Professional Documents

Culture Documents

50 KG Mini Potato Quote Hyderabad Party

50 KG Mini Potato Quote Hyderabad Party

Uploaded by

amresh signhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

50 KG Mini Potato Quote Hyderabad Party

50 KG Mini Potato Quote Hyderabad Party

Uploaded by

amresh signhCopyright:

Available Formats

Date: 29 May,2017

Dear Mr. Narsinghji,

Subject: Quotation for Mini Automatic Potato Chips Line 50 Kg/hr

Dear Sir,

Please refer to your enquiry about Automatic Continuous Potato chips mini plant.

We are pleased to quote our lowest rates as under.

1. 50 Kg/hr Mini Automatic continuous potato chips line SS(AISI304)

model for Potato chips based on indirect edible oil heating by edible oil

based heat exchanger ,

PRICE IN INR 20, 65,000/-

POWER MOTOR SPACE REQ

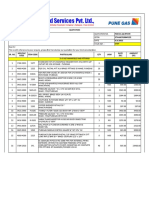

SNO ITEM PRICE 50 KG IN HP MAKE (LXWXH)

POTATO PEELER 14 3 FT X 3 FT

1 INCH MODEL 45000 0.5 GODREJ X 3 FT

POTATO SLICER 3 FT X 3 FT

2 PS250 MODEL 45000 0.5 GODREJ X 3FT

CENTRIFUGE 1/2 HP

MODEL,14X12 INCH 3 FT X 3 FT

3 DRUM 25000 0.5 GODREJ X 3FT

6 FT X 3

4 INFEED SHAKER 150000 1 HINDUSTAN FT X 4 FT

CONTINUOUS FRYER

WITH PANEL

,FILTER,PUMP,DAY ROTOMOTIVE 17 FT X 10

5 TANK 1400000 5.5 & CROMPTON FT X 4 FT

7 ELEVATOR 10 FT 150000 0.5 ROTOMOTIVE 10 FT X 3

FACTORY:37,B SANWER ROAD INDUSTRIAL AREA, SECTOR C , INDORE, MP,INDIA

OFFICE:214 ,PALSIKAR COLONY,INDORE,MP,INDIA 452007

SINGLE MACHINE FT X 4 FT

2 FT X 3 FT

8 SPICE FEEDER 50000 0.5 ROTOMOTIVE X 5 FT

6 FT X 3 FT

9 SPICE DRUM 200000 0.5 ROTOMOTIVE X 4 FT

GRAND TOTAL 2,065,000 9.5

SNO ITEMS CAPACITY

1 POTATO 50 kg / hr

CHIPS/SULLY/LACCHA/STICKS/

SHREDDINGS READY

SNO EQUIPMENTS SUPPLIED WITH THIS QUOTE

POTATO PEELER,POTATO SLICER, CENTRIFUGAL

1 DRYER SS MODEL

2 INFEED SHAKER FOR FEEDING CHIPS IN THE FRYER

CONTINUOUS FRYER FOR POTATO CHIPS HEAT

3 EXCHANGER BASED

DIESEL BASED EDIBLE OILHEAT EXCHANGER

4 SYSTEM WITH JHONSON PUMP,MAX 15 BURNER

5 DAY TANK

GEARED HOOD LIFTING SYSTEM FOR EASY

6 CLEANING OF FRYER

7 BATCH FILTER

8 MAIN ELECTRIC PANEL FOR THE FRYER

FACTORY:37,B SANWER ROAD INDUSTRIAL AREA, SECTOR C , INDORE, MP,INDIA

OFFICE:214 ,PALSIKAR COLONY,INDORE,MP,INDIA 452007

9 CHIPS COOLING ELEVATOR CONVEYOR

10 CHIPS INSPECTION VIBRATING TABLE

11 FLAVOURING DRUM WITH SPICES DISPENSER

FACTORY:37,B SANWER ROAD INDUSTRIAL AREA, SECTOR C , INDORE, MP,INDIA

OFFICE:214 ,PALSIKAR COLONY,INDORE,MP,INDIA 452007

TERMS & CONDITIONS

Ex Factory , Ex Packaging,

VAT tax (2 % against

advance C Form or 12 %

security deposit of the billing

amount )& Excise Extra as

per billing date, No taxes on

1 PRICE Export

90-120 days weeks from the

receipt of your clear order &

2 DELIVERY advance payment.

PAYMENT Advance 40%, Rest before

3 TERMS delivery,

4 WARRANTY The standard warranty period

for the machines begins from

the date of commissioning of

the plant

• This warranty does not

include any damage to the

goods sold, caused by

electrical break down due to

short circuit, explosion,due to

faulty wiring, violent voltage

