Professional Documents

Culture Documents

IJCRTICGT029

IJCRTICGT029

Uploaded by

maheshCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- Erwin Panofsky - Early Netherlandish Painting - Its Origins and Character by Erwin Panofsky (1966, Harvard University Press) PDFDocument632 pagesErwin Panofsky - Early Netherlandish Painting - Its Origins and Character by Erwin Panofsky (1966, Harvard University Press) PDFDaniel Pinna100% (3)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Vernacular Architecture of JaisalmerDocument25 pagesVernacular Architecture of Jaisalmervijay meena100% (3)

- Design and Operating Parameter f2Document8 pagesDesign and Operating Parameter f2maheshNo ratings yet

- Ecm Unit I MCQDocument5 pagesEcm Unit I MCQmahesh100% (1)

- VGADocument40 pagesVGAmaheshNo ratings yet

- Unit 1Document18 pagesUnit 1maheshNo ratings yet

- Study Thermal Stratification Analysis of Solar Water Heating SystemsDocument6 pagesStudy Thermal Stratification Analysis of Solar Water Heating SystemsmaheshNo ratings yet

- Checklist - Clearing & Grubbing 201Document20 pagesChecklist - Clearing & Grubbing 201LakshithaGonapinuwalaWithanageNo ratings yet

- Axonometric ProjectionDocument6 pagesAxonometric ProjectionSivaram NayakNo ratings yet

- Toilet DesignDocument7 pagesToilet DesignShah PrachiNo ratings yet

- Roman Architecture: History of Architecture - IvDocument48 pagesRoman Architecture: History of Architecture - IvMaria MohanNo ratings yet

- Indian Standard: Methods of Sampling and Analysis of ConcreteDocument46 pagesIndian Standard: Methods of Sampling and Analysis of Concretehari6krishnanNo ratings yet

- ETTINGER Spacers CatalogueDocument71 pagesETTINGER Spacers CatalogueMihhail KoltsovNo ratings yet

- Stair CaseDocument2 pagesStair CasevanacharlabobbyNo ratings yet

- LSMW C1D MassuserDocument7 pagesLSMW C1D MassuserAnish ChattopadhyayNo ratings yet

- Hand Book: Delhi Development AuthorityDocument58 pagesHand Book: Delhi Development AuthorityKanika AggarwalNo ratings yet

- MeterView 4 Users Manual v420Document75 pagesMeterView 4 Users Manual v420Star UetNo ratings yet

- Email Config PDFDocument5 pagesEmail Config PDFAnonymous YUDAcRNo ratings yet

- Storage Protocol PerfDocument6 pagesStorage Protocol PerfrichardgeelenNo ratings yet

- International CatalogDocument128 pagesInternational CatalogDavid HicksNo ratings yet

- Black and White (And A Bit in Between) by Celerie Kemble - ExcerptDocument22 pagesBlack and White (And A Bit in Between) by Celerie Kemble - ExcerptCrown Publishing Group0% (2)

- CCNA R&S-Scaling NetworksDocument1 pageCCNA R&S-Scaling NetworksEmily Owen0% (1)

- Computer Application in Business With Tally ERP9 P Rizwan AhmedDocument14 pagesComputer Application in Business With Tally ERP9 P Rizwan AhmedRizwan Ahmed100% (1)

- Mughal Garden: by - Ganpati Prasad Gupta B. Planning, Sem-VDocument10 pagesMughal Garden: by - Ganpati Prasad Gupta B. Planning, Sem-VGanpati Prasad GuptaNo ratings yet

- Comparison of Pipe Flow EquationsDocument6 pagesComparison of Pipe Flow EquationsJohn HarkenNo ratings yet

- Ass Mtech QBDocument12 pagesAss Mtech QBravirainbowNo ratings yet

- Acoustic EnclosureDocument11 pagesAcoustic EnclosurempwasaNo ratings yet

- Function of OrnamentationDocument13 pagesFunction of OrnamentationsyafrilamirmuhammadNo ratings yet

- How To Use Mail Merge in Microsoft WordDocument15 pagesHow To Use Mail Merge in Microsoft WordAvegail MantesNo ratings yet

- Early British Trackways - Alfred WatkinsDocument82 pagesEarly British Trackways - Alfred Watkinsoftaran100% (6)

- Pic Programer RCDDocument8 pagesPic Programer RCDvikixxxNo ratings yet

- The Leaning Tower of PisaDocument4 pagesThe Leaning Tower of PisaGrace TranNo ratings yet

