Professional Documents

Culture Documents

Lesson Plan Subject Name-Theory of Metal Forming Branch - Production Engineering Subject Code - BPE 2603 Semester - 6

Lesson Plan Subject Name-Theory of Metal Forming Branch - Production Engineering Subject Code - BPE 2603 Semester - 6

Uploaded by

Raja RamachandranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lesson Plan Subject Name-Theory of Metal Forming Branch - Production Engineering Subject Code - BPE 2603 Semester - 6

Lesson Plan Subject Name-Theory of Metal Forming Branch - Production Engineering Subject Code - BPE 2603 Semester - 6

Uploaded by

Raja RamachandranCopyright:

Available Formats

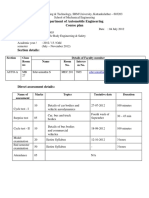

LESSON PLAN

Subject Name- Theory of Metal Forming Branch- Production Engineering

Subject Code- BPE 2603 Semester- 6th

Period/

S/N Module Topic(s)

Hours

1 I Review of 2-D stress and strain 1

2 I State of stress in 3-D,Stress tensor, Invariants 2-3

Mohr’s circle for 3-D State of Stress, Strain at a point-Mohr’s

3 I 4-5

circle for strain

4 I Hydrostatic & Deviatory components of Stress 6

5 I Elastic stress-strain relations 7

6 I Tutorial 8

Elements of theory of plasticity: Flow curve, True stress & true

7 II strain, Yield criteria for ductile metal,Von Misses & Tresca 9-12

yield criteria, Combined stress tests

8 II The yield locus, Anisotropy in yielding, Yield surface 13-14

9 II Levy-Misses,Prandtl-Reuss Stress-Strain relation 15-16

Classification of forming processes variables in metal forming

10 II 17

and their optimization

11 II Tutorial 18

Analysis of deformation processes-Method based on

12 III 19-20

homogeneous compression slip line field theory

13 III Upper bounds & lower bounds 21

14 III Slab method analysis 22-23

15 III Tutorial 24

16 III Flow stress determination 25

Period/

S/N Module Topic(s)

Hours

17 III Hot working, Cold working, Strain rate effect 26

18 III Friction and lubrication, Deformation zone geometry, 27-28

19 III Workability, Residual stress. 29

20 III Tutorial 30

Analysis of metal forming processes, Forging: Load calculation

21 IV 31

in plane strain forging

Rolling: Forces & geometrical relationship in rolling, Rolling

22 IV 32-33

load and torque in cold rolling,

23 IV Von-Karman work equation 34-35

25 IV Tutorial 36

24 IV Extrusion: Analysis of extrusion process, extrusion pressure 37

25 IV Drawing: Drawing load 38-39

26 IV Tutorial 40

You might also like

- Mechanics of Structures Vol I by DR H J Shah JunarkarDocument4 pagesMechanics of Structures Vol I by DR H J Shah JunarkarRaj Rathva27% (11)

- Ebook. Fluid Mechanics by Yunus A. Cengel, John M. CimbalaDocument5 pagesEbook. Fluid Mechanics by Yunus A. Cengel, John M. CimbalaKiki DhanieNo ratings yet

- Refrigeration & Air Conditioning - Stoecker & JonesDocument440 pagesRefrigeration & Air Conditioning - Stoecker & JonesJherson Gravides100% (1)

- Cambridge International As and A Level Physics Revision GuideDocument40 pagesCambridge International As and A Level Physics Revision GuideR Mathew50% (8)

- Schaum's Outline of College Mathematics, Fourth EditionFrom EverandSchaum's Outline of College Mathematics, Fourth EditionRating: 4 out of 5 stars4/5 (6)

- Evaluation For VesselDocument10 pagesEvaluation For VesselEngineering ESIINo ratings yet

- Lesson Plan Subject Name-Strength of Materials Branch - Production Engineering Subject Code - BPE2401 Semester - 4Document2 pagesLesson Plan Subject Name-Strength of Materials Branch - Production Engineering Subject Code - BPE2401 Semester - 4Raja RamachandranNo ratings yet

- Lesson Plan Subject Name-Theory Metal Cutting Branch - Production Engineering Subject Code - BPE 2504 Semester - 5Document2 pagesLesson Plan Subject Name-Theory Metal Cutting Branch - Production Engineering Subject Code - BPE 2504 Semester - 5Raja RamachandranNo ratings yet