fluctuation,Tempering with

the equipment

• This warranty includes all or

any part manufactured by our

company , electrical parts

such as motors,MCB, their

warranty is covered by the

respective suppliers

• Warranty is void if the

FACTORY:37,B SANWER ROAD INDUSTRIAL AREA, SECTOR C , INDORE, MP,INDIA

OFFICE:214 ,PALSIKAR COLONY,INDORE,MP,INDIA 452007

machine is subject to any

modification, repair or

replacement which is

unauthorized

Our engineer(s)/ Technicians

would be

available for the Installation

free of cost

for a period of 1 week.

However their traveling,

lodging/ boarding and local

conveyance

Expenses to born and paid by

you.

5 INSTALLATION

We hope you shall find this in order, hope you shall favor us, by placing your

valuable order with us.

Thanking you

Sincerely

For DYNAMECH ENGINEERS

R. Mirchandani

FACTORY:37,B SANWER ROAD INDUSTRIAL AREA, SECTOR C , INDORE, MP,INDIA

OFFICE:214 ,PALSIKAR COLONY,INDORE,MP,INDIA 452007

FLOW CHART

READY

RAW POTATOES FLAVOURING DRUM SHREDDINGS/

CHIPS

CLEANED

CHIPS

PEELING IN POTATO PEELER POTATO

CHIPS/SULLY

/LACCHA AUTO INSPECTION TABLE

PEELED POTATOES FRYING

PROCESS

FRIED

POTATO

CHIPS

SLICING IN POTATO

SLICER VARIOUS

SIZES OF STICKS CHIPS

AUTOMATIC CONTINUOUS

RIPPLED CHIPS

FRYER FOR

POTATO CHIPS

SHREDDINGS/ DE WATERING IN

Juliennes/CHIPS CENTRIFUGAL FEEDING ON INFEED CLEANED

DRYER SHAKER CHIPS

WITHOUT

BROKEN

AND SMALL CHIPS

FEATURES POTATO PEELER

• Standard SS peeler with inner drum coated with emery powder

FACTORY:37,B SANWER ROAD INDUSTRIAL AREA, SECTOR C , INDORE, MP,INDIA

OFFICE:214 ,PALSIKAR COLONY,INDORE,MP,INDIA 452007

• Washed potatoes are poured into the drum of the potato peeler from the top,

the inner of the drum is coated with abrasive carborundum, as the base of the

drum rotates the potatoes strike against the abrasive inner wall which

removes the skin, this processing requires minor flow of water through a pipe

to remove the skin from the walls,

• The peeled potatoes are removed from the side of the drum through a gate,

• The Peeler is a heavy duty model, it is made from a SS Pipe 5 mm thickness,

than grooves are done inside the Pipe so that emery (abrasive ) stick to the

pipe properly

FEATURES POTATO SLICER

• Peeled potatoes are fed in to the SS model slicer from the top ,

• The rotor pushes the potatoes against the wall of the cutter , the slices are

cut according to the cutter fitted

• The slices slide down with flow of water into a trough

FEATURES CENTRIFUGAL DRYER

• Sliced chips have to be dewatered so that at the stage of frying the fuel

consumption is less and the quality of chips is better

• To remove the excess water the sliced chips are fed in to a basket which

rotates at high RPM (1200)

• Excess water is removed by a pipe

• The basket is removed after dewatering and the slices are emptied on a

shaker

FEATURES INFEED SHAKER

• The sliced chips have some small pieces which have to be removed as they

can burn in the hot oil and oxidize the oil , also they choke the filter.

