Professional Documents

Culture Documents

Sugar Mill

Sugar Mill

Uploaded by

Omprakash Uppaladinni0 ratings0% found this document useful (0 votes)

45 views2 pagesThe document summarizes an industrial visit by mechanical engineering students to Kadva Cooperative Sugar Factory on March 29, 2017. The objectives of the visit were to give students practical insight into boiler equipment and accessories and study the overall plant layout and co-generation plant utilization. Key points covered include an overview of the sugar factory's two water tube boilers that generate steam from bagasse, a single turbine unit powered by superheated steam, and utilization of exhausted steam for concentration and crystallization processes. Students observed testing and operating protocols of equipment and recorded technical details explained by plant operators.

Original Description:

ghh

Original Title

33452597-Sugar-Mill

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes an industrial visit by mechanical engineering students to Kadva Cooperative Sugar Factory on March 29, 2017. The objectives of the visit were to give students practical insight into boiler equipment and accessories and study the overall plant layout and co-generation plant utilization. Key points covered include an overview of the sugar factory's two water tube boilers that generate steam from bagasse, a single turbine unit powered by superheated steam, and utilization of exhausted steam for concentration and crystallization processes. Students observed testing and operating protocols of equipment and recorded technical details explained by plant operators.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

45 views2 pagesSugar Mill

Sugar Mill

Uploaded by

Omprakash UppaladinniThe document summarizes an industrial visit by mechanical engineering students to Kadva Cooperative Sugar Factory on March 29, 2017. The objectives of the visit were to give students practical insight into boiler equipment and accessories and study the overall plant layout and co-generation plant utilization. Key points covered include an overview of the sugar factory's two water tube boilers that generate steam from bagasse, a single turbine unit powered by superheated steam, and utilization of exhausted steam for concentration and crystallization processes. Students observed testing and operating protocols of equipment and recorded technical details explained by plant operators.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

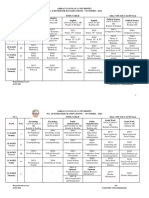

Sandip Foundation's

Sandip Institute of Technology & Research Centre, Nashik

Department of Mechanical Engineering

Academic Year 2016-17

Report on Visit to Kadva Cooperative Sugar Factory

1. Name of Event: Industrial Visit to Kadava Cooperative Sugar Factory

2. Date of Workshop: 29th March 2017

3. Event Conduction Duration : 11.00am to 04.30pm

4. Event Venue: Kadava Cooperative Sugar Factory.

5. Number of Participants: All students of B.E.(Mechanical)

6. Event Resource Person Details :

Mr. D.P. Patil, Shift Engineer, Kadva Sugar Factory,Materiwadi

7. Name of Event Coordinator : Prof. P.D. Badgujar, Prof. S.V. Kasar

8. Event Objective & Outcome:

Objective of Workshop:

1. To give practical insight of boiler equipment and accessories

2. To study overall plant layout and co generation plant utilization

Outcomes of Workshop:

1. Students understood location wise installation of equipment and overall plant layout

2. Prior testing, operating protocols were appreciated.

Description of Event:-

Final year students of Mechanical Engineering are studying a course on Power Plant

Engineering. The course is framed to enable graduating students to take up the challenges in

power engineering such as design equipment, processes and whole system. In this endeavor, a

visit to study thermal power plant with co generation unit was planned as per curriculum.

Kadva sugar mill plant visited has been installed by Walchand Industries,Sangli and

periodically upgraded with technological advancements. It was shut down for maintenance

work after closure of their crushing season of this year. This also helped to show the interior

parts of some leading equipment such as furnaces, boiler tubes, co generation system etc. It

comprises two water tube boiler units operating at 21 bar with yield of 20 ton of steam

generation per hour. Each boiler is supported by two furnaces which consume bagasse which is

a refused material after crushing sugarcane. Furnaces are provided with hot air passing over

preheaters creating forced draft. The steam generated being wet is superheated while passing

through superheaters tubes. Then superheated steam expands across single turbine unit to 6

bar. The exhausted steam is supplied for sugarcane juice concentration as a part of process

heating. Also, it is used in crystallizers. Also, as a measure of efficiency improvement,

economisers are installed in the flow path of flue gases leaving the furnaces.

All the students were given illustrations regarding testing and operating protocols. Students

observed and recorded technical details shown by operators of respective sections.

