Professional Documents

Culture Documents

General Notes

General Notes

Uploaded by

John Paul IldefonsoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Notes

General Notes

Uploaded by

John Paul IldefonsoCopyright:

Available Formats

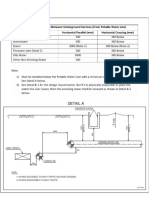

GENERAL NOTES 3.

BORED PILES

THE REQUIRED ULTIMATE BEARING PER BORED PILE SHALL BE AS TABULATED BELOW:

I. DESIGN CRITERIA: CUT-OFF BORED PILE

LOCATION DIAMETER (mm) LENGTH (m) ULTIMATE BEARING ELEV. , m TIP ELEV. , m

CAPACITY, kN

1. SPECIFICATIONS: III. CONSTRUCTION

1.1 AASHTO STANDARD SPECIFICATIONS FOR HIGHWAY BRIDGES, 17TH EDITION, 2002 ABUTMENT A 1600 50 8,600 -- -3.773 DPWH STANDARD SPECIFICATIONS , 2013 EDITION, VOL.II- HIGHWAYS, BRIDGES AND AIRPORTS SHALL BE

1.1 NATIONAL STRUCTURAL CODE OF THE PHILIPPINES- BRIDGES VOL. II - 1997

ABUTMENT B 1600 50 8,600 -- -3.773 FOLLOWED. ALL DIMENSIONS ARE IN MILLIMIMETERS UNLESS OTHERWISE NOTED. IN CASE OF CONFLICT

1.2 DPWH, STANDARD SPECIFICATIONS FOR HIGHWAYS, BRIDGES & AIRPORTS- BRIDGES VOL. II - 2013

PIER 1 1500 50 11,300 -- -3.773 ON INTERPRETATIONS OF DRAWINGS, NUMERICAL FIGURES OF DIMENSION SHALL PREVAIL OVER SCALED

2. LOADS AND WEIGHTS VALUES. UNLESS OTHERWISE SHOWN, ALL BAR SPACINGS REFER TO THE CENTER OF BARS AND THE MI-

PIER 2 1500 50 11,300 -- -3.773

2.1 ROADWAY LIVE LOAD _ _ _ _ _ _ (HL93) NIMUM COVERING FROM SURFACE OF CONCRETE TO THE FACE OF THE NEAREST BAR SHALL BE 50mm. ALL

2.2 INCLUDES AN ALLOWANCE FOR FUTURE 50mm THICK BITUMINOUS WEARING PIER 3 1800 50 11,300 -- -3.773 EXPOSED EDGES SHALL BE CHAMFERED AT LEAST 25 mm EXCEPT RAILINGS AND RE-ENTRANT ANGLES

COURSE = 1.05 kPa OF ROADWAY WHICH SHALL BE CHAMFERED AND FILLETED 13 mm RESPECTIVELY.

2.3 IMPACT LOAD _ _ _ _ _ _ _ I = 15.24/ ( L + 38 )

2.4 SIDEWALK LIVE LOAD _ _ _ _ _ 4.07 KPa OF SIDEWALK AREA

SLAB FORM SHALL BE PROVIDED WITH THE AMOUNT OF CAMBER NECESSARY TO COMPENSATE FOR THE

2.5 EARTHQUAKE LOAD _ _ _ _ _ _ _ _ _ _ GROUND ACCELERATION COEFF. = 0.40 g

AS PER AASHTO DIV. IA VERTICAL ALIGNMENT OR ANTICIPATED DEFLECTION OF THE STRUCTURE.

SEISMIC PERFORMANCE CATEGORY , SPC = D 3.1 THE BOTTOM OF BORED PILES SHALL BE EMBEDDED AT LEAST THREE(3)TIMES PILE DIAMETER (3D) INTO ALL CONCRETE SHALL BE POURED WHERE THERE IS A PERMISSIBLE WEATHER CONDITION AND NO OTHER

2.6 EARTH PRESSURE _ _ _ _ _ _ _ _ _ _ _ COULOMB'S FORMULA - NORMAL TIME HARD STRATA WITH AN N-VALUE OF AT LEAST 40 CAPABLE OF DEVELOPING THE REQUIRED ULTIMATE ENVIRONMENTAL HAZARD WILL AFFECT THE POURING.

