Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

9 viewsPag 6 Astm C 1116

Pag 6 Astm C 1116

Uploaded by

Paolita Zubieta Bellopag 6 astm c 1116

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Experto en Nivelacion IngecyrDocument91 pagesExperto en Nivelacion IngecyrPaolita Zubieta Bello100% (6)

- (M01) Obras ComplementariasDocument14 pages(M01) Obras ComplementariasPaolita Zubieta BelloNo ratings yet

- MezclasDocument17 pagesMezclasBengyJironVicenteNo ratings yet

- Astm 1579Document7 pagesAstm 1579Paolita Zubieta BelloNo ratings yet

- Tema 4 - Metodologias de Evaluacion de Impactos 27.10 PDFDocument54 pagesTema 4 - Metodologias de Evaluacion de Impactos 27.10 PDFPaolita Zubieta BelloNo ratings yet

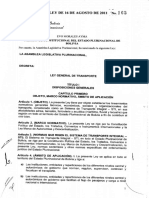

- Ley 165 BoliviaDocument96 pagesLey 165 BoliviaPaolita Zubieta BelloNo ratings yet

- Tema 1 EIAy Desarollo Sostenible PDFDocument36 pagesTema 1 EIAy Desarollo Sostenible PDFPaolita Zubieta BelloNo ratings yet

- Marco Institucional AmbientalDocument15 pagesMarco Institucional AmbientalPaolita Zubieta BelloNo ratings yet

Pag 6 Astm C 1116

Pag 6 Astm C 1116

Uploaded by

Paolita Zubieta Bello0 ratings0% found this document useful (0 votes)

9 views1 pagepag 6 astm c 1116

Original Title

pag 6 astm c 1116

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpag 6 astm c 1116

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

9 views1 pagePag 6 Astm C 1116

Pag 6 Astm C 1116

Uploaded by

Paolita Zubieta Bellopag 6 astm c 1116

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 1

11.2 Continuously mixed fiber-reinforced concrete, whether

prepared on site of at a location remote from the site, shall be

mixed and delivered to the point designated by the purchaser in

accordance with the applicable requirements of Specification

C685/C 685M,

113 Fiber-reinforced concrete shall be fiee of fiber balls,

when delivered.

12, Bateh Ticket Information

12.1 The manufacturer of the fiber-reinforced concrete shall

fumish to the purchaser a delivery ticket or statement of

particulars on which is printed, stamped, of written, inf

tion in one of the following two alternative formats:

ID.A.L Batch-Mixing Format—The details ide

applicable requirements of Specification C94/C 94M, and

details of the type, brand, and amount of fibers used.

12.12 Continuous Mixing Format—The details identified

inthe applicable requirements of Specification C 685/C 685M,

and details of the type, brand, and amount of fibers used.

13. Inspection of Materials, Production, and Delivery

13.1 ‘The manufacturer shall afford the inspector all reason-

able aceess, without charge, for making necessary checks of

the production facilites and for securing necessary samples to

determine if the materials used in the fiber-reinforced concrete

‘or shotcrete comply with the requirements of this specification,

Inspection, sampling, and testing shall not interfere unneces-

sarily with the manufacturing and delivery operations.

14, Sampling

14.1 The contractor shall afford the inspector all reasonable

‘access, without charge, for the procurement of samples of

freshly mixed fiber-reinforced concrete or shoterete at the time

‘of placement to determine compliance with the requirements of

this specification.

14.2 Samples of batch-mixed fiber-teinforced conerete shall

be obtained in accordance with Practice C172, except that

Wwet-sieving shall not be permitted, Sampling for uniformity

tests shall be in accordance with Specification C 94/C 94M.

14.3 Samples af continuously mixed fiber-reinforced con-

crete shall be obrained in accordance with the applicable

requirements of Specification C 685/C 685M, except that wet

sieving shall not be permitted. Sampling for uniformity tests

shall be in accordance with Specification C 685/C 685M.

