Professional Documents

Culture Documents

Dewatering Municipal Wastewater Sludges - Part34

Dewatering Municipal Wastewater Sludges - Part34

Uploaded by

Irvan Vatoni0 ratings0% found this document useful (0 votes)

9 views1 page1

Original Title

Dewatering Municipal Wastewater Sludges_Part34

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

9 views1 pageDewatering Municipal Wastewater Sludges - Part34

Dewatering Municipal Wastewater Sludges - Part34

Uploaded by

Irvan Vatoni1

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 1

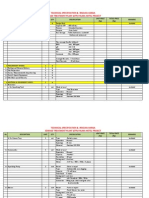

Figure 3-4, Procoss macs balance.

‘Sludge Yild Without Primary Claifcation

‘Sludge Production,

a

Solids Retention Time, days

‘Sludge Vield With Primary Clarification

°c.

2080.

sore:

00/800, = 1520

12

‘788/800, = 0:

Primary Treotment

@ 60% TSS Removal

30% Inet in Pa

Eftuent TSS

Bee eeee

‘Sludge Production, y, Ib TSS/Ib BOD, Rem

BAOSOET TE2 3 ABCTEDIO TS 2) DDD

Solids Rototion Tima, dave

this procedure effectively with minor changes in the

design approach and negligible additional costs.

Where the primary clarifier must serve a dual function

of clarifying the wastewater as well as delivering a

concentrated sludge for digestion or dewatering, the

‘conventional primary clarifier design configuration is

inappropriate. This is particularly true for primary

clarifiers in smaller plants, where it may be necessary

to have 1.6-2.0 days SRT in the clarifier to croate a

1.0 to 1.5 m (8-5 ft) sludge blanket above the

sludge withdrawal pipe. The build-up of sludge to

produce a thicker underflow interferes with

Clarification (lower efficiency) and sometimes results

in gasification, odors, and tloating sludges.

However, in the new plants there is an easy remedy

for this problem. Construct the smaller clarifiers with

the standard thickener floor slope of 2.78:12. In larger

dlarifiers, use a dual slope clarifier where the inner

slope of 2.76:12 is the thickening zone and the outer

zone is 1:12. On a primary clarifier, only 40-50

percent of the diameter would be required for sludge

thickening; thus it is sufficient to modify the floor

slope at mid-radius.

Figure 3-5 shows the types of clarifier floor

configurations of which only three are suitable for

efficient combined clarification and thickening. Type A

is the design most commonly employed, but it iS not

suitable for combined clarification and thickening.

Types B, C and D all can provide much better

performance in terms of thickened sludge

Concentrations and lowest sludge inventory; hence,

they provide freshest sludge and highest flexibility in

terms of sludge removal and ease of operation,

Pertinent dimensions for a 30 ft diameter and 80 ft

diameter primary clarifier-thickener are also shown

in Table 3-2,

Process data used’ to construct the sludge level in

Table 3-2 are provided below. Underflow

concentrations were based ‘on general experiences

with sludge thickening,

RPS @ 120 mgf

WAS @ 80 mgi

Total =

1,000 ib TSSimgd

667 Ib TSSimgd

7,667 Ib TSSimgd

8.1 m (30 f) diameter @ 1.36 m3/m2d (800 galisq

fi:

TSSq (TSS removed) = 943 Ib TSSid

24 m (80 tt) diameter @ 32.6 mim2d (800 galisq

tay

TSSR = 6,706 lb TSSid

Sludge blanket depth in small clarifiers is a two-fold

problem in units with the 1:12 floor slope. As shown

in Table 3-2, the 1.0 day SRT sludge depth is only

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Evaluation and Ranking of Electric Scooters: A Case StudyDocument9 pagesEvaluation and Ranking of Electric Scooters: A Case StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Wind Prospect LTD Method Statement: Project: Method Statement Title Ref No: Date: Prepared byDocument7 pagesWind Prospect LTD Method Statement: Project: Method Statement Title Ref No: Date: Prepared byjaouad id boubkerNo ratings yet

- Material Safety Data Sheet: Section 1 - Product InformationDocument2 pagesMaterial Safety Data Sheet: Section 1 - Product Informationmohamed AdelNo ratings yet

