pages13 Electrical Pole's TrasverseReza PahlepiNo ratings yet

- Chap04 Test BankDocument47 pagesChap04 Test BankJacob MullerNo ratings yet

- Eu Law ExamDocument14 pagesEu Law ExamOla PietruszewskaNo ratings yet

- Introduction To SAP SD - ConditionsDocument17 pagesIntroduction To SAP SD - ConditionspipocaazulNo ratings yet

- Activity Proposal-Stakeholders Forum 2Document6 pagesActivity Proposal-Stakeholders Forum 2Rob MachiavelliNo ratings yet

- TSE Dec 19 - WebDocument52 pagesTSE Dec 19 - Web伟雄No ratings yet

- 8DG61258GAAATCZZA - V1 - 1830 Photonic Service Switch (PSS) Release 7.0 User Provisioning Guide PDFDocument1,946 pages8DG61258GAAATCZZA - V1 - 1830 Photonic Service Switch (PSS) Release 7.0 User Provisioning Guide PDFNishant DosiNo ratings yet

- Drmg152 PDFDocument116 pagesDrmg152 PDFGuillaumeRicherNo ratings yet

- Essar Steel-Defaulting On Debt RepaymentDocument9 pagesEssar Steel-Defaulting On Debt RepaymentSudani Ankit100% (1)

- (Download PDF) Computer System Architecture M Morris Mano Online Ebook All Chapter PDFDocument42 pages(Download PDF) Computer System Architecture M Morris Mano Online Ebook All Chapter PDFrichard.yelton559100% (10)

- Issue #72Document84 pagesIssue #72baltazzar_90No ratings yet

- 1 - Definition and Importance of Specification Writing - NewDocument16 pages1 - Definition and Importance of Specification Writing - Newprajoshi62No ratings yet

- Compiled LR PDFDocument13 pagesCompiled LR PDFFrh RzmnNo ratings yet

- Pent4343 XS-96 Uk L PDFDocument84 pagesPent4343 XS-96 Uk L PDFLOUKILkarimNo ratings yet

- Advances Photonic CrystalsDocument348 pagesAdvances Photonic CrystalsMuhammad Shemyal NisarNo ratings yet

- TDC Book Parte6Document44 pagesTDC Book Parte6QUARCISSUSNo ratings yet

- Thefirstdayofschoolharrywong PDFDocument339 pagesThefirstdayofschoolharrywong PDFsauldez100% (1)

- Mahindra Computer Notes in English (Misc MCQS) (Sscstudy - Com)Document15 pagesMahindra Computer Notes in English (Misc MCQS) (Sscstudy - Com)Suprakash KumarNo ratings yet

- Floorplan Design of VLSIDocument18 pagesFloorplan Design of VLSIAtul Prakash DwivediNo ratings yet

- Cranfield University: Attempt All QuestionsDocument6 pagesCranfield University: Attempt All QuestionsFabio BosioNo ratings yet

- Advanced Digital Image Processing-QBDocument2 pagesAdvanced Digital Image Processing-QBSiva Dharshan ValuvanNo ratings yet

Wigva BGTM15 PDF

Wigva BGTM15 PDF

Uploaded by

Goutham KSOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wigva BGTM15 PDF

Wigva BGTM15 PDF

Uploaded by

Goutham KSCopyright:

Available Formats

GEAR OPERATORS

Figure BGTM Bevel Gear

OVERVIEW

On occasion, linear valves such as wedge and knife gate valves are

installed in areas where mechanical advantage is needed, or where the

valve hand wheel needs to be moved from the horizontal plane to the

vertical. The BGTM enclosed right-angle bevel gear operator provides

thrust and torque advantage, making it easier to operate

rising and non-rising multi-turn valves. The heavy design

and hammer-blow feature makes the BGTM perfect for

industrial application.

OPTIONS

Not every valve installation with gear operator places the handwheel

in an ideal position for the user. Options and WIGVA’s fabrication

capabilities are available to provide this accessibility. Options include,

but are not limit to:

• Square Drive Nuts - For valves installed below grade or otherwise

inaccessible directly, or as a means to limit operation to only those with the

proper tee-handle, the handwheel can be replaced with a square drive nut

on the input shaft.

• Miters - Used in conjunction with the BGTM, a 1:1 ratio miter can reorient the

input shaft by 90° for accessibility or addition of further options.