15. Workability and Air Content Tests

15.1. Make tests for workability and air content at the time

‘of placement at the option of the inspector as often as necessary

for control checks and acceptance purposes, and always when

specimens for tests on hardened concrete are made. When

Water is added in aecordance with the requirements of this

specification (see Tolerances in Workability Section16), repeat

all tests, and use the results of the second set of tests (©

establish whether or not the requirements of this specification

are met.

18.2 Whe messuved clump, sims of flow, oF air content fall

‘outside the limits permitted by this specification, make a check

test immediately on another portion of the same sample, IF the

results again fall outside the permitted limits, the material

represented by the sample fails to meet the requirements of this

specification,

16. Tolerances in Workability

16.1 Unless other tolerances are included in the project

specifications, the following shall apply to all forms of fiber-

reinforced conerete except dry-mix shoterete.

16.1.1. When ihe project specifications for Sump are writen

as a “maximum” or “not to exceed” requirement:

Spec Sump

Sia @Smm) cries iHmete than 3 (75 mm)

Mowe Tolrarce 13218 (29m) 2¥2in (65 mm)

‘When the project specifications for time of flow are written

as a “minimum” or “not less than” requirement

peated Time ef Flow

Ps Tornoe se we

nue Telerance| oe os

These tolerances apply only if one addition of water is

permitted on the job provided such addition does not increase

the water-cemeni ratio above the maximum permitted by the

project specifications.

Nore 14—The slump of a tberseinforced concrete iy les than the

slump of an otherwise identical concrete without fibers. The magnitude of

the eilference depends wrongly nthe amount and type of fibers st

feconmended that tial mixtures represening the amount and type of

fibers wo be wsed in the work be prepared and tested w ensure thatthe

spccitied simp requirements are met. This revommentaton is also

appropriate when workability is specified in terms of time of How

16.1.2 When the project specifications for slump are not

written as a “maximum” or “not to exceed” requirement

Terances for Nominal Sums

For Spected Stump of Tolerance

2. (60m and ess = Sin (15 mm)

20 Ain. (600 100m) = in 25mm)

more han 4 in (100 mm) = 140. (40m)

When the project specific

‘written as a “minimuny" or

tions for time of flow are not

requirement

not less that

Telerances for Tene of Flow

Fer Spacing Tene of Fou of Tedernce

ats sas

more than 15 © 25s

16.2 Fiber-reinforced concrete shall be available within the

permissible range of slump or time of flow for a period of 30

min starting either on arrival at the job site or after the

permitted slump adjustment, whichever is later. The first and

last v4 yd? or Yam’ discharged a re exempt from this require-

‘ment, Ifthe user is unprepared for discharge of the material at

the job site, the manufacturer shall not be responsible for

faltite to meet slump or time of flow requirements after 30 min

have elapsed beyond either the actual arrival time at the job site

fo the requested delivery time, whichever is later.

17. Tolerance in Air Content

17.1 When air-entrainment is specified, the total air content

‘measured using Test Method C 173 of Test Method C 231 shall

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Experto en Nivelacion IngecyrDocument91 pagesExperto en Nivelacion IngecyrPaolita Zubieta Bello100% (6)

- (M01) Obras ComplementariasDocument14 pages(M01) Obras ComplementariasPaolita Zubieta BelloNo ratings yet

- MezclasDocument17 pagesMezclasBengyJironVicenteNo ratings yet

- Astm 1579Document7 pagesAstm 1579Paolita Zubieta BelloNo ratings yet

- Tema 4 - Metodologias de Evaluacion de Impactos 27.10 PDFDocument54 pagesTema 4 - Metodologias de Evaluacion de Impactos 27.10 PDFPaolita Zubieta BelloNo ratings yet

- Ley 165 BoliviaDocument96 pagesLey 165 BoliviaPaolita Zubieta BelloNo ratings yet

- Tema 1 EIAy Desarollo Sostenible PDFDocument36 pagesTema 1 EIAy Desarollo Sostenible PDFPaolita Zubieta BelloNo ratings yet

- Marco Institucional AmbientalDocument15 pagesMarco Institucional AmbientalPaolita Zubieta BelloNo ratings yet