Professional Documents

Culture Documents

Op63 Fpa PDF

Op63 Fpa PDF

Uploaded by

Madhuranjan KumarCopyright:

Available Formats

You might also like

- DAILY CHECK LIST Crawler CraneDocument1 pageDAILY CHECK LIST Crawler CraneAditya Enterprise100% (1)

- IPB-OCS-KEA-MEC-DAT-0024 Rev0 Mechanical Data Sheet For Fire Water PumpDocument4 pagesIPB-OCS-KEA-MEC-DAT-0024 Rev0 Mechanical Data Sheet For Fire Water PumpsudjonoNo ratings yet

- Lube Oil System Inspection Checklist: Section A - Customer DataDocument1 pageLube Oil System Inspection Checklist: Section A - Customer DatangueadoumNo ratings yet

- IPASOLINK VR10 SpecificationsDocument32 pagesIPASOLINK VR10 SpecificationsWisam Hassan100% (1)

- MOSCAD L Owners Manual PDFDocument126 pagesMOSCAD L Owners Manual PDFJesús Valdés100% (1)

- Coil Inspection ReportDocument3 pagesCoil Inspection ReportVINAYNo ratings yet

- Laporan CemsDocument17 pagesLaporan CemsairhabieNo ratings yet

- DAILY CHECK LIST Tyre Mounted CraneDocument1 pageDAILY CHECK LIST Tyre Mounted CraneAditya Enterprise100% (1)

- Food Processing Centrifuge FP-35Document36 pagesFood Processing Centrifuge FP-35Edgar Josue C. CosNo ratings yet

- Production Report Shift WiseDocument5 pagesProduction Report Shift WiseOBSC PerfectionNo ratings yet

- KHP ManualDocument13 pagesKHP Manualthreephase electricNo ratings yet

- Diagrama de Flujo PropuestaDocument12 pagesDiagrama de Flujo PropuestaSofia GonzálezNo ratings yet

- 09 Datasheet ATGDocument11 pages09 Datasheet ATGFadlila MuhammadNo ratings yet

- 7 CompressorDocument2 pages7 CompressorMithun Singh RajputNo ratings yet

- SL No Earth Tekniks - Impa 2000 Fluke Motor Analyzer (438-II)Document2 pagesSL No Earth Tekniks - Impa 2000 Fluke Motor Analyzer (438-II)Manikchand GuptaNo ratings yet

- Signa Power Monitor Functional Test Declaration Form Signa Release 9.X & 10.0 SRFD 1.0T/1.5T & SRFD2 CABINET Power Monitor Functional Test Declaration SiteDocument1 pageSigna Power Monitor Functional Test Declaration Form Signa Release 9.X & 10.0 SRFD 1.0T/1.5T & SRFD2 CABINET Power Monitor Functional Test Declaration SiteTony KututoNo ratings yet

- Form PS Fuel TruckDocument9 pagesForm PS Fuel Truckzaid chidmahNo ratings yet

- Inflatable Rescue Boat Log: Report For Irb CaptainDocument2 pagesInflatable Rescue Boat Log: Report For Irb CaptainLuis ZapataNo ratings yet

- Avr Decs 300Document1 pageAvr Decs 300Michael ManzanoNo ratings yet

- Report 1 Paut Sts 409Document12 pagesReport 1 Paut Sts 409DEBJYOTI SENGUPTA100% (2)

- DS - DP Type Level TransmitterDocument5 pagesDS - DP Type Level TransmitterNawfel ArafathNo ratings yet

- Excel 2000 or XP UsersDocument44 pagesExcel 2000 or XP Usersanon_929347044No ratings yet

- Bar FeederDocument1 pageBar FeederPiyush VyasNo ratings yet

- W I TOOLDocument3 pagesW I TOOLram_jamdhadeNo ratings yet

- SA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02Document5 pagesSA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02altipatlarNo ratings yet

- Form PS Lube TruckDocument5 pagesForm PS Lube Truckzaid chidmahNo ratings yet

- General Deliverable of Piping Industry All DepartmentDocument3 pagesGeneral Deliverable of Piping Industry All Departmentsujay Avati100% (1)

- Dokumen - Tips 3b6 Mtech Service ManualDocument36 pagesDokumen - Tips 3b6 Mtech Service ManualLin LeninNo ratings yet

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueDocument6 pagesFeuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueBilel MahjoubNo ratings yet

- MOV DatasheetDocument98 pagesMOV Datasheetsrik11No ratings yet

- Smart 2: User and M Maintenance Manual Warranty InformationDocument20 pagesSmart 2: User and M Maintenance Manual Warranty InformationRogério PereiraNo ratings yet

- Universal FMS UNS 1Ksv604 Operators ChecklistDocument25 pagesUniversal FMS UNS 1Ksv604 Operators Checklistvamsikrishna vallabhaneni0% (1)

- Frequency Inverter: 3Vfmac-Dsp 6PDocument46 pagesFrequency Inverter: 3Vfmac-Dsp 6PMartynas Karkauskas100% (4)

- Equipment Commissioning: Perennial Technologies Pvt. LTDDocument1 pageEquipment Commissioning: Perennial Technologies Pvt. LTDkhansiphan7No ratings yet

- WHITE Operating ManualDocument32 pagesWHITE Operating ManualJaime Asis LopezNo ratings yet

- Weld Engine (Driven) Pre MobDocument1 pageWeld Engine (Driven) Pre MobGuruh SuprayitnoNo ratings yet

- Satr-P-3912 Transformer InsulationDocument8 pagesSatr-P-3912 Transformer InsulationSurendren R100% (1)

- ITAC-EWP-CKL-F-02 (Checklist)Document3 pagesITAC-EWP-CKL-F-02 (Checklist)harris.itacNo ratings yet