FACTORY:37,B SANWER ROAD INDUSTRIAL AREA, SECTOR C , INDORE, MP,INDIA

OFFICE:214 ,PALSIKAR COLONY,INDORE,MP,INDIA 452007

• The shaker machine consist of wire mesh sieve with square holes , on this

sieve the chips travel forward due to the shaking movement of rubber

elements

• As the chips move forward the smaller pieces fall into the bin , the rest of

the slices move in to the fryer

FEATURES CONTINUOUS FRYER

• Low total oil volume results in low oil turnover per minute and lower FFA

(Free Fatty Acids) values. Protecting the oil from light and oxygen is an

essential criteria for the quality of your final product.

• The frying system consists of five main parts:

1. Fryer pan

2. Continuous oil filter system

3. Oil circulation pump

4. Heat exchanger (for thermo oil or high pressure steam)

5. Oil storage tank

• The fryer pan has multiple oil in and outlets. The temperature profile along

the pan is easily set and adjusted. In the fryer hood, a paddle belt and a

submerged belt are mounted. The paddle belt maintains accurate frying

time in the first section. The submerged belt conveys the product bed with

accurately regulated speed.

• All the oil in the frying system is filtered every 30 – 45 seconds through

the continuous mesh belt filter. Particles are scraped off and removed by a

scraper.

• The heat exchanger, placed close to the fryer can be heated by thermal oil

or diesel or Gas

SNO PARTICULARS DETAILS

1 Model 15” POTATO CHIPS FRYER EDIBLE OIL

FACTORY:37,B SANWER ROAD INDUSTRIAL AREA, SECTOR C , INDORE, MP,INDIA

OFFICE:214 ,PALSIKAR COLONY,INDORE,MP,INDIA 452007

HEAT EXCHANGER BASED

2 Capacity 50 KG / HR

3 Products Potato chips , Sully

,Pellets,Kurkure,Namkeen(besan based)

4 Heat Load 150,000 kcal/hr

5 Oil in system 250 LTRS

6 Fryer size 4500 mm long x width 673 mm x Height

920 mm

Frying area Belt width – 381 mm

Length – 4500 mm

FRYER – PROCESS CONTROLS

1 Frying Time AC DRIVE Based

control

2 Oil Filtration Batch filter

3 Oil Level Included

control

Fryer Cleaning

1 Hood Lifting Geared based 4 screw cylinders ,with

limit switch

2 Hot oil 20 cu mtr per hr 3 HP power load

circulation

pump

3 Access Easy access for daily cleaning

4 Day tank Included – for make-up oil & storage.

Oil Heating System

1 Heating External diesel to edible oil heating by1

system pass based heat exchanger ,with burner

and chimney and complete pipelines

2 All SS Pipe Included with fryer

lines

FACTORY:37,B SANWER ROAD INDUSTRIAL AREA, SECTOR C , INDORE, MP,INDIA

OFFICE:214 ,PALSIKAR COLONY,INDORE,MP,INDIA 452007

3 Control Panel Included, AC Drive based

4 Installation 2 days

time

Technical specifications for 15” Fryer

MODE OF HEATING > Indirect by heat exchanger

CONVEYER>SS(AISI304) wire knitting type 15” upper conveyor is for pressing

the Product & middle conveyer is for carrying & take off, middle conveyer is fine

woven While upper is coarse woven.

TANK> SS(AISI304) Bottom 5 mm thick side 3mm thick with oil capacity 250 ltr

for 15” model. Jacketed by glass wool

FILTER UNIT> On line continuous mesh belt filter is provided.

CONTROL PANEL> A good quality control panel will be provided with machine

this shall have contactor, push button operation all type of protection i.e.,

overload , single Phasing, short circuit, this panel will have AC drive and

temperature indicator.

