Professional Documents

Culture Documents

Typical Velocities Piping Design Chemical Engineering Robert Kern

Typical Velocities Piping Design Chemical Engineering Robert Kern

Uploaded by

hugo mendozaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Typical Velocities Piping Design Chemical Engineering Robert Kern

Typical Velocities Piping Design Chemical Engineering Robert Kern

Uploaded by

hugo mendozaCopyright:

Available Formats

CE REFRESHER •••

1IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIImlllllllllllllllllllliUlIIIIIIIIIUlllllilmmlllllllllllllllllllllllllllli1IIIIIIIIIIIImmlllllllllUlil!II1mlllllllllWIIIIIIIIIJI 11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111

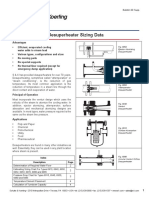

Typical Sections of Steam Tables-Table II Typical Liquid Velocities in Steel

- - - - - - - - Saturated steam and saturated water - - - - - - - Pipelines-Table III

e

Pressure Pressure Temperature. Heat of the Latent Heat of

Absolute, P', Gage, p- (, Liquid, Evaporation, Nominal Pipe Sizes. In. 2 or less 3to 10 10 to 20

Psia Psig OF Btu/Lb Btu/Lb

Liquid and Line Velocity. FIlS Velocity. FilS Velocity. FtlS

110,0 95,3 334.79 305,8 883.1

111.0 96,3 335.46 306,5 882,5 Water

112,0 97,3 336,12 307,2 ' 882,0 Pump suction 1 to 2 2to 4 3 t06

124,0 109,3 343.74 315,2 875.8 Pump discharge (long) 2 to 3 3to 5 4 to 7

125,0 110,3 344,35 315,8 875,3 Discharge leads (short) 4 to 9 5to 12 8 to 14

126,0 111,3 344,95 316.4 874,8 Boiler feed 4 to 9 5 to 12 8 to 14

127,0 112,3 345,55 317,1 874,3 Drains 3 to 4 3to 5 -

Sloped sewer - 3 to 5 4 to 7

Superheated steam Hydrocarbon liquids

Pressure Pressure Saturated (Normal viscosities)

Total Temperature, OF

Absolute, P'. Gage, p, Temperature, Pump suction 1.5 to 2,'5 2to 4 3 to 6

PSig t, OF 500 600 700 800 Discharge header (long) 2,5 to 3,5 3to 5 4 to 7

Psia

--- --- --- ---- Discharge leads (~lJort) 4to 9 5to 12 8 to 15

400,0 385,3 444,60 111.2841 1.4763 1.6499 1.8151 Drains 3 to 4 3 to 5 -

h. 1,245,1 1,307.4 1,363.4 1,417,0 Viscous oils

r

I 420,0 405,3 449.40 11 1,2148 1.4007 1.5676 1.7258

Pump suction,

Medium viscosity - 1,5to 3 2,5 to 5

I

h. 1,242.4 1,305,8 1,362,3 1,416,2 Tar and fuel oils - 0.4 to 0.75 1),5 to 1

440,0 425,3 454,03 11 1,1517 1,3319 1.4926 1.6445 Discharge (short) - 3 to 5 4 to 6

h. 1,239.7 1,304,2 1,361.1 1,415,3 Drains 1 1.5 to 3 -

~

~

v is specific volume, ft /1b; and h, is total heat of 9te@m, Btullb,

3

I 11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111 11111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111111

1

IIIUmllllJIIllUilUIlmlllllllllllllllllllHIII1I1IUIIlIIIHillUilltlllllllli1U1UIIUnltllllUIIIIIIIIIIIIUlillIHtlUlllllllllllflllllllllllHlI!UIIIIIIIIIIUlIlII

(Line b to c in Fig. 2). During this stage, both liquid

and vapor phases are present. After sufficient heat ab- Typical Velocities in Gas and Vapor

sorption, all of the liquid vaporizes (Point c). At this Lines-Table IV

point, the vapor is saturated. Further heating (Line c-d)

~ will cause both the temperature and the volume of vapor Saturated Steam or Superheated Steam,

Saturated Vapor Superheated Vapor. or Gas

to increase. Vapor above the saturation temperature is

1 Low Pressure Medium Pressure High Pressure

1 superheated. Nominal

,

\ j;\ At a higher constant pressure, the boiling temperature Pipe Size.