- Feuilles Des Données de Nouveau Groupe Électrogène GE 4Document9 pagesFeuilles Des Données de Nouveau Groupe Électrogène GE 4Bilel MahjoubNo ratings yet

- SATR-P-3825 LV Panelboard - Pre-Energized TestingDocument4 pagesSATR-P-3825 LV Panelboard - Pre-Energized TestingheikelNo ratings yet

- vs1 DatasheetDocument22 pagesvs1 DatasheetMojtabaNo ratings yet

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur DieselDocument7 pagesFeuilles Des Données de Nouveau Groupe de Pompage Moteur DieselBilel MahjoubNo ratings yet

- Astra V Astra V1.2 1.2: User'S ManualDocument38 pagesAstra V Astra V1.2 1.2: User'S ManualMalik Asif100% (1)

- API 610 11th Data Sheets Centrifugal Pump Si Units 79-P-906 Rev BDocument9 pagesAPI 610 11th Data Sheets Centrifugal Pump Si Units 79-P-906 Rev BMichael PiñaNo ratings yet

- Inspection Sheet Peralatan: Brand/Type: Nama Kapal: NO Detail Pengecekan Hasil KeteranganDocument5 pagesInspection Sheet Peralatan: Brand/Type: Nama Kapal: NO Detail Pengecekan Hasil KeteranganILHAM PALSUNo ratings yet

- Em 474 N 09 02 Cincinnati CL 7a Laser System With PC Control Operation Safety and Maintenance ManualDocument149 pagesEm 474 N 09 02 Cincinnati CL 7a Laser System With PC Control Operation Safety and Maintenance ManualManolo MedranoNo ratings yet

- Gen Set Service ReportDocument1 pageGen Set Service ReportReman MarykanNo ratings yet

- Microcomputer Components: 8-Bit CMOS Single-Chip MicrocontrollerDocument62 pagesMicrocomputer Components: 8-Bit CMOS Single-Chip MicrocontrollerJose CNo ratings yet

- RC9RC5-10.01-150677-MTCO-A1001-0001-Rev.0-Data Sheet For UPSDocument9 pagesRC9RC5-10.01-150677-MTCO-A1001-0001-Rev.0-Data Sheet For UPSNguyen Hong QuyetNo ratings yet

- Coulter Gen-S - AddendumDocument110 pagesCoulter Gen-S - AddendumluisNo ratings yet

- SATR-A-2004 Calibration Test Report - Pressure RecorderDocument2 pagesSATR-A-2004 Calibration Test Report - Pressure Recorderjohn ajitNo ratings yet

- 14960-000-ME-DAS-003 Data Sheet For Sump PumpsDocument8 pages14960-000-ME-DAS-003 Data Sheet For Sump PumpsAshish TIwariNo ratings yet

- Ge 745Document8 pagesGe 745nathansri93No ratings yet

- Instruction Manual For Models Sadp, Sadp-Tr & Sadp-D: For Information About: See PageDocument22 pagesInstruction Manual For Models Sadp, Sadp-Tr & Sadp-D: For Information About: See PagecristhianNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 24-Mar-16 MechSajid ShaikhNo ratings yet

- Saudi Aramco Test ReportDocument3 pagesSaudi Aramco Test ReportMa.socorro SaballaNo ratings yet

- Kartu Proses 20231120355Document1 pageKartu Proses 20231120355ghilteaNo ratings yet

- Ashok Garden Fire Checklist JUN 2020Document3 pagesAshok Garden Fire Checklist JUN 2020mayurchaturNo ratings yet

- Making PIC Microcontroller Instruments and ControllersFrom EverandMaking PIC Microcontroller Instruments and ControllersNo ratings yet

- Fuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachFrom EverandFuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachNo ratings yet

- Catalog UFSBIDocument3 pagesCatalog UFSBINilangshu DasNo ratings yet

- 202 - EE8601, EE6601 Solid State Drives - NotesDocument140 pages202 - EE8601, EE6601 Solid State Drives - NotesUdayNo ratings yet

- Installing Windows On The MinnowBoardDocument6 pagesInstalling Windows On The MinnowBoardalcuin99No ratings yet

- Samsung GT-N8000 Service ManualDocument84 pagesSamsung GT-N8000 Service ManualMario DeejayNo ratings yet

- Abacus MS-DOS For Beginners PDFDocument198 pagesAbacus MS-DOS For Beginners PDFanon_483649166No ratings yet

- TS00E v1.2 Student Noteset PDFDocument303 pagesTS00E v1.2 Student Noteset PDFpatrick morris100% (1)

- RF MEMS Filters RF MEMS Filters RF MEMS Filters RF MEMS FiltersDocument38 pagesRF MEMS Filters RF MEMS Filters RF MEMS Filters RF MEMS Filtersstanpjames2309No ratings yet

- Lecture - 3.1.7Document46 pagesLecture - 3.1.7simranjotkaur735No ratings yet

- Panasonic's Basic Electrical Safety TipsDocument13 pagesPanasonic's Basic Electrical Safety TipsRobert Oconer AguilarNo ratings yet

- Chapter2 - Machine Instructions and ProgramsDocument54 pagesChapter2 - Machine Instructions and ProgramsPriyankar KumarNo ratings yet

- Rathyon MK2Document107 pagesRathyon MK2Ashish DharjiyaNo ratings yet

- 更新版datasheet-166mm bifacial solar panel 440-455Document2 pages更新版datasheet-166mm bifacial solar panel 440-455tasmirozNo ratings yet

- Drager Fabius CE Service Manual Rev.C Unprotected (226-266)Document41 pagesDrager Fabius CE Service Manual Rev.C Unprotected (226-266)Den LunNo ratings yet

