Professional Documents

Culture Documents

RTJ PDF

RTJ PDF

Uploaded by

Emiliano ZappaterraCopyright:

Available Formats

You might also like

- Session # 7 - Sociogram As A Diagnositic ToolDocument18 pagesSession # 7 - Sociogram As A Diagnositic ToolSHWETA SINGHAL PGPHRM 2021-23 Batch0% (1)

- Keystone Butterfly Valve F 631Document4 pagesKeystone Butterfly Valve F 631Robi KeiNo ratings yet

- Ecoline Est 150-600Document21 pagesEcoline Est 150-600Yosses Sang NahkodaNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Calc Bend Radii Tensile Elong DataDocument7 pagesCalc Bend Radii Tensile Elong Dataritesh_4luv7679No ratings yet

- Dynamic Response of Fixed Offshore Structures Under Environmental LoadsDocument16 pagesDynamic Response of Fixed Offshore Structures Under Environmental LoadsxautraixxxxxxNo ratings yet

- Jsa R B 6 ForkliftDocument3 pagesJsa R B 6 ForkliftsinghajitbNo ratings yet

- InstrManual SCO1-1Document29 pagesInstrManual SCO1-1Juan Felipe AlvarezNo ratings yet

- 06-076-080 Ring Joints RTJDocument5 pages06-076-080 Ring Joints RTJmohamedNo ratings yet

- Ring Joint RTJDocument6 pagesRing Joint RTJzulikram100% (1)

- CC231 - Velan-F0114c - CutsheetDocument4 pagesCC231 - Velan-F0114c - Cutsheetjacquesstrappe06No ratings yet

- Globe Valves - ASME Class 900 & 1500: Flanged EndDocument1 pageGlobe Valves - ASME Class 900 & 1500: Flanged EndMunishTrichyNo ratings yet

- 113 115 Lens GasketsDocument3 pages113 115 Lens GasketsAiZeCK IvanovNo ratings yet

- Diaphragm ValveDocument2 pagesDiaphragm ValveHardik ShahNo ratings yet

- Ficha Tecnica Anillos Oval RingDocument8 pagesFicha Tecnica Anillos Oval RingAndres AlfonsoNo ratings yet

- GB235 MetalsDocument12 pagesGB235 MetalsAhmet HamamcıoğluNo ratings yet

- Astm A 879-06Document3 pagesAstm A 879-06Bill100% (1)

- Flowbiz Cast Steel Nd40 Globe ValvesDocument2 pagesFlowbiz Cast Steel Nd40 Globe ValvesFlowBiz Exports Pvt. Ltd.No ratings yet

- Catalogue CNA 50Hz Rev.1 Update 6-1Document6 pagesCatalogue CNA 50Hz Rev.1 Update 6-1Rido MardanNo ratings yet

- Swing Check Valve 900 Class SpecDocument1 pageSwing Check Valve 900 Class SpecMunishTrichyNo ratings yet

- 21-36-002 Avkcms enDocument3 pages21-36-002 Avkcms enbrilian pungkyNo ratings yet

- Globe Valves Cast Steel Bolted Bonnet Flanged End Class 150, 300 & 600 2"-10"Document4 pagesGlobe Valves Cast Steel Bolted Bonnet Flanged End Class 150, 300 & 600 2"-10"dmitosNo ratings yet

- Gate Valve AvkDocument3 pagesGate Valve AvkIwan SetiawanNo ratings yet

- Ni Inco 4421 Weldingofflakeandspheroidalgraphiteni ResistcastingsDocument6 pagesNi Inco 4421 Weldingofflakeandspheroidalgraphiteni ResistcastingsLeandro Dilkin ConsulNo ratings yet

- Avk Gate Valve, Flanged, Bs STD, Pn25 21/60-004: BS 5163/EN558 Ser.3, Ductile Iron, Stainless Steel Stem, DN50-400Document2 pagesAvk Gate Valve, Flanged, Bs STD, Pn25 21/60-004: BS 5163/EN558 Ser.3, Ductile Iron, Stainless Steel Stem, DN50-400brilian pungkyNo ratings yet

- Tdi 50000 Tpy, GNFCDocument6 pagesTdi 50000 Tpy, GNFCkrunal panchalNo ratings yet

- Girth Flange Load Calculation Using by FEA TechniquesDocument12 pagesGirth Flange Load Calculation Using by FEA TechniqueskingstonNo ratings yet

- ARE 725 Cold-Formed Steel Design: Chapter B: ElementsDocument44 pagesARE 725 Cold-Formed Steel Design: Chapter B: ElementsTodd MaxeyNo ratings yet

- Hes A1002-01 Selection Reference of Steel Bolt MaterialsDocument5 pagesHes A1002-01 Selection Reference of Steel Bolt MaterialsPreetam KumarNo ratings yet

- Hilco Bronsil Aws A5.6 e Cusn-CDocument1 pageHilco Bronsil Aws A5.6 e Cusn-CVICENTE CABALLERONo ratings yet

- Technical Sheet BSA3TDocument4 pagesTechnical Sheet BSA3TMalik DaniyalNo ratings yet

- 16 StaticgasketsDocument10 pages16 StaticgasketsRobinReyndersNo ratings yet

- Material Cross Reference List 1Document3 pagesMaterial Cross Reference List 1vinothcdmNo ratings yet

- Sea Cort Jan Dix Seal Ring GasketsDocument5 pagesSea Cort Jan Dix Seal Ring GasketsmohamedNo ratings yet

- GL 125 150Document1 pageGL 125 150FABIONo ratings yet

- Copper and Copper Alloy Clad Steel Plate: Standard Specification ForDocument6 pagesCopper and Copper Alloy Clad Steel Plate: Standard Specification ForAdnan KhanNo ratings yet

- AVK - Gate Valve OS&Y UL - FM - OutdoorDocument2 pagesAVK - Gate Valve OS&Y UL - FM - OutdoorVINOD PAULNo ratings yet

- V1-2 Severe Service Metal Seated Ball ValvesDocument2 pagesV1-2 Severe Service Metal Seated Ball ValvesSergio Gana GonzalezNo ratings yet

