Professional Documents

Culture Documents

Industrial Arts - Electrical Installation and Maintenance (Exploratory)

Industrial Arts - Electrical Installation and Maintenance (Exploratory)

Uploaded by

Jobert r. TotanesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industrial Arts - Electrical Installation and Maintenance (Exploratory)

Industrial Arts - Electrical Installation and Maintenance (Exploratory)

Uploaded by

Jobert r. TotanesCopyright:

Available Formats

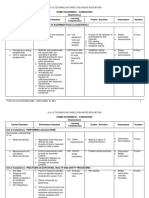

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS – ELECTRICAL INSTALLATION AND MAINTENANCE

(Exploratory)

Learning

Content Standard Performance Standard Project/ Activities Assessment Duration

Competencies

LESSON 1: PREPARE ELECTRICAL MATERIALS AND TOOLS

Demonstrate understanding

of/on:

• Identify materials and 1. Tools and materials are LO1. Identify 1. Skin wires using the • Written test 12 hours

tools applicable to a identified as per job electrical following tools: • Performance

specific job requirement. materials and a. electricians knife, test

Electrical tools and 2. Tools are classified according tools b. combination pliers

equipment to their function as per job applicable to a &side cutting pliers,

Electrical materials requirements. specific job c. wire Stripper.

• Common splices and 3. Materials are classified 2. Connecting the skinned

joints according to their uses to a wires to the terminals of:

• Extension cord specific project. a. bulb receptacles,

4. Tools and materials are b. switches, and

selected as per job c. fuse boxes.

requirement. 3. Perform Splices and joints,

4. Making an extension cord.

• Different forms 1. Needed materials and tools LO2. Request 1. Identify different types of • Direct

• Job order slip are listed as per job appropriate forms use in the shop and observation

• Tools and materials requirement. electrical explain how it is being • Written test

requisition slip 2. Materials and tools are materials and used. • Performance

• Borrower’s Slip requested according to the list tools test

• Requisition procedures prepared.

3. Requests are done as per 2. Simulate student to act as

company standard operating tool keeper and the other is

procedures (SOP). a borrower.

4. Materials and tools are

substituted provided required

materials and tools are

unavailable without sacrificing

*TWG on K to 12 Curriculum Guide – version January 31, 2012 1

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS – ELECTRICAL INSTALLATION AND MAINTENANCE

(Exploratory)

Learning

Content Standard Performance Standard Project/ Activities Assessment Duration

Competencies

cost and quality of work.

• Procedures in receiving 1. Materials and tools are LO3. Receive and 1. Simulation: • Direct

tools and materials received and inspected as per inspect a. One student act as a observation

• Proper inspection of tools quantity and specification electrical supplier and the other • Written test

and materials received. based on requisition. materials as the receiver of • Performance

• Proper handling of tools 2. Tools and materials are supplies test

and materials. checked for damages and

manufacturing defects.

3. Materials and tools received

are handled with appropriate

safety devices.

4. Materials and tools are set

aside to appropriate location

nearest to the workplace.

*TWG on K to 12 Curriculum Guide – version January 31, 2012 2

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS – ELECTRICAL INSTALLATION AND MAINTENANCE

(Exploratory)

Learning

Content Standard Performance Standard Project/ Activities Assessment Duration

Competencies

LESSON 2: PERFORM MENSURATIONS AND CALCULATIONS

Demonstrate understanding

of/on:

• Measuring 1. Measuring tools are LO1.Select 1. Perform measurement of: • Actual 6 hours

Instruments/Measuring selected/identified as per electrical a. teachers table, demonstration

Tools object to be measured or job measuring b. the classroom. • Direct

• Proper handling of requirements. instruments. 2. Measure the ff.: observation

measuring instruments 2. Measurements are obtained a. Voltage of the outlet, • Written test

• Ohms Law according to job requirements. b. Voltage of a dry cell • Performance

3. Computation for resistance, battery, and test

current and voltage using c. Resistance of

Ohms Law are obtained. resistors.