- Metal Forming PDFDocument89 pagesMetal Forming PDFNikhil KanojiNo ratings yet

- Lesson Plan Subject Name-Advanced Casting and Welding Branch - Production Engineering Subject Code - BPE 2605 Semester - 8Document2 pagesLesson Plan Subject Name-Advanced Casting and Welding Branch - Production Engineering Subject Code - BPE 2605 Semester - 8Raja RamachandranNo ratings yet

- Mechanics of Materials Theory - KesavarajDocument13 pagesMechanics of Materials Theory - KesavarajkumareshNo ratings yet

- 4403 Course Outline 2017 Without ColourDocument3 pages4403 Course Outline 2017 Without ColourirqoviNo ratings yet

- Stresses and Strains:-: Lesson PlanDocument2 pagesStresses and Strains:-: Lesson PlanksrsunilNo ratings yet

- Lesson 1641562246Document2 pagesLesson 1641562246Jhon Tron HansdaNo ratings yet

- Shigleys Mechanical Engineering Design PDFDocument6 pagesShigleys Mechanical Engineering Design PDFPhemi258040% (5)

- CE6302 Mechanics of Solids 11Document75 pagesCE6302 Mechanics of Solids 11Meenu ChoudharyNo ratings yet

- Lesson Plan Subject Name-Basic Manufacturing Process Branch - Production Engineering Subject Code - BPE2301 Semester - 3Document2 pagesLesson Plan Subject Name-Basic Manufacturing Process Branch - Production Engineering Subject Code - BPE2301 Semester - 3Raja RamachandranNo ratings yet

- Video PDFDocument2 pagesVideo PDFRaja RamachandranNo ratings yet

- ENGINEERING DESIGN GUIDELINES Instrumentation Sizing and Selection Rev Web PDFDocument23 pagesENGINEERING DESIGN GUIDELINES Instrumentation Sizing and Selection Rev Web PDFEslam ShiblNo ratings yet

- Refrigeration & Air Conditioning by W.F. Stoecker & J.W JhonesDocument440 pagesRefrigeration & Air Conditioning by W.F. Stoecker & J.W JhonesJuniel CalixtroNo ratings yet

- Stress Distribution in A Curved Plate Girder Bridge: Fritz EngineeringDocument62 pagesStress Distribution in A Curved Plate Girder Bridge: Fritz EngineeringEngr Zin Myo MinNo ratings yet

- Refrigeration & Air Conditioning by W.F. Stoecker & J.W Jhones-1-2Document2 pagesRefrigeration & Air Conditioning by W.F. Stoecker & J.W Jhones-1-2rayzjrNo ratings yet

- Ada 306263Document48 pagesAda 306263Mohamed WeyimiNo ratings yet

- Stoecker Jones - Refrigeration Air Conditioning 2nd Ed PDFDocument440 pagesStoecker Jones - Refrigeration Air Conditioning 2nd Ed PDFpascky100% (1)

- CG634EXPL01Document24 pagesCG634EXPL01CHANDAN GOWDA B NNo ratings yet

- Stoecker Jones - Refrigeration Air Conditioning 2nd Ed McGraw HillDocument440 pagesStoecker Jones - Refrigeration Air Conditioning 2nd Ed McGraw HillJavier Mazo100% (1)

- Class Viii Syllabus All SubjectDocument4 pagesClass Viii Syllabus All SubjectAyush Soni 7:- परिश्रम 3678No ratings yet

- Lesson Plan: Veer Surendra Sai University of TechnologyDocument2 pagesLesson Plan: Veer Surendra Sai University of Technologysanthi saranyaNo ratings yet

- Deformations and Velocities During The Cold RollinDocument10 pagesDeformations and Velocities During The Cold Rollinnisha.pipesandtubesNo ratings yet

- 04 ContentDocument2 pages04 ContentDeepu 5697No ratings yet

- Fem Lesson Plan: Unit No Less On No No of Periods Topic DescriptionDocument3 pagesFem Lesson Plan: Unit No Less On No No of Periods Topic DescriptionGopinath GangadhariNo ratings yet

- Tensionr Egulatioinn A Metalr Ollingm IllDocument74 pagesTensionr Egulatioinn A Metalr Ollingm IllJorge HadechineNo ratings yet