- A. BALL - FloatingDocument3 pagesA. BALL - FloatingSaputraNo ratings yet

- Restriction Orifice T95500enDocument2 pagesRestriction Orifice T95500enCarlos SopasNo ratings yet

- Copperfil Cusi3: MIG-MAG Wires Nickel and Copper AlloysDocument1 pageCopperfil Cusi3: MIG-MAG Wires Nickel and Copper AlloyssatnamNo ratings yet

- 13 - Check ValvesDocument14 pages13 - Check ValvesSiles LimberdsNo ratings yet

- Cast Steel Globe Valve Class: Figure No. Gl1Rcb8 Gl1Bcb8 Gl1Jcb8Document4 pagesCast Steel Globe Valve Class: Figure No. Gl1Rcb8 Gl1Bcb8 Gl1Jcb8Sushil ChauhanNo ratings yet

- Datasheet CHK VLV (14in #150)Document1 pageDatasheet CHK VLV (14in #150)chintanNo ratings yet

- Accuseal CR2: Applications Features and BenefitsDocument3 pagesAccuseal CR2: Applications Features and BenefitsPratik SinghNo ratings yet

- MS 01 147 Pipe FittingsDocument16 pagesMS 01 147 Pipe FittingsJacques StrappeNo ratings yet

- 02b Globe Valves Pressure SealDocument3 pages02b Globe Valves Pressure SealAndri AjaNo ratings yet

- C.S Gate ValveDocument4 pagesC.S Gate Valvearmin heidariNo ratings yet

- AVK Gate Valve130 - EN 2214Document2 pagesAVK Gate Valve130 - EN 2214Citra masNo ratings yet

- GRINNELL Figure 772 Grooved Rigid Coupling 1-1/4 - 24 Inch (DN32 - DN600) Sizes 1/2 Inch (M12) Bolt For 2 - 4 Inch (DN50 - DN100) Sizes General Description Technical DataDocument4 pagesGRINNELL Figure 772 Grooved Rigid Coupling 1-1/4 - 24 Inch (DN32 - DN600) Sizes 1/2 Inch (M12) Bolt For 2 - 4 Inch (DN50 - DN100) Sizes General Description Technical DataСергей КолесниковNo ratings yet

- AVK RSV ValvesDocument2 pagesAVK RSV Valvesaviwetangosc01No ratings yet

- Details of Flange, Gasket and Bolt For PlantDocument11 pagesDetails of Flange, Gasket and Bolt For Plantsikandert4uNo ratings yet

- Api 602 Forged Steel Valve PDFDocument4 pagesApi 602 Forged Steel Valve PDFThomasFrenchNo ratings yet

- Comdiflex RTJ Ring Type Joints CatalogueDocument6 pagesComdiflex RTJ Ring Type Joints CatalogueMaged AliNo ratings yet

- Fig.731 Cast Iron: Features & Benefits Material SpecificationDocument1 pageFig.731 Cast Iron: Features & Benefits Material SpecificationKarim Galal IsmailNo ratings yet

- Rev.2 Calculation Tag# HAA10AA201Document4 pagesRev.2 Calculation Tag# HAA10AA201psaayoNo ratings yet

- Profile SurveyDocument10 pagesProfile Surveygalici2002No ratings yet

- 600scjs#cy 2-12 - 15Document2 pages600scjs#cy 2-12 - 15MohamadIbnuHassanNo ratings yet

- Rod End SeriesDocument14 pagesRod End SeriesNopNo ratings yet

- Ball Valve Full PortDocument2 pagesBall Valve Full PortHardik ShahNo ratings yet

- Uploads - Valvulas - Valvulas de Bola - Bola Flotante Aop - Aop CT 3000 Especificacion PDFDocument8 pagesUploads - Valvulas - Valvulas de Bola - Bola Flotante Aop - Aop CT 3000 Especificacion PDFMonica CarrenoNo ratings yet

- Quick Sheet: API 594 Cast Steel Swing Check ValveDocument3 pagesQuick Sheet: API 594 Cast Steel Swing Check ValveUmesh chandra PancholiNo ratings yet

- Steel and Its Heat Treatment: Bofors HandbookFrom EverandSteel and Its Heat Treatment: Bofors HandbookRating: 2.5 out of 5 stars2.5/5 (3)

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- Astm F467MDocument9 pagesAstm F467Mhouk sukNo ratings yet

- Ficha Tecnica Inverter Mini SplitDocument1 pageFicha Tecnica Inverter Mini SplitpabloabelgilsotoNo ratings yet

- AIM R16 WS02 Rear SpoilerDocument30 pagesAIM R16 WS02 Rear SpoilerAnonymous PJP78mSxNo ratings yet

- Handbook Measuring Equity Education 2018 enDocument142 pagesHandbook Measuring Equity Education 2018 endanyjorgeNo ratings yet

- Corona Rotate Lec MachDocument2 pagesCorona Rotate Lec Machr_chulinNo ratings yet

- 2013 Rotary Index Drives Manual1Document16 pages2013 Rotary Index Drives Manual1Manoj TiwariNo ratings yet

- Chapter3 Electropneumatic UpdatedDocument60 pagesChapter3 Electropneumatic UpdatedViệt Đặng XuânNo ratings yet

- CP GeoDocument123 pagesCP GeoJakovPoliakovNo ratings yet

- Volkswagen TransporterDocument3 pagesVolkswagen TransporterTasawar ShahNo ratings yet

- Lesson Plan Template - Social EmotionalDocument2 pagesLesson Plan Template - Social Emotionalapi-573540610No ratings yet

- Paint Finishing Quality and Defect AnalysisDocument6 pagesPaint Finishing Quality and Defect AnalysisAnurag SrivastavaNo ratings yet

- Forces and Motion Using Part 2 - FrictionDocument3 pagesForces and Motion Using Part 2 - FrictionEDuardo MaflaNo ratings yet

- WhitePaper AVEVA PredictiveAnalyticsPower 22-04Document6 pagesWhitePaper AVEVA PredictiveAnalyticsPower 22-04matiasnNo ratings yet