Event photos :

Students and staff at Main Gate of Kadva Sugar Factory

Operator showing Turbine unit to the students

You might also like

- Universal Parallel Accounting: Scope Information: SymptomDocument29 pagesUniversal Parallel Accounting: Scope Information: Symptomdgz5qm8kcwNo ratings yet

- DESIGN of Sodium Carbonate PRODUCTION PLANT (Comprehensive Design Project)Document149 pagesDESIGN of Sodium Carbonate PRODUCTION PLANT (Comprehensive Design Project)Mir Hasib Ul Latif100% (13)

- Earth (Tell Me Why #116)Document98 pagesEarth (Tell Me Why #116)Minute Mali86% (7)

- Process Engineer-M UsmanDocument3 pagesProcess Engineer-M UsmanUsɱâñ MåâñNo ratings yet

- Regadi NAGRAJ, Diploma in Mechanical Engineering, 39-1-16, Sector-1, Muralinagar, Visakhapatnam - 530007, AndhraDocument5 pagesRegadi NAGRAJ, Diploma in Mechanical Engineering, 39-1-16, Sector-1, Muralinagar, Visakhapatnam - 530007, AndhraRaj PalatiNo ratings yet

- Industrial Report 2014Document9 pagesIndustrial Report 2014Er Mahesh KhairnarNo ratings yet

- Saransh Chemical Engineer ResumeDocument3 pagesSaransh Chemical Engineer ResumeprashantsahNo ratings yet

- Case Study of A Condemned Boiler & Methods To Re-Establish ItDocument44 pagesCase Study of A Condemned Boiler & Methods To Re-Establish Its sivaNo ratings yet

- Aman Kumar Singh: Career SummaryDocument4 pagesAman Kumar Singh: Career SummaryKaran SinghNo ratings yet

- Anantrao Pawar College of Engineering & Research, Parvati, PuneDocument3 pagesAnantrao Pawar College of Engineering & Research, Parvati, PuneHarishPatilNo ratings yet

- Energy Integration in Sponge Iron Plant Using Heat of Waste GasDocument55 pagesEnergy Integration in Sponge Iron Plant Using Heat of Waste GasAsim Kumar SahuNo ratings yet

- Industrial Boiler Project Final ReportDocument34 pagesIndustrial Boiler Project Final Reportvanshita7020No ratings yet

- Junaid Resume 1Document2 pagesJunaid Resume 1Arif AliNo ratings yet

- CV - Denny Firmansyah - Epc O&gDocument5 pagesCV - Denny Firmansyah - Epc O&gDenny FirmansyahNo ratings yet

- Final Internship SeminarDocument17 pagesFinal Internship SeminarPrajwal Uttur100% (2)

- Jasbir Singh Presentation For Indonesian Sugar IndustryDocument36 pagesJasbir Singh Presentation For Indonesian Sugar IndustryraviNo ratings yet

- Resume Someswara Prasad K.MDocument3 pagesResume Someswara Prasad K.MkalyangudluruNo ratings yet

- Internship Notice1Document29 pagesInternship Notice1Saura Shuvra KumarNo ratings yet

- Case Study of A Condemned Boiler & Methods To Re-Establish ItDocument43 pagesCase Study of A Condemned Boiler & Methods To Re-Establish Its sivaNo ratings yet

- Shahzeb Hassan: Career ObjectiveDocument2 pagesShahzeb Hassan: Career ObjectiveomairNo ratings yet

- P S Kulkarni Report On VIPL Visit by SYEDDocument5 pagesP S Kulkarni Report On VIPL Visit by SYEDSanjana SinghaniyaNo ratings yet

- AMIE ProjectDocument37 pagesAMIE ProjectDev SwainNo ratings yet

- ResumeDocument9 pagesResumeAVES HUSAINYNo ratings yet

- Pawana DamDocument3 pagesPawana DamSweet Era100% (1)

- Avijit Shaw M Tech Dairy Engineer Resume 2012Document5 pagesAvijit Shaw M Tech Dairy Engineer Resume 2012Avijit Shaw100% (1)

- Muhammad Mursalin - Curriculum VitaeDocument2 pagesMuhammad Mursalin - Curriculum VitaeEngr BalajiNo ratings yet

- Heg Minor Training ReportDocument23 pagesHeg Minor Training ReportSourabh SenNo ratings yet

- M.SC Sugar Tech SyllabusDocument39 pagesM.SC Sugar Tech SyllabusCandra AvengerzNo ratings yet

- Ramunaik Resume 2023Document5 pagesRamunaik Resume 2023ramu naik malothNo ratings yet

- Report On "Industrial Visit To Thermal Power Station: L.D. College of Engineering, AhmedabadDocument5 pagesReport On "Industrial Visit To Thermal Power Station: L.D. College of Engineering, AhmedabadPallavi PophaleNo ratings yet

- Engr Awais AliDocument5 pagesEngr Awais Aliawaiszulfiqar050No ratings yet

- PROCESS ENGINEER CV (06 Years Experience) .Document3 pagesPROCESS ENGINEER CV (06 Years Experience) .Shoaib JadoonNo ratings yet