MAIN MOTOR> conveyor drive AC motor ½ HP ‘ROTOMOTIVE’ make variable

speed type 3 motors total ½ HP each

HIGH PRESSURE PUMP FOR OIL HEATER>3 HP crompton 3 phase

INFEED SHAKER > 1 HP MARATHON 3 phase

INSPECTION & COOLING BELT > ½ HP ROTOMOTIVE 3 phase

FACTORY:37,B SANWER ROAD INDUSTRIAL AREA, SECTOR C , INDORE, MP,INDIA

OFFICE:214 ,PALSIKAR COLONY,INDORE,MP,INDIA 452007

INSPECTION SHAKER > 1 HP MARATHON 3 phase

SPICE DISPENSER > ½ HP ROTOMOTIVE GEARED MOTOR 3 Phase

SPICE DRUM > ½ HP ROTOMOTIVE GEARED MOTOR 3 Phase

DIMENSION

CONVEYER>Width 15” for 15” model.

OVERALL DIMENSION>40 long, 40” high , 40” wide

Not in scope of supply- electrical cable/wire.

FEATURES COOLING CONVEYOR & INSPECTION SHAKER

• The cooling conveyor is a inclined elevator system , with a coarse SS belt ,

the purpose of this conveyor is to let the oil drip from the potato chips ,

and to bring down the temperature of chips, the conveyor is speed

controlled

• The fried chips than move to inspection shaker, this machine served dual

purposes allows easy access to remove the rejected chips , and also to

remove the fine particles that come along with the chips

FEATURES FLAVORING DRUM AND SPICES DISPENSER

• Fried chips are coated with seasoning in this machine , it consist of spices

dispensing unit which has a storage hopper and a screw feeder for feeding

spices on a vibratory tray, the fried chips are tumbled in the SS drum

which has internal fins to turn the chips over

• Both the Drum motor and spices screw motor are speed controlled

FACTORY:37,B SANWER ROAD INDUSTRIAL AREA, SECTOR C , INDORE, MP,INDIA

OFFICE:214 ,PALSIKAR COLONY,INDORE,MP,INDIA 452007

Technical specifications for Inspection Belt

• Electric motor 1 HP

• SS Mesh Conveyor VFD controlled

Technical specifications for Inspection Shaker

• Electric motor 1 HP

• SS sheet with holes to remove fine powder

• Rubber elements fitted beneath the tray

Technical specifications for Flavoring Drum

• SS hopper, Screw Feeder for Spices storage and dispensing.

• Both Screw feeder and drum controlled by VFD

• Inbuilt SS fins inside the Drum

TOTAL POWER REQUIREMENT 15.5 HP or 13.1 KW

FACTORY:37,B SANWER ROAD INDUSTRIAL AREA, SECTOR C , INDORE, MP,INDIA

OFFICE:214 ,PALSIKAR COLONY,INDORE,MP,INDIA 452007

You might also like

- S488 S588 S688 PartsDocument229 pagesS488 S588 S688 PartsHai Van75% (4)

- Firm Profile FormatDocument13 pagesFirm Profile FormatSURANA1973No ratings yet

- Runner Design Guide Lines-Issue 5Document15 pagesRunner Design Guide Lines-Issue 5sivanandp100% (1)

- 3.7 Types of Protein Exam QuestionDocument3 pages3.7 Types of Protein Exam QuestionjnfjngsdjNo ratings yet

- Rs 7120 Trainning MaterialDocument145 pagesRs 7120 Trainning Materialirfan100% (1)

- Packing List PulselithDocument1 pagePacking List PulselithyopiNo ratings yet

- Mascot's Company ProfileDocument6 pagesMascot's Company ProfileMascot InternationalNo ratings yet

- Rental De-Watering Offer - ABDK Colliery BCCLDocument4 pagesRental De-Watering Offer - ABDK Colliery BCCLAshish ShahNo ratings yet

- 2018 C&R CatalogDocument164 pages2018 C&R Catalog5jdesign0% (1)

- Neptune IM-SeriesJGJDMixDocument19 pagesNeptune IM-SeriesJGJDMixHipólito galindoNo ratings yet

- Shreeji MahrasatraDocument4 pagesShreeji MahrasatraShivam AcharyaNo ratings yet

- Metatech Polishing QuotDocument13 pagesMetatech Polishing QuotRohitShingadeNo ratings yet

- Dinshaw Filtration Systems PVT LTDDocument15 pagesDinshaw Filtration Systems PVT LTDAsif AliNo ratings yet