• Stem Extensions - Since the BGTM reduces the input torque and provides the thrust needed to operate a linear valve,

a lower torque non-rising stem extension can be applied to the input shaft. Stem extensions can be fabricated to meet

many installation requirements.

• Chainwheel Operators - For remote overhead installations, a chainwheel operator can be applied to the handwheel.

Galvanized chain can be supplied with the chainwheel provided the drop is known.

SIZING CALCULATIONS

In addition to picking a gear that can achieve the desired output torque and accept the valve

stem characteristics, use the following formulas to determine the input torque and handwheel

rim pull. Gear operators have a maximum input torque that should not be exceeded.

TQIN = ( HW x RP

2 )

÷ 12

TQIN - Input Torque: The amount of torque required at the gear’s input shaft to achieve TQOUT

TQIN =

a certain output torque, expressed as “Lbs-Ft” in these equations MA

TQOUT - Output Torque: The amount of torque produced at the gear’s stem bushing TQOUT = TQIN x MA

based on a certain input torque, expressed as “Lbs-Ft” in these equations

HW - Handwheel Diameter: Diameter of the handwheel expressed in inches

MA - Mechanical Advantage: Based on the physical characteristics of the gear

RP = ( 2 x TQIN

HW )

x 12

configuration, expressed as a multiplier

TRIN = GR x TROUT

RP - Rim Pull: The amount of force, expressed in pounds (Lbs), required or desired

on the handwheel TROUT = LFT ÷ LD

GR - Gear Ratio: Based on the physical characteristics of the gear configuration,

TROUT = TRIN ÷ GR

expressed as a fraction (e.g. - A ratio of “3.5 : 1” is expressed as “3.5/1” or “3.5”)

TRIN - Input Turns: The number of turns required at the gear operator’s handwheel to Lbs-In = Lbs-Ft x 12

fully stroke a valve Lbs-Ft = Lbs-In ÷ 12

TROUT - Output Turns: The number of turns required at the valve stem to fully stroke the

valve

LFT - Lift: The overal linear distance the valve’s stem moves to complete one stroke (close to open)

LD - Lead: A characteristic of the valve stem, it is the linear distance the stem moves with one turn of the valve’s

handwheel

Phone: 503-287-8383 ~ www.WIGVA.com

Materials

Description Material

Housing Ductile Iron A536-65-45-12

Base Ductile Iron A536-65-45-12

Bevel Gear Carbon Steel A576-1045

Bevel Pinion Alloy Steel A332-4140

L1 L2 Drive Sleeve Ductile Iron A536-65-45-12

PF

Lock Nuts Carbon Steel A576-1045

Aluminum Bronze

Stem Bushing

B584-C86200

PD M Input Cap Ductile Iron A536-65-45-12

H3

H2 H1

Base/Cap Bolts Alloy Steel A332-4140

H4

Input Shaft Bearings Bearing Steel A295-52100

H

Thrust Bearings Bearing Steel A295-52100

MAX STEM

Housing Plug Carbon Steel A307 Gr B

D1

Housing/Cap O-rings Buna N (NBR)

D3

Collar Steel Pipe A53

D2 (B.C.)

Bearing Washer Carbon Steel A576-1045

Bearing Nut Carbon Steel A576-1045

Zinc Plated Carbon Steel

Grease Fitting

A307 Gr B

N- S - DP

Set Screw Stainless Steel A276-304

Base/Cap Gaskets Nonasbestos

Key Carbon Steel A576-1045

Dimensions (inches)

Part Number Flange ØD1 ØD2 N ØS DP ØD3 H H1 H2 H3 H4 L1 L2 ØPD KEY ØM PF (Straight)

WVABGTMB1 F10 2.756 4.016 4 3/8-16 0.59 4.92 0.08 2.20 2.62 4.06 1.97 4.96 1.38 0.98 0.315X0.276 11.81 2" - 11

WVABGTMB3 F14 3.937 5.512 4 5/8-11 0.79 6.89 0.12 2.52 2.83 4.53 2.28 6.26 1.38 1.18 0.394X0.315 15.75 2-1/2" - 11

WVABGTMB5 F20 5.512 8.071 8 5/8-11 1.18 9.65 0.12 3.58 4.09 6.02 3.15 7.80 1.38 1.18 0.394X0.315 24.80 3" - 11

Mechanical Specifications

Maximum Maximum Max Stem

Gear Torque (lbs-ft) Mechanical Wt.