- 1031 Goodworth Drive, Apex, NC 27539, USA ISO 9001 Registered CompanyDocument2 pages1031 Goodworth Drive, Apex, NC 27539, USA ISO 9001 Registered CompanyAlfonso HernandezNo ratings yet

- Akio Morita Failure To SuccessDocument2 pagesAkio Morita Failure To SuccessLesterNo ratings yet

- Ece IV Microcontrollers 10es42 Question PaperDocument3 pagesEce IV Microcontrollers 10es42 Question PaperkirannrgNo ratings yet

- Build A Microwave Transformer Homemade WelderDocument24 pagesBuild A Microwave Transformer Homemade Weldermarius_danila8736No ratings yet

- As CT1 (1) - Mechanics, WavesDocument10 pagesAs CT1 (1) - Mechanics, WavesShabbir H. KhanNo ratings yet

- Ansi CodesDocument3 pagesAnsi CodesMunavwar ProfessNo ratings yet

- Updated Brushless Controller Schematic 2015 DIY Electric Car, Masina ElectricaDocument32 pagesUpdated Brushless Controller Schematic 2015 DIY Electric Car, Masina ElectricaSyed Hassan TariqNo ratings yet

- Valve Amplifier For Proportional Pressure Valves: FeaturesDocument12 pagesValve Amplifier For Proportional Pressure Valves: FeaturesInbanesan AkNo ratings yet

- Literature Review For Temperature Based Fan Speed ControllerDocument4 pagesLiterature Review For Temperature Based Fan Speed Controllerc5qxzdj7No ratings yet

- Assignment ManaliDocument31 pagesAssignment ManaliManali OjhaNo ratings yet

- Gpmp0760 Manual v2Document2 pagesGpmp0760 Manual v2Virendra GaurNo ratings yet

- Current Transformer, Potential Transformer, LTCT, Low Tension CT, Combined CTPT Unit, Metering Unit, Metering Cubicle, Resin Cast CT, Cast Resin CT, Cast Resin PT, RVT, Residual Voltatge TransformerDocument12 pagesCurrent Transformer, Potential Transformer, LTCT, Low Tension CT, Combined CTPT Unit, Metering Unit, Metering Cubicle, Resin Cast CT, Cast Resin CT, Cast Resin PT, RVT, Residual Voltatge TransformerSharafatNo ratings yet

- Ga-z68p-Ds3 v2.x eDocument104 pagesGa-z68p-Ds3 v2.x ejohnsonlimNo ratings yet

- UT58D Eng ManualDocument34 pagesUT58D Eng ManualkalizamNo ratings yet

- CaseStudy - EFACECDocument3 pagesCaseStudy - EFACECArpit SharmaNo ratings yet

Op63 Fpa PDF

Op63 Fpa PDF

Uploaded by

Madhuranjan KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Op63 Fpa PDF

Op63 Fpa PDF

Uploaded by

Madhuranjan KumarCopyright:

Available Formats

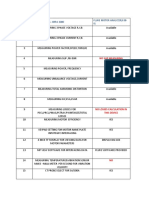

FIRST PART APPROVAL REPORT

STAGE_LASER

MODEL: OP63_MAIN_BOARD DATE: SHIFT: TIME: LINE_NO:

SR.NO CHECK-POINT SPECIFICATION VERIFIED BY-PROCESS VALIDATE BY-QA REMARKS

1 PCB MODEL NAME OP63_MB_V2.0

2 PCB REV. NO V2.0

3 MACHINE PROGRAM NAME & REV OP63_MB_V2.2_TOP

MODEL CODE(OP63)-YEAR(18)-

MONTH(MM)-DATE(DD)-FACTORY

4 BARCODE INFORMATION ID(S)-SHIFT(A,B,C)-MACHINE

ID(1,2)- SERAIL(0000)-

MASTER/SLAVE(00- 03)

CHECK COUNTER SET AT ZERO (DURING

5 REFER MACHINE DISPLAY

CHANGEOVER ONLY)

6 PCB IS NOT OXIDIZED PAD COLOR SHOULD NOT BE RED

BARCODE IS SCANNABLE WITH OK

7 REFER SOP

PRINTING AT RIGHT LOCATION

8 MACHINE AIR PRESSURE 0.4mpa to 0.7mpa

MACHINE PROGRAM IS IN OPERATOR

9 CHECK MACHINE PROGRAM MODE

MODE

10 AUTHORIZED OPERATOR AVAILABILE REFER SKILL MATRIX CHART

OPERATOR USE ESD PPE's (APPRON,

11 ALL MUST USED

SLIPPER, GLOVES, WRIST BAND)

CONTROLLED SOP, SETUP PARAMTER,

12 DEFECT JUDGEMENT SHEET AVAILABLE AT LINE

SIGN: SIGN: QA ENG. SIGN

Controlled Document :LAVA-SMPQC-FA-000-0052 RevNo:00 RevDate:08/08/2018 User:64760 Date:9/10/2018 7:05:25 AM

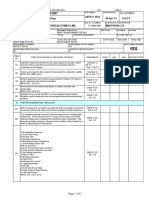

FIRST PART APPROVAL REPORT

STAGE_PASTE PRINTER

MODEL: OP63_MAIN_BOARD DATE: SHIFT: TIME: LINE_NO:

SR.NO CHECK-POINT SPECIFICATION VERIFIED BY-PROCESS VALIDATE BY-QA REMARKS

OP63_MB_V2.2_TOP

1 MACHINE PROGRAM NAME & REV

OP63_MB_V2.2_BOTTOM

2 SOLDER PASTE MAKE AND NAME ALPHA OM340

CHECL : SOLDER PASTE EXPIRY DATE, 6 MONTH FROM MFG DATE &

3 THAWING TIME, MIXING TIME, PASTE REFER PASTE JAR LABEL, PASTE

TRACKING SHEET TRACKING SHEET FILLED PROPERLY

TOP: SMT7708/SMT7821

4 STENCIL NAME AND VER (LABEL ON STENCIL)

BOTTOM: SMT7709

TEMP:18-26

5 TEMP \ RH INSIDE MACHINE

RH:40-70%

30-60 MM/S & 5-9 KG FOR FRONT

& REAR IN TOP

6 SQUEEZE SPEED AND PRESURE 45-75 MM/S & 4.8-8.8 KG FOR

FRONT & REAR IN BOTTOM

NO BLOCKAGE AND DENT ON

7 STENCIL APPERTURE AND CONDITION

STENCIL

8 PASTE IS LOADED IN AUTO DISPENSER CHECK VISUALLY

BOT. (W-D-V) -AFTER EACH BOARD

9 CLEANING CYCLE

TOP( W-V )-AFTER EACH BOARD

BARCODE IS SCANNABLE WITH OK

10 REFER SOP

PRINTING AT RIGHT LOCATION

11 MACHINE AIR PRESSURE 0.4mpa to 0.7mpa

MACHINE PROGRAM IS IN OPERATOR

12 CHECK MACHINE PROGRAM MODE

MODE

13 AUTHORIZED OPERATOR AVAILABILE REFER SKILL MATRIX CHART

OPERATOR USE ESD PPE's (APPRON,

14 ALL MUST USED

SLIPPER, GLOVES, WRIST BAND)

CONTROLLED SOP, SETUP PARAMTER,

15 AVAILABLE AT LINE

DEFECT JUDGEMENT, PASTE MANAGEMENT

SIGN: SIGN: QA ENG. SIGN

Controlled Document :LAVA-SMPQC-FA-000-0052 RevNo:00 RevDate:08/08/2018 User:64760 Date:9/10/2018 7:05:25 AM

FIRST PART APPROVAL REPORT

STAGE_SPI

MODEL: OP63_MAIN_BOARD DATE: SHIFT: TIME: LINE_NO:

SR.NO CHECK-POINT SPECIFICATION VERIFIED BY-PROCESS VALIDATE BY-QA REMARKS

OP63_MB_V2_2_TOP

1 MACHINE PROGRAM NAME & REV OP63_MB_V2_2_BOTTOM

2 CHECK 1ST BOARD VISUALLY

2.1 MISSING PASTE NO OBERVATION

2.2 EXCESS SOLDER PASTE OR SOLDER SPLASH NO OBERVATION

2.3 SHORTING OR BRIDGING NO OBERVATION

2.4 OFFSET PRINTING NO OBERVATION

SET UP PARAMETER FOR HEIGHT AREA AND

3 REFER SETUP PARAMETER SHEET

VOLUME

4 MACHINE AIR PRESSURE 0.4mpa to 0.7mpa

MACHINE PROGRAM IS IN OPERATOR

5 CHECK MACHINE PROGRAM MODE

MODE

6 AUTHORIZED OPERATOR AVAILABILE REFER SKILL MATRIX CHART

OPERATOR USE ESD PPE's (APPRON,

7 ALL MUST USED

SLIPPER, GLOVES, WRIST BAND)

CONTROLLED SOP, SETUP PARAMTER,

8 DEFECT JUDGEMENT SHEET AVAILABLE AT LINE

SIGN: SIGN: QA ENG. SIGN

Controlled Document :LAVA-SMPQC-FA-000-0052 RevNo:00 RevDate:08/08/2018 User:64760 Date:9/10/2018 7:05:25 AM

FIRST PART APPROVAL REPORT

STAGE_MOUNTER (M1, M2, M3, M4, M5 & M6)

MODEL: OP63_MAIN_BOARD DATE: SHIFT: TIME: LINE_NO:

SR.NO CHECK-POINT SPECIFICATION VERIFIED BY-PROCESS VALIDATE BY-QA REMARKS

OP63_MB_V2_2_TOP

1 MACHINE PROGRAM NAME & REV

OP63_MB_V2_2_BOTTOM

VERIFIED FEEDER VERIFICATION SHEET AND CONTROLLED SHEET AVAILABLE AT

2

SPLICING SHEET LINE

NO EXPIRED MSL LEVEL COMPONENT REFER LABEL ON MSL COMPONENT

3

LOADED ON LINE PACKING

4 TRAYS PLACED IN RIGHT DIRECTION REFER LOADING CHART

5 IS FAI RESULT OK (FOR CHANGEOVER ONLY) FAI RESULT

EXPIRED MSL LEVEL SHOULD HAVE BAKING REFER BAKING MARKING ON

6

IDENTIFICATION (IF ANY) PACKET

7 MACHINE AIR PRESSURE 0.4mpa to 0.7mpa

MACHINE PROGRAM IS IN OPERATOR

8 CHECK MACHINE PROGRAM MODE

MODE

9 AUTHORIZED OPERATOR AVAILABILE REFER SKILL MATRIX CHART

OPERATOR USE ESD PPE's (APPRON,

10 ALL MUST USED

SLIPPER, GLOVES, WRIST BAND)

CONTROLLED SOP, SETUP PARAMTER,

11 DEFECT JUDGEMENT SHEET AVAILABLE AT LINE

SIGN: SIGN: QA ENG. SIGN

Controlled Document :LAVA-SMPQC-FA-000-0052 RevNo:00 RevDate:08/08/2018 User:64760 Date:9/10/2018 7:05:25 AM

FIRST PART APPROVAL REPORT

STAGE_PRE-AOI

MODEL: OP63_MAIN_BOARD DATE: SHIFT: TIME: LINE_NO:

SR.NO CHECK-POINT SPECIFICATION VERIFIED BY-PROCESS VALIDATE BY-QA REMARKS

OP63_MB_V2.2_TOP

1 MACHINE PROGRAM NAME & REV OP63_MB_V2.2_BOTTOM

2 CHECK 1ST BOARD VISUALLY

2.1 MSSING COMPONENT NO OBERVATION

2.2 WRONG POLARITY NO OBERVATION

2.3 WRONG COMPONENT NO OBERVATION

2.4 SHIFTING COMPONENT NO OBERVATION

3 MACHINE AIR PRESSURE 0.4mpa to 0.7mpa

MACHINE PROGRAM IS IN OPERATOR

4 CHECK MACHINE PROGRAM MODE

MODE

5 AUTHORIZED OPERATOR AVAILABILE REFER SKILL MATRIX CHART

OPERATOR USE ESD PPE's (APPRON,

6 ALL MUST USED

SLIPPER, GLOVES, WRIST BAND)

CONTROLLED SOP, SETUP PARAMTER,

7 DEFECT JUDGEMENT SHEET AVAILABLE AT LINE

SIGN: SIGN: QA ENG. SIGN

Controlled Document :LAVA-SMPQC-FA-000-0052 RevNo:00 RevDate:08/08/2018 User:64760 Date:9/10/2018 7:05:25 AM

FIRST PART APPROVAL REPORT

STAGE_REFLOW

MODEL: OP63_MAIN_BOARD DATE: SHIFT: TIME: LINE_NO:

SR.NO CHECK-POINT SPECIFICATION VERIFIED BY-PROCESS VALIDATE BY-QA REMARKS

1 MACHINE PROGRAM NAME & REV OP63_MB_V2.2_TOP+BOTTOM

2 ZONE WISE REFLOW TEMP TOP HEATER BOT. HEATER

2.1 ZONE 1 120 120

2.2 ZONE 2 135 135

2.3 ZONE 3 170 170

2.4 ZONE 4 180 180

2.5 ZONE 5 190 190

2.6 ZONE 6 210 210

2.7 ZONE 7 210 210

2.8 ZONE 8 238 238

2.9 ZONE 9 260 260

2.10 ZONE 10 260 260

910mm/min Rail 2

2.11 CONVEYOR SPEED

910mm/min Rail 1

3 PWI IS LESS THAN 100% REFER REFLOW PROFILE

MACHINE PROGRAM IS IN OPERATOR CHECK MACHINE PROGRAM

4

MODE MODE

5 AUTHORIZED OPERATOR AVAILABILE REFER SKILL MATRIX CHART

CONTROLLED SOP, SETUP PARAMTER,

6 AVAILABLE AT LINE

DEFECT JUDGEMENT SHEET

SIGN: SIGN: QA ENG. SIGN

Controlled Document :LAVA-SMPQC-FA-000-0052 RevNo:00 RevDate:08/08/2018 User:64760 Date:9/10/2018 7:05:25 AM

FIRST PART APPROVAL REPORT

STAGE_PRE-AOI

MODEL: OP63_MAIN_BOARD DATE: SHIFT: TIME: LINE_NO:

SR.NO CHECK-POINT SPECIFICATION VERIFIED BY-PROCESS VALIDATE BY-QA REMARKS

OP63_MB_V2.2_TOP

1 MACHINE PROGRAM NAME & REV OP63_MB_V2.2_BOTTOM

2 CHECK 1ST BOARD VISUALLY

2.1 MSSING COMPONENT NO OBERVATION

2.2 WRONG POLARITY NO OBERVATION

2.3 WRONG COMPONENT NO OBERVATION

2.4 SHIFTING COMPONENT NO OBERVATION

3 MACHINE AIR PRESSURE 0.4mpa to 0.7mpa

MACHINE PROGRAM IS IN OPERATOR

4 CHECK MACHINE PROGRAM MODE

MODE

5 AUTHORIZED OPERATOR AVAILABILE REFER SKILL MATRIX CHART

OPERATOR USE ESD PPE's (APPRON,

6 ALL MUST USED

SLIPPER, GLOVES, WRIST BAND)

CONTROLLED SOP, SETUP PARAMTER,

7 DEFECT JUDGEMENT SHEET AVAILABLE AT LINE

SIGN: SIGN: QA ENG. SIGN

Controlled Document :LAVA-SMPQC-FA-000-0052 RevNo:00 RevDate:08/08/2018 User:64760 Date:9/10/2018 7:05:25 AM

FIRST PART APPROVAL REPORT

STAGE_ROUTER

MODEL: OP63_MAIN_BOARD DATE: SHIFT: TIME: LINE_NO:

SR.NO CHECK-POINT SPECIFICATION VERIFIED BY-PROCESS VALIDATE BY-QA REMARKS

1 MACHINE PROGRAM NAME & REV OP63_MB_V2_2_TOP

2 CHECK 1ST BOARD VISUALLY

2.1 UNDER CUTTING NO OBERVATION

2.2 OVER CUTTING NO OBERVATION

2.3 TRACK OR PAD DAMAGE NO OBERVATION

2.4 EXCESS BUR OR DUST ON PCBA NO OBERVATION

3 MACHINE AIR PRESSURE 0.4mpa to 0.7mpa

MACHINE PROGRAM IS IN OPERATOR

4 CHECK MACHINE PROGRAM MODE

MODE

5 AUTHORIZED OPERATOR AVAILABILE REFER SKILL MATRIX CHART

OPERATOR USE ESD PPE's (APPRON,

6 ALL MUST USED

SLIPPER, GLOVES, WRIST BAND)

CONTROLLED SOP, SETUP PARAMTER,

7 DEFECT JUDGEMENT SHEET AVAILABLE AT LINE

SIGN: SIGN: QA ENG. SIGN

Controlled Document :LAVA-SMPQC-FA-000-0052 RevNo:00 RevDate:08/08/2018 User:64760 Date:9/10/2018 7:05:25 AM