MONONOBE - OKABE - EQ. TIME BEARING CAPACITY. IF THE ABOVE CONDITION CANNOT BE MET DURING CONSTRUCTION, THE DESIGNER FORMWORK DRAWINGS AND DESIGN ANALYSIS SHALL BE PREPARED BY THE CONTRACTOR AND SUBMITTED

2.7 WEIGHTS SHALL BE NOTIFIED FOR ADJUSTMENT OF PILE LENGTH IF NECESSARY. TO THE ENGINEER FOR HIS APPROVAL BEFORE ACTUAL CONSTRUCTION. ALL ELEVATIONS AND STA-

A. CONCRETE, PLAIN OR REINFORCED 24.0 KN/m TIONINGS SHALL BE VERIFIED BEFORE CONSTRUCTION.

B. STRUCTURAL STEEL 77.0KN/m3 3.2 LOW-STRAIN DYNAMIC TESTING (PIT) SHALL BE CONDUCTED ON 50% OF THE TOTAL NUMBER OF BORED

HANDLING HOOK DEVICES

C. COMPACTED EARTH 18.0 KN/m3 PILES PER STRUCTURE (AT ABUTMENTS AND PIERS) TO VERIFY AND CHECK THE CONCRETE HOMOGENEITY

HANDLING HOOK DEVICES OF PSCG GIRDERS SHALL BE AS SHOWN ON THE PLANS OR ANY

AND TO LOCATE/EVALUATE ANY IRREGULARITY IN THE COMPLETED BORED PILES.

2.8 OTHER LOADS - IN ACCORDANCE WITH 2002 AASHTO SPECIFICATION (17TH EDITION) SUITABLE DEVICES PREPARED BY THE CONTRACTOR AND APPROVED BY THE ENGINEER

3.3 HIGH-STRAIN DYNAMIC TEST USING PILE DRIVING ANALYZER (PDA) SHALL BE CONDUCTED ONE (1) AT

REINFORCING STEEL BARS

PIER 1, 2, 3, 4, 5, 6 AND ABUT. A & B TO DETERMINE/CHECK THE ACTUAL BEARING

II. MATERIALS CAPACITY OF THE COMPLETED BORED PILES PRIOR TO CONSTRUCTION OF SIMILAR PILES. THE TESTS SHALL A. FABRICATION

BE WITNESSED BY REPRESENTATIVES FROM THE IMPLEMENTING OFFICE, CONTRACTOR AND BOD. THE RESULTS REINFORCING BARS SHALL BE ACCURATELY FORMED TO THE SHAPES AND THE DIMENSIONS INDICATED

SHALL BE SUBMITTED SUBJECT TO APPROVAL BY THE DESIGNER. PRIOR TO CONSTRUCTION OF PILE CAP ON THE PLAN.

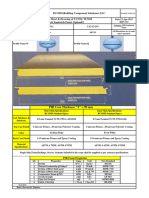

1. CONCRETE

UNLESS OTHERWISE INDICATED ON THE PLANS, THE MINIMUM CYLINDER STRENGTH OF CONCRETE AND SUPERSTRUCTURE. B. BAR BENDING

@ 28 DAYS SHALL BE :

3.4 HIGH STRAIN DYNAMICS TEST SHALL BE DONE SUCH THAT THE REQUIRED ULTIMATE BEARING UNLESS OTHERWISE PERMITTED, ALL REINFORCING BARS REQUIRING BENDING SHALL BE BENT COLD.

CLASS 28TH DAY CYLINDER MAX. SIZE OF COARSE AGGREGATES STRUCTURAL MEMBER CAPACITY IS MOBILIZED AND/OR THE MAXIMUM PERMANENT PILE SET OF D/120 IS REACHED. WHEN REINFORCING BARS ARE BENT BY HEATING, THE ENTIRE OPERATION SHALL BE APPROVED BY

STRENGTH

SUPERSTRUCTURE (DECK SLAB) HAMMER WEIGHT OF ABOUT 1.5 TO 2.0% OF THE REQUIRED ULTIMATE CAPACITY OF BORED THE ENGINEER.

AA 28.0 MPa 20 MM

PILES SHALL BE USED AND DROPPED FROM A GRADUAL HEIGHT INCREASE. COMPLETE PILE

AA 28.0 MPa 20 MM PIER COPING,ABUTMENT,BORED PILES,COLUMNS,APPROACH SLAB FORMWORKS:

TESTS RESULTS INCLUDING TABULATED RESULT OF ALL BLOWS.