3. Compute for :

a. Resistance

b. Current

c. Voltage

• Kinds of measurement 1. Numerical computations are LO2.Carry out 1. Read the following • Direct

• Dimensions self-checked and corrected for measurements measurements: observation

• Conversion accuracy. and calculations. a. Inch • Written test

2. Accurate measurements are Graduation • Performance

obtained according to job b. Centimeter test

requirements. graduation

3. Identified and converted 2. Solving problems:

systems of measurement a. Conversion of English

according to job requirements. unit to Metric unit and

4. Measured work pieces vice versa.

according to job requirements.

*TWG on K to 12 Curriculum Guide – version January 31, 2012 3

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS – ELECTRICAL INSTALLATION AND MAINTENANCE

(Exploratory)

Learning

Content Standard Performance Standard Project/ Activities Assessment Duration

Competencies

LESSON 3: INTERPRET TECHNICAL DRAWINGS AND PLANS

Demonstrate understanding

of/on:

• Drawing electrical 1. Sign, symbols, and data are LO1. Analyze 1. Draw the different signs • Direct 6 hours

symbols and signs identified according to job signs, commonly used in the observation

• Drawing wiring diagrams: specifications. electrical industry in illustration board • Written test

Pictorial 2. Sign, symbols and data are symbols and or any hard carton board. • Performance

Schematic determined according to data. 2. Identify the different test

classification or as appropriate electrical symbols

in drawing. 3. Draw wiring diagram:

a. Pictorial

b. Schematic

• Technical plans and 1. Necessary tools, materials and LO2. Interpret 1. Draw an electrical plan. • Direct

Schematic Diagram equipment are identified technical observation

according to the plan. drawings and • Written test

Electrical plan 2. Components, assemblies or plans. • Performance

object are recognized as per

• Symbols and job requirement.

Abbreviations 3. Dimensions and specification

are identified according to job

requirements.

*TWG on K to 12 Curriculum Guide – version January 31, 2012 4

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS – ELECTRICAL INSTALLATION AND MAINTENANCE

(Exploratory)

Learning

Content Standard Performance Standard Project/ Activities Assessment Duration

Competencies

LESSON 4: MAINTAIN TOOLS AND EQUIPMENT

Demonstrate understanding

of/on:

• Types of Tools and 1. Tools and equipment are LO1. Check 1. Identify hand tools, • Direct 8 hours

Equipments identified according to condition of pneumatic tools and observation

Safety reminders classification/ specification and tools and electric power tools. • Written test

• Classification of job .requirements. equipment. • Performance

functional and non- 2. Non-functional tools and test

functional tools equipment are segregated and

• Uses of Personal labeled according to

Protective Equipment classification.

(PPE). 3. Safety of tools and equipment

are observed in accordance

with manufacturer’s

instructions

4. Conditions of PPE are

checked in accordance with

manufacturer’s instructions.

• Types uses of lubricants 1. Lubricants are identified LO2. Perform basic 1. Perform cleaning and • Direct

• Types and uses of according to types of preventive lubricating of tools. observation

cleaning equipment. maintenance. 2. Calibrate measuring tools. • Written test

materials/solvent 2. Tools and equipment are 3. Perform 5’s. • Performance

• OSHC workplace lubricated according to test

regulations preventive maintenance

• Types and uses of schedule or manufacturer’s

measuring instruments specifications.

and equipment. 3. Measuring instruments are

• Preventive maintenance checked and calibrated in

techniques and accordance with

*TWG on K to 12 Curriculum Guide – version January 31, 2012 5

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS – ELECTRICAL INSTALLATION AND MAINTENANCE

(Exploratory)

Learning

Content Standard Performance Standard Project/ Activities Assessment Duration

Competencies

procedures. manufacturer’s instructions.

4. Tools are cleaned and

lubricated according to

standard procedures

5. Defective equipment and tools

are inspected and replaced

according to manufacturer’s

specification.

6. Work place is cleaned and

kept in safe state in line with

OSHC regulations.

• Inventory of electrical 1. Inventory of tools, instruments, LO3. Store 1. Preparing inventory of tools • Practical exam

tools and equipment and equipment are conducted electrical tools and equipment. • Direct

• Tools and Equipment and recorded as per company and observation

Handling practices. equipment. • Written test

• Tool safe-keeping/storage 2. Tools are inspected, and

replaced after use.