Velocity. FIlS Velocity. FtlS Velocity. FIlS

will be higher, and less heat will be required to vaporize

l

) the liquid. At the critical point (see Fig. 2), the densities

In.

2 or less 45 to 100 40 to 80 30 to 60

of liquid and vapor become identical. Just below the

3 to 4 50 to 110 45 to 90 35 to 70

critical temperature, the substance is considered liquid;

6 60 to 120 50 to 120 45 to 90

just above, it is considered vapor. 8 to 10 65 to 125 80 to 160 65 to 125

The quantity of heat needed to vaporize a unit weight 12to 14 70 to 130 100 to 190 80 to 145

I

of saturated liquid at constant pressure (Line b-c in 16 to 18 75 to 135 110 to 210 90 to 160

Fig. 2) is called the latent heat (usually expressed In 20 80 to 140 120 to 220 100 to 170

Btu/lb). Note: Within the above velocilies and line·size ranges, (a) large lines can have

Thermodynamic properties for various substances have higher velocities than smalier ones, and (b) short lines, and leads from headers,

can have higher velocities than long lines and headers,

been established and are available. Part of a typical page

is shown in Table II, for saturated steam [1,5b J. EqUipment Lines Velocity. FIlS

Reboiler, down comer (liquid) . , .3to 7

Reboiler, riser (liquid and vapor) , 35 to 45

Flashing Liquid

When a liquid is flowing near its saturation point (also

called the equilibrium point or boiling point) in a pipe-

Overhead condenser.

Two-phase flow . , ..

Compressor, suction ..

Compressor, discharge.

. 25to 100

.35 to 75

.75 to 200

100 to 250

t

I

line, decreased pressure will cause vaporization. The Inlet, steam turbine .. 120 to 320 ~

greater the pressure difference, the greater the vaporiza- Inlet, gas turbine ... 150 to 350

tion. When flashing occurs, pipe resistance cannot be

calculated as for liquid flow. We will now have a two-

Relief valve. discharge.

Relief valve. entry point at silencer .

0,5v/,

v/, f

phase flow problem. The quantity of vaporized liquid can *' Obtain sonic or critical velocity, Vet from:

be estimated by using the data of the thermodynamic v, = 68yk(P' Ip), Itls, k from Table I.

properties of the liquid. IIIIUIIIHlflllHHlmtllllllllUUlUI1J111111111U1Hl1IIIIIlUHlIll1ll1111ll1JIlJIlUtrmtlll1ll1UUliUI11IIJ!lfllIllIlllIIlIIllIIllIIllIIltlllllllllllUlIIlIIlIlIlII1

62 DECEMBER 23, 1974/CHEMICAL ENGINEERING

f

You might also like

- Distillation - How To Specify & Install Cartridge TraysDocument7 pagesDistillation - How To Specify & Install Cartridge TraysRafaelNo ratings yet

- Maintaining Valves: Module 08408-07Document16 pagesMaintaining Valves: Module 08408-07cjcp04No ratings yet

- Smith Et al-1958-AIChE Journal PDFDocument3 pagesSmith Et al-1958-AIChE Journal PDFAlastairNo ratings yet

- Process Duty Specification For 01-Pk-051 Vacuum System: Ejectors CapacityDocument5 pagesProcess Duty Specification For 01-Pk-051 Vacuum System: Ejectors CapacityvasudhaNo ratings yet

- Heat Exchangers Designing For Super-Critical Fluid ServiceDocument6 pagesHeat Exchangers Designing For Super-Critical Fluid ServiceHsein WangNo ratings yet

- Knovel Charts For Water & Steam, SI & English Units, 2006, Norwich, 26pgDocument26 pagesKnovel Charts For Water & Steam, SI & English Units, 2006, Norwich, 26pgVlad ElenaNo ratings yet

- Predict Storage-Tank Heat Transfer: PreciselyDocument6 pagesPredict Storage-Tank Heat Transfer: PreciselyRuben LealNo ratings yet

- HRSG Understand The BasicsDocument14 pagesHRSG Understand The BasicsMazen Darwish100% (1)

- A An ND D Ffo Orr: Increase CapacityDocument7 pagesA An ND D Ffo Orr: Increase CapacityLuis Enrique Leyva OvalleNo ratings yet