- Syllabus PDFDocument51 pagesSyllabus PDFPalashNo ratings yet

- Contoh Soal Utbk Bahasa InggriDocument43 pagesContoh Soal Utbk Bahasa InggriGIYAN DWINo ratings yet

- Andrew GroveDocument16 pagesAndrew GroveArslanNo ratings yet

- Spanning Space, Horizontal-Span Building Structures, Wolfgang SchuellerDocument752 pagesSpanning Space, Horizontal-Span Building Structures, Wolfgang Schuellerwolfschueller91% (11)

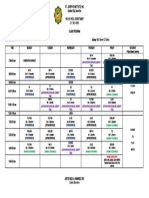

- 9 St. Catherine Class ScheduleDocument1 page9 St. Catherine Class ScheduleAleah TungbabanNo ratings yet

- POWER TAKE-OFF NewHolland TM165Document2 pagesPOWER TAKE-OFF NewHolland TM165Dra MiNo ratings yet

- Sarcasm Detection For Hindi English Code Mixed Twitter DataDocument8 pagesSarcasm Detection For Hindi English Code Mixed Twitter DataIJRASETPublicationsNo ratings yet

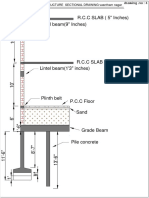

- R.C.C SLAB (5" Inches) Lintel Beam (9" Inches) : Structure Sectional Drawing Vasntham NagarDocument1 pageR.C.C SLAB (5" Inches) Lintel Beam (9" Inches) : Structure Sectional Drawing Vasntham NagarsanthoshNo ratings yet

- Faulty Code Description SolutionDocument5 pagesFaulty Code Description SolutionOppoNo ratings yet

- Air Entrainment - 02Document16 pagesAir Entrainment - 02ThejaswiniNo ratings yet

- Renderoc SMDocument2 pagesRenderoc SMMas DaffiNo ratings yet

- Young & CluelessDocument26 pagesYoung & Cluelessaparnaiyer88No ratings yet

RTJ PDF

RTJ PDF

Uploaded by

Emiliano ZappaterraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RTJ PDF

RTJ PDF

Uploaded by

Emiliano ZappaterraCopyright:

Available Formats

Ring joints RTJ

Ring joint gaskets are made from metallic materials. The The application thresholds values of oval octagonal RTJ gas-

requirements in terms of dimensional accuracy and surface kets can be more accurately calculated in relation to mate-

quality are therefore high. This relates to both the gasket and rial, diameter, pressure, temperature and the surface pres-

the sealing section of the flange. sure limits.

The necessary surface quality depends substantially on the Here the fictitions sealing characteristic values in accord-

Brinell hardness of the gasket material The relationship ance with AD are replaced with the values of σv and σϑ.

RZ[µm] < 300/HB provides a useful indication.

Ring joint gaskets in accordance with API and ASME stand-

A distinction is made between two kinds of ring joint gaskets ards are mainly used in the petrochemical industry and in

and two different calculation methods are therefore used: refineries as a reliable gasket for production pipelines.

1. RTJ gaskets with osculating radius (Figure 1) We are permitted to give our products the API Monogram.

This guarantees that our products meet the latest API stand-

06 a) The convex octagonal RTJ gaskets, Profile AR 13, in ards.

which the convex cone case surfaces of the gasket are

pressed against the even cone case surfaces of the It should be noted that in Profile A12 the flanges have metal-

groove when tensioned. to-metal contact. Profile AR13 with convex sealing surfaces.

b) The oval ring-joint gasket, Profile A11, in which the cir- Ring joint gaskets can be produced as blind gaskets in Pro-

cular surface is pressed against the cone case sur- file A11S, A13S etc. or as blind spectacle gaskets in Profile

faces of the groove. A11BS, A13BS (see Blind Gaskets).

Figure 1

Material

The sealing surface

Code designation Material no. Hardness US-Type Code

pressure increases or

(HB) AISI

decreases to a lesser

Pure iron, e.g. Armco 1.1003 90-100 Soft iron D

extent in response to

Stwfi4mod - 90-110 Soft iron D

any change in the bolt Low-carbon - 120 Low- S

load. steel carbonsteel

AR13 A11 13 CrMo 4 4 1.7335 ca. 160 - 7335

12 CrMo 19 5 mod 1.7362 mod ca. 130 501 F5

X6 Cr 13 1.4000 ca. 160 410 S 410

2. RTJ gaskets with flat sealing surfaces (Figure 2) X5 CrNi 18 10 1.4301 ca. 160 304 S 304

X5 CrNiMo 17 12 2 1.4401 ca. 160 316 S 316

X6 CrNiTi 18 10 1.4541 ca. 160 321 S 321

The octagonal RTJ gasket, Profiles A13 and A14, are flat

X6 CrNiNb 18 10 1.4550 ca. 160 347 S 347

gaskets in which the sealing surfaces are two cone case

X6 CrNiMoTi 17 12 2 1.4571 ca. 160 316 Ti 316 Ti

surfaces. The projection in the direction of the bolting force

bG = b1 + b2 should be set as the sealing surface width. * Further technical data see section “Materials commonly used”.

Figure 2

The sealing surface

pressure increases

or decreases propor-

tionally in response

to any change in the

bolt load.

A13 A14

Kempchen Dichtungstechnik GmbH · Tel. +49 (0)208 8482 0 · Fax. +49 (0)208 8482 285 · info@kempchen.de · www.kempchen.de

76 Ring joints RTJ

Ring joints RTJ

Material, profiles, surface pressure limits, surface roughness

With the addition of a protective ring made from sheet metal Gasket profiles

to Profile F22, disruptive turbulence and accretions are

avoided. At small edge widths the protective gaskets are Profile Cross-section

symmetrical, at larger edge widths they are centred on one

side. We can supply soft-iron compensating caps for dam- A11

aged grooves, such as Profile AK11, AK12, AK13, AK14.

For a complete estimate on sealing flange connections, our A12

efficient sealing estimate service is available.