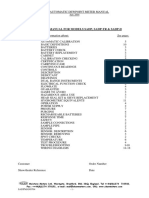

FIRST PART APPROVAL REPORT

STAGE_TESTING

MODEL: OP63_MAIN_BOARD DATE: SHIFT: TIME: LINE_NO:

SR.NO CHECK-POINT SPECIFICATION VERIFIED BY-PROCESS VALIDATE BY-QA REMARKS

LAVAZ61_1_16_V1.0_S117_20180

1 SOFTWARE NAME IN DOWNLOADING

622_ENG_IN

2 CALIBRATION TOOL TEST PLAN FILE NAME test_plan_mtk_cal_ini

BARCODE, WIFI, BT, FM, GPS, G-SENSOR,

ALS/PS, TOUCH PANNEL, MAIN CAMERA,

3 SUB-CAMERA, T-CARD, SIM, KEYPAD, ALL TEST CASE SHOULD BE ENABLE

RECEIVER, SPEAKER,HEADSET, VIBRATOR,

CHARGER, LCM

4 PARAMETER FOR ALL MMI TEST CASE REFER SETUP PARAMETER SHEET

5 JIGS WIRE CONNECTION NOT LOOSE

6 ALL JIG's CONNECTED TO GROUND MUST CONNECTED

7 AUTHORIZED OPERATOR AVAILABILE REFER SKILL MATRIX CHART

OPERATOR USE ESD PPE's (APPRON,

8 ALL MUST USED

SLIPPER, GLOVES, WRIST BAND)

CONTROLLED SOP, SETUP PARAMTER,

9 DEFECT JUDGEMENT SHEET AVAILABLE AT LINE

SIGN: SIGN: QA ENG. SIGN

Controlled Document :LAVA-SMPQC-FA-000-0052 RevNo:00 RevDate:08/08/2018 User:64760 Date:9/10/2018 7:05:25 AM

FIRST PART APPROVAL REPORT

STAGE_UNDERFILL

MODEL: OP63_MAIN_BOARD DATE: SHIFT: TIME: LINE_NO:

SR.NO CHECK-POINT SPECIFICATION VERIFIED BY-PROCESS VALIDATE BY-QA REMARKS

OP63 Y1.g

1 MACHINE PROGRAM NAME & REV

OP63 Y2.g

2 CHECK 1ST BOARD VISUALLY

2.1 OVER GLUE SPILLAGE NO OBERVATION

2.2 GLUE ON UNWANTED AREA NO OBERVATION

2.3 PROPER CURING OF GLUE NO OBERVATION

2.4 EXCESS BUR OR DUST ON PCBA NO OBERVATION

3 MACHINE AIR PRESSURE 6-8KFG

MACHINE PROGRAM IS IN OPERATOR

4 CHECK MACHINE PROGRAM MODE

MODE

5 AUTHORIZED OPERATOR AVAILABILE REFER SKILL MATRIX CHART

OPERATOR USE ESD PPE's (APPRON,

6 ALL MUST USED

SLIPPER, GLOVES, WRIST BAND)

CONTROLLED SOP, SETUP PARAMTER,

7 DEFECT JUDGEMENT SHEET AVAILABLE AT LINE

SIGN: SIGN: QA ENG. SIGN

Controlled Document :LAVA-SMPQC-FA-000-0052 RevNo:00 RevDate:08/08/2018 User:64760 Date:9/10/2018 7:05:25 AM

You might also like

- DAILY CHECK LIST Crawler CraneDocument1 pageDAILY CHECK LIST Crawler CraneAditya Enterprise100% (1)

- IPB-OCS-KEA-MEC-DAT-0024 Rev0 Mechanical Data Sheet For Fire Water PumpDocument4 pagesIPB-OCS-KEA-MEC-DAT-0024 Rev0 Mechanical Data Sheet For Fire Water PumpsudjonoNo ratings yet

- Lube Oil System Inspection Checklist: Section A - Customer DataDocument1 pageLube Oil System Inspection Checklist: Section A - Customer DatangueadoumNo ratings yet

- IPASOLINK VR10 SpecificationsDocument32 pagesIPASOLINK VR10 SpecificationsWisam Hassan100% (1)

- MOSCAD L Owners Manual PDFDocument126 pagesMOSCAD L Owners Manual PDFJesús Valdés100% (1)

- Coil Inspection ReportDocument3 pagesCoil Inspection ReportVINAYNo ratings yet

- Laporan CemsDocument17 pagesLaporan CemsairhabieNo ratings yet

- DAILY CHECK LIST Tyre Mounted CraneDocument1 pageDAILY CHECK LIST Tyre Mounted CraneAditya Enterprise100% (1)

- Food Processing Centrifuge FP-35Document36 pagesFood Processing Centrifuge FP-35Edgar Josue C. CosNo ratings yet

- Production Report Shift WiseDocument5 pagesProduction Report Shift WiseOBSC PerfectionNo ratings yet

- KHP ManualDocument13 pagesKHP Manualthreephase electricNo ratings yet

- Diagrama de Flujo PropuestaDocument12 pagesDiagrama de Flujo PropuestaSofia GonzálezNo ratings yet

- 09 Datasheet ATGDocument11 pages09 Datasheet ATGFadlila MuhammadNo ratings yet

- 7 CompressorDocument2 pages7 CompressorMithun Singh RajputNo ratings yet

- SL No Earth Tekniks - Impa 2000 Fluke Motor Analyzer (438-II)Document2 pagesSL No Earth Tekniks - Impa 2000 Fluke Motor Analyzer (438-II)Manikchand GuptaNo ratings yet