- Vacuum Unit Pressure Control PTQ Revamps 2006Document5 pagesVacuum Unit Pressure Control PTQ Revamps 2006majope1966No ratings yet

- 6DSUPP Desuperheater Supplement BrochureDocument4 pages6DSUPP Desuperheater Supplement BrochureПавел ЛукьяновNo ratings yet

- CEeNews2 04 PDFDocument6 pagesCEeNews2 04 PDFJohn AnthoniNo ratings yet

- Article - 1001191 Managing Fouling in Refinery PDFDocument13 pagesArticle - 1001191 Managing Fouling in Refinery PDFDavid Diaz PadillaNo ratings yet

- Flow Instabilities in A Horizontal Thermosyphon Reboiler LoopDocument22 pagesFlow Instabilities in A Horizontal Thermosyphon Reboiler Loopwylie01No ratings yet

- Modelling and Simulation of Steam Jet Ejectors PDFDocument8 pagesModelling and Simulation of Steam Jet Ejectors PDFLucas RossiniNo ratings yet

- IFP Materials PDFDocument20 pagesIFP Materials PDFProcess EngineerNo ratings yet

- 1996 - Misplon - Pinhole Grate Conversions ofDocument4 pages1996 - Misplon - Pinhole Grate Conversions ofmchoi23No ratings yet

- Facts at Your Fingertips-200802-Pressure ReliefDocument1 pageFacts at Your Fingertips-200802-Pressure Reliefonizuka-t2263No ratings yet

- Designing Atmospheric Crude Distillation For Bitumen Service PDFDocument6 pagesDesigning Atmospheric Crude Distillation For Bitumen Service PDFfawmer61No ratings yet

- List of FiguresDocument11 pagesList of FiguresShamsMohdNo ratings yet

- Reboiler Case StudyDocument6 pagesReboiler Case StudyamlhrdsNo ratings yet

- Safe Operation of Reboilers Condensers in Air Separation UnitsDocument31 pagesSafe Operation of Reboilers Condensers in Air Separation UnitsTusenkrishNo ratings yet

- Appendix-2 Ejector System TroubleshootingDocument13 pagesAppendix-2 Ejector System Troubleshootingmahmoud abd elfatahNo ratings yet

- Themodynamic Model Selection For CHEMCADDocument19 pagesThemodynamic Model Selection For CHEMCADratnakar patharkarNo ratings yet

- Steam Jet Ejector: Can A Fit Your Vacuum Process?Document5 pagesSteam Jet Ejector: Can A Fit Your Vacuum Process?Tiến Mạnh NguyễnNo ratings yet

- Specifying Shell and Tube Heat ExchangersDocument10 pagesSpecifying Shell and Tube Heat ExchangersMicheal BrooksNo ratings yet

- Boiler Dan ReboilerDocument15 pagesBoiler Dan ReboilerLia SeptianaNo ratings yet

- PD2055E1 MEP Multi Effect Plate DistillerDocument4 pagesPD2055E1 MEP Multi Effect Plate Distillergochi bestNo ratings yet

- Crane Vs Eqvlnt Length Method For FittingsDocument177 pagesCrane Vs Eqvlnt Length Method For FittingsSamuel OnyewuenyiNo ratings yet

- Condenser - Valuable Book PDFDocument6 pagesCondenser - Valuable Book PDFRajesh OwaiyarNo ratings yet

- Express User Guide: Part 1. Background To Use of Express in Design and Operation of E-Shell Heat Exchangers in Single Phase DutiesDocument42 pagesExpress User Guide: Part 1. Background To Use of Express in Design and Operation of E-Shell Heat Exchangers in Single Phase DutiesLaurikNo ratings yet

- 2342-AA00-ML-201 - 0 - Hazards Analysis (HAZAN)Document32 pages2342-AA00-ML-201 - 0 - Hazards Analysis (HAZAN)yusuf.yuzuakNo ratings yet

- Water in Cracked Gas Dryer Vessel Outlets: Application NoteDocument2 pagesWater in Cracked Gas Dryer Vessel Outlets: Application Noteluciole60No ratings yet

- Thermosiphon ReboilersDocument3 pagesThermosiphon ReboilersMuhammadNo ratings yet

