Professional Documents

Culture Documents

Camber Tolerances Hendrick

Camber Tolerances Hendrick

Uploaded by

Dhivhya0 ratings0% found this document useful (0 votes)

10 views1 pageCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances Hendrick

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances Hendrick

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

10 views1 pageCamber Tolerances Hendrick

Camber Tolerances Hendrick

Uploaded by

DhivhyaCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances HendrickCamber Tolerances Hendrick

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Cutting Edge Metal Solutions

Perforating & Fabrication

www.hendrickcorp.com/perf

perf@hendrickcorp.com

800-225-7373

Carbondale, PA & Elgin, IL

Camber Tolerances

Technical Resources—Perforated Metal Standards

Camber is the measured deviation of the side

of a sheet from a straight edge. Camber is

caused by one side of a sheet being elongated

more than the other side during perforation

or leveling. Camber often results from having

unequal side margins on a sheet.

Camber is measured by placing a straight

edge along the concave side of the sheet

and measuring the maximum distance

from the straight edge to the edge of the

sheet (Figure 1).

A sheet can be sheared after it is perforat-

ed and leveled, which will make the sheet

square, but the perforated pattern will still

be cambered on the sheet (Figure 2).

If sheets are cut after perforation, the

camber refers only to the perforated pat-

tern. (See sketch below F & G)

Designers are requested to avoid different

margins whenever possible.

Maximum Camber

Maximum camber for all metals after perforating:

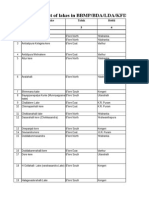

Coils & Cut Length in Ft. Commercial Quality Superior Quality Special Quality

To 4 Ft. Inclusive 1/8” 4’ = .062” -

Over 4-6 Ft. Inclusive 3/16” 5’ = .098” -

Over 6-8 Ft. Inclusive 1/2” 6’ = .140” -

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- HR List PuneDocument65 pagesHR List Punetelakshay83% (87)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Online GroceryDocument45 pagesOnline GroceryDhivhyaNo ratings yet

- Hey, Amol: Why Should You Pick UsDocument2 pagesHey, Amol: Why Should You Pick UsDhivhyaNo ratings yet

- D 86673 BFF 00012 BC 807Document2 pagesD 86673 BFF 00012 BC 807DhivhyaNo ratings yet

- 10N-11D Aussie-GT GRPDocument7 pages10N-11D Aussie-GT GRPDhivhyaNo ratings yet

- Tata+Sky+Packs 6jun2019Document308 pagesTata+Sky+Packs 6jun2019DhivhyaNo ratings yet

- Critical Path Analysis: Basic ConceptsDocument38 pagesCritical Path Analysis: Basic ConceptsDhivhyaNo ratings yet

- Listof 210lake BDA, BBMP, LDA, KFD, MILIstDocument33 pagesListof 210lake BDA, BBMP, LDA, KFD, MILIstDhivhyaNo ratings yet

- 1 Lakme Lever - HUL Shreya Parashar: Sr. No Name of The Company Name of ContactDocument3 pages1 Lakme Lever - HUL Shreya Parashar: Sr. No Name of The Company Name of ContactDhivhyaNo ratings yet

- Indian Decorative Paint IndustryDocument26 pagesIndian Decorative Paint IndustryDhivhyaNo ratings yet

- A Framework For Media Comparison AnalysisDocument20 pagesA Framework For Media Comparison AnalysisDhivhyaNo ratings yet

- HR Conatct DetailsDocument32 pagesHR Conatct DetailsDhivhyaNo ratings yet

- TestDocument39 pagesTestDhivhyaNo ratings yet

- Company HR Manager DetailsDocument6 pagesCompany HR Manager DetailsDhivhyaNo ratings yet