- 01-06225-226 Manual Mezc ScottDocument26 pages01-06225-226 Manual Mezc ScottLaura MalagarrigaNo ratings yet

- Quotation For LG Commercial Laundry EquipmentDocument2 pagesQuotation For LG Commercial Laundry EquipmentErica NicolasuraNo ratings yet

- Proforma Invoice / Estimate: Kind Attn: Buehler - A Division of Itw IncDocument2 pagesProforma Invoice / Estimate: Kind Attn: Buehler - A Division of Itw IncNihar Ranjan TripathyNo ratings yet

- Quot 2 Cavity Hand Feed Automatic PET Blowing Machine Mr. AravindDocument2 pagesQuot 2 Cavity Hand Feed Automatic PET Blowing Machine Mr. Aravindsaiarvind0809No ratings yet

- Checklist Hari2Document1 pageChecklist Hari2nizamNo ratings yet

- Carrier 424 Parts ManualDocument10 pagesCarrier 424 Parts Manualarturo100% (56)

- TFT Catalog 2018 PDFDocument244 pagesTFT Catalog 2018 PDFMario PazNo ratings yet

- UntitledDocument13 pagesUntitledabhishek purkarNo ratings yet

- Nre BBLDocument2 pagesNre BBLRammurthy JVNo ratings yet

- 2945 EMCO PUG MILL 500MM - 27 - 4 - 2018 Ver03 PDFDocument26 pages2945 EMCO PUG MILL 500MM - 27 - 4 - 2018 Ver03 PDFsamar209No ratings yet

- Treadmill ManualDocument47 pagesTreadmill Manualerik nugrahaNo ratings yet

- Screw Press SNP 1-210 - SS Engineering Corporation PDFDocument6 pagesScrew Press SNP 1-210 - SS Engineering Corporation PDFDeepakNo ratings yet

- 3599 Chana Dal Mil Plant 5 Ton Per Day (Rill Machine Machine) PDFDocument2 pages3599 Chana Dal Mil Plant 5 Ton Per Day (Rill Machine Machine) PDFMahesh Raje BhosaleNo ratings yet

- Dal Mill ProjectDocument2 pagesDal Mill ProjectMahesh Raje BhosaleNo ratings yet

- Grinding Equipment: Product CatalogueDocument32 pagesGrinding Equipment: Product CatalogueSebastian Nuñez RiquelmeNo ratings yet

- Quotation Sheet From Farfly 11-17Document15 pagesQuotation Sheet From Farfly 11-17douglas guedez100% (1)

- 12 HP Ogeneral VRF Quotation For Proposed Residence 30 11 2023Document9 pages12 HP Ogeneral VRF Quotation For Proposed Residence 30 11 2023sonam gargNo ratings yet

- Sucker & Pony RodDocument15 pagesSucker & Pony Rodtaufik arisNo ratings yet

- 424 Parts CarrierDocument173 pages424 Parts Carriermarcosluna68No ratings yet

- ABSTRACT OF BIDS (Version 1)Document10 pagesABSTRACT OF BIDS (Version 1)Feruel PatalagsaNo ratings yet

- AMFE50 Plus Shapes Catalog - CompressedDocument25 pagesAMFE50 Plus Shapes Catalog - CompressedJoey DEDOMNo ratings yet

- Q-11650, Cage Bin - 600 LTRSDocument4 pagesQ-11650, Cage Bin - 600 LTRSanita shindeNo ratings yet

- Introduction Letter: Subject: Company ProfileDocument21 pagesIntroduction Letter: Subject: Company ProfilePritam JadhavNo ratings yet

- Eco-Friendly: Ruian Zhenjing Machinery. PVT - LTDDocument8 pagesEco-Friendly: Ruian Zhenjing Machinery. PVT - LTDBikash NayakNo ratings yet

- Maharashtra Multi Distributors LTD: GSTIN No. 27AABCM2661D1ZSDocument3 pagesMaharashtra Multi Distributors LTD: GSTIN No. 27AABCM2661D1ZSPUNEGAS RetailNo ratings yet

- Dispensador de Mostarda (398-CN)Document10 pagesDispensador de Mostarda (398-CN)Amauri RogérioNo ratings yet