A13

AR13

06

A14

F22

AK11

AK12

Ak13

AK14

Compensating caps, protective gaskets

Compensating caps for damaged grooves Protective gaskets Profile F22

Gasket limiting values

Profile A11, A11S, A11BS, A12, A13, A13S, A13BS, AR13, AR13S, AR13BS, A14

Materials

Stainless Steel

Stainless Steel

Stainless steel

Heat-resistant

Heat-resistant

Copper2.0090

copper-plated

Monel 2.4360

1.4541silver-

Steel St 35

Stw24modd

mild steel

Iron 1.100

mild steel

1.5415

1.7362

1.4541

1.4828

plated

Recommended max. roughness from 3,2 3,2 3,2 1,6 1,6 3,2 6,3 3,2 3,2

µm

of the flange surfaces to 6,3 6,3 6,3 3,2 3,2 6,3 12,5 6,3 6,3

Surface pressure σv 235 300 400 335 400 135 100 135 260

N/mm2 σϑ

limits for 20 °C 525 675 900 750 900 600 750 300 660

E modulus at 20 °C kN/mm2 210 210 210 200 200 210 200 128 178

Surface pressure σv 235 300 400 335 400 135 100 135 260

N/mm2 σϑ

limits for 300 °C 315 585 730 630 750 390 630 150 650

E modulus at 300 °C kN/mm2 185 185 190 186 186 185 186 114 175

Kempchen Dichtungstechnik GmbH · Tel. +49 (0)208 8482 0 · Fax. +49 (0)208 8482 285 · info@kempchen.de · www.kempchen.de

Ring joints RTJ 77

Ring joint gaskets, Type R

Ring joint gaskets, Type R, dimensions in accord-

ance with ASME B 16.20, API Std 6 A for flanges

in accordance with ASME B16.5 and ASME

B16.47 Series A in accordance with EN 12560-5

Ordering example for an oval ring joint gasket, Profile A11,

NPS 5, Class 150, made of ...1):

Ring joint gasket R 40 A11/1.4541

Ordering example for an octagonal ring joint gasket, Profile

A13, NPS 20, Class 1500, made of ...1):

Ring joint gasket R 75 A13/1.4541

Ring joint gaskets, Type R

06 NPS class

Ring-No. Ring measurements

dm b h h1 NPS class

Ring-No. Ring measurements

dm b h h1

1

/2 300 bis 600 R 11 34,13 6,35 11,11 9,53 12 2500 R 60 406,40 31,75 39,69 38,10

1

/2 900, 1 500 R 12 39,69 7,94 14,29 12,70 14 300 bis 600 R 61 419,10 11 ,11 17,46 15,88

1

/2 2500 R 13 42,86 7,94 14,29 12,70 14 900 R 62 419,10 15,88 22,22 20,64

3

/4 300 bis 600 R 13 42,86 7,94 14,29 12,70 14 1500 * R 63 419,10 25,40 33,34 31,75

3

/4 900, 1500 R 14 44,45 7,94 14,29 12,70 16 150 R 64 454,00 7,94 14,29 12,70

1 150 R 15 47,63 7,94 14,29 12,70 16 300 bis 600 * R 65 469,90 11,11 17,46 15,88

3

/4 2500 R 16 50,80 7,94 14,29 12,70 16 900 * R 66 469,90 15,88 22,23 20,64

1 300 bis 1500 R 16 50,80 7,94 14,29 12,70 16 1500 R 67 469,90 28,58 36,51 34,93

1 /4

1

150 R 17 57,15 7,94 14,29 12,70 18 150 R 68 517,53 7,94 14,29 12,70

1 2500 R 18 60,33 7,94 14,29 12,70 18 300 bis 600 * R 69 533,40 11 ,11 17,46 15,88

1 1/ 4 300 bis 1500 R 18 60,33 7,94 14,29 12,70 18 900 * R 70 533,40 19,05 25,40 23,81

1 1/ 2 150 R 19 65,09 7,94 14,29 12,70 18 1500 R 71 533,40 28,58 36,51 34,93

1 1/ 2 300 bis 1500 * R 20 68,26 7,94 14,29 12,70 20 150 R 72 558,80 7,94 14,29 12,70

1 1/ 4 2500 R 21 72,23 11,11 17,46 15,88 20 300 bis 600 * R 73 584,20 12,70 19,05 17,46

2 150 R 22 82,55 7,94 14,29 12,70 20 900 * R 74 584,20 19,05 25,40 23,81

1 1/ 2 2500 * R 23 82,55 11,11 17,46 15,88 20 1500 R 75 584,20 31,75 39,68 38,10

2 300 bis 600 * R 23 82,55 11,11 17,46 15,88 24 150 R 76 673,10 7,94 14,29 12,70

2 900, 1500 * R 24 95,25 11,11 17,46 15,88 24 300 bis 600 R 77 692,15 15,88 22,23 20,64

2 1/ 2 150 R 25 101,60 7,94 14,29 12,70 24 900 R 78 692,15 25,40 33,34 31,75

2 2500 * R 26 101,60 11,11 17,46 15,88 24 1500 R 79 692,15 34,92 44,45 41,28

2 1/ 2 300 bis 600 * R 26 101,60 11,11 17,46 15,88 22 150 R 80 615,95 7,93 - 12,70

2 1/ 2 900, 1500 * R 27 107,95 11,11 17,46 15,88 22 300 bis 600 R 81 635,00 14,28 - 19,05

2 1/ 2 2500 R 28 111,13 12,70 19,05 17,46 1 10000 * R 82 57,15 11,11 - 15,87

3 150 R 29 114,30 7,94 14,29 12,70 1 1/2 10000 * R 84 63,50 11,11 - 15,87

3 300 bis 600 * R 30 117,48 11,11 17,46 15,88 2 10000 * R 85 79,37 12,70 - 17,46

3 300 bis 900 * R 31 123,83 11,11 17,46 15,88 2 1/2 10000 * R 86 90,49 15,87 - 20,63

