Professional Documents

Culture Documents

Textile Technology (Degree Standard) : Unit-I: Fibre Identification and Blend Analysis

Textile Technology (Degree Standard) : Unit-I: Fibre Identification and Blend Analysis

Uploaded by

Yatri Yatri0 ratings0% found this document useful (0 votes)

41 views3 pagesThe document outlines the 10 units of a Textile Technology degree program. The units cover topics such as fiber identification, physical properties of fibers, synthetic fiber spinning processes, principles of spinning and weaving, quality control testing, chemical processing, knitting and garments, nonwovens and technical textiles, and textile management and environmental conservation. Some of the specific topics mentioned include fiber structure and identification methods, mechanical and optical properties of fibers, melt spinning and post-spinning operations, principles of drafting and roving formation, loom motions and shedding, fabric construction and testing, dyeing and printing techniques, and effluent treatment.

Original Description:

Textile related notes

Original Title

Textile Technology

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines the 10 units of a Textile Technology degree program. The units cover topics such as fiber identification, physical properties of fibers, synthetic fiber spinning processes, principles of spinning and weaving, quality control testing, chemical processing, knitting and garments, nonwovens and technical textiles, and textile management and environmental conservation. Some of the specific topics mentioned include fiber structure and identification methods, mechanical and optical properties of fibers, melt spinning and post-spinning operations, principles of drafting and roving formation, loom motions and shedding, fabric construction and testing, dyeing and printing techniques, and effluent treatment.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

41 views3 pagesTextile Technology (Degree Standard) : Unit-I: Fibre Identification and Blend Analysis

Textile Technology (Degree Standard) : Unit-I: Fibre Identification and Blend Analysis

Uploaded by

Yatri YatriThe document outlines the 10 units of a Textile Technology degree program. The units cover topics such as fiber identification, physical properties of fibers, synthetic fiber spinning processes, principles of spinning and weaving, quality control testing, chemical processing, knitting and garments, nonwovens and technical textiles, and textile management and environmental conservation. Some of the specific topics mentioned include fiber structure and identification methods, mechanical and optical properties of fibers, melt spinning and post-spinning operations, principles of drafting and roving formation, loom motions and shedding, fabric construction and testing, dyeing and printing techniques, and effluent treatment.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

TEXTILE TECHNOLOGY

(DEGREE STANDARD)

SUBJECT CODE: 306

UNIT- I: FIBRE IDENTIFICATION AND BLEND ANALYSIS

i) Textile fibre Classification

ii) Fine, gross structure and properties of fibres

iii) Microscopic, physical and chemical test methods for fibre identification;

blend analysis

iv) Morphology characterization – Density, XRD, Electron microscopy

v) Thermal characterization methods - DSC, DMA / TMA, TGA.

UNIT- II: PHYSICAL PROPERTIES OF FIBRES

i) Mechanical – Tensile, Elastic recovery, Time Effect, Bending, Twisting &

Compression

ii) Optical - Absorption and dichroism, Reflection and lustre.

iii) Electrical and Thermal Properties - Dielectric property, Static Electricity,

Structural changes in fibres on thermal treatment.

UNIT- III: SYNTHETIC FIBRE SPINNING AND POST SPINNING OPERATIONS

i) Requirements of fibre forming polymers

ii) Spinning of Polymers - Melt Spinning, Wet spinning, Dry spinning

iii) Post Spinning Operations – Drawing, Crimping, Heat setting, Tow-to-top

conversion, Texturing methods.

UNIT- IV: SPINNING

i) Principles of opening, cleaning and mixing/blending of fibrous materials

ii) Draft and Drafting, Irregularity introduced by drafting

iii) Roller arrangements in drafting systems;

iv) Combing cycle, combing efficiency, lap preparation;

v) Mechanism of roving bobbin building, roving twist;

vi) Ring Cop formation, forces acting on yarn and traveller;

vii) Single and folded yarn twist, production of core spun / compact spun yarn.

viii) Alternate Spinning systems - rotor spinning, air jet spinning, friction

spinning.

ix) Principles of long staple spinning – Jute, Wool.