- Schramm T130XD SpecificationDocument3 pagesSchramm T130XD SpecificationAl FarrNo ratings yet

- WTE-ENDOM2021001505-R12-AS Cooling-SSF and DSDocument26 pagesWTE-ENDOM2021001505-R12-AS Cooling-SSF and DSDeepak Patil100% (1)

- RT4 Odisha - Project Cost EstimationDocument23 pagesRT4 Odisha - Project Cost EstimationRAMODSNo ratings yet

- Rukmani Enclave Maan Boisar PalgharDocument5 pagesRukmani Enclave Maan Boisar Palgharsanjay singhNo ratings yet

- Countertop Baker Unit: Instruction ManualDocument15 pagesCountertop Baker Unit: Instruction ManualChristian Geis-SchäferNo ratings yet

- MIXERDocument20 pagesMIXERsubashNo ratings yet

- Commercial Ro Plant 250 LPHDocument8 pagesCommercial Ro Plant 250 LPHBORN 2 KILLNo ratings yet

- Gari Plant QuotationDocument3 pagesGari Plant QuotationCyril AtambiNo ratings yet

- Rotex EsfDocument3 pagesRotex EsfPRASANTH PRASANTHNo ratings yet

- Cotation Economode PDFDocument2 pagesCotation Economode PDFdinero dahustleNo ratings yet

- Bejo Personal Job Tcs Apache TGL 10,11 & 14 Juni 2023 Revisi 03-1Document4 pagesBejo Personal Job Tcs Apache TGL 10,11 & 14 Juni 2023 Revisi 03-1rkalamullah2No ratings yet

- Piranha P120 Ironworker ManualDocument52 pagesPiranha P120 Ironworker ManualEduardo Ricardo Puga RomeroNo ratings yet

- Dual Trip Whipstock PDFDocument2 pagesDual Trip Whipstock PDFRahul KumarNo ratings yet

- PT Crevis Tex Jaya Profile 2019 (2019.02.19)Document11 pagesPT Crevis Tex Jaya Profile 2019 (2019.02.19)Yandi RaifaNo ratings yet

- Parts-Manual 70380 Chipper-Shredders 12152 19961201 X00098-Y05265 199900098-200005265Document18 pagesParts-Manual 70380 Chipper-Shredders 12152 19961201 X00098-Y05265 199900098-200005265JoeNo ratings yet

- 4ZD34 1Document12 pages4ZD34 1Edwin Patricio Taco ChuseteNo ratings yet

- ACE GEN-PO-HO-67-2020-21 PO For Oilwell Tools ServicesDocument3 pagesACE GEN-PO-HO-67-2020-21 PO For Oilwell Tools ServicesYusuf BagewadiNo ratings yet

- E P1704 302 007 00Document5 pagesE P1704 302 007 00Raajjhesh KanawadayNo ratings yet

- ARL07008 IIW Design Report (Rev 01)Document72 pagesARL07008 IIW Design Report (Rev 01)Fareed KhanNo ratings yet

- 122254R6 Induamerica 4.5 MTPH Rice Husk Conveying - BellavistaDocument4 pages122254R6 Induamerica 4.5 MTPH Rice Husk Conveying - BellavistaRaul RojasNo ratings yet

- Dorman HD Solutions - New Product Guide, Spring 2014Document40 pagesDorman HD Solutions - New Product Guide, Spring 2014Chris DentNo ratings yet

- 5+5 Vot System, Bharat Electronics LTDDocument2 pages5+5 Vot System, Bharat Electronics LTDPUNEGAS RetailNo ratings yet

- Hi 306 - 240213 - 190915Document1 pageHi 306 - 240213 - 190915rudrainteriors001No ratings yet

- Bosch Tune Up Parts PDFDocument9 pagesBosch Tune Up Parts PDFdwebs262No ratings yet

- Balun Assemblies Balun Assemblies Balun AssembliesDocument12 pagesBalun Assemblies Balun Assemblies Balun AssemblieshtilanowNo ratings yet

- Soal Latihan Bahasa Inggri1sDocument5 pagesSoal Latihan Bahasa Inggri1sGabriela KoloNo ratings yet