3 2500 R 32 127,00 12,70 19,05 17,46 3 10000 * R 87 100,01 15,87 - 20,63

3 1/ 2 150 R 33 131,76 7,94 14,29 12,70 4 10000 * R 88 123,83 19,05 - 23,81

3 1/ 2 300 bis 600 R 34 131,76 11,11 17,46 15,88 3 1/2 10000 * R 89 114,30 19,05 - 23,81

3 1500 * R 35 136,53 11,11 17,46 15,88 5 10000 * R 90 155,58 22,22 - 26,98

4 150 R 36 149,23 7,94 14,29 12,70 10 10000 * R 91 260,35 31,75 - 38,10

4 300 bis 900 * R 37 149,23 11,11 17,46 15,88 R 92 228,60 11,11 17,46 15,87

4 2500 R 38 157,16 15,88 22,23 20,64 26 300, 400, 600 R 932) 749,30 19,05 - 23,81

4 1500 * R 39 161,93 11,11 17,46 15,88 28 300, 400, 600 R 942) 800,10 19,05 - 23,81

5 150 R 40 171,45 7,94 14,29 12,70 30 300, 400, 600 R 952) 857,25 19,05 - 23,81

5 300 bis 900 * R 41 180,98 11,11 17,46 15,88 32 300, 400, 600 R 962) 914,40 22,22 - 26,98

5 2500 R 42 190,50 19,05 25,40 23,81 34 300, 400, 600 R 972) 965,2 22,22 - 26,98

6 150 R 43 193,68 7,94 14,29 12,70 36 300, 400, 600 R 982) 1022,35 22,22 - 26,98

5 1500 * R 44 193,68 11,11 17,46 15,88 8 2000, 3000 * R 99 234,95 11,11 - 15,87

6 300 bis 900 * R 45 211,14 11,11 17,46 15,88 26 900 R 1002) 749,30 28,57 - 34,92

6 1500 * R 46 211,14 12,70 19,05 17,46 28 900 R 1012) 800,10 31,75 - 38,10

6 2500 * R 47 228,60 19,05 25,40 23,81 30 900 R 1022) 857,25 31,75 - 38,10

8 150 R 48 247,65 7,94 14,29 12,70 32 900 R 1032) 914,40 31,75 - 38,10

8 300 bis 900 * R 49 269,88 11,11 17,46 15,88 34 900 R 1042) 965,20 34,92 - 41,27

8 1500 * R 50 269,88 15,88 22,23 20,64 36 900 R 1052) 1022,35 34,92 - 41,27

8 2500 R 51 279,40 22,23 28,58 26,99

- Flanges compliant with the standard not available Dimensions in mm

10 150 R 52 304,80 7,94 14,29 12,70

10 300 bis 900 * R 53 323,85 11 ,11 17,46 15,88

* These rings conform to API standard 6A. The measurements given in mm are converted

10 1500 * R 54 323,85 15,88 22,23 20,64 measurements and will differ marginally from the metric API table.

10 2500 R 55 342,90 28,58 36,51 34,93 1) Specify material when placing order

12 150 R 56 381,00 7,94 14,29 12,70

12 300 bis 900 * R 57 381,00 11,11 17,46 15,88 2) Ring for flanges in accordance with ASME B16.47 Series A

12 1500 R 58 381,00 22,23 28,58 26,99

14 150 R 59 396,88 7,94 14,29 12,70

Dimensions in mm

Kempchen Dichtungstechnik GmbH · Tel. +49 (0)208 8482 0 · Fax. +49 (0)208 8482 285 · info@kempchen.de · www.kempchen.de

78 Ring joints RTJ

Ring joint gaskets, Type RX

Ring joint gaskets, Type RX, dimensions in accord-

ance with ASME B 16.20 and/or API Std 6 A for API

6B flanges

Ordering example for an oval ring joint gasket, Profile A14,

NPS 4, Class 3000, made of ...1):