3. Tools and equipment are

stored safely in accordance

with manufacturer’s

specifications or company

procedures.

*TWG on K to 12 Curriculum Guide – version January 31, 2012 6

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS – ELECTRICAL INSTALLATION AND MAINTENANCE

(Exploratory)

Learning

Content Standard Performance Standard Project/ Activities Assessment Duration

Competencies

LESSON 5: PRACTICE OCCUPATIONAL HEALTH AND SAFETY PROCEDURES

Demonstrate understanding

of/on:

• Hazards and risks 1. Workplace hazards and risks LO1. Identify 1. Making an internet • Written test 10 hours

identification and control are identified and clearly hazards and research on different

• Organizational safety and explained. risks. company hazards and

health protocol 2. Hazards/risks and their risks.

• Threshold limit value (TLV) corresponding indicators are

• OHS indicators identified in with the company

procedures.

3. Contingency measures are

recognized and established in

accordance with organizational

procedures.

• TLV table 1. Terms of maximum tolerable LO2. Evaluate 1. Present a video regarding • Written test

• Philippine OHS standards limits are identified based on hazards and workplace hazards and • Performance

• Effects of hazards in the threshold limit values (TLV). risks. risk. test

workplace 2. Effects of hazards are 2. Simulation

• Ergonomics determined.

• ECC Regulations 3. OHS issues and concerns are

identified in accordance with

workplace requirements and

relevant workplace OHS

legislation.

• Safety regulations 1. OHS procedures for controlling LO3. Control 1. Do an information • Written test

• Clean air act hazards and risk are strictly hazards and campaign

• Electrical and fire safety followed. risks. a. Poster making on

code 2. Procedures in dealing with safety rules and

*TWG on K to 12 Curriculum Guide – version January 31, 2012 7

K to 12 TECHNOLOGY AND LIVELIHOOD EDUCATION

INDUSTRIAL ARTS – ELECTRICAL INSTALLATION AND MAINTENANCE

(Exploratory)

Learning

Content Standard Performance Standard Project/ Activities Assessment Duration

Competencies

• Waste management workplace accidents, fire and regulations

• Disaster preparedness emergencies are followed in b. Proper waste

and management accordance with the management

• Contingency measures organization’s OHS policies. exercises

and procedures 3. Personal protective equipment

(PPE) is correctly used in

accordance with organization’s

OHS procedures and

practices.

4. Procedures in providing

appropriate assistance in the

event of workplace

emergencies are identified in

line with the established

organizational protocol.

• Operational health and 1. Procedures in emergency LO4.Maintain 1. Do an emergency training Demonstration

safety procedure, related drill are strictly followed occupational exercises: Interview

practices and regulations in line with the established health and a. Fire drill Written

• Emergency-related drills organization guidelines and safety b. Life saving drill examination

and training procedures. awareness. Portfolio

2. OHS personal records are assessment

filled up in accordance with

workplace requirements.

3. PPE are maintained in line

with organization guidelines

and procedures.

42 hours

*TWG on K to 12 Curriculum Guide – version January 31, 2012 8

You might also like

- Mil Cim Q4Document6 pagesMil Cim Q4ruffNo ratings yet

- Assess Notes Nursing AssessmentDocument206 pagesAssess Notes Nursing Assessmenttostc100% (7)

- HandbookDocument60 pagesHandbookyachiru121No ratings yet

- Bar Exam Answers Useful Introductory LinesDocument18 pagesBar Exam Answers Useful Introductory LinesEron Roi Centina-gacutanNo ratings yet

- Revised Syllabus THC2 Mirasol A. YturraldeDocument6 pagesRevised Syllabus THC2 Mirasol A. YturraldeCristy Lansangan MejiaNo ratings yet

- Unit:1 Measurement and Evaluation in EducationDocument109 pagesUnit:1 Measurement and Evaluation in EducationMukul SaikiaNo ratings yet

- Deped K To 12 Technology and Livelihood Education - Computer Hardware ServicingDocument7 pagesDeped K To 12 Technology and Livelihood Education - Computer Hardware Servicingyachiru121100% (4)

- Computer System ServicingDocument30 pagesComputer System ServicingjheraNo ratings yet