- Performance Analysis of A Pebble Bed Air Heater Using CFD TechniqueDocument64 pagesPerformance Analysis of A Pebble Bed Air Heater Using CFD TechniquevenkatesananushatkuNo ratings yet

- Design Project OfferedDocument8 pagesDesign Project OfferedMuhammadAliMughalNo ratings yet

- CV - Nainish Sahare Oil and GasDocument5 pagesCV - Nainish Sahare Oil and GasNitai DuraisamiNo ratings yet

- Internship Report 2022Document25 pagesInternship Report 2022trick masterNo ratings yet

- Andre Syahputra: (Jalan. Ngareng No. 1, Kec. Cepu, Kab. Blora, Jawa Tengah, Indonesia)Document1 pageAndre Syahputra: (Jalan. Ngareng No. 1, Kec. Cepu, Kab. Blora, Jawa Tengah, Indonesia)Andre SyahputraNo ratings yet

- Micro Project: Latthe Education Society's Polytechnic, SangliDocument26 pagesMicro Project: Latthe Education Society's Polytechnic, SangliAtharv SalunkheNo ratings yet

- Mukesh Makwana: Degree Year of Passing Board/University PercentageDocument5 pagesMukesh Makwana: Degree Year of Passing Board/University Percentagelecturer.parulNo ratings yet

- Shawket G. Ghedan, PHD: Highlight of Experience 1. Oil Industry ExperienceDocument7 pagesShawket G. Ghedan, PHD: Highlight of Experience 1. Oil Industry ExperiencetotongsNo ratings yet

- Bio Data - VK Misra NewDocument5 pagesBio Data - VK Misra NewRajneesh KatochNo ratings yet

- Report On Educational VisitDocument3 pagesReport On Educational VisitRaja HindustaniNo ratings yet

- All India Shri Shivaji Memorial Society's Polytechnic, Pune-01Document12 pagesAll India Shri Shivaji Memorial Society's Polytechnic, Pune-012031 Ayush KshirsagarNo ratings yet

- Muhammad Asyraf Afif - CV PDFDocument2 pagesMuhammad Asyraf Afif - CV PDFVinoth KumarNo ratings yet

- Gujarat Technological University: Project Report ON Scope of Utility Reduction in Chemical IndustryDocument24 pagesGujarat Technological University: Project Report ON Scope of Utility Reduction in Chemical IndustryPradeep SutharNo ratings yet

- EPG Report - Lets Print It PDFDocument17 pagesEPG Report - Lets Print It PDFhrishikesh barveNo ratings yet

- Pradnya - Design Engineer - 4 Years - ImmediateDocument2 pagesPradnya - Design Engineer - 4 Years - ImmediatebharathlalamNo ratings yet

- A Study On Labour UnrestDocument169 pagesA Study On Labour UnrestShanmuka SreenivasNo ratings yet

- Tayyab CVDocument1 pageTayyab CVTayyab AttariNo ratings yet

- P Rama Krishna: SummaryDocument5 pagesP Rama Krishna: SummaryKrishna RamaNo ratings yet

- UntitledDocument12 pagesUntitledBetiNo ratings yet

- Fyp Booklet 2015Document48 pagesFyp Booklet 2015Anonymous ohCM2ktv100% (1)

- Gas Industy Training ReportDocument23 pagesGas Industy Training ReportshivangNo ratings yet

- PPE Microproject 3504Document10 pagesPPE Microproject 3504SohamNo ratings yet

- Industrial Training - Report BookDocument19 pagesIndustrial Training - Report BookJason KNo ratings yet

- Ajay Sheth Vadodara 27 (1) (1) .00 YrsDocument3 pagesAjay Sheth Vadodara 27 (1) (1) .00 YrsmeenuNo ratings yet

- Amarjeet KumarDocument3 pagesAmarjeet Kumaramarjeet kumarNo ratings yet

- Internship Poster - TemplateDocument1 pageInternship Poster - TemplateGoutham ReddyNo ratings yet

- Daud CV PersonnelDocument4 pagesDaud CV Personneldaud.exptb100% (1)

- Adnan MumtazDocument3 pagesAdnan Mumtazadnan samiNo ratings yet

- GSFC Energy EfficiencyDocument28 pagesGSFC Energy EfficiencyRajeshkumar ElangoNo ratings yet

- FCI Category 3 Recruitment 2022 Notification Emp News 2 1Document11 pagesFCI Category 3 Recruitment 2022 Notification Emp News 2 1Omprakash UppaladinniNo ratings yet