Ring joint gasket R 37 A14/1.4541

1) Specify material when placing order

Ring joint gaskets, Type RX

Ring-No. Bore* 06

NPS class d1 b c h1 h e

1 1/ 2 2000, 3000,5000 RX 20 76,2 8,73 4,62 19,05 3,18 -

2 2000 RX 23 93,27 11,91 6,45 25,4 4,24 -

2 3000, 5000 RX 24 105,97 11,91 6,45 25,4 4,24 -

3 1/ 8 5000 RX 25 109,54 8,73 4,62 19,05 3,18 -

2 1/ 2 2000 RX 26 111,92 11,91 6,45 25,4 3,78 -

2 1/ 2 3000, 5000 RX 27 118,27 11,91 6,45 25,4 4,24 -

3 2000, 3000 RX 31 134,54 11,91 6,45 25,4 4,24 -

3 5000 RX 35 147,24 11,91 6,45 25,4 4,24 -

4 2000, 3000 RX 37 159,94 11,91 6,45 25,4 4,24 -

4 5000 RX 39 172,64 11,91 6,45 25,4 4,24 -

5 2000, 3000 RX 41 191,69 11,91 6,45 25,4 4,24 -

5 5000 RX 44 204,39 11,91 6,45 25,4 4,24 -

6 2000, 3000 RX 45 221,85 11,91 6,45 25,4 4,24 -

6 5000 RX 46 222,25 13,49 6,68 28,58 4,78 -

8 crossover flange RX 47 245,3 19,84 10,34 41,28 6,88 -

8 2000, 3000 RX 49 280,59 11,91 6,45 25,4 4,24 -

8 5000 RX 50 283,37 16,67 8,51 31,75 5,28 -

10 2000, 3000 RX 53 334,57 11,91 6,45 25,4 4,24 -

10 5000 RX 54 337,34 16,67 8,51 31,75 5,28 -

12 2000, 3000 RX 57 391,72 11,91 6,45 25,4 4,24 -

14 5000 RX 63 441,72 26,99 14,78 50,8 8,46 -

16 2000 RX 65 480,62 11,91 6,45 25,4 4,24 -

16 3000 RX 66 483,39 16,67 8,51 31,75 5,28 -

18 2000 RX 69 544,1 11,91 6,45 25,4 4,24 -

18 3000 RX 70 550,1 19,84 10,34 41,28 6,88 -

20 2000 RX 73 596,1 13,49 6,68 31,75 5,28 -

20 3000 RX 74 600,87 19,84 10,34 41,28 6,88 -

1 10000 RX 82 67,87 11,91 6,45 25,4 4,24 1,6

1 1/ 2 10000 RX 84 74,22 11,91 6,45 25,4 4,24 1,6

2 10000 RX 85 90,09 13,49 6,68 25,4 4,24 1,6

2 1/ 2 10000 RX 86 103,58 15,08 8,51 28,58 4,78 2,4

3 10000 RX 87 113,11 15,08 8,51 28,58 4,78 2,4

4 10000 RX 88 139,3 17,46 10,34 31,75 5,28 3,2

3 1/ 2 10000 RX 89 129,78 18,26 10,34 31,75 5,28 3,2

5 10000 RX 90 174,62 19,84 12,17 44,45 7,42 3,2

10 10000 RX 91 286,94 30,16 19,81 45,24 7,54 3,2

8 2000, 3000 RX 99 245,67 11,91 6,45 25,4 4,24 -

1 1/4 5000 RX 201 51,46 5,74 3,2 11,3 1,45 -

1 3/4 5000 RX 205 62,31 5,56 3,05 11,1 1,83 -

2 1/2 5000 RX 210 97,63 9,53 5,41 19,05 3,18 -

4 5000 RX 215 140,89 11,91 5,33 25,4 4,24 -

4x 41/4 5000 RX 215 140,89 11,91 5,33 25,4 4,24 -

- Flanges compliant with the standard not available Dimensions in mm

* A compensating bore on the ring circumference. The

compensating bore equalises the pressure in both air

chambers.

Kempchen Dichtungstechnik GmbH · Tel. +49 (0)208 8482 0 · Fax. +49 (0)208 8482 285 · info@kempchen.de · www.kempchen.de

Ring joints RTJ 79

Ring joint gasket, Type RX

Ring joint gasket, Type BX, dimensions in ac-

cordance with API Std 6 A for API 6BX flanges

Ordering example for an ring joint gasket, Profile A12, NPS 3

1/16, Class 15000, made of ...1):

Ring joint gasket BX 154 A12/1.4541

1) Specify material when placing order

Ring joint gaskets, Type BX

06 Ring-No. Bore*

NPS class d1 b h e

1 11/16 10000 ,15000 BX 150 72,19 9,30 9,30 1,6

1 13/16 10000 ,15000,20000 BX 151 76,40 9,63 9,63 1,6

2 1/16 10000 ,15000,20000 BX 152 84,68 10,24 10,25 1,6

2 9/16 10000 ,15000,20000 BX 153 100,94 11,38 11,38 1,6

3 1/16 10000 ,15000,20000 BX 154 116,84 12,40 12,40 1,6

4 1/16 10000 ,15000,20000 BX 155 147,96 14,22 14,22 1,6

7 1/16 10000 ,15000,20000 BX 156 237,92 18,62 18,62 3,2

9 10000 ,15000 BX 157 294,46 20,98 20,98 3,2

11 10000 ,15000 BX 158 352,04 23,14 23,14 3,2

13 5/8 10000 BX 159 426,72 25,70 25,70 3,2

13 5/8 5000 BX 160 402,59 13,74 23,83 3,2

16 3/4 BX 161 491,41 16,20 28,07 3,2

16 3/4 5000,10000 BX 162 475,49 14,22 14,22 1,6

18 3/4 5000 BX 163 556,16 17,37 30,10 3,2

18 3/4 10000 BX 164 570,56 24,59 30,10 3,2

21 1/4 5000 BX 165 624,71 18,49 32,03 3,2

21 1/4 10000 BX 166 640,03 26,14 32,03 3,2

26 3/4 2000 BX 167 759,36 13,11 35,86 1,6

26 3/4 3000 BX 168 765,25 16,05 35,86 1,6

5 1/8 10000 BX 169 173,52 12,93 15,84 1,6

9 BX 170 218,03 14,22 14,22 1,6

11 BX 171 267,44 14,22 14,22 1,6

13 5/8 BX 172 333,07 14,22 14,22 1,6

30 2000 , 3000 BX 303 852,75 16,97 37,95 1,6

Dimensions in mm

* A compensating bore on the ring circumference.

The compensating bore equalises the pressure in both air

chambers.

Kempchen Dichtungstechnik GmbH · Tel. +49 (0)208 8482 0 · Fax. +49 (0)208 8482 285 · info@kempchen.de · www.kempchen.de

80 Ring joints RTJ

You might also like

- Session # 7 - Sociogram As A Diagnositic ToolDocument18 pagesSession # 7 - Sociogram As A Diagnositic ToolSHWETA SINGHAL PGPHRM 2021-23 Batch0% (1)

- Keystone Butterfly Valve F 631Document4 pagesKeystone Butterfly Valve F 631Robi KeiNo ratings yet

- Ecoline Est 150-600Document21 pagesEcoline Est 150-600Yosses Sang NahkodaNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Calc Bend Radii Tensile Elong DataDocument7 pagesCalc Bend Radii Tensile Elong Dataritesh_4luv7679No ratings yet

- Dynamic Response of Fixed Offshore Structures Under Environmental LoadsDocument16 pagesDynamic Response of Fixed Offshore Structures Under Environmental LoadsxautraixxxxxxNo ratings yet

- Jsa R B 6 ForkliftDocument3 pagesJsa R B 6 ForkliftsinghajitbNo ratings yet

- InstrManual SCO1-1Document29 pagesInstrManual SCO1-1Juan Felipe AlvarezNo ratings yet

- 06-076-080 Ring Joints RTJDocument5 pages06-076-080 Ring Joints RTJmohamedNo ratings yet

- Ring Joint RTJDocument6 pagesRing Joint RTJzulikram100% (1)

- CC231 - Velan-F0114c - CutsheetDocument4 pagesCC231 - Velan-F0114c - Cutsheetjacquesstrappe06No ratings yet

- Globe Valves - ASME Class 900 & 1500: Flanged EndDocument1 pageGlobe Valves - ASME Class 900 & 1500: Flanged EndMunishTrichyNo ratings yet