- Syllbus 2Document1 pageSyllbus 2pradeeNo ratings yet

- Mechanics of Materials 71E44Document3 pagesMechanics of Materials 71E44OblackNo ratings yet

- Adsec8.4 TheoryDocument62 pagesAdsec8.4 TheorypajipitarNo ratings yet

- Principles: StructuralDocument9 pagesPrinciples: StructuralLindita BakiuNo ratings yet

- A Perspective On Residual Stresses in Welding-A. de and T. DebRoy-2011Document5 pagesA Perspective On Residual Stresses in Welding-A. de and T. DebRoy-2011Angelo GontijoNo ratings yet

- Konstruiranje 1 500 11 20Document10 pagesKonstruiranje 1 500 11 20dikembergmutombowskiNo ratings yet

- LessonPlan New TheoryDocument7 pagesLessonPlan New TheoryelarajaNo ratings yet

- Phy Sr-Chaina PDFDocument5 pagesPhy Sr-Chaina PDFGNT N40No ratings yet

- Lesson Plan: Einstein Academy of Technology and ManagementDocument4 pagesLesson Plan: Einstein Academy of Technology and ManagementJITENDRA BISWALNo ratings yet

- Clamp FEM AnalysisDocument27 pagesClamp FEM AnalysisRicardo Paz SoldanNo ratings yet

- Sarojini Institute of Technology: Lesson PlanDocument3 pagesSarojini Institute of Technology: Lesson PlansatyavanapalliNo ratings yet

- J.K.K.Munirajah College of Technology: Lesson Plan Faculty Name: S.KarthikeyanDocument5 pagesJ.K.K.Munirajah College of Technology: Lesson Plan Faculty Name: S.KarthikeyanKARTHIKEYAN SNo ratings yet

- Sloane John H19650Document77 pagesSloane John H19650Ryan RafaelNo ratings yet

- CE - G552 - 526 Adv STR Mech and StabilityDocument4 pagesCE - G552 - 526 Adv STR Mech and StabilityAdithya SKNo ratings yet

- (R18A0383) Strength of Materials LabDocument55 pages(R18A0383) Strength of Materials LabJacks Test MailNo ratings yet

- Engineering Standards: Transredes Guidelines For Lowering Pipelines While in ServiceDocument25 pagesEngineering Standards: Transredes Guidelines For Lowering Pipelines While in ServiceMarvin Guerrero PadillaNo ratings yet

- X Maths Study Material 2023-24Document235 pagesX Maths Study Material 2023-24n88478802100% (1)

- R. Nachoul - Flatness Defect in Thin Strip Cold Rolling and The Friction Impact On ItDocument11 pagesR. Nachoul - Flatness Defect in Thin Strip Cold Rolling and The Friction Impact On ItMochamad Kamal IhsanNo ratings yet

- Jntuk M Tech r16 Se SyllabusDocument26 pagesJntuk M Tech r16 Se SyllabusbhargavkakaniNo ratings yet

- Me Gate 2024Document2 pagesMe Gate 2024ME 09 Aditya Singh ChauhanNo ratings yet

- Lesson Plan Subject Name-Theory of Machine Branch - Production Engineering Subject Code - BPE2402 Semester - 4Document2 pagesLesson Plan Subject Name-Theory of Machine Branch - Production Engineering Subject Code - BPE2402 Semester - 4Raja RamachandranNo ratings yet

- Detail Syllabus For Static Equipment DesignDocument9 pagesDetail Syllabus For Static Equipment DesignGuru KguruNo ratings yet

- III-B.Sc MathematicsDocument15 pagesIII-B.Sc MathematicsGanesh ENo ratings yet

- Flatness Defect in Cold RollingDocument11 pagesFlatness Defect in Cold RollingEwo50 NewNo ratings yet

- Steady Flow Analysis of Pipe Networks - An Instructional ManualDocument85 pagesSteady Flow Analysis of Pipe Networks - An Instructional Manualjeff_shaw100% (1)

- MODULE 12 Mechanical Testing of WeldsDocument66 pagesMODULE 12 Mechanical Testing of WeldsIkeNo ratings yet

- Understanding Lightning and Lightning Protection: A Multimedia Teaching GuideFrom EverandUnderstanding Lightning and Lightning Protection: A Multimedia Teaching GuideNo ratings yet