- UML DiagramsDocument12 pagesUML DiagramsKannan DeenadayalanNo ratings yet

- TEC 312319 MET DoR 001 (Method Statement For Dewatering Works) (K)Document7 pagesTEC 312319 MET DoR 001 (Method Statement For Dewatering Works) (K)Aryaa ArrNo ratings yet

- GEZE Installation Instructions en 808460Document28 pagesGEZE Installation Instructions en 808460PiotrNo ratings yet

IJCRTICGT029

IJCRTICGT029

Uploaded by

maheshCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IJCRTICGT029

IJCRTICGT029

Uploaded by

maheshCopyright:

Available Formats

www.ijcrt.

org © 2017 IJCRT | International Conference Proceeding ICGTETM Dec 2017 | ISSN: 2320-2882

IJCRT Publish Paper record is available at DOI: http://doi.one/10.1727/IJCRT.17149

Performance Analysis of Hot Water Storage Tank

in Solar Water Heating System with Different

Insulation Using ANSYS

Dr. Dheeraj. S. Deshmukh Mahesh V. Kulkarni Dr. S. P. Shekhawat

Associate Professor, Research Scholar & Asstt. Prof. Professor, & HOD

Mechanical Engineering Mechanical Engineering Mechanical Engineering

DBACER ,YCCE Campus, SSBT`s, COET, SSBT`s, COET

Wanadongri, Nagpur Bambhori, Jalgaon Bambhori, Jalgaon

Abstract – Analysis of solar domestic hot water (SDHW) storage tank carried out by using CATIA and ANSYS software. The tank

fluid is in steady mode. The storage tanks made up of MS plate, 50 mm Polyurethane, Glass wool and Rockwool insulation, outer-

cladding cover. Hot water storage tank model made in CATIA software and effect of different insulation materials such as

Polyurethane, Glass wool and Rockwool analyzed in ANSYS. Due to improper insulation material the constant hot water temperature

inside the tank drops after of certain period due to heat diffusion and natural convection from the tank walls and it is difficult to get

constant temperature all the time. To keep constant temperature polyurethane is best insulation than Glass wool and Rockwool. Also

for minimum night heat losses polyurethane is best insulation than Glass wool and Rockwool

Keywords— Polyurethane, Glass wool, Rockwool, Solar Hot Water Storage Tank, CATIA and ANSYS

I. INTRODUCTION

To minimize the loss of heat during the night the heat insulation of the storage tank of a solar thermal system is of vital importance.

Typical insulation materials are foamed polyurethane, polyethylene or polypropylene, at least 100 mm thick. Alternatively also

organic materials made from cellulose or raw wool can be used, demanding a somewhat higher thickness or more layers of insulation

to get the same effect. Since solar storage tanks are thermally stratified – with cold-water layers at the bottom and hot-water layers at

the top – many state-of-the-art tanks are asymmetrically insulated, meaning an increasing insulation thickness from bottom to top.

II. TYPES OF INSULATING MATERIALS

POLYURETHANE FOAM

Polyurethane foam is widely used in high resiliency flexible foam seating, rigid foam insulation panels, microcellular foam seals and

gaskets, durable elastomeric wheels and tires, automotive suspension bushings, electrical potting compounds, seals, gaskets, carpet

underlay, and hard plastic parts (such as for electronic instruments).

One of the best commercially available choices of insulation material is polyurethane foam. It has good thermal insulating properties,

low moisture-vapour permeability, and high resistance to water absorption, relatively high mechanical strength and low density. In

addition, it is relatively easy and economical to install.

Polyurethane foam is effective as an insulator because it has a high proportion (90 percent minimum) of non-connected closed

microcells, filled with inert gas. Until recently, the inert gas most commonly used in polyurethane foams was R-11

(trichlorofluoromethane).

IJCRTICGT029 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 215

www.ijcrt.org © 2017 IJCRT | International Conference Proceeding ICGTETM Dec 2017 | ISSN: 2320-2882

IJCRT Publish Paper record is available at DOI: http://doi.one/10.1727/IJCRT.17149

Fig.1 Polyurethane foam

GLASS FIBRE ( GLASSWOOL)

Rigid board panels can be made with compressed fibre glass. These lightweight insulation boards have relatively high R-values for

their thickness.