- Session Plan (Diagnosing and Troubleshooting Computer System)Document3 pagesSession Plan (Diagnosing and Troubleshooting Computer System)Alfie LariosaNo ratings yet

- Eim 8 Lesson 4Document6 pagesEim 8 Lesson 4accel sillaNo ratings yet

- 2nd Week EIM DailyDocument5 pages2nd Week EIM DailyDelvin Jan del RosarioNo ratings yet

- Epas Week2 DLLDocument3 pagesEpas Week2 DLLJoseph GutierrezNo ratings yet

- W4 Volume, Area and CircumferenceDocument2 pagesW4 Volume, Area and CircumferenceShirlyn Navarro RamirezNo ratings yet

- Cot 1 - Hand ToolsDocument3 pagesCot 1 - Hand ToolsMaria Jerecca Sierra100% (1)

- G12 Eimncii Q1 2022-2023Document2 pagesG12 Eimncii Q1 2022-2023francisco macatugobNo ratings yet

- CSS - Q2 - Week 8 - BNHSDocument4 pagesCSS - Q2 - Week 8 - BNHSNathaniel MirandaNo ratings yet

- Technology and Livelihood Education: Industrial Arts Electrical Installation and Maintenance Quarter 1 - Module 1Document40 pagesTechnology and Livelihood Education: Industrial Arts Electrical Installation and Maintenance Quarter 1 - Module 1Ronel FerasolNo ratings yet

- Tle 7 EimDocument2 pagesTle 7 EimFrank Michael JaclaNo ratings yet

- Lesson Plan in Empowerment Technology June 7Document1 pageLesson Plan in Empowerment Technology June 7Angelo DiyNo ratings yet

- Ia Eim 11 Q4 Las4 FinalDocument6 pagesIa Eim 11 Q4 Las4 FinalElron KarlNo ratings yet

- Pretest G7Document3 pagesPretest G7Paul Senen DiduloNo ratings yet

- Eim-11 q1 w1 Mod1.PDF-editedDocument11 pagesEim-11 q1 w1 Mod1.PDF-editedMarie TuraNo ratings yet

- EIM GRADE 10 1stQUARTER Week 1 4 EDITEDDocument32 pagesEIM GRADE 10 1stQUARTER Week 1 4 EDITEDkimmheanNo ratings yet

- TLE ExamDocument3 pagesTLE ExamJennNo ratings yet

- Grade 9 EPAS Quarter 1 Module 1 REVISEDDocument22 pagesGrade 9 EPAS Quarter 1 Module 1 REVISEDMarfe Montelibano100% (1)

- Applying 5s On Your ComputerDocument7 pagesApplying 5s On Your ComputerJuliusSarmientoNo ratings yet

- Sunday Monday Tuesda Y Wednes DAY Thursd AY Friday Saturd AYDocument2 pagesSunday Monday Tuesda Y Wednes DAY Thursd AY Friday Saturd AYJaymark FlotildesNo ratings yet

- Consumer Electronics Servicing CG - 2 PDFDocument25 pagesConsumer Electronics Servicing CG - 2 PDFPedro Diaz86% (7)

- Maintain, Organize and Be Safe!: Epas 9 (Electronics Products Assembly and Servicing)Document18 pagesMaintain, Organize and Be Safe!: Epas 9 (Electronics Products Assembly and Servicing)Lambert De VeraNo ratings yet

- To Protect Both Yourself and The Equipment, Observe The Safety PrecautionsDocument3 pagesTo Protect Both Yourself and The Equipment, Observe The Safety Precautionsapi-196541959No ratings yet

- DLL EIM11 1stSem1stQuarter Week1Document4 pagesDLL EIM11 1stSem1stQuarter Week1Gelo Dela TorreNo ratings yet

- Department of Education: Melcs-Based Budget of LessonsDocument6 pagesDepartment of Education: Melcs-Based Budget of LessonsJacquilen CondeNo ratings yet

- Module 6 PREPARE ELECTRICAL POWER TOOLSDocument22 pagesModule 6 PREPARE ELECTRICAL POWER TOOLSOtep CamaroteNo ratings yet

- CSS Q1 WK1 D1Document4 pagesCSS Q1 WK1 D1Reymond SumayloNo ratings yet

- Mil QaDocument7 pagesMil QaRosenia Santiago Pascual100% (1)