- 113 115 Lens GasketsDocument3 pages113 115 Lens GasketsAiZeCK IvanovNo ratings yet

- Diaphragm ValveDocument2 pagesDiaphragm ValveHardik ShahNo ratings yet

- Ficha Tecnica Anillos Oval RingDocument8 pagesFicha Tecnica Anillos Oval RingAndres AlfonsoNo ratings yet

- GB235 MetalsDocument12 pagesGB235 MetalsAhmet HamamcıoğluNo ratings yet

- Astm A 879-06Document3 pagesAstm A 879-06Bill100% (1)

- Flowbiz Cast Steel Nd40 Globe ValvesDocument2 pagesFlowbiz Cast Steel Nd40 Globe ValvesFlowBiz Exports Pvt. Ltd.No ratings yet

- Catalogue CNA 50Hz Rev.1 Update 6-1Document6 pagesCatalogue CNA 50Hz Rev.1 Update 6-1Rido MardanNo ratings yet

- Swing Check Valve 900 Class SpecDocument1 pageSwing Check Valve 900 Class SpecMunishTrichyNo ratings yet

- 21-36-002 Avkcms enDocument3 pages21-36-002 Avkcms enbrilian pungkyNo ratings yet

- Globe Valves Cast Steel Bolted Bonnet Flanged End Class 150, 300 & 600 2"-10"Document4 pagesGlobe Valves Cast Steel Bolted Bonnet Flanged End Class 150, 300 & 600 2"-10"dmitosNo ratings yet

- Gate Valve AvkDocument3 pagesGate Valve AvkIwan SetiawanNo ratings yet

- Ni Inco 4421 Weldingofflakeandspheroidalgraphiteni ResistcastingsDocument6 pagesNi Inco 4421 Weldingofflakeandspheroidalgraphiteni ResistcastingsLeandro Dilkin ConsulNo ratings yet

- Avk Gate Valve, Flanged, Bs STD, Pn25 21/60-004: BS 5163/EN558 Ser.3, Ductile Iron, Stainless Steel Stem, DN50-400Document2 pagesAvk Gate Valve, Flanged, Bs STD, Pn25 21/60-004: BS 5163/EN558 Ser.3, Ductile Iron, Stainless Steel Stem, DN50-400brilian pungkyNo ratings yet

- Tdi 50000 Tpy, GNFCDocument6 pagesTdi 50000 Tpy, GNFCkrunal panchalNo ratings yet

- Girth Flange Load Calculation Using by FEA TechniquesDocument12 pagesGirth Flange Load Calculation Using by FEA TechniqueskingstonNo ratings yet

- ARE 725 Cold-Formed Steel Design: Chapter B: ElementsDocument44 pagesARE 725 Cold-Formed Steel Design: Chapter B: ElementsTodd MaxeyNo ratings yet

- Hes A1002-01 Selection Reference of Steel Bolt MaterialsDocument5 pagesHes A1002-01 Selection Reference of Steel Bolt MaterialsPreetam KumarNo ratings yet

- Hilco Bronsil Aws A5.6 e Cusn-CDocument1 pageHilco Bronsil Aws A5.6 e Cusn-CVICENTE CABALLERONo ratings yet

- Technical Sheet BSA3TDocument4 pagesTechnical Sheet BSA3TMalik DaniyalNo ratings yet

- 16 StaticgasketsDocument10 pages16 StaticgasketsRobinReyndersNo ratings yet

- Material Cross Reference List 1Document3 pagesMaterial Cross Reference List 1vinothcdmNo ratings yet

- Sea Cort Jan Dix Seal Ring GasketsDocument5 pagesSea Cort Jan Dix Seal Ring GasketsmohamedNo ratings yet

- GL 125 150Document1 pageGL 125 150FABIONo ratings yet

- Copper and Copper Alloy Clad Steel Plate: Standard Specification ForDocument6 pagesCopper and Copper Alloy Clad Steel Plate: Standard Specification ForAdnan KhanNo ratings yet

- AVK - Gate Valve OS&Y UL - FM - OutdoorDocument2 pagesAVK - Gate Valve OS&Y UL - FM - OutdoorVINOD PAULNo ratings yet

- V1-2 Severe Service Metal Seated Ball ValvesDocument2 pagesV1-2 Severe Service Metal Seated Ball ValvesSergio Gana GonzalezNo ratings yet

- A. BALL - FloatingDocument3 pagesA. BALL - FloatingSaputraNo ratings yet

- Restriction Orifice T95500enDocument2 pagesRestriction Orifice T95500enCarlos SopasNo ratings yet

- Copperfil Cusi3: MIG-MAG Wires Nickel and Copper AlloysDocument1 pageCopperfil Cusi3: MIG-MAG Wires Nickel and Copper AlloyssatnamNo ratings yet

- 13 - Check ValvesDocument14 pages13 - Check ValvesSiles LimberdsNo ratings yet

- Cast Steel Globe Valve Class: Figure No. Gl1Rcb8 Gl1Bcb8 Gl1Jcb8Document4 pagesCast Steel Globe Valve Class: Figure No. Gl1Rcb8 Gl1Bcb8 Gl1Jcb8Sushil ChauhanNo ratings yet

- Datasheet CHK VLV (14in #150)Document1 pageDatasheet CHK VLV (14in #150)chintanNo ratings yet

- Accuseal CR2: Applications Features and BenefitsDocument3 pagesAccuseal CR2: Applications Features and BenefitsPratik SinghNo ratings yet

- MS 01 147 Pipe FittingsDocument16 pagesMS 01 147 Pipe FittingsJacques StrappeNo ratings yet

- 02b Globe Valves Pressure SealDocument3 pages02b Globe Valves Pressure SealAndri AjaNo ratings yet

- C.S Gate ValveDocument4 pagesC.S Gate Valvearmin heidariNo ratings yet

- AVK Gate Valve130 - EN 2214Document2 pagesAVK Gate Valve130 - EN 2214Citra masNo ratings yet