UNIT- V: WEAVING

i) Warp winding - random and precision winding, winding parameters

ii) Yarn clearers and Tensioners; yarn splicing

iii) Types of warping - beam and sectional warping, pirn winding process;

iv) Sizing Techniques, sizing of spun and filament yarns

v) Primary, Secondary and Tertiary motions of loom, Loom timings.

vi) Tappet, Dobby and Jacquard shedding;

vii) Principles of Shuttleless Weft insertion systems.

viii) Principles of Circular and Multiphase weaving

ix) Basic woven fabric constructions and its derivatives.

UNIT - VI: TESTING & QUALITY CONTROL

i) Sample selection techniques using statistics.

ii) Measurement of fibre length, strength , fineness, maturity

iii) HVI and AFIS techniques

iv) Determination of yarn count, twist and hairiness

v) Tensile testing of fibres, yarns and fabrics

vi) Evenness testing of slivers, rovings and yarns

vii) fabric properties - air permeability, drape, crease recovery, tear / bursting

strength & abrasion.

viii) Objective Evaluation of fabric hand - FAST and KESF

ix) Statistical analysis of experimental results – Mean, SD, CV%

UNIT - VII: CHEMICAL PROCESSING

i) Preparatory processes for natural fibres, synthetics and common blends

ii) Dyeing of fibres using various dye classes.

iii) Batch-wise and continuous dyeing techniques

iv) Styles of printing. Printing thickeners and auxiliaries.

v) Printing of cotton with reactive dyes.

vi) Printing of polyester with disperse dyes.

vii) Mechanical and chemical finishing of cotton.

UNIT - VIII: KNITTING & GARMENTS

i) Knitting - Yarn quality requirements, principles of weft and warp knitting

ii) Basic weft and warp knitted structures and its properties

iii) Garments - Pattern making, Spreading, Cutting, Marker efficiency

iv) Stitches and Seams

v) Types of Sewing machine

vi) Sewing thread attributes

vii) Inspection and Merchandising.

UNIT- IX: NONWOVENS & TECHNICAL TEXTILES

i) Nonwovens - Web formation

ii) Bonding methods – mechanical, thermal and chemical.

iii) Finishing and Application of nonwovens

iv) Technical Textiles - Property requirements

v) Industrial Textiles - Belts, Ropes, Tyre-cords, Coated abrasives

vi) Automotive Textiles - Filter fabrics, Airbags, Carpets

vii) Geotextiles – Applications in civil engineering

viii) Agriculture Textiles – Crop covers, bird nets, soil mats and sacks

ix) Packaging Textiles – Food packing and bags.

UNIT- X: TEXTILE MANAGEMENT & ENVIRONMENT CONSERVATION

i) Industrial Engineering – Work study, method study,

ii) Costing – Elements, Balance sheet, P & L Account

iii) Tools – TQM, 5S, Kaizen, MIS.

iv) Marketing Management

v) Industrial relations and Labour laws

vi) Energy conservation in textile production process

vii) Characteristics of Effluent

viii) Effluent treatment.

You might also like

- H&M Fabric Inspection GuidelineDocument10 pagesH&M Fabric Inspection GuidelineRAYHAN KABIR100% (1)

- Woven Fabric EngineeringDocument436 pagesWoven Fabric Engineeringbrg_shekhar80% (5)

- The Universalization of L'Oreal - SampleDocument3 pagesThe Universalization of L'Oreal - SampleKhushbu PalNo ratings yet

- Business Plan Template For Your Bakery PDFDocument22 pagesBusiness Plan Template For Your Bakery PDFRhemaz Mendaza MillanNo ratings yet