C 21.0 MPa 20 MM BRIDGE RAILINGS AND SIDEWALK, WINGWALLS FORMWORKS SHALL BE SO CONSTRUCTED AS TO ADEQUATELY SUSTAIN ANTICIPATED LOADS AND SUCH

3.5 SOIL PENETRATION TEST (SPT) SHALL BE CONDUCTED THREE (3) TIMES PILE DIAMETER BEFORE THAT EVERY PART OF THE STRUCTURE WILL BE IN ITS TRUE LINE AND SHAPE. FORMS AND SHORING

PILE TIP ELEVATION. SPT IS A SUBSIDIARY ITEM OF ITEM 400(17a) CONCRETE PILES CAST IN DRILLED SHALL BE REMOVED AS DIRECTED BY THE ENGINEER. THE FOLLOWING GUIDELINES MAY BE USED:

HOLES (1.50m DIA.), ITEM 400(17b) CONCRETE PILES CAST IN DRILLED HOLES (2.20m DIA.). FOOTING AND NEAT FOUNDATION - - - - - - - - - - - - - - - - - - - 1 DAY

COPING AND PILE CAP - - - - - - - - - - - - - - - - - - - - - - 14 DAYS

PIER AND ABUTMENT - - - - - - - - - - - - - - - - - - - - - - - -7 DAYS

DECK SLAB - - - - - - - - - - - - - - - - - - - - - - - - - - 14 DAYS

2. REINFORCING STEEL 3.6 PILE INTEGRITY TESTING (PIT) SHALL BE CONDUCTED IN 50% OF THE TOTAL NUMBER OF PILES

REINFORCING BARS SHALL BE DEFORMED BILLET STEEL BARS INTERMEDIATE GRADE CONFORMING TO ASTM A TO VERIFY/CHECK THE CONCRETE HOMOGENEITY AND TO LOCATE/EVALUATE ANY POSSIBLE IRREGULA-

615 EQUIVALENT TO AASHTO M - 31 DESIGNATION. GRADE 60 (Fy = 414 MPa) FOR BARS LARGER THAN

RITY IN THE COMPLETED BORED PILES. ITEM 505 GROUTED RIPRAP and ITEM 506 STONE MASONRY

16 mm DIAMETER. GRADE 40 (Fy= 275.8 MPa) FOR BARS 16mm DIAMETER AND SMALLER. ALL REBARS

SHALL BE FREE OF MILL SCALES, OIL OR ANY SUBSTANCE THAT MAY IMPAIR/WEAKEN BOND WITH CONCRETE.

2a. STONE

THE STONE SHALL BE SOUND, TOUGH, DURABLE, DENSE, RESISTANT TO THE ACTION OF AIR

8. NOTES ON APPROACHES AND WATER, AND SUITABLE IN ALL RESPECTS FOT THE PURPOSED INTENDED.

2.1 REINFORCING BAR SPLICING THE EMBANKMENT AT THE JUNCTION OF THE ABUTMENT, WINGWALL AND THE ROAD

SHOULD BE COMPACTED THOROUGHLY IN ACCORDANCE WITH ITEM 104.3, 2b. MORTAR

WHERE SPLICING IS PERMITTED, THE 60 DIAMETER OF BARS SHALL BE AS PER AASHTO ARTICLE 8.32. THE MORTAR FOR THE GROUTED RIPRAP SHALL BE MIXED IN THE PROPORTION OF ONE PART

ALL SPLICES SHALL BE STAGGERED AT LEAST 60 BAR DIAMETER. WHERE BUTT WELD IS USED IN LIEU CONSTRUCTION METHOD OF THE STANDARD SPECIFICATIONS FOR HIGHWAYS

CEMENT TO THREE PARTS SAND BY VOLUME, AND FOR STONE SHALL BE COMPOSED OF

OF LAPPED CONNECTIONS, THIS SHALL DEVELOP AT LEAST 125 % OF THE SPECIFIED YIELD STRENGTH OF SHALL BE BROUGHT UP IN EQUAL LAYERS ON ALL SIDES OF THE BULKHEAD COLUMNS ONE PART OF PORTLAND CEMENT AND TWO PARTS OF FINE AGGREGATES BY VOLUME AND

THE REINFORCING STEEL BAR. WHERE BUNDLED REINFORCEMENT IS USED, BARS IN BUNDLE SHALL TER- OR WALL TO PREVENT DISTORTION TO ANY OF THESE PARTS . AREAS INACCESSIBLE SUFFICIENT WATER TO OBTAINED THE REQUIRED CONSISTENCY.