- Utility Request Form (SAP BRP) Revision2Document2 pagesUtility Request Form (SAP BRP) Revision2junaidi100% (1)

- Root Words, Prefixes .Suffixes in Medical FieldDocument26 pagesRoot Words, Prefixes .Suffixes in Medical FieldLazorde At TLNo ratings yet

- HP ExpertOne Certification PathsDocument34 pagesHP ExpertOne Certification PathsSaurabh0% (1)

- Section1 WhatisCartography TranscriptDocument15 pagesSection1 WhatisCartography TranscriptSGA-UIS BucaramangaNo ratings yet

- Live Lesson 14 Funk Drumming PDFDocument10 pagesLive Lesson 14 Funk Drumming PDFAndrews Rocha100% (3)

- c5 Conc1 EnergeticsDocument7 pagesc5 Conc1 EnergeticsAlexandra AlexandraNo ratings yet

- Nursing Care PlanDocument25 pagesNursing Care PlanIndah MardianiNo ratings yet

- MATHEMATICS Compulsory Part 2011/12 Mock Exam Paper 2Document24 pagesMATHEMATICS Compulsory Part 2011/12 Mock Exam Paper 2mkan_3No ratings yet

- Worked Example To Eurocode 2 Vol 1Document228 pagesWorked Example To Eurocode 2 Vol 1Mohd RafiqNo ratings yet

- Light Mild Brown Girl in Glasses Sales Brochuryye (Yyyyyyyyyyyy1)Document2 pagesLight Mild Brown Girl in Glasses Sales Brochuryye (Yyyyyyyyyyyy1)Althea KimNo ratings yet

- VST Shakti MT 270 Viraat Plus 4WDocument49 pagesVST Shakti MT 270 Viraat Plus 4Wbharath100% (1)

- WHO 9789241565639-EngDocument476 pagesWHO 9789241565639-Engsofiabloem100% (1)

- Silane BrochureDocument12 pagesSilane Brochurehakanaltiparmak88No ratings yet

- Differential Equations - MTH401 Fall 2006 Final Term Paper Session 1Document6 pagesDifferential Equations - MTH401 Fall 2006 Final Term Paper Session 1Faizan Zafar SahiNo ratings yet

- 02nd To 04th December 2023 International Cotton Advisory Committee - 81st Plenary Meeting 2023Document11 pages02nd To 04th December 2023 International Cotton Advisory Committee - 81st Plenary Meeting 2023sabirNo ratings yet

- Benito Canfield - Rule of Perfection PDFDocument81 pagesBenito Canfield - Rule of Perfection PDFcalenduloNo ratings yet

- 2008MP Year11 12Document7 pages2008MP Year11 12Duy Nguyen Le Quang100% (1)

- Test Bank For Biology of Plants 7th Edition Peter H RavenDocument9 pagesTest Bank For Biology of Plants 7th Edition Peter H RavenElaine Scully100% (38)

- Global Problem AMR-NAP - EATDocument32 pagesGlobal Problem AMR-NAP - EATWolfy D Harold100% (1)

- National Luna 74 Litre ManualDocument6 pagesNational Luna 74 Litre Manualmarsian77No ratings yet

- PhET Simulation - Determination of Planck's ConstantDocument3 pagesPhET Simulation - Determination of Planck's ConstantDaniel CruzNo ratings yet

- Hex 6.3 User Manual: Dave Ritchie Team Orpailleur INRIA Nancy Grand Est, LORIA 54506 Vavdoeuvre-les-Nancy, FranceDocument69 pagesHex 6.3 User Manual: Dave Ritchie Team Orpailleur INRIA Nancy Grand Est, LORIA 54506 Vavdoeuvre-les-Nancy, FranceParisha SinghNo ratings yet

- Unit 5.1 Introduction To Operations ManagementDocument17 pagesUnit 5.1 Introduction To Operations ManagementJun Woo YangNo ratings yet

- Troubleshooting The Stencil Printing Process: Chrys Shea, Shea Engineering ServicesDocument44 pagesTroubleshooting The Stencil Printing Process: Chrys Shea, Shea Engineering ServicesXuan HoangNo ratings yet