- dETAILED PT AIDocument6 pagesdETAILED PT AIGlezelBayubayNo ratings yet

- Applying Quality StandardDocument33 pagesApplying Quality StandardRowel ReponteNo ratings yet

- TVL - Ia: Quarter 2Document14 pagesTVL - Ia: Quarter 2Chiarnie LopezNo ratings yet

- Diagnostic Test ElectronicsDocument21 pagesDiagnostic Test ElectronicsCastor Jr JavierNo ratings yet

- TLE10 Electronics Q1 Wk7 Mathematical - Analysis of Parallel CircuitDocument12 pagesTLE10 Electronics Q1 Wk7 Mathematical - Analysis of Parallel Circuitismael delosreyesNo ratings yet

- Lubricate Electric Tools in Line With Manufacturer's SpecificationDocument52 pagesLubricate Electric Tools in Line With Manufacturer's SpecificationKeempee ArconadaNo ratings yet

- Tle-Epas: Quarter 1 - Module 3: Performing Mensuration and Calculation (PMC)Document34 pagesTle-Epas: Quarter 1 - Module 3: Performing Mensuration and Calculation (PMC)Riezl SocoNo ratings yet

- Eim8 Check Condition of Tools and EquipmentDocument18 pagesEim8 Check Condition of Tools and EquipmentJoel Arce100% (1)

- EPAS-9 Q2 W1 Mod1Document12 pagesEPAS-9 Q2 W1 Mod1Princess Dirk Reyes DananNo ratings yet

- Tle Quarter 4 Electrical Installation and Maintenance (Eim)Document23 pagesTle Quarter 4 Electrical Installation and Maintenance (Eim)Kong ArciagaNo ratings yet

- Information Sheet: 1. Clean Dirt and Debris From Tools After Each UseDocument3 pagesInformation Sheet: 1. Clean Dirt and Debris From Tools After Each Usemyco sauraNo ratings yet

- DLL 14Document1 pageDLL 14Abigail MontesNo ratings yet

- WSTP 112ME: Metrology and Benchwork: Learning ModuleDocument54 pagesWSTP 112ME: Metrology and Benchwork: Learning ModulesheeellyyyNo ratings yet

- Apply Safety Practices: Lesson 4Document14 pagesApply Safety Practices: Lesson 4Russell francis o. Mañago100% (1)

- Information LiteracyDocument27 pagesInformation LiteracyCharline A. Radislao100% (1)

- Technology and Livelihood Education (TLE) Electrical Installation and MaintenanceDocument10 pagesTechnology and Livelihood Education (TLE) Electrical Installation and MaintenanceMikaylla Arian RochaNo ratings yet

- Syllabus: Don Bosco Technical Institute - TarlacDocument2 pagesSyllabus: Don Bosco Technical Institute - TarlacEdwin SorianoNo ratings yet

- K To 12 Technology and Livelihood Education: Home Economics - Caregiving (Exploratory)Document14 pagesK To 12 Technology and Livelihood Education: Home Economics - Caregiving (Exploratory)Bri CorpuzNo ratings yet

- Digital: Grade 8 Daily Lesson Log Pulo National High SchoolDocument3 pagesDigital: Grade 8 Daily Lesson Log Pulo National High SchoolGladys Patacsil100% (1)

- EIM 9 September 18Document2 pagesEIM 9 September 18Book NoyPi0% (1)

- Mintal Comprehensive High School: Detailed Lesson Plan (DLP) SY 2019-2020Document4 pagesMintal Comprehensive High School: Detailed Lesson Plan (DLP) SY 2019-2020Teofilo BuenoNo ratings yet

- Use of Tools in PC Hardware ServicingDocument31 pagesUse of Tools in PC Hardware ServicingEunice Abapo Alvarado100% (1)

- Afa Agri-Crop 9 q2w4Document17 pagesAfa Agri-Crop 9 q2w4Ma. Amor GenonNo ratings yet

- EIM Y2 Module 2Document39 pagesEIM Y2 Module 2Ysmael DramanNo ratings yet

- Grade9 - Split Cable TapDocument6 pagesGrade9 - Split Cable TapEu NiceNo ratings yet