Part Number Thrust

Ratio Advantage Keyed Threaded (lbs)

(lbs) Input Output

WVABGTMB1 2.5 : 1 16,964 80 183 2.3 0.87 1.10 20

WVABGTMB3 3.5 : 1 28,419 159 507 3.2 1.50 1.81 38

WVABGTMB5 4.0 : 1 42,739 320 1151 3.6 2.17 2.44 75

© 2015 - WIGVA. All rights reserved.

Wolseley Industrial Group, Valve & Automation (WIGVA) is a member of Wolseley Industrial Group

The contents of this publication are presented for information purposes only, and while effort has been made

to ensure their accuracy, they are not to be construed as warranties or guarantees, expressed or implied,

regarding the products or services described herein or their use or applicability. All sales are governed by

our terms and conditions, which are available on request. We reserve the right to modify or improve the

designs or specifications of our products at any time without notice. ID: WIGVA_BGTM15 Ver. 06/2015

You might also like

- EDUC5711 Week 8 Discussion Assignment Unit 8Document3 pagesEDUC5711 Week 8 Discussion Assignment Unit 8Meleisa WrayNo ratings yet

- Brand AuditDocument17 pagesBrand AuditAVINASH TOPNONo ratings yet

- TC FLS Sihi Akhx enDocument12 pagesTC FLS Sihi Akhx enandrescaligoNo ratings yet

- Turbogenerator ConceptDocument10 pagesTurbogenerator ConceptJorge MontalvoNo ratings yet

- 06 Casquillos de Agujas Sin Fondo Clutch SimilarDocument98 pages06 Casquillos de Agujas Sin Fondo Clutch SimilarSara Sarmiento EcheverryNo ratings yet

- WILO SCP RangeDocument48 pagesWILO SCP RangeSaikat PurkaitNo ratings yet

- Catalogo Colheitadeira Case 2388-2399aDocument2,384 pagesCatalogo Colheitadeira Case 2388-2399aThiago RomeroNo ratings yet

- C Series: Cutter ImpellerDocument6 pagesC Series: Cutter ImpellerNichamon NNo ratings yet

- Enerpac WHC WHR Series CatalogDocument1 pageEnerpac WHC WHR Series CatalogTitanplyNo ratings yet

- Bomba Agua dulceTC - FLS - SIHI - AKHA - ENDocument18 pagesBomba Agua dulceTC - FLS - SIHI - AKHA - ENOscar CaviedesNo ratings yet

- FICHA - ARMSTRONG Recirculadores Series S y H EspecificacionesDocument4 pagesFICHA - ARMSTRONG Recirculadores Series S y H EspecificacionesSalvador RiveraNo ratings yet

- Jl. Perak Timur 102 Surabaya: Weight SummaryDocument74 pagesJl. Perak Timur 102 Surabaya: Weight SummaryhajarNo ratings yet

- Katalog POMPA ARITA 2022Document30 pagesKatalog POMPA ARITA 2022Washiul RizkiNo ratings yet

- Katalog Produk PompaDocument35 pagesKatalog Produk PompaRiyan SiregarNo ratings yet

- MD-500 Torque SpecDocument7 pagesMD-500 Torque SpecBiswanath LenkaNo ratings yet

- Configuration: Price Lead TimeDocument2 pagesConfiguration: Price Lead TimeiudexisNo ratings yet

- Warren ValvesDocument1 pageWarren ValvesNebstereNo ratings yet

- Pumpworks 610-BB3Document6 pagesPumpworks 610-BB3Padmanabhan VenkateshNo ratings yet

- WEG Part Number Configuration Weg Motors Usapnconf Quick Guide EnglishDocument1 pageWEG Part Number Configuration Weg Motors Usapnconf Quick Guide EnglishGustavo Gaibar0% (1)

- PumpWorks 610 PWD Brochure1Document6 pagesPumpWorks 610 PWD Brochure1Octa RioNo ratings yet

- HT Cable ScheduleDocument2 pagesHT Cable ScheduletceterexNo ratings yet

- Planetary Gearbox For Servo Motor 2014Document40 pagesPlanetary Gearbox For Servo Motor 2014Blaze123xNo ratings yet

- D00 RSRT STD EN ED01 REV03 WebDocument68 pagesD00 RSRT STD EN ED01 REV03 WebRedOne KhasmiNo ratings yet