MINATE AT DIFFERENT POINTS WITH A MINIMUM STAGGER OF 60 BAR DIAMETER UNLESS ALL BAR END IN A TO THE TAMPING OR POWER ROLLER SHALL BEHAND TAMPED UNTIL THOROUGHLY

SUPPORT OR OTHERWISE NOTED IN THE PLANS. BARS SHALL BE BENT COLD AND NO BARS PARTIALLY EM- COMPACTED. BORROW IS ESTIMATED TO BE DETERMINED BY THE HIGHWAY 2c. EXCAVATION AND PLACING

BEDDED IN CONCRETE SHALL BE BENT UNLESS PERMITTED BY THE ENGINEER. DESIGN ENGINEER, BUT NOT TO EXCEED 7%.

- THE BED FOR RIPRAP SHALL BE PROPERLY COMPACTED, TRIMMED AND SHAPED. STONES PLACED

BELOW THE WATER LINE SHALL BE DISTRIBUTED SO THAT THE MAXIMUM THICKNESS OF THE

ELASTOMERIC BEARING PAD RIPRAP IS NOT LESS THAN THAT SPECIFIED.

2.2 HOOKS AND BENDS

HOOKS AND BENDS SHALL BE AS SHOWN IN THE FOLLOWING TABLE ELASTOMERIC BEARING PADS SHALL BE 100 % VIRGIN CHLOROPENE NEOPRENE PADS

- STONES ABOVE THE WATER LINE SHALL BE PLACED BY HAND OR INDIVIDUALLY BY MACHINES.

MILD STEEL SHEET. ELASTOMERIC PADS SHALL CONFORM TO THE REQUIREMENTS AS THEY SHALL BE LAID WITH CLOSED, BROKEN JOINTS AND SHALL BE FIRMLY BEDDED INTO THE

TABLE FOR VALUES OF A OR G PRESCRIBED IN THE DPWH D.O. NO. 25 SERIES OF 1997 " REVISED DPWH STANDARD SLOPE AND AGAINST THE ADJOINING STONES. EACH STONE SHALL BE LAID WITH ITS LONGEST

SPECIFICATIONS FOR ELASTOMERIC BEARING PAD " AXIS PERPENDICULAR TO THE SLOPE CLOSED CONTACT WITH EACH ADJACENT STONE.

SIZE END HOOKS STIRRUP & TIE

OF GRADE (DUROMETER) PHYSICAL PROPERTIES - THE RIPRAP SHALL BE THROUGHLY RAMMED INTO PLACED AS CONSTRUCTION PROGRESS AND

BARS 180° 90° 90° 135° 135° THE FINISHED SURFACE SHALL PRESENT AN EVEN TIGHT SURFACE, INTERSECTCS BETWEEN

A. BEFORE AGING CHLOROPRENE RUBBER (CR) STONES SHALL FILLED WITH SMALL BROKEN FRAGMENTS RAMMED IN PLACED

10 125 150 100 100 125 END HOOK TENSILE STRENGTH, MPa ( D412 15.5(min.) 15.5 (min.)

ELONGATION, % (D412) 350(min.) 300 (min.) 2d. GROUTING

12 150 200 113 113 163 DUROMETER HARDNESS 60 ±5 70 ±5

SHORE PTS.(D2240) THE SPACES BETWEEN THE STONES SHALL BE FILLED WITH CEMENT MORTAR THROUGHOUT

16 175 250 150 138 200 TEAR RESISTANCE, N/mm.(D624) 31.5(min.) 31.5(min.) THE THICKNESS OF THE RIPRAP. SUFFICIENT MORTAR SHALL BE USED. COMPLETELY FILL ALL

COMPRESSION SET, %(D395) 35 (max.) 35 (max)

METHOD B, TEMPERATURE,°C 100 100 VOIDS EXCEPT THE FACE SURFACE OF THE STONE SHALL BE LEFT EXPOSED. GROUT SHALL

20 200 300 90Ø - - BE PLACED FROM BOTTOM TO TOP OF THE SURFACE SWEPT WITH A STIFF BROOM. AFTER

WITH DUROMETER HARDNESS OF 60 AND SHALL BE LAMINATED AND NON - CORROSIVE GROUTING IS COMPLETED, THE SURFACE SHALL BE CURED FOR A PERIOD OF AT LEAST

25 275 400 90Ø - - THREE DAYS.

B. AFTER AGING

- - TEMPERATURE OF THE TEST,° 100 100

28 380 475 90Ø

STIRRUP & TIE HOOK STIRRUP - TIE AGING TIME, HOURS 70 70

- - TENSILE STRENGTH % (D573) 60 ±5 70 ±5

32 430 560 90Ø ELONGATION, % -15(max.) -15(max.)