- Tle G8-EpasDocument22 pagesTle G8-EpasAaron Ansaldo100% (1)

- DLL - Smaw - Q3 - W7Document6 pagesDLL - Smaw - Q3 - W7Renato Reyes Jr.No ratings yet

- Deped K To 12 Technology and Livelihood Education - PlumbingDocument8 pagesDeped K To 12 Technology and Livelihood Education - Plumbingyachiru12175% (4)

- Deped K To 12 Technology and Livelihood Education - CarpentryDocument8 pagesDeped K To 12 Technology and Livelihood Education - Carpentryyachiru121No ratings yet

- Deped K To 12 Technology and Livelihood Education - SmawDocument6 pagesDeped K To 12 Technology and Livelihood Education - Smawyachiru121No ratings yet

- Anatomy Thorax ReviewDocument18 pagesAnatomy Thorax Reviewyachiru121No ratings yet

- AP Review NotesDocument15 pagesAP Review Notesyachiru121No ratings yet

- Bacteriology ReviewDocument47 pagesBacteriology ReviewDeti ParidlahNo ratings yet

- Anatomy and Physiology I Fall 2009 Exam I Study GuideDocument1 pageAnatomy and Physiology I Fall 2009 Exam I Study Guideyachiru121No ratings yet

- Anatomy Lower Extr ReviewDocument12 pagesAnatomy Lower Extr Reviewabuzeid5No ratings yet

- API Review Muscles f2009Document1 pageAPI Review Muscles f2009yachiru121No ratings yet

- First Aid ManualDocument225 pagesFirst Aid ManualHugo MartinsNo ratings yet

- Anatomy Levels and Planes ReviewDocument3 pagesAnatomy Levels and Planes Revieware4erNo ratings yet

- Anatomy Head ReviewDocument34 pagesAnatomy Head ReviewJordan BrooksNo ratings yet

- Anatomy and Physiology Unit III: Objectives/RationaleDocument16 pagesAnatomy and Physiology Unit III: Objectives/Rationaleyachiru121No ratings yet

- Bones of The Upper LimbDocument14 pagesBones of The Upper Limbyachiru121No ratings yet

- Bones of The Pelvis and PerineumDocument6 pagesBones of The Pelvis and Perineumyachiru121No ratings yet

- Bones and Cartilages of The Head and NeckDocument27 pagesBones and Cartilages of The Head and Neckyachiru121100% (1)

- Anatomy Tables - Bones of The Thorax: Bone Structure Description Notes RibDocument3 pagesAnatomy Tables - Bones of The Thorax: Bone Structure Description Notes Ribyachiru121No ratings yet

- Bones of The Back RegionDocument9 pagesBones of The Back Regionyachiru121No ratings yet

- Bones of The Lower LimbDocument15 pagesBones of The Lower Limbyachiru121No ratings yet

- Bones of The Abdominal RegionDocument7 pagesBones of The Abdominal Regionyachiru121No ratings yet

- DEPED 2012 - K TO 12 - MTB RationaleDocument30 pagesDEPED 2012 - K TO 12 - MTB Rationaleyachiru121100% (3)

- DEPED 2012 - K TO 12 - Learning DR VillanezaDocument32 pagesDEPED 2012 - K TO 12 - Learning DR Villanezayachiru121100% (1)

- DEPED 2012 - K TO 12 - L1-L2-L3-Dr. GironDocument56 pagesDEPED 2012 - K TO 12 - L1-L2-L3-Dr. Gironyachiru121No ratings yet

- DEPED 2012 - Classroom DR VillanezaDocument17 pagesDEPED 2012 - Classroom DR Villanezayachiru121100% (1)

- DEPED - The K To 12 Basic Education Programv2 - 2012Document38 pagesDEPED - The K To 12 Basic Education Programv2 - 2012yachiru121100% (1)

- GHCPregistrationform 2012Document1 pageGHCPregistrationform 2012yachiru121No ratings yet

- HandbookDocument48 pagesHandbookyachiru121100% (1)

- HandbookDocument53 pagesHandbookyachiru121No ratings yet

- Education in The UkDocument7 pagesEducation in The UkIulia ArmenciuNo ratings yet