- The Secret of Great Bread: Let Time Do The Work: For Double + Larger BatchDocument9 pagesThe Secret of Great Bread: Let Time Do The Work: For Double + Larger BatchbudhistsluvcopyrightNo ratings yet

- GATE SyllabusDocument3 pagesGATE SyllabusMahesh PurbiaNo ratings yet

- I Semester 15Tt01 Quantitative Techniques in Textile Engineering 3 0 0 3Document26 pagesI Semester 15Tt01 Quantitative Techniques in Textile Engineering 3 0 0 3RAGHUL MNo ratings yet

- Modified Btech Tex 6th Semester SyllabusDocument11 pagesModified Btech Tex 6th Semester SyllabusPulak DebnathNo ratings yet

- Textile Engineering mtqp12Document4 pagesTextile Engineering mtqp12Ankit SinghNo ratings yet

- M.SC Fashion DesigningDocument27 pagesM.SC Fashion DesigningAIM INSTITUTENo ratings yet

- Technical Textile SyllabusDocument5 pagesTechnical Textile SyllabusSujit GulhaneNo ratings yet

- Textured Yarn TechDocument1 pageTextured Yarn TechRaja Sekar100% (1)

- Books List On YarnDocument5 pagesBooks List On YarnSohanur Rahman Sobuj100% (1)

- TX 7th (SY) 170811065857dfdfDocument11 pagesTX 7th (SY) 170811065857dfdfAnkit KumarNo ratings yet

- Textile EngineeringDocument14 pagesTextile EngineeringNabeel BhuttaNo ratings yet

- Introduction To Textile TechnologyDocument2 pagesIntroduction To Textile Technologyabhijeet9solankiNo ratings yet

- TT (TC)Document41 pagesTT (TC)mann2dil2000No ratings yet

- Clothing and TextilesDocument7 pagesClothing and TextilesMr Dampha100% (1)

- B.tech. 4th Year CBCS Carpet and Textile Tech2019-20Document21 pagesB.tech. 4th Year CBCS Carpet and Textile Tech2019-20Rajit YadavNo ratings yet

- Textile CurriculumDocument37 pagesTextile CurriculumSabbir HossainNo ratings yet

- M.tech. Textile TechnologyDocument26 pagesM.tech. Textile TechnologyNilesh Shingote100% (1)

- Chapter 1 - INTRODUCTION OF SEWING MATERIALSDocument24 pagesChapter 1 - INTRODUCTION OF SEWING MATERIALSXuanNo ratings yet

- Diploma Lect Textile Technology PDFDocument2 pagesDiploma Lect Textile Technology PDFRevappa YeddeNo ratings yet

- Common For The Subjects/Streams Mentioned Below: Textile Engineering and Fibre Science (Max. Marks: 70)Document4 pagesCommon For The Subjects/Streams Mentioned Below: Textile Engineering and Fibre Science (Max. Marks: 70)Ambika RajawatNo ratings yet

- General Textile Technology: Unit - IDocument1 pageGeneral Textile Technology: Unit - ISrini KalmulaNo ratings yet

- SLV 3Document1 pageSLV 3mohsinNo ratings yet

- Yarn Manufacturing - IDocument1 pageYarn Manufacturing - ISiva Jagadish Kumar M100% (2)

- TT IIIDocument21 pagesTT IIIVedha ThangavelNo ratings yet

- FF III SyllabusDocument3 pagesFF III SyllabusBinal TivarNo ratings yet

- Manmade Fibre TechnologyDocument4 pagesManmade Fibre Technologykanagaraj sreenathNo ratings yet

- Textile Engineering Books ListDocument12 pagesTextile Engineering Books ListMd Mezbah Uddin Masud100% (1)

- Ft6007 Leather Garment Technology L T P CDocument2 pagesFt6007 Leather Garment Technology L T P CBhuva_janaNo ratings yet