Do = 6 db for db < 30 D = 4 db for db < 20

Do = 8.7 db for db > 30 D = 6 db for db > 30 -40(max.) -40(max.)

36 485 600 90Ø - - DUROMETER HARDNESS +15(max.) +15(max.)

SHORE PTS.

DESIGNED BY:

PROJECT & LOCATION : SHEET CONTENTS : CHECKED BY : SUBMITTED BY: RECOMMENDING APPROVAL : APPROVED : SET NO. SHEET NO.

Republic of the Philippines

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS EUGENIO Q. ARQUERO IV

REGIONAL OFFICE I WIDENING OF PERMANENT BRIDGES ENGINEER II

RAMOS BRIDGE (B0277LZ) GENERAL NOTES DEXTER L. CAVANEYRO

Planning and Design Division PREPARED BY: CHIEF, BRIDGES AND OTHER PUBLIC WORKS DESIGN BALTAZAR F. LAVARIAS EMMANUEL W. DIAZ, CESE RONNEL M. TAN, CESO IV 4

ALONG JUDGE JOSE DE VENECIA SR. AVENUE

SECTION CHIEF PLANNING & DESIGN DIVISION OIC - ASSISTANT REGIONAL DIRECTOR OIC - REGIONAL DIRECTOR

Bridges and Other Public Works Design Section

San Fernando City, La Union CALASIAO, PANGASINAN JOHN MICHAEL L. HIDALGO

ENGINEER I

DATE : DATE : DATE : DATE :

You might also like

- Proposed 2-Storey Residential House-FootingDocument1 pageProposed 2-Storey Residential House-FootingZiur18100% (1)

- Construction of Multi-Level ParkingDocument13 pagesConstruction of Multi-Level Parkingdunknown15No ratings yet

- Main Fire Station-1Document1 pageMain Fire Station-1Jhon CenaNo ratings yet

- Typical Beam Details Typical Footing Details: Schedule of Footings Schedule of BeamsDocument1 pageTypical Beam Details Typical Footing Details: Schedule of Footings Schedule of BeamsRenel GarciaNo ratings yet

- Amar Factory To Jail Road Culvert-710Document1 pageAmar Factory To Jail Road Culvert-710AATVIK SHRIVASTAVANo ratings yet

- General Notes Foundations: Two - Storey Residential Building With Roof DeckDocument1 pageGeneral Notes Foundations: Two - Storey Residential Building With Roof DeckKarlo CabanginNo ratings yet

- General Notes:: Fillet Weld TableDocument1 pageGeneral Notes:: Fillet Weld Tablefrancis sebastian lagamayoNo ratings yet

- North Direction: Makkah: Steel Structural PlatformDocument8 pagesNorth Direction: Makkah: Steel Structural PlatformDer3'am Al m7armehNo ratings yet

- Notes (General) : Steel CDocument1 pageNotes (General) : Steel CpastorgeeNo ratings yet

- BH Plans ST 1Document1 pageBH Plans ST 1Soner, John LloydNo ratings yet

- General Notes: (Roads, Drainage and Structures) I. at SpecificationsDocument1 pageGeneral Notes: (Roads, Drainage and Structures) I. at SpecificationsDarren ValienteNo ratings yet

- Legend: Footpath 2.8.1 Continuous Footpath TreatmentsDocument1 pageLegend: Footpath 2.8.1 Continuous Footpath TreatmentsGhassan Abood HabeebNo ratings yet

- Satna SiteDocument1 pageSatna SiteRavpreet SinghNo ratings yet

- A-1803b - Landscape Sections & Details - 03Document1 pageA-1803b - Landscape Sections & Details - 03karthikeyan dhanasekaranNo ratings yet

- General NotesDocument1 pageGeneral Notesalex abestadoNo ratings yet

- Bulta Fly-Over ProjectDocument27 pagesBulta Fly-Over ProjectParvez Syed Rafi100% (1)

- SCL-CRC21B (JV) : DRG - No. Section Lalpur Station YardDocument1 pageSCL-CRC21B (JV) : DRG - No. Section Lalpur Station YardWORLD OF videosNo ratings yet

- Chauraghat Road Structural GAD R1Document18 pagesChauraghat Road Structural GAD R1Aicons Engineering Pvt. Ltd.No ratings yet

- This Site: Going TO Digos City ProperDocument14 pagesThis Site: Going TO Digos City ProperJude Darwin EmanoNo ratings yet