- Child Development and Pedagogy Question Paper Answers Teacher Eligibility Test 2011Document9 pagesChild Development and Pedagogy Question Paper Answers Teacher Eligibility Test 2011Rameshbabu BandamNo ratings yet

- Alcohol-Free Workplace Policy & ProgramDocument3 pagesAlcohol-Free Workplace Policy & ProgramAviects Avie JaroNo ratings yet

- Guidelines in Test ConstructionDocument19 pagesGuidelines in Test Constructionmark Jayson marinasNo ratings yet

- Application For CTFL Certification v2.3Document3 pagesApplication For CTFL Certification v2.3Elise ShingNo ratings yet

- CetDocument209 pagesCetSwiti ChoudharyNo ratings yet

- Sir Syed University of Engineering & Technology: Final Examinations Spring 2021Document2 pagesSir Syed University of Engineering & Technology: Final Examinations Spring 2021Engr. Nasir AliNo ratings yet

- SCSA For The Solaris 10 OS Upgrade Exam (CX-310-203)Document5 pagesSCSA For The Solaris 10 OS Upgrade Exam (CX-310-203)Anonymous 4eoWsk3No ratings yet

- Difference Between Account and Report WritingDocument2 pagesDifference Between Account and Report WritingSabina Saba100% (3)

- Administering, Analyzing and Improving The Test (Item Analysis)Document18 pagesAdministering, Analyzing and Improving The Test (Item Analysis)Floravie OnateNo ratings yet

- Proceedings of The Xxi Annual Symposium of The Finnish Association of Mathematics and Science Education ResearchDocument611 pagesProceedings of The Xxi Annual Symposium of The Finnish Association of Mathematics and Science Education ResearchDwi Puji Astini100% (5)

- IELTS Reading TipsDocument9 pagesIELTS Reading TipsnamNo ratings yet

- Indian Air Force: Air Force Common Admission Test Admit Card - Afcat 01/2021 (Afcat & Ekt)Document7 pagesIndian Air Force: Air Force Common Admission Test Admit Card - Afcat 01/2021 (Afcat & Ekt)Anmol SinghNo ratings yet

- UPJEE Process Document - 23rdjune2022Document46 pagesUPJEE Process Document - 23rdjune2022priyanshupandeyNo ratings yet

- Ielts Reading Tips SimonDocument6 pagesIelts Reading Tips SimonhenryNo ratings yet

- 01Document6 pages01Damian EmilioNo ratings yet

- Rajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal (University of Technology of Madhya Pradesh)Document2 pagesRajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal (University of Technology of Madhya Pradesh)Nitesh Kumar SoniNo ratings yet

- CE-365-01 F2017 Environmental Engineering Lab 9069 PDFDocument3 pagesCE-365-01 F2017 Environmental Engineering Lab 9069 PDFHayden Chappelear-RobbinsNo ratings yet

- Diary 2021 - 2022Document105 pagesDiary 2021 - 2022Jandd Clarenz BeñasNo ratings yet

- Chem 1011-1021 Syllabus - Fall 2020Document33 pagesChem 1011-1021 Syllabus - Fall 2020Mariam M. ElgendiNo ratings yet

- 3422B (Basic Pay and Allowances)Document179 pages3422B (Basic Pay and Allowances)ulisesnava50% (2)

- Ar 601-20 The Interservice Physician Assistant Training ProgramDocument19 pagesAr 601-20 The Interservice Physician Assistant Training ProgramMark CheneyNo ratings yet

- Mock Test 2 (2012-13) English Language Paper 3 Part A Question-Answer BookDocument22 pagesMock Test 2 (2012-13) English Language Paper 3 Part A Question-Answer Book沐辛No ratings yet

- MUET WritingDocument3 pagesMUET WritingLai Kee KongNo ratings yet

- HEC Paris - Fact Sheet 2012-2013Document6 pagesHEC Paris - Fact Sheet 2012-2013王 长宇No ratings yet

- Item 0 20180516015421505Document8 pagesItem 0 20180516015421505sanat kr pratiharNo ratings yet

- GATE Mining Engineering Solved 2012Document13 pagesGATE Mining Engineering Solved 2012Maheswaran Pandian100% (1)