- (Tt305) Advcned Yarn Manufacutring: Unit - VDocument1 page(Tt305) Advcned Yarn Manufacutring: Unit - VAnonymous fhTeZJtNo ratings yet

- Report v6Document28 pagesReport v6Farukh AzizzNo ratings yet

- PCC-TC-205 G Preparatory Wet Processing PCC-TC-205 G: Professional Core CourseDocument2 pagesPCC-TC-205 G Preparatory Wet Processing PCC-TC-205 G: Professional Core CourseamitmadNo ratings yet

- B.SC SubjectsDocument24 pagesB.SC Subjectsranju93No ratings yet

- Compressed Textile Technology and Design SyllabusDocument6 pagesCompressed Textile Technology and Design SyllabusVimbai ChinoonekaNo ratings yet

- SyllabusDocument6 pagesSyllabusHasmukh ShahNo ratings yet

- Books On Fibre - Yarn - Fabric - Textile IndustryDocument15 pagesBooks On Fibre - Yarn - Fabric - Textile Industryhaw100% (1)

- 8.nonwovens & Technical TextilesDocument51 pages8.nonwovens & Technical Textilesmuskan KhanNo ratings yet

- MBA Elective - Apperal MarchandiseDocument5 pagesMBA Elective - Apperal MarchandiseShweta GoyalNo ratings yet

- Gate Syllabus For TextileDocument2 pagesGate Syllabus For Textileshubham_yadav51710% (1)

- IslamMolla Umn 0130E 21756Document397 pagesIslamMolla Umn 0130E 21756Fahim 500No ratings yet

- Prediction of Polyester/cotton Blended Rotor-Spun Yarns Hairiness Based On The Machine ParametersDocument7 pagesPrediction of Polyester/cotton Blended Rotor-Spun Yarns Hairiness Based On The Machine ParametersRavi KumarNo ratings yet

- B.A. (Fashion Designing)Document12 pagesB.A. (Fashion Designing)moniskhmohdNo ratings yet

- Testing of Fibres, Yarns and Fabrics in Textiles and Its InterpretationsDocument12 pagesTesting of Fibres, Yarns and Fabrics in Textiles and Its InterpretationsagasengabrielaNo ratings yet

- SemesterDocument40 pagesSemestergokulsaravananNo ratings yet

- Textile Engineering and Fibre ScienceDocument3 pagesTextile Engineering and Fibre ScienceNikhil TakbhateNo ratings yet

- Syllabus Diri-NewcouseDocument11 pagesSyllabus Diri-NewcouseGopi VinothNo ratings yet

- GATE SyllabusDocument3 pagesGATE Syllabusgotita shuklaNo ratings yet

- Textile Testing - IIDocument1 pageTextile Testing - IIMohammad Vaseem Chavhan0% (1)

- Elements of Textile and Garment TechnologyDocument7 pagesElements of Textile and Garment Technologypavan panwalaNo ratings yet

- Technical Embroidery For Smart Textiles: Review: April 2015Document9 pagesTechnical Embroidery For Smart Textiles: Review: April 2015Alejandra SchiavoniNo ratings yet

- BTech Textile Tech Syllabus PDFDocument48 pagesBTech Textile Tech Syllabus PDFDurjoy RoyNo ratings yet

- Syllabus Lect Textile Designing (TechEduDeptt)Document3 pagesSyllabus Lect Textile Designing (TechEduDeptt)hk_scribdNo ratings yet

- Es2 KTDocument3 pagesEs2 KTPalash BaruaNo ratings yet

- IV B.E. (Textile Technology)Document6 pagesIV B.E. (Textile Technology)9y9aNo ratings yet

- Course Outline 1Document2 pagesCourse Outline 1kkkgn007No ratings yet

- Advanced Nonwoven-Part 1Document86 pagesAdvanced Nonwoven-Part 1vamshi SiddharthNo ratings yet

- Fiber Science Bookby KSVDocument134 pagesFiber Science Bookby KSVGolda MadhuNo ratings yet