- Minimum Clearances Between Underground ServicesDocument5 pagesMinimum Clearances Between Underground ServicesRaizen KingNo ratings yet

- Enrique Fajardo Bible Baptist ChurchDocument1 pageEnrique Fajardo Bible Baptist ChurchAaron CayasNo ratings yet

- Standard Drawing 4071 Guard Fence Layouts For Bridge Approaches July 2020Document1 pageStandard Drawing 4071 Guard Fence Layouts For Bridge Approaches July 2020soumya1986No ratings yet

- Structural Notes: General: Reinforcing SteelDocument1 pageStructural Notes: General: Reinforcing SteelMark Allan RojoNo ratings yet

- Transformer Foundation 5Document1 pageTransformer Foundation 5A.K.M Shafiq MondolNo ratings yet

- Structural Notes: General: Reinforcing SteelDocument1 pageStructural Notes: General: Reinforcing SteelJohn Eric D. WongNo ratings yet

- QAHD Office Building 30 M Structural Plans-S100.0Document1 pageQAHD Office Building 30 M Structural Plans-S100.0Adrian PachecoNo ratings yet

- Typical Application For Painting Centre Line in City Area (Less Than 24 HRS)Document2 pagesTypical Application For Painting Centre Line in City Area (Less Than 24 HRS)Ummi SurayaNo ratings yet

- General Construction Notes: Schedule of Minimum Slab ReinforcementDocument2 pagesGeneral Construction Notes: Schedule of Minimum Slab ReinforcementDominic Robiso DatuinNo ratings yet

- General Construction Notes: Schedule of Minimum Slab ReinforcementDocument1 pageGeneral Construction Notes: Schedule of Minimum Slab ReinforcementDominic Robiso DatuinNo ratings yet

- Genral NotesDocument1 pageGenral NotesArjay AletaNo ratings yet

- S-1 RevisedDocument1 pageS-1 Revisedbernard1agoncillioNo ratings yet

- 07 Asn Ifc STR TR - R00Document1 page07 Asn Ifc STR TR - R00saeed hijabNo ratings yet

- Structural Steelwork For Reinforced Concrete Structural Steelwork For Steel Trusses General Notes Concrete BlockworkDocument1 pageStructural Steelwork For Reinforced Concrete Structural Steelwork For Steel Trusses General Notes Concrete BlockworkOladunni AfolabiNo ratings yet

- General Construction Notes: Typical Connection Detail of Masonry WallDocument1 pageGeneral Construction Notes: Typical Connection Detail of Masonry WallMItchNo ratings yet

- Mega-Stup-St-Ns-Apm-Pk1-Fdn-04 R0Document1 pageMega-Stup-St-Ns-Apm-Pk1-Fdn-04 R0swapan.boseNo ratings yet

- A. General Notes: B. Notes and Concrete Mixes and PlacingDocument1 pageA. General Notes: B. Notes and Concrete Mixes and Placingdomin domNo ratings yet

- HPC 2x1000Document1 pageHPC 2x1000Shivam SharmaNo ratings yet

- Structurals 2Document1 pageStructurals 2seulipark2629No ratings yet

- COMP WALL WITH RETAINING WALL ModelDocument1 pageCOMP WALL WITH RETAINING WALL ModelAmarjit KulkarniNo ratings yet

- Schedule of Loads and Computation: General NotesDocument1 pageSchedule of Loads and Computation: General NotesRommel DollenteNo ratings yet

- Banga School Electrical - 2Document1 pageBanga School Electrical - 2santosmichael.rrfcNo ratings yet

- Bharat Heavy Electricals Limited, Bhopal Traction Machines Engineering DivisionDocument2 pagesBharat Heavy Electricals Limited, Bhopal Traction Machines Engineering DivisionJfsgksktsNo ratings yet

- Level 1 Confidentiality: H S Lim EngineersDocument1 pageLevel 1 Confidentiality: H S Lim Engineersdharunesh182No ratings yet

- 05 StruDocument72 pages05 Strushady masoodNo ratings yet

- R A S L I M S-01 Proposed 3-Storey Mix-Used Commercial BuildingDocument1 pageR A S L I M S-01 Proposed 3-Storey Mix-Used Commercial BuildingShariah MelonNo ratings yet

- Bridge DrawingsDocument14 pagesBridge DrawingsFahad NaveedNo ratings yet

- Ns2-Vk02-P0ucb-171652 - CHS Electrical & Control Building - Beam & Girder Re-Bar Schedule - Fi-2Document3 pagesNs2-Vk02-P0ucb-171652 - CHS Electrical & Control Building - Beam & Girder Re-Bar Schedule - Fi-2Doan Ngoc DucNo ratings yet