- 15W (150HP) BLHSeriesBrushlessDCMotorSpeedControlSystemsDocument3 pages15W (150HP) BLHSeriesBrushlessDCMotorSpeedControlSystemsHậu Trần TrọngNo ratings yet

- Teaching Modules For Steel Instruction: Developed by Scott Civjan University of Massachusetts, AmherstDocument28 pagesTeaching Modules For Steel Instruction: Developed by Scott Civjan University of Massachusetts, AmherstkiranNo ratings yet

- Chelsea 880 - PTODocument2 pagesChelsea 880 - PTOkaabach80No ratings yet

- Project Data: DesignDocument18 pagesProject Data: DesignMarco ZanellaNo ratings yet

- Part List Ebara 3MDocument2 pagesPart List Ebara 3MEddie GuillénNo ratings yet

- NC Rotary Tables: Standard TypeDocument2 pagesNC Rotary Tables: Standard TypeNathan ChenNo ratings yet

- Brochure FSA, 60 HZDocument6 pagesBrochure FSA, 60 HZIbrahim SanusiNo ratings yet

- HY25-0152-B1 - US870 Series Chelsea PTODocument2 pagesHY25-0152-B1 - US870 Series Chelsea PTORobbie GlezNo ratings yet

- Fsa - Ebara End Suction Volute PumpDocument6 pagesFsa - Ebara End Suction Volute PumpkhristprasatyaNo ratings yet

- 4A Reg-Da Panel Existing Control PanelDocument2 pages4A Reg-Da Panel Existing Control Panelangga wira pramanaNo ratings yet

- MIT Screws and Gears GWDocument37 pagesMIT Screws and Gears GWmohanavenkateshNo ratings yet

- Screw ForcesDocument10 pagesScrew ForceskasreedharNo ratings yet

- Pumps Spec Series2400 8 09Document8 pagesPumps Spec Series2400 8 09Hamatouty TottiNo ratings yet

- Output Shaft Lube Nozzle Bearings Bolts RCM Face-Gear PMC Face-GearsDocument9 pagesOutput Shaft Lube Nozzle Bearings Bolts RCM Face-Gear PMC Face-GearsMichael KinneyNo ratings yet

- Caseih Staiger PBDocument1,366 pagesCaseih Staiger PBFernando SabinoNo ratings yet

- DanlyIEM PunchCalcPrefPress 0903Document2 pagesDanlyIEM PunchCalcPrefPress 0903salvador hernandezNo ratings yet

- LP1 TK 10HSD M M8 Deg 1001 C PDFDocument13 pagesLP1 TK 10HSD M M8 Deg 1001 C PDFnguyenanhtuanbNo ratings yet

- LP1 TK 10HSD M M8 Deg 1001 CDocument13 pagesLP1 TK 10HSD M M8 Deg 1001 CnguyenanhtuanbNo ratings yet

- Brochure FSA, 50 Hz1-Dikonversi - Pdf. TerbaruDocument6 pagesBrochure FSA, 50 Hz1-Dikonversi - Pdf. TerbaruDt BarusNo ratings yet

- Ball Valve Full PortDocument2 pagesBall Valve Full PortHardik ShahNo ratings yet

- 735fe, 735xm, 834xm CatlougeDocument143 pages735fe, 735xm, 834xm Catlougedadu tractor83% (30)

- Series1 Steel Bandejas B LineDocument26 pagesSeries1 Steel Bandejas B LineJorge ChavezNo ratings yet

- Hendrix Sole Source LetterDocument9 pagesHendrix Sole Source Lettersaeid.power63No ratings yet

- 12-1/4" Hole Drilling Performance - S-927, Jan 2013: 0 15 Wob (Kdan)Document1 page12-1/4" Hole Drilling Performance - S-927, Jan 2013: 0 15 Wob (Kdan)Balkis FatihaNo ratings yet

- Fire Pump 50HZ-2016 PDFDocument12 pagesFire Pump 50HZ-2016 PDFSinggih MechanicNo ratings yet

- PDF Katalog BallscrewsDocument32 pagesPDF Katalog BallscrewsSaka WahyuNo ratings yet

- Materials: For A Ins MusDocument7 pagesMaterials: For A Ins MusSoumya SameerNo ratings yet

- Technical Specifications Premium 5-1/2" OD Heavy-Weight Drill Pipe, 1340, TT-550 Conn's. NewDocument2 pagesTechnical Specifications Premium 5-1/2" OD Heavy-Weight Drill Pipe, 1340, TT-550 Conn's. NewbkprodhNo ratings yet