- GRINNELL Figure 772 Grooved Rigid Coupling 1-1/4 - 24 Inch (DN32 - DN600) Sizes 1/2 Inch (M12) Bolt For 2 - 4 Inch (DN50 - DN100) Sizes General Description Technical DataDocument4 pagesGRINNELL Figure 772 Grooved Rigid Coupling 1-1/4 - 24 Inch (DN32 - DN600) Sizes 1/2 Inch (M12) Bolt For 2 - 4 Inch (DN50 - DN100) Sizes General Description Technical DataСергей КолесниковNo ratings yet

- AVK RSV ValvesDocument2 pagesAVK RSV Valvesaviwetangosc01No ratings yet

- Details of Flange, Gasket and Bolt For PlantDocument11 pagesDetails of Flange, Gasket and Bolt For Plantsikandert4uNo ratings yet

- Api 602 Forged Steel Valve PDFDocument4 pagesApi 602 Forged Steel Valve PDFThomasFrenchNo ratings yet

- Comdiflex RTJ Ring Type Joints CatalogueDocument6 pagesComdiflex RTJ Ring Type Joints CatalogueMaged AliNo ratings yet

- Fig.731 Cast Iron: Features & Benefits Material SpecificationDocument1 pageFig.731 Cast Iron: Features & Benefits Material SpecificationKarim Galal IsmailNo ratings yet

- Rev.2 Calculation Tag# HAA10AA201Document4 pagesRev.2 Calculation Tag# HAA10AA201psaayoNo ratings yet

- Profile SurveyDocument10 pagesProfile Surveygalici2002No ratings yet

- 600scjs#cy 2-12 - 15Document2 pages600scjs#cy 2-12 - 15MohamadIbnuHassanNo ratings yet

- Rod End SeriesDocument14 pagesRod End SeriesNopNo ratings yet

- Ball Valve Full PortDocument2 pagesBall Valve Full PortHardik ShahNo ratings yet

- Uploads - Valvulas - Valvulas de Bola - Bola Flotante Aop - Aop CT 3000 Especificacion PDFDocument8 pagesUploads - Valvulas - Valvulas de Bola - Bola Flotante Aop - Aop CT 3000 Especificacion PDFMonica CarrenoNo ratings yet

- Quick Sheet: API 594 Cast Steel Swing Check ValveDocument3 pagesQuick Sheet: API 594 Cast Steel Swing Check ValveUmesh chandra PancholiNo ratings yet

- Steel and Its Heat Treatment: Bofors HandbookFrom EverandSteel and Its Heat Treatment: Bofors HandbookRating: 2.5 out of 5 stars2.5/5 (3)

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- Astm F467MDocument9 pagesAstm F467Mhouk sukNo ratings yet

- Ficha Tecnica Inverter Mini SplitDocument1 pageFicha Tecnica Inverter Mini SplitpabloabelgilsotoNo ratings yet

- AIM R16 WS02 Rear SpoilerDocument30 pagesAIM R16 WS02 Rear SpoilerAnonymous PJP78mSxNo ratings yet

- Handbook Measuring Equity Education 2018 enDocument142 pagesHandbook Measuring Equity Education 2018 endanyjorgeNo ratings yet

- Corona Rotate Lec MachDocument2 pagesCorona Rotate Lec Machr_chulinNo ratings yet

- 2013 Rotary Index Drives Manual1Document16 pages2013 Rotary Index Drives Manual1Manoj TiwariNo ratings yet

- Chapter3 Electropneumatic UpdatedDocument60 pagesChapter3 Electropneumatic UpdatedViệt Đặng XuânNo ratings yet

- CP GeoDocument123 pagesCP GeoJakovPoliakovNo ratings yet

- Volkswagen TransporterDocument3 pagesVolkswagen TransporterTasawar ShahNo ratings yet

- Lesson Plan Template - Social EmotionalDocument2 pagesLesson Plan Template - Social Emotionalapi-573540610No ratings yet

- Paint Finishing Quality and Defect AnalysisDocument6 pagesPaint Finishing Quality and Defect AnalysisAnurag SrivastavaNo ratings yet

- Forces and Motion Using Part 2 - FrictionDocument3 pagesForces and Motion Using Part 2 - FrictionEDuardo MaflaNo ratings yet

- WhitePaper AVEVA PredictiveAnalyticsPower 22-04Document6 pagesWhitePaper AVEVA PredictiveAnalyticsPower 22-04matiasnNo ratings yet

- Syllabus PDFDocument51 pagesSyllabus PDFPalashNo ratings yet

- Contoh Soal Utbk Bahasa InggriDocument43 pagesContoh Soal Utbk Bahasa InggriGIYAN DWINo ratings yet

- Andrew GroveDocument16 pagesAndrew GroveArslanNo ratings yet

- Spanning Space, Horizontal-Span Building Structures, Wolfgang SchuellerDocument752 pagesSpanning Space, Horizontal-Span Building Structures, Wolfgang Schuellerwolfschueller91% (11)

- 9 St. Catherine Class ScheduleDocument1 page9 St. Catherine Class ScheduleAleah TungbabanNo ratings yet

- POWER TAKE-OFF NewHolland TM165Document2 pagesPOWER TAKE-OFF NewHolland TM165Dra MiNo ratings yet

- Sarcasm Detection For Hindi English Code Mixed Twitter DataDocument8 pagesSarcasm Detection For Hindi English Code Mixed Twitter DataIJRASETPublicationsNo ratings yet

- R.C.C SLAB (5" Inches) Lintel Beam (9" Inches) : Structure Sectional Drawing Vasntham NagarDocument1 pageR.C.C SLAB (5" Inches) Lintel Beam (9" Inches) : Structure Sectional Drawing Vasntham NagarsanthoshNo ratings yet

- Faulty Code Description SolutionDocument5 pagesFaulty Code Description SolutionOppoNo ratings yet

- Air Entrainment - 02Document16 pagesAir Entrainment - 02ThejaswiniNo ratings yet

- Renderoc SMDocument2 pagesRenderoc SMMas DaffiNo ratings yet

- Young & CluelessDocument26 pagesYoung & Cluelessaparnaiyer88No ratings yet