- A Design Adn Rating Method For Shell and Tube Heat ExchangerDocument8 pagesA Design Adn Rating Method For Shell and Tube Heat Exchangerhuynhthanhtamga1981100% (1)

- CHE 165A L11 - Heat Exchanger Design PDFDocument61 pagesCHE 165A L11 - Heat Exchanger Design PDFLi ChNo ratings yet

- Vapor Liquid Equilibrium of Water + Ethanol + GlycerolDocument8 pagesVapor Liquid Equilibrium of Water + Ethanol + GlycerolcsandrasNo ratings yet

- Controlling Heat ExchangersDocument11 pagesControlling Heat ExchangersgermanaponteNo ratings yet

- Turbine GeneratorDocument3 pagesTurbine GeneratorNagamuthu Pandian100% (2)

- Reboilers & VaporisersDocument17 pagesReboilers & VaporisersKamran MalikNo ratings yet

- High Integrity Protection Systems (HIPS) - Making SIL Calculations EffectiveDocument4 pagesHigh Integrity Protection Systems (HIPS) - Making SIL Calculations Effective陳國政No ratings yet

- 3.methodology of Pressure Settings On Storage Tanks.Document10 pages3.methodology of Pressure Settings On Storage Tanks.heyheyNo ratings yet

- Peggen03 PDFDocument5 pagesPeggen03 PDFMohamedNo ratings yet

- Kettle Reboilers Chemical Engineering Design Ray SinnoyDocument6 pagesKettle Reboilers Chemical Engineering Design Ray SinnoyFederico BogettiNo ratings yet

- DynsimDocument22 pagesDynsimAbdomatarNo ratings yet

- Calculate Saturated-Gas Loads For Vacuum SystemsDocument3 pagesCalculate Saturated-Gas Loads For Vacuum SystemsFred Faber100% (1)

- Section 1 Chapter XII Safety Aspects & MSDS PrintedDocument86 pagesSection 1 Chapter XII Safety Aspects & MSDS PrintedrajuNo ratings yet

- CHE Facts 1211Document1 pageCHE Facts 1211kumar_chemicalNo ratings yet

- IntroKGTowerV2 0 PDFDocument14 pagesIntroKGTowerV2 0 PDFrasyid93No ratings yet

- Shut-Down of The PlantDocument3 pagesShut-Down of The PlantrajuNo ratings yet

- Allowable Vapor Control ValveDocument9 pagesAllowable Vapor Control Valvejohn VilladaNo ratings yet

- Freeze Protection: Heat TracingDocument4 pagesFreeze Protection: Heat TracingNaser JahangiriNo ratings yet

- Vacuum CondenserDocument4 pagesVacuum CondenserCecilia Tan50% (2)

- Mehran University of Engineering and Technology SZAB Campus Khairpur Mir'sDocument64 pagesMehran University of Engineering and Technology SZAB Campus Khairpur Mir'sMarcusHuynh88No ratings yet

- Distillation Column InternalsDocument7 pagesDistillation Column InternalsRicardo BecNo ratings yet

- Mr. C.H.Park / Project Manager 03-May-06Document30 pagesMr. C.H.Park / Project Manager 03-May-06Ali YassineNo ratings yet

- E 106Document1 pageE 106Bith SMGNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Perhitungan Laura & JasmineDocument7 pagesPerhitungan Laura & JasmineDinda CahyuniNo ratings yet

- Brochure Uk ProductsDocument2 pagesBrochure Uk ProductsJavier TrujillanoNo ratings yet

- Api 12JDocument1 pageApi 12Jhugo mendozaNo ratings yet

- Exp FinalDocument4 pagesExp Finalhugo mendozaNo ratings yet

- Catalogo Bombas Centrifugas Grundfos CRDocument25 pagesCatalogo Bombas Centrifugas Grundfos CRhugo mendozaNo ratings yet

- Bufete IndustrialDocument8 pagesBufete Industrialhugo mendozaNo ratings yet

- Data Sheet 150X125 FSS4KC 5 37 HDocument4 pagesData Sheet 150X125 FSS4KC 5 37 HPakin SornNo ratings yet

- Review Exercise - Chapter 1 - SolutionDocument9 pagesReview Exercise - Chapter 1 - SolutionSaifulizmin MustapaNo ratings yet