- English Language and Comprehension: Careerwill Batch Noun Practice SheetDocument9 pagesEnglish Language and Comprehension: Careerwill Batch Noun Practice Sheet19-2310 AmitNo ratings yet

- Solvay 索尔维 乳化剂和单体手册Document6 pagesSolvay 索尔维 乳化剂和单体手册陈辉No ratings yet

- CMHC Septic and Well Question ChecklistDocument8 pagesCMHC Septic and Well Question Checklistwahixo2362No ratings yet

- Chapter - Four Soil Permeability and SeepageDocument19 pagesChapter - Four Soil Permeability and SeepageBefkadu KurtaileNo ratings yet

- DESTEP AnalysisDocument4 pagesDESTEP AnalysisYan Myo ZawNo ratings yet

- Report On Long Term Strategy For The Transport Sector of HMA-2041 Volume-I Main Report PDFDocument397 pagesReport On Long Term Strategy For The Transport Sector of HMA-2041 Volume-I Main Report PDFVivek Eadara100% (1)

- Penentuan Pola Operasi Pintu Pelimpah Dalam Rangka Pengendalian Banjir Bendungan Delingan, Jawa TengahDocument14 pagesPenentuan Pola Operasi Pintu Pelimpah Dalam Rangka Pengendalian Banjir Bendungan Delingan, Jawa TengahDanish RifaiNo ratings yet

- Research Paper On Rainfall AnalysisDocument6 pagesResearch Paper On Rainfall Analysiscampsxek100% (1)

- Gold Book 2007 RevisedDocument88 pagesGold Book 2007 RevisedHoward VelasquezNo ratings yet

- AGRI 2 - Activity 2Document8 pagesAGRI 2 - Activity 2Alexis LopezNo ratings yet

- Glass Design Olympiad - Oct 07Document6 pagesGlass Design Olympiad - Oct 07Garima KamraNo ratings yet

- Peraturan Pemarkahan Kertas Amali Kimia: Manipulated HidroklorikDocument2 pagesPeraturan Pemarkahan Kertas Amali Kimia: Manipulated HidroklorikSyakir FahmieNo ratings yet

- Energy Conservation and Green Building (Elective)Document4 pagesEnergy Conservation and Green Building (Elective)RavindraNo ratings yet

- Session 2. Legal, Technological, Accounting, Political Environments and The Role of CultureDocument25 pagesSession 2. Legal, Technological, Accounting, Political Environments and The Role of CulturesyilaNo ratings yet

- Bim 10 DimensionsDocument1 pageBim 10 DimensionsWole LabiranNo ratings yet

- Contoh Laporan Time Activity SP KinasihDocument15 pagesContoh Laporan Time Activity SP KinasihFani ImmaNo ratings yet

- Environmental LawDocument22 pagesEnvironmental LawMayank PokhriyalNo ratings yet

- Architects Have A Significant Impact On The EnvironmentDocument2 pagesArchitects Have A Significant Impact On The Environmentdvbtkt9ngrNo ratings yet

- CRZ RulesDocument15 pagesCRZ RulesABIRAMI K ANo ratings yet

- Technical Specification & Rincian Harga Sewage Treatment Plant (STP) Palma Hotel ProjectDocument6 pagesTechnical Specification & Rincian Harga Sewage Treatment Plant (STP) Palma Hotel ProjectrudiawanNo ratings yet

- Xiiray NB ProposalDocument29 pagesXiiray NB ProposalAhmed HonestNo ratings yet

- 20 Ideas For Saving Money and Time in The GardenDocument24 pages20 Ideas For Saving Money and Time in The GardenHaritharaj S.No ratings yet

- Architecture: in Brunei DarussalamDocument22 pagesArchitecture: in Brunei DarussalamMark Jemuel Domingo100% (1)

- Activated Sludge ProcessDocument48 pagesActivated Sludge Processrozma khanNo ratings yet

- 832 00053 01 Walocel MK 3000 PF Hydroxypropyl Methyl CelluloseDocument2 pages832 00053 01 Walocel MK 3000 PF Hydroxypropyl Methyl CelluloseasuxNo ratings yet

- Upvc Final Code BDocument142 pagesUpvc Final Code ButkarshsabberwalNo ratings yet

- Mullaperiyar Dam IssueDocument3 pagesMullaperiyar Dam IssueEldho VargheseNo ratings yet