- Unit Iv Secondary and Auxilary Motions 12Document3 pagesUnit Iv Secondary and Auxilary Motions 129043785763No ratings yet

- Omfed SCMDocument25 pagesOmfed SCMpratick0% (2)

- Carpets and Other Textile Floor CoveringsDocument6 pagesCarpets and Other Textile Floor Coveringsabverma91No ratings yet

- GucciDocument3 pagesGucciflowerNo ratings yet

- Act 1 A Simple Present Personal InfoDocument2 pagesAct 1 A Simple Present Personal InfoMau MetNo ratings yet

- Kumpulan SoalDocument11 pagesKumpulan SoalValina Ihza AuliaNo ratings yet

- Guide Electrcial Workers Safety EquipmentDocument78 pagesGuide Electrcial Workers Safety EquipmentKy TaNo ratings yet

- Embroidery ThreadDocument18 pagesEmbroidery ThreadMarittaKarmaNo ratings yet

- Chocolate Chip CookiesDocument91 pagesChocolate Chip CookiesVarsha KulkarniNo ratings yet

- Basic RiggingDocument156 pagesBasic RiggingDoni Hardi100% (3)

- McMaster CarrDocument16 pagesMcMaster CarrIsrar UllahNo ratings yet

- Marketing Plan of Nestle Pure LifeDocument109 pagesMarketing Plan of Nestle Pure LifeRida RamzanNo ratings yet

- A Study On Brand Audit For Hindustan Coca-Cola Beverages in Madurai DistrictDocument77 pagesA Study On Brand Audit For Hindustan Coca-Cola Beverages in Madurai DistrictNaga ManiNo ratings yet

- Caregiving 7 Lesson 1Document66 pagesCaregiving 7 Lesson 1Tadeja Jen100% (2)

- Retail Companies in IndiaDocument3 pagesRetail Companies in IndiaNitansha BhutaniNo ratings yet

- Pastry Best 2 PDFDocument32 pagesPastry Best 2 PDFGeorge Petrakos80% (5)

- GCS Tactical Guide 2010Document84 pagesGCS Tactical Guide 2010jadkison21520No ratings yet

- 4. TA1-K61-KEY - Bài tập ôn tập - Grammar & Vocabulary - Reading & WritingDocument3 pages4. TA1-K61-KEY - Bài tập ôn tập - Grammar & Vocabulary - Reading & WritingNg Chau AnhNo ratings yet

- EQUCHEF CATALOGUE 1 Ilovepdf CompressedDocument36 pagesEQUCHEF CATALOGUE 1 Ilovepdf CompressedSandeep SinghNo ratings yet

- Training Manual - Housekepping - WTTCDocument20 pagesTraining Manual - Housekepping - WTTCGpm Gerakan Pemuda MushollaNo ratings yet

- Fashion of Early 20th Century Part2Document38 pagesFashion of Early 20th Century Part2MaggieWoods100% (2)

- Role of Merchandiser in Apparel Industry - Textile Learner PDFDocument11 pagesRole of Merchandiser in Apparel Industry - Textile Learner PDFria100% (2)

- Inventory Numericals SolvedDocument3 pagesInventory Numericals Solvedwahab_pakistan100% (1)

- Washing Machine: Owner'S ManualDocument80 pagesWashing Machine: Owner'S ManualLaurentEuniceNo ratings yet

- MKC10-2015 (1) FDocument6 pagesMKC10-2015 (1) FPeterlao Chua-LaoNo ratings yet

- Gapping Text Exercise 20210311Document2 pagesGapping Text Exercise 20210311Rachel Lee100% (1)

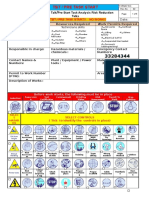

- TBT Paper or STARRT CARDDocument5 pagesTBT Paper or STARRT CARDSAmy91% (11)