- Water-Lithium Bromide Vapor Absorption SystemDocument15 pagesWater-Lithium Bromide Vapor Absorption SystemSagar MoreNo ratings yet

- AHRI Standard 440 I-P 2019Document26 pagesAHRI Standard 440 I-P 2019Mahmoud GwailyNo ratings yet

- Topic 4 Dimensional Analysis Similititude Modelling 1Document78 pagesTopic 4 Dimensional Analysis Similititude Modelling 1Riker SiNo ratings yet

- Airframes and Systems Oxford QuestionsDocument40 pagesAirframes and Systems Oxford QuestionsbadboynashtaNo ratings yet

- Kishore AtdDocument14 pagesKishore AtdKumar SamyanaikNo ratings yet

- Perge Brochure Log Fired Heating BoilersDocument2 pagesPerge Brochure Log Fired Heating BoilersglynisNo ratings yet

- Lecture Notes 03 Mass and Heat Transfer in Steady State 1276989501 Phpapp01Document51 pagesLecture Notes 03 Mass and Heat Transfer in Steady State 1276989501 Phpapp01rejie magnayeNo ratings yet

- Chương 3 - P1Document17 pagesChương 3 - P1Linh Nguyễn Thị HồngNo ratings yet

- Fdocuments - in Flowirl 87002Document77 pagesFdocuments - in Flowirl 87002johnNo ratings yet

- 3LPE Coating SpecificationDocument21 pages3LPE Coating SpecificationHướng PhạmNo ratings yet

- Internal Fluid Flow: The Fluid Dynamics of Flow On Pipes and Ducts, by A. J. Ward-Smith, Oxford University PressDocument1 pageInternal Fluid Flow: The Fluid Dynamics of Flow On Pipes and Ducts, by A. J. Ward-Smith, Oxford University PressRonan Freire GoisNo ratings yet

- Spalart AllmarasDocument14 pagesSpalart AllmarasIlie Viorel100% (1)

- Siting and Installation of PumpsDocument5 pagesSiting and Installation of PumpsGAMUCHIRAI MUGADZANo ratings yet

- Ammonia Revision QuestionsDocument64 pagesAmmonia Revision QuestionsfikaduNo ratings yet

- Plant Technical & Equipment Manuals (Engineering Dossiers) : NIOEC-SP-00-60Document28 pagesPlant Technical & Equipment Manuals (Engineering Dossiers) : NIOEC-SP-00-60amini_mohi100% (1)

- Experiment 4 Group 4Document23 pagesExperiment 4 Group 4amin shukriNo ratings yet

- Water Pressure Problems in Your Caravan by Greg Lakeman PDFDocument3 pagesWater Pressure Problems in Your Caravan by Greg Lakeman PDFBenito CazNo ratings yet

- Control Valve Sourcebook - Chemical Unit Operations: Distillation ColumnDocument6 pagesControl Valve Sourcebook - Chemical Unit Operations: Distillation Columnkumar_chemicalNo ratings yet

- BS en 1759-4 - 2003Document20 pagesBS en 1759-4 - 2003Tausif LodhiNo ratings yet

- Cre MCQDocument17 pagesCre MCQAditya WaghNo ratings yet

- Incompressible Flow Over AirfoilsDocument11 pagesIncompressible Flow Over AirfoilsD.ViswanathNo ratings yet

- 2 - Turbopump TypesDocument28 pages2 - Turbopump Typesمصطفى أشرفNo ratings yet

- vn48 1009MeasuringAirflow PDFDocument2 pagesvn48 1009MeasuringAirflow PDFحسان السوفانيNo ratings yet

- FM Lab ManualDocument49 pagesFM Lab ManualNithin GowdaNo ratings yet

- LAUNDRY - Mechanical BOQ (Revised)Document2 pagesLAUNDRY - Mechanical BOQ (Revised)psn_kylmNo ratings yet

- PT. Guna Karya Mekanika: Engineering Procurement and ContractingDocument1 pagePT. Guna Karya Mekanika: Engineering Procurement and ContractingHukleberipenNo ratings yet

- Flange Pressure (Kpa) Vs Temperature (Oc) RatingDocument1 pageFlange Pressure (Kpa) Vs Temperature (Oc) RatingMSNo ratings yet