- Thermodynamics - SunilDocument5 pagesThermodynamics - SunilRaja RamachandranNo ratings yet

- Vehicle Body EnggDocument6 pagesVehicle Body EnggRaja RamachandranNo ratings yet

- Lesson Plan-CE1016 - Structural Design - Steel Academic Year 2015-16 (Semester Commencing in June 2015)Document3 pagesLesson Plan-CE1016 - Structural Design - Steel Academic Year 2015-16 (Semester Commencing in June 2015)Raja RamachandranNo ratings yet

- Theory of Automotive EnginesDocument7 pagesTheory of Automotive EnginesRaja RamachandranNo ratings yet

- Department of Automobile Engineering Course PlanDocument4 pagesDepartment of Automobile Engineering Course PlanRaja RamachandranNo ratings yet

- Non Traditional Machining TechniquesDocument4 pagesNon Traditional Machining TechniquesRaja RamachandranNo ratings yet

- CE1205 Lesson PlanDocument2 pagesCE1205 Lesson PlanRaja RamachandranNo ratings yet

- CE1008 Lesson PlanDocument3 pagesCE1008 Lesson PlanRaja RamachandranNo ratings yet

- Sources and Types of Municipal Solid WastesDocument2 pagesSources and Types of Municipal Solid WastesRaja RamachandranNo ratings yet

- CE1008 Lesson PlanDocument3 pagesCE1008 Lesson PlanRaja RamachandranNo ratings yet

- CE1006 Lesson PlanDocument2 pagesCE1006 Lesson PlanRaja RamachandranNo ratings yet

- CE1006 Lesson PlanDocument2 pagesCE1006 Lesson PlanRaja RamachandranNo ratings yet

- Faculty Name: Sucheta Panda: Total Number of Hours 48Document1 pageFaculty Name: Sucheta Panda: Total Number of Hours 48Raja RamachandranNo ratings yet

- Lesson Plan Subject Name-Automation & Numerical Control Machines Branch-Production Engineering Subject Code - BPE 2701 Semester - 7Document2 pagesLesson Plan Subject Name-Automation & Numerical Control Machines Branch-Production Engineering Subject Code - BPE 2701 Semester - 7Raja RamachandranNo ratings yet

- Video 9Document1 pageVideo 9Raja RamachandranNo ratings yet

- Veer Surendra Sai University of Technology, Burla Department of Metallurgy& Materials Engineering Lecture Plan-Transport PhenomenaDocument3 pagesVeer Surendra Sai University of Technology, Burla Department of Metallurgy& Materials Engineering Lecture Plan-Transport PhenomenaRaja RamachandranNo ratings yet

- Video PDFDocument2 pagesVideo PDFRaja RamachandranNo ratings yet

- Video 8Document2 pagesVideo 8Raja RamachandranNo ratings yet

- Lesson Plan Subject Name-Robotics and Flexible Manufacturing Systems Branch-Production Engineering Subject Code-BPE 2802 Semester - 8Document2 pagesLesson Plan Subject Name-Robotics and Flexible Manufacturing Systems Branch-Production Engineering Subject Code-BPE 2802 Semester - 8Raja RamachandranNo ratings yet

- Veer Surendra Sai University of Technology, Burla Department of Metallurgy& Materials Engineering Lecture Plan-PT&HTDocument4 pagesVeer Surendra Sai University of Technology, Burla Department of Metallurgy& Materials Engineering Lecture Plan-PT&HTRaja RamachandranNo ratings yet

- Lesson Plan: Veer Surendra Sai University of TechnologyDocument4 pagesLesson Plan: Veer Surendra Sai University of TechnologyRaja RamachandranNo ratings yet

- Lesson Plan Subject Name-Advanced Casting and Welding Branch - Production Engineering Subject Code - BPE 2605 Semester - 8Document2 pagesLesson Plan Subject Name-Advanced Casting and Welding Branch - Production Engineering Subject Code - BPE 2605 Semester - 8Raja RamachandranNo ratings yet

- MCQ 1to 10 VIPDocument17 pagesMCQ 1to 10 VIPBishal Roy SarkarNo ratings yet

- CE 382 Structural Analysis Handout NotesDocument154 pagesCE 382 Structural Analysis Handout NotesBenjamin Benicarlo Juanillo IIINo ratings yet