- Sihi Aeh enDocument12 pagesSihi Aeh enIrvan NouriNo ratings yet

- Spindle Ball Bearings (HY) KH 6005 E: Precision Class P4 / ABEC7Document1 pageSpindle Ball Bearings (HY) KH 6005 E: Precision Class P4 / ABEC7skohhcslzypqtdhkvaNo ratings yet

- A2-Pile Calculation - BH M1Document90 pagesA2-Pile Calculation - BH M1Priya GopalNo ratings yet

- U18sl 900 6TDocument3 pagesU18sl 900 6TLuis fernando100% (1)

- Engine Differences 1 1Document1 pageEngine Differences 1 1Jamal ShaikhNo ratings yet

- Crane GirderDocument55 pagesCrane GirderRaveendra Babu Cherukuri100% (1)

- Mel346 16Document33 pagesMel346 16ch301202jdocsNo ratings yet

- Thrust Block Design - Presentationhanson PDFDocument10 pagesThrust Block Design - Presentationhanson PDFSaravanan MuthuramanNo ratings yet

- Fv-Kupplung: Couplings General Catalogue - 2015Document28 pagesFv-Kupplung: Couplings General Catalogue - 2015Ivano VerbiNo ratings yet

- Catalog Varvel RS RTDocument60 pagesCatalog Varvel RS RTNikola VojisavljevicNo ratings yet

- Biffi 4Document1 pageBiffi 4Goutham KSNo ratings yet

- Biffi 8Document1 pageBiffi 8Goutham KSNo ratings yet

- GeM Bidding 6498355Document86 pagesGeM Bidding 6498355Goutham KSNo ratings yet

- Mean Well 03252021 NTS 250P Spec-2238450Document7 pagesMean Well 03252021 NTS 250P Spec-2238450Goutham KSNo ratings yet

- ABB Scoop Reference PricingDocument1 pageABB Scoop Reference PricingGoutham KSNo ratings yet

- Biffi 1Document4 pagesBiffi 1Goutham KSNo ratings yet

- Biffi 2Document6 pagesBiffi 2Goutham KSNo ratings yet

- Roots OCRDocument556 pagesRoots OCRGoutham KSNo ratings yet

- Valintec VAEngineering Manejo VaporDocument8 pagesValintec VAEngineering Manejo VaporGoutham KSNo ratings yet

- Psa in Pol LocationsDocument47 pagesPsa in Pol LocationsGoutham KSNo ratings yet

- Hipps Interactive Solutions Tool en Us 176516 PDFDocument62 pagesHipps Interactive Solutions Tool en Us 176516 PDFGoutham KSNo ratings yet

- Discover Valve Automation: Cover Graphic Should Fill and Not Exceed The Defined Grey BoxDocument17 pagesDiscover Valve Automation: Cover Graphic Should Fill and Not Exceed The Defined Grey BoxGoutham KS0% (1)

- MIL 41000 New - Heavy Duty Cage Guided Control ValvesDocument36 pagesMIL 41000 New - Heavy Duty Cage Guided Control ValvesGovarthanan GopalanNo ratings yet

- E SeriesBrochure 000Document6 pagesE SeriesBrochure 000Goutham KSNo ratings yet

- Control ValvesDocument20 pagesControl ValvesGoutham KSNo ratings yet

- Electric Actuators For Use in Nuclear Power Plants: by Michael Herbstritt, Auma Riester GMBH & Co. KG, GermanyDocument5 pagesElectric Actuators For Use in Nuclear Power Plants: by Michael Herbstritt, Auma Riester GMBH & Co. KG, GermanyGoutham KSNo ratings yet

- Electric Actuation - Bernard ControlsDocument4 pagesElectric Actuation - Bernard ControlsGoutham KSNo ratings yet

- New Doc 2019-10-15 21.46.56Document17 pagesNew Doc 2019-10-15 21.46.56Goutham KSNo ratings yet

- Brochure Bettis m2cp Electric Valve Actuators en 86630Document16 pagesBrochure Bettis m2cp Electric Valve Actuators en 86630Goutham KSNo ratings yet

- Waterman CastGate SpecBooklet 4-24-17Document24 pagesWaterman CastGate SpecBooklet 4-24-17Goutham KSNo ratings yet