- Signa Power Monitor Functional Test Declaration Form Signa Release 9.X & 10.0 SRFD 1.0T/1.5T & SRFD2 CABINET Power Monitor Functional Test Declaration SiteDocument1 pageSigna Power Monitor Functional Test Declaration Form Signa Release 9.X & 10.0 SRFD 1.0T/1.5T & SRFD2 CABINET Power Monitor Functional Test Declaration SiteTony KututoNo ratings yet

- Form PS Fuel TruckDocument9 pagesForm PS Fuel Truckzaid chidmahNo ratings yet

- Inflatable Rescue Boat Log: Report For Irb CaptainDocument2 pagesInflatable Rescue Boat Log: Report For Irb CaptainLuis ZapataNo ratings yet

- Avr Decs 300Document1 pageAvr Decs 300Michael ManzanoNo ratings yet

- Report 1 Paut Sts 409Document12 pagesReport 1 Paut Sts 409DEBJYOTI SENGUPTA100% (2)

- DS - DP Type Level TransmitterDocument5 pagesDS - DP Type Level TransmitterNawfel ArafathNo ratings yet

- Excel 2000 or XP UsersDocument44 pagesExcel 2000 or XP Usersanon_929347044No ratings yet

- Bar FeederDocument1 pageBar FeederPiyush VyasNo ratings yet

- W I TOOLDocument3 pagesW I TOOLram_jamdhadeNo ratings yet

- SA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02Document5 pagesSA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02altipatlarNo ratings yet

- Form PS Lube TruckDocument5 pagesForm PS Lube Truckzaid chidmahNo ratings yet

- General Deliverable of Piping Industry All DepartmentDocument3 pagesGeneral Deliverable of Piping Industry All Departmentsujay Avati100% (1)

- Dokumen - Tips 3b6 Mtech Service ManualDocument36 pagesDokumen - Tips 3b6 Mtech Service ManualLin LeninNo ratings yet

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueDocument6 pagesFeuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueBilel MahjoubNo ratings yet

- MOV DatasheetDocument98 pagesMOV Datasheetsrik11No ratings yet

- Smart 2: User and M Maintenance Manual Warranty InformationDocument20 pagesSmart 2: User and M Maintenance Manual Warranty InformationRogério PereiraNo ratings yet

- Universal FMS UNS 1Ksv604 Operators ChecklistDocument25 pagesUniversal FMS UNS 1Ksv604 Operators Checklistvamsikrishna vallabhaneni0% (1)

- Frequency Inverter: 3Vfmac-Dsp 6PDocument46 pagesFrequency Inverter: 3Vfmac-Dsp 6PMartynas Karkauskas100% (4)

- Equipment Commissioning: Perennial Technologies Pvt. LTDDocument1 pageEquipment Commissioning: Perennial Technologies Pvt. LTDkhansiphan7No ratings yet

- WHITE Operating ManualDocument32 pagesWHITE Operating ManualJaime Asis LopezNo ratings yet

- Weld Engine (Driven) Pre MobDocument1 pageWeld Engine (Driven) Pre MobGuruh SuprayitnoNo ratings yet

- Satr-P-3912 Transformer InsulationDocument8 pagesSatr-P-3912 Transformer InsulationSurendren R100% (1)

- ITAC-EWP-CKL-F-02 (Checklist)Document3 pagesITAC-EWP-CKL-F-02 (Checklist)harris.itacNo ratings yet

- Feuilles Des Données de Nouveau Groupe Électrogène GE 4Document9 pagesFeuilles Des Données de Nouveau Groupe Électrogène GE 4Bilel MahjoubNo ratings yet

- SATR-P-3825 LV Panelboard - Pre-Energized TestingDocument4 pagesSATR-P-3825 LV Panelboard - Pre-Energized TestingheikelNo ratings yet

- vs1 DatasheetDocument22 pagesvs1 DatasheetMojtabaNo ratings yet

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur DieselDocument7 pagesFeuilles Des Données de Nouveau Groupe de Pompage Moteur DieselBilel MahjoubNo ratings yet

- Astra V Astra V1.2 1.2: User'S ManualDocument38 pagesAstra V Astra V1.2 1.2: User'S ManualMalik Asif100% (1)

- API 610 11th Data Sheets Centrifugal Pump Si Units 79-P-906 Rev BDocument9 pagesAPI 610 11th Data Sheets Centrifugal Pump Si Units 79-P-906 Rev BMichael PiñaNo ratings yet

- Inspection Sheet Peralatan: Brand/Type: Nama Kapal: NO Detail Pengecekan Hasil KeteranganDocument5 pagesInspection Sheet Peralatan: Brand/Type: Nama Kapal: NO Detail Pengecekan Hasil KeteranganILHAM PALSUNo ratings yet

- Em 474 N 09 02 Cincinnati CL 7a Laser System With PC Control Operation Safety and Maintenance ManualDocument149 pagesEm 474 N 09 02 Cincinnati CL 7a Laser System With PC Control Operation Safety and Maintenance ManualManolo MedranoNo ratings yet

- Gen Set Service ReportDocument1 pageGen Set Service ReportReman MarykanNo ratings yet

- Microcomputer Components: 8-Bit CMOS Single-Chip MicrocontrollerDocument62 pagesMicrocomputer Components: 8-Bit CMOS Single-Chip MicrocontrollerJose CNo ratings yet

- RC9RC5-10.01-150677-MTCO-A1001-0001-Rev.0-Data Sheet For UPSDocument9 pagesRC9RC5-10.01-150677-MTCO-A1001-0001-Rev.0-Data Sheet For UPSNguyen Hong QuyetNo ratings yet

- Coulter Gen-S - AddendumDocument110 pagesCoulter Gen-S - AddendumluisNo ratings yet

- SATR-A-2004 Calibration Test Report - Pressure RecorderDocument2 pagesSATR-A-2004 Calibration Test Report - Pressure Recorderjohn ajitNo ratings yet