- Thesis WangDocument15 pagesThesis WangDasheng WangNo ratings yet

- Static and Dynamic Properties of Leighton Buzzard Sand From Labor PDFDocument7 pagesStatic and Dynamic Properties of Leighton Buzzard Sand From Labor PDFJohnny SmithNo ratings yet

- Schott-Tubing Brochure Technical-Glasses EnglishDocument44 pagesSchott-Tubing Brochure Technical-Glasses Englishpsychedelic_lullaby100% (1)

- A Comparative Study and Stiffness Analysis of Angular Contact Ball Bearings Under Different Preload MechanismsDocument17 pagesA Comparative Study and Stiffness Analysis of Angular Contact Ball Bearings Under Different Preload MechanismskhelifiNo ratings yet

- CDP For Shear WallsDocument19 pagesCDP For Shear WallsLaxmith ShettyNo ratings yet

- CANDE-2019 User ManualDocument330 pagesCANDE-2019 User ManualTemesgen M. MandersoNo ratings yet

- Lecture10 Combined FootingsDocument31 pagesLecture10 Combined FootingsGopalram Sudhirkumar100% (3)

- Prob SETDocument2 pagesProb SETFlorence AgsaludNo ratings yet

- t34 09 PDFDocument16 pagest34 09 PDFdevdownNo ratings yet

- Cracking in BeamsDocument21 pagesCracking in BeamsimranNo ratings yet

- Cengr 520 - Steel Design & Cengr3220 - Timber & Steel Design - 03192021 - 1Document9 pagesCengr 520 - Steel Design & Cengr3220 - Timber & Steel Design - 03192021 - 1Benjamin EngelNo ratings yet

- EDOC-Technology & Testing of Interphase SpacersDocument27 pagesEDOC-Technology & Testing of Interphase SpacersEl Comedor BenedictNo ratings yet

- Thin CylindersDocument6 pagesThin CylindersEdwinNo ratings yet

- Brick-Mortar Interaction in Masonry Under Compression: Citation For Published Version (APA)Document237 pagesBrick-Mortar Interaction in Masonry Under Compression: Citation For Published Version (APA)dsvdfbgNo ratings yet

- TP 2005 212505 - ERRATAAug2011Document191 pagesTP 2005 212505 - ERRATAAug2011TeodoraNo ratings yet

- 4 - Bending of PlatesDocument14 pages4 - Bending of PlatesTushar Vinay MehtaNo ratings yet

- Rock MechanicsDocument33 pagesRock MechanicsErnesto Oporto VergaraNo ratings yet

- Cement and Concrete CompositesDocument18 pagesCement and Concrete CompositesKrishna MurariNo ratings yet

- Mechanical Engineering Paper DDocument16 pagesMechanical Engineering Paper DAbhilash G NairNo ratings yet

- Structural Analysis by Minimum Strain Energy Methods PDFDocument70 pagesStructural Analysis by Minimum Strain Energy Methods PDFSanjay TiwariNo ratings yet

- Aircraft Code Bolt2023r01Document14 pagesAircraft Code Bolt2023r01Dinesh GanapathyNo ratings yet

- SY BTech Mech 1 JulyDocument32 pagesSY BTech Mech 1 JulyVishwajeet PatilNo ratings yet

- Characterization of Anisotropic Polymeric FoamDocument9 pagesCharacterization of Anisotropic Polymeric FoamWilliam Pinto HernándezNo ratings yet

- Effect of Dental Implant Parameters On Stress Distribution at Bone-Implant InterfaceDocument4 pagesEffect of Dental Implant Parameters On Stress Distribution at Bone-Implant InterfaceIjsrnet EditorialNo ratings yet

- Chapter1 - SunumDocument52 pagesChapter1 - SunumAlper AslanNo ratings yet

- ISRM-EUROCK-2010-012 - Determination of Direct Tensile Strength and Stiffness of Intact RocksDocument4 pagesISRM-EUROCK-2010-012 - Determination of Direct Tensile Strength and Stiffness of Intact Rocksamy75No ratings yet

- Fatigue Strength Determination of Ship Structural JointsDocument9 pagesFatigue Strength Determination of Ship Structural JointsDele TedNo ratings yet