- Barauni Kanpur Pipeline, Barauni: Indian Oil Corporation LimitedDocument3 pagesBarauni Kanpur Pipeline, Barauni: Indian Oil Corporation LimitedGoutham KSNo ratings yet

- Types of Valves PDFDocument1 pageTypes of Valves PDFGoutham KSNo ratings yet

- Base WorksheetDocument4 pagesBase WorksheetNicola StephensNo ratings yet

- ISR4321-V/K9 Datasheet: Quick SpecsDocument6 pagesISR4321-V/K9 Datasheet: Quick SpecsDjibril FayeNo ratings yet

- 4.202324 Module Handbook PPDDocument15 pages4.202324 Module Handbook PPDAyesha IrumNo ratings yet

- The Management of Foreign Exchange RiskDocument97 pagesThe Management of Foreign Exchange RiskVajira Weerasena100% (1)

- Merged E-Portfolio HRM 2021-1-286-2Document16 pagesMerged E-Portfolio HRM 2021-1-286-2DrKomal KhalidNo ratings yet

- Case Study TipsDocument4 pagesCase Study TipsUjjawal PandeyNo ratings yet

- C. Health Problems Common in ToddlerDocument72 pagesC. Health Problems Common in ToddlerRika MaeNo ratings yet

- 13 Electrical Pole's TrasverseDocument7 pages13 Electrical Pole's TrasverseReza PahlepiNo ratings yet

- Chap04 Test BankDocument47 pagesChap04 Test BankJacob MullerNo ratings yet

- Eu Law ExamDocument14 pagesEu Law ExamOla PietruszewskaNo ratings yet

- Introduction To SAP SD - ConditionsDocument17 pagesIntroduction To SAP SD - ConditionspipocaazulNo ratings yet

- Activity Proposal-Stakeholders Forum 2Document6 pagesActivity Proposal-Stakeholders Forum 2Rob MachiavelliNo ratings yet

- TSE Dec 19 - WebDocument52 pagesTSE Dec 19 - Web伟雄No ratings yet

- 8DG61258GAAATCZZA - V1 - 1830 Photonic Service Switch (PSS) Release 7.0 User Provisioning Guide PDFDocument1,946 pages8DG61258GAAATCZZA - V1 - 1830 Photonic Service Switch (PSS) Release 7.0 User Provisioning Guide PDFNishant DosiNo ratings yet

- Drmg152 PDFDocument116 pagesDrmg152 PDFGuillaumeRicherNo ratings yet

- Essar Steel-Defaulting On Debt RepaymentDocument9 pagesEssar Steel-Defaulting On Debt RepaymentSudani Ankit100% (1)

- (Download PDF) Computer System Architecture M Morris Mano Online Ebook All Chapter PDFDocument42 pages(Download PDF) Computer System Architecture M Morris Mano Online Ebook All Chapter PDFrichard.yelton559100% (10)

- Issue #72Document84 pagesIssue #72baltazzar_90No ratings yet

- 1 - Definition and Importance of Specification Writing - NewDocument16 pages1 - Definition and Importance of Specification Writing - Newprajoshi62No ratings yet

- Compiled LR PDFDocument13 pagesCompiled LR PDFFrh RzmnNo ratings yet

- Pent4343 XS-96 Uk L PDFDocument84 pagesPent4343 XS-96 Uk L PDFLOUKILkarimNo ratings yet

- Advances Photonic CrystalsDocument348 pagesAdvances Photonic CrystalsMuhammad Shemyal NisarNo ratings yet

- TDC Book Parte6Document44 pagesTDC Book Parte6QUARCISSUSNo ratings yet

- Thefirstdayofschoolharrywong PDFDocument339 pagesThefirstdayofschoolharrywong PDFsauldez100% (1)

- Mahindra Computer Notes in English (Misc MCQS) (Sscstudy - Com)Document15 pagesMahindra Computer Notes in English (Misc MCQS) (Sscstudy - Com)Suprakash KumarNo ratings yet

- Floorplan Design of VLSIDocument18 pagesFloorplan Design of VLSIAtul Prakash DwivediNo ratings yet

- Cranfield University: Attempt All QuestionsDocument6 pagesCranfield University: Attempt All QuestionsFabio BosioNo ratings yet

- Advanced Digital Image Processing-QBDocument2 pagesAdvanced Digital Image Processing-QBSiva Dharshan ValuvanNo ratings yet