- 14960-000-ME-DAS-003 Data Sheet For Sump PumpsDocument8 pages14960-000-ME-DAS-003 Data Sheet For Sump PumpsAshish TIwariNo ratings yet

- Ge 745Document8 pagesGe 745nathansri93No ratings yet

- Instruction Manual For Models Sadp, Sadp-Tr & Sadp-D: For Information About: See PageDocument22 pagesInstruction Manual For Models Sadp, Sadp-Tr & Sadp-D: For Information About: See PagecristhianNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 24-Mar-16 MechSajid ShaikhNo ratings yet

- Saudi Aramco Test ReportDocument3 pagesSaudi Aramco Test ReportMa.socorro SaballaNo ratings yet

- Kartu Proses 20231120355Document1 pageKartu Proses 20231120355ghilteaNo ratings yet

- Ashok Garden Fire Checklist JUN 2020Document3 pagesAshok Garden Fire Checklist JUN 2020mayurchaturNo ratings yet

- Making PIC Microcontroller Instruments and ControllersFrom EverandMaking PIC Microcontroller Instruments and ControllersNo ratings yet

- Fuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachFrom EverandFuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachNo ratings yet

- Catalog UFSBIDocument3 pagesCatalog UFSBINilangshu DasNo ratings yet

- 202 - EE8601, EE6601 Solid State Drives - NotesDocument140 pages202 - EE8601, EE6601 Solid State Drives - NotesUdayNo ratings yet

- Installing Windows On The MinnowBoardDocument6 pagesInstalling Windows On The MinnowBoardalcuin99No ratings yet

- Samsung GT-N8000 Service ManualDocument84 pagesSamsung GT-N8000 Service ManualMario DeejayNo ratings yet

- Abacus MS-DOS For Beginners PDFDocument198 pagesAbacus MS-DOS For Beginners PDFanon_483649166No ratings yet

- TS00E v1.2 Student Noteset PDFDocument303 pagesTS00E v1.2 Student Noteset PDFpatrick morris100% (1)

- RF MEMS Filters RF MEMS Filters RF MEMS Filters RF MEMS FiltersDocument38 pagesRF MEMS Filters RF MEMS Filters RF MEMS Filters RF MEMS Filtersstanpjames2309No ratings yet

- Lecture - 3.1.7Document46 pagesLecture - 3.1.7simranjotkaur735No ratings yet

- Panasonic's Basic Electrical Safety TipsDocument13 pagesPanasonic's Basic Electrical Safety TipsRobert Oconer AguilarNo ratings yet

- Chapter2 - Machine Instructions and ProgramsDocument54 pagesChapter2 - Machine Instructions and ProgramsPriyankar KumarNo ratings yet

- Rathyon MK2Document107 pagesRathyon MK2Ashish DharjiyaNo ratings yet

- 更新版datasheet-166mm bifacial solar panel 440-455Document2 pages更新版datasheet-166mm bifacial solar panel 440-455tasmirozNo ratings yet

- Drager Fabius CE Service Manual Rev.C Unprotected (226-266)Document41 pagesDrager Fabius CE Service Manual Rev.C Unprotected (226-266)Den LunNo ratings yet

- 1031 Goodworth Drive, Apex, NC 27539, USA ISO 9001 Registered CompanyDocument2 pages1031 Goodworth Drive, Apex, NC 27539, USA ISO 9001 Registered CompanyAlfonso HernandezNo ratings yet

- Akio Morita Failure To SuccessDocument2 pagesAkio Morita Failure To SuccessLesterNo ratings yet

- Ece IV Microcontrollers 10es42 Question PaperDocument3 pagesEce IV Microcontrollers 10es42 Question PaperkirannrgNo ratings yet

- Build A Microwave Transformer Homemade WelderDocument24 pagesBuild A Microwave Transformer Homemade Weldermarius_danila8736No ratings yet

- As CT1 (1) - Mechanics, WavesDocument10 pagesAs CT1 (1) - Mechanics, WavesShabbir H. KhanNo ratings yet

- Ansi CodesDocument3 pagesAnsi CodesMunavwar ProfessNo ratings yet

- Updated Brushless Controller Schematic 2015 DIY Electric Car, Masina ElectricaDocument32 pagesUpdated Brushless Controller Schematic 2015 DIY Electric Car, Masina ElectricaSyed Hassan TariqNo ratings yet

- Valve Amplifier For Proportional Pressure Valves: FeaturesDocument12 pagesValve Amplifier For Proportional Pressure Valves: FeaturesInbanesan AkNo ratings yet

- Literature Review For Temperature Based Fan Speed ControllerDocument4 pagesLiterature Review For Temperature Based Fan Speed Controllerc5qxzdj7No ratings yet

- Assignment ManaliDocument31 pagesAssignment ManaliManali OjhaNo ratings yet

- Gpmp0760 Manual v2Document2 pagesGpmp0760 Manual v2Virendra GaurNo ratings yet

- Current Transformer, Potential Transformer, LTCT, Low Tension CT, Combined CTPT Unit, Metering Unit, Metering Cubicle, Resin Cast CT, Cast Resin CT, Cast Resin PT, RVT, Residual Voltatge TransformerDocument12 pagesCurrent Transformer, Potential Transformer, LTCT, Low Tension CT, Combined CTPT Unit, Metering Unit, Metering Cubicle, Resin Cast CT, Cast Resin CT, Cast Resin PT, RVT, Residual Voltatge TransformerSharafatNo ratings yet

- Ga-z68p-Ds3 v2.x eDocument104 pagesGa-z68p-Ds3 v2.x ejohnsonlimNo ratings yet

- UT58D Eng ManualDocument34 pagesUT58D Eng ManualkalizamNo ratings yet

- CaseStudy - EFACECDocument3 pagesCaseStudy - EFACECArpit SharmaNo ratings yet