- General Notes BridgeDocument6 pagesGeneral Notes BridgeEnglish for KidsNo ratings yet

- R0 - All Structural Details - Foundation 15.11.22-A2-ANCHOR BOLT DETAILS (02 OF 02)Document1 pageR0 - All Structural Details - Foundation 15.11.22-A2-ANCHOR BOLT DETAILS (02 OF 02)Farhan DanishNo ratings yet

- Front Elevation Escalator Section Escalator Section: Top Support Enlarge Scale 1: 4Document1 pageFront Elevation Escalator Section Escalator Section: Top Support Enlarge Scale 1: 4Habibulla BavajiNo ratings yet

- General Structural Notes Page 1Document1 pageGeneral Structural Notes Page 1piyadang16No ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesCarlo M. FloresNo ratings yet

- RCC Design & DetailsDocument1 pageRCC Design & DetailsKanhaiya PanwarNo ratings yet

- Structural-19063 KenoraSH S IFT 2021-03-266Document6 pagesStructural-19063 KenoraSH S IFT 2021-03-266aminNo ratings yet

- PDW-TV-495 6.0 Meters Wide Bituminous Carpet Road-Iso A3Document1 pagePDW-TV-495 6.0 Meters Wide Bituminous Carpet Road-Iso A3ihsan ul haqNo ratings yet

- Outline: Screenstar 0.65X Wide Angle AdapterDocument1 pageOutline: Screenstar 0.65X Wide Angle AdapterdnyaneshwaNo ratings yet

- Rfid Forms PDFDocument1 pageRfid Forms PDFJohn Paul IldefonsoNo ratings yet

- ATG - Subscriber Enrollment Form PDFDocument1 pageATG - Subscriber Enrollment Form PDFJohn Paul IldefonsoNo ratings yet

- Satellite Plan of The ProjectDocument2 pagesSatellite Plan of The ProjectJohn Paul IldefonsoNo ratings yet

- Improvement of Hulo-Malaya-Dolores Farm-To-Market Road With Two Lane Bridge Package Ii - Proposed Replacement/ Construction of Dolores BridgeDocument2 pagesImprovement of Hulo-Malaya-Dolores Farm-To-Market Road With Two Lane Bridge Package Ii - Proposed Replacement/ Construction of Dolores BridgeJohn Paul IldefonsoNo ratings yet

- Improvement of Hulo-Malaya-Dolores Farm-To-Market Road With Two Lane Bridge Package Ii - Proposed Replacement/ Construction of Dolores BridgeDocument1 pageImprovement of Hulo-Malaya-Dolores Farm-To-Market Road With Two Lane Bridge Package Ii - Proposed Replacement/ Construction of Dolores BridgeJohn Paul IldefonsoNo ratings yet

- Liquidation: Total Liquidation Amount Received Amount ReturnDocument2 pagesLiquidation: Total Liquidation Amount Received Amount ReturnJohn Paul IldefonsoNo ratings yet

- T. J. Velasco Construction & Supply / Cad Construction Corporation (Joint Venture)Document1 pageT. J. Velasco Construction & Supply / Cad Construction Corporation (Joint Venture)John Paul IldefonsoNo ratings yet

- Liquidation: Total Liquidation Amount Received Amount ReturnDocument1 pageLiquidation: Total Liquidation Amount Received Amount ReturnJohn Paul IldefonsoNo ratings yet

- Existing Bridge: Framing PlanDocument1 pageExisting Bridge: Framing PlanJohn Paul IldefonsoNo ratings yet

- Existing Bridge: Framing PlanDocument1 pageExisting Bridge: Framing PlanJohn Paul IldefonsoNo ratings yet

- Transverse Section Transverse SectionDocument1 pageTransverse Section Transverse SectionJohn Paul IldefonsoNo ratings yet

- Foundation Engineering: Kousik DebDocument9 pagesFoundation Engineering: Kousik DebInduSaran AttadaNo ratings yet

- Wall Inteference Effects - Analysis and Correction For Automotive Wind TunnelsDocument10 pagesWall Inteference Effects - Analysis and Correction For Automotive Wind TunnelsVyssionNo ratings yet

- Aircraft Structures-II - U1 - L1 - T3 - Direct Stress Distribution Due To BendingDocument11 pagesAircraft Structures-II - U1 - L1 - T3 - Direct Stress Distribution Due To Bendingsarathkumar sebastinNo ratings yet