- Surge Absorbers Are Used For Protection Against 5eb3bfdff60d5d3027dce60aDocument2 pagesSurge Absorbers Are Used For Protection Against 5eb3bfdff60d5d3027dce60aOmprakash UppaladinniNo ratings yet

- Detailed Advt AOT 2022 CLAT DTD 9th May 2022Document7 pagesDetailed Advt AOT 2022 CLAT DTD 9th May 2022Omprakash UppaladinniNo ratings yet

- Sugar Factory ReportDocument2 pagesSugar Factory ReportOmprakash UppaladinniNo ratings yet

- Busbar Design GuideDocument22 pagesBusbar Design Guidejohnwu_2009100% (6)

- SQL Essentials PDFDocument36 pagesSQL Essentials PDFMadalina GrigoroiuNo ratings yet

- Some Properties of The Lozinskii Logarithmic Norm: Ordinary Differential EquationsDocument10 pagesSome Properties of The Lozinskii Logarithmic Norm: Ordinary Differential EquationsCavia PorcellusNo ratings yet

- Ethics Report GRP 3Document3 pagesEthics Report GRP 3MikaNo ratings yet

- MSM Tech List 125mm TapnaDocument2 pagesMSM Tech List 125mm TapnaThanosaekk P.No ratings yet

- Laboratory: Building Transportation System ObjectivesDocument3 pagesLaboratory: Building Transportation System ObjectivesyunhogNo ratings yet

- Grade 1: Random Variable and Probability DistributionDocument13 pagesGrade 1: Random Variable and Probability DistributionMarie RamosNo ratings yet

- MORRIS, CRAIG (1974) - Reconstructing Patterns of Non-Agricultural Production in The Inca Economy. Archaeology and Documents in Institutional Analysis PDFDocument21 pagesMORRIS, CRAIG (1974) - Reconstructing Patterns of Non-Agricultural Production in The Inca Economy. Archaeology and Documents in Institutional Analysis PDFTrejaucasNo ratings yet

- International Economics 4th Edition Feenstra Test Bank 1Document48 pagesInternational Economics 4th Edition Feenstra Test Bank 1steven100% (42)

- Ancon 25-14 Restraint SystemDocument2 pagesAncon 25-14 Restraint SystemabudabeejajaNo ratings yet

- Flight Attendant Cover Letter ExampleDocument4 pagesFlight Attendant Cover Letter Examplef6a5mww867% (3)

- Lab Report 3 Solubility SaponificationDocument9 pagesLab Report 3 Solubility SaponificationJeric Miguel Raquel TabionNo ratings yet

- Consumer Behaviour On MicromaxDocument28 pagesConsumer Behaviour On Micromaxpiku06051992100% (2)

- ECONOMIZERDocument17 pagesECONOMIZERTrần Văn Trọng 7350No ratings yet

- Research Paper On FmeaDocument8 pagesResearch Paper On Fmeahyz0tiwezif3100% (3)

- A Survey On Nongeostationary Satellite Systems The Communication PerspectiveDocument32 pagesA Survey On Nongeostationary Satellite Systems The Communication PerspectiveSwattic GhoseNo ratings yet

- Mosd 10page PDFDocument15 pagesMosd 10page PDFOriginalo Versiona100% (3)

- 100 AutoCAD Commands You Should KnowDocument37 pages100 AutoCAD Commands You Should KnowAnonymous TxYttIqsPNo ratings yet

- Kurt Lewin and KohlbergDocument4 pagesKurt Lewin and KohlbergSarah Dela RosaNo ratings yet

- Ya 8800 10-14reDocument44 pagesYa 8800 10-14remartin_jaitmanNo ratings yet

- specSPCT00rev01 PDFDocument10 pagesspecSPCT00rev01 PDFharsh_1582No ratings yet

- Priya Cement Raw MixDocument6 pagesPriya Cement Raw MixJCS100% (1)

- Console Output CLI ConsoleDocument7 pagesConsole Output CLI Consolejaved.rafik.1No ratings yet

- 2023 01 Earth CoreDocument5 pages2023 01 Earth CoreNico Vercellino KrauseNo ratings yet

- Bayloc Style Dry Disconnect - 2016Document8 pagesBayloc Style Dry Disconnect - 2016Eduardo Luna MaggiNo ratings yet

- Elective Chapter 1 and 2Document5 pagesElective Chapter 1 and 2Edward James TablazonNo ratings yet

- Many Teachers Assign Homework To Students Every Day EssayDocument4 pagesMany Teachers Assign Homework To Students Every Day Essaycfgdxfs8100% (1)

- PG II Semester Time Table 26-09-2022Document10 pagesPG II Semester Time Table 26-09-2022tirumala ReddyNo ratings yet