- Welded Beam To Column Moment Connection PDFDocument4 pagesWelded Beam To Column Moment Connection PDFRahaman khan100% (1)

- Exam Preparation Chartered Member Solutions 20130405Document97 pagesExam Preparation Chartered Member Solutions 20130405Shaikh Muhammad AteeqNo ratings yet

- CONCRETEDocument68 pagesCONCRETEJazella RasonabeNo ratings yet

- Wind Tunnel Technique Notes For Aeronautical Engineers TP 1 PDFDocument2 pagesWind Tunnel Technique Notes For Aeronautical Engineers TP 1 PDFRamji Veerappan50% (2)

- Saic A 2010Document13 pagesSaic A 2010jerinNo ratings yet

- Fatigue Lifetime Prediction For Oil Tube Material Based On Abaqus and Fe-SafeDocument8 pagesFatigue Lifetime Prediction For Oil Tube Material Based On Abaqus and Fe-Safenferreira_245024No ratings yet

- Department of Civil Engineering: Q.No Questions BT Level CompetenceDocument11 pagesDepartment of Civil Engineering: Q.No Questions BT Level Competencecharvi shinyNo ratings yet

- Figure 1 Model Geometry and Boundary ConditionsDocument3 pagesFigure 1 Model Geometry and Boundary ConditionsadrianliviubugeaNo ratings yet

- Types of RaftersDocument34 pagesTypes of RaftersJeriza AquinoNo ratings yet

- Hep O: Sanitary Waste ValveDocument4 pagesHep O: Sanitary Waste ValveJitheesh SahadevanNo ratings yet

- Evaluation of Portland/Limestone Performance Cements (ASTM C1157) in Colorado and Utah Transportation and Commercial Projects - 2007 To PresentDocument35 pagesEvaluation of Portland/Limestone Performance Cements (ASTM C1157) in Colorado and Utah Transportation and Commercial Projects - 2007 To Presentmm mmNo ratings yet

- Civil-Natural Cooling TowerDocument52 pagesCivil-Natural Cooling TowerAmir Abbaszadeh100% (2)

- XDocument316 pagesXsom_bs790% (1)

- Chung and Vander Doelen - GI - Cambridge ON - 0.6 and 1.2m - GWT 4.6mDocument65 pagesChung and Vander Doelen - GI - Cambridge ON - 0.6 and 1.2m - GWT 4.6mChachi CNo ratings yet

- Pof 6Document100 pagesPof 6Mohamed Omar IbrahimNo ratings yet

- Test 1 MKAJ 1033Document4 pagesTest 1 MKAJ 1033Malik Abed100% (1)

- Effect of Vertical & Horizontal Geometric Irregularities On The Seismic Response of RC Structures - Zabihullah, Priyanka Singh, Mohammad Zamir AryanDocument10 pagesEffect of Vertical & Horizontal Geometric Irregularities On The Seismic Response of RC Structures - Zabihullah, Priyanka Singh, Mohammad Zamir AryanStructural SpreadsheetsNo ratings yet

- Beth Plumbing Trade Projec1Document15 pagesBeth Plumbing Trade Projec1bonface80% (5)

- Module 1Document6 pagesModule 1Jose Carlos ArgeñalNo ratings yet

- Bridge Engineering Assignment ReportDocument31 pagesBridge Engineering Assignment ReportChiranjaya HulangamuwaNo ratings yet

- Design of Seismic Force On BuildingDocument12 pagesDesign of Seismic Force On BuildingAjay DalviNo ratings yet

- EMPUJE DE TIERRAS - Active Earth PressureDocument1 pageEMPUJE DE TIERRAS - Active Earth PressuremistakyNo ratings yet

- AK DESAI Corrected CVDocument64 pagesAK DESAI Corrected CVJay ParmarNo ratings yet

- Technical Information ASSET DOC LOC 4899132Document10 pagesTechnical Information ASSET DOC LOC 4899132Zac Francis DaymondNo ratings yet

- SikaTop-Seal 107 PDFDocument4 pagesSikaTop-Seal 107 PDFSed BeelzeNo ratings yet

- CA3-23-219 (TDS TAWQ 90 MM) Option-2 (REV 01)Document1 pageCA3-23-219 (TDS TAWQ 90 MM) Option-2 (REV 01)ahmed ahmadNo ratings yet

- Polymer Modified Binder, 2018Document11 pagesPolymer Modified Binder, 2018anjanaNo ratings yet