Fig.2 Glasswool

ROCKWOOL

Rockwool is general name for fibre materials that are formed by spinning or drawing molten minerals. Applications of rockwool

includes thermal insulation, filtration, soundproofing, hydroponic growth medium

Though the individual fibers conduct heat very well, when pressed into rolls and sheets, their ability to partition air makes them

excellent insulators and sound absorbers. Though not immune to the effects of a sufficiently hot fire, the fire resistance of fiberglass,

stone wool, and ceramic fibers makes them common building materials when passive fire protection is required, being used as spray

fireproofing, in stud cavities in drywall assemblies and as packing materials in firestops.

Other uses are in resin bonded panels, as filler in compounds for gaskets, in brake pads, in plastics in the automotive industry, as a

filtering medium, and as a growth medium in hydroponics.

Mineral fibers are produced in the same way, without binder. The fiber as such is used as a raw material for its reinforcing purposes

in various applications, such as friction materials, gaskets, plastics, and coatings.

IJCRTICGT029 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 216

www.ijcrt.org © 2017 IJCRT | International Conference Proceeding ICGTETM Dec 2017 | ISSN: 2320-2882

IJCRT Publish Paper record is available at DOI: http://doi.one/10.1727/IJCRT.17149

III. DIMENSIONS SPECIFICATION OF TANK

Length of tank = 1100 mm

Diameter of pipe = 25 mm

Diameter of tank = 500 mm

Layer 1 is of stainless steel of 2mm thickness

Layer 2 is of insulation of 50mm thickness

Layer 3 is of stainless steel of 2mm thickness

Capacity of tank = 120 liters

IV. ANALYSIS OF SOLAR WATER STORAGE TANK

Steps In ANSYS For Analysis Of Solar Water Storage Tank

1.Create the model (Geometry) in CATIA.

2.Import the geometry from CATIA to ANSYS software.

3.Mesh the model.

4.Applying the Load and obtaining the solution

4.1 Defining the analysis type

4.2 Applying loads

4.2.1 Constant Temperature

4.2.2 Heat Flow Rate

4.2.3 Convections

4.2.3 Heat Fluxes

4.2.4 Heat Generation Rates

4.3 Applying the Boundary Conditions

5.Reviewing the Analysis report

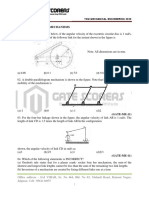

Fig. Geometry imported to ANSYS from CATIA Fig. Mesh the geometry

Since solar water storage tank having three layers it occurred convection layer by layer simultaneously.Hence design of tank in

ANSYS given below

IJCRTICGT029 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 217

www.ijcrt.org © 2017 IJCRT | International Conference Proceeding ICGTETM Dec 2017 | ISSN: 2320-2882

IJCRT Publish Paper record is available at DOI: http://doi.one/10.1727/IJCRT.17149

Fig.

Fig. Design of tank Fig.- Apply Heat Flux In ANSYS

Since solar storage tank has contact with sun so it will be goes through heat flux. Hence design of tank in ANSYS for heat fluxes :

Object Name Fluid Soli Convection Convectio Convectio Convectio

d Interface n n3 n

2 4

Film Coefficien 11.3 W/m²·° 2.25 W/m²·°C 7.9

t C W/m²·°C

Ambient 76° 70° 30° 25°

Temperature

Table - convection value

V. RESULT

FOR POLYURETHANE

Object Temp Temp Temp Temp Temp Temp Temp Temp

Name Global Global (°c) 1 2 3 4 5

Max Min (°c) (°c) (°c) (°c) (°c)

(°c) (°c)

Min 75.029 -21.418 71.557 71.532 71.57 71.541 65.208 64.106

Max 76.665 46.475 75.786 75.787 75.789 75.78 75.202 75.009

Table. Temperature variation for polyurethane

Time (s) Minimum (W/m²) Maximum (W/m²)

360 1.9607e-003 6480.6

720 5.6688e-004 11056

IJCRTICGT029 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 218

www.ijcrt.org © 2017 IJCRT | International Conference Proceeding ICGTETM Dec 2017 | ISSN: 2320-2882

IJCRT Publish Paper record is available at DOI: http://doi.one/10.1727/IJCRT.17149

1800 3.2531e-005 17195

5040 3.1829e-003 20905

8640 3.3541e-002 21473

12240 3.9079e-002 21406

15840 4.1972e-002 21263

19440 4.3501e-002 21141

23040 4.4179e-002 21045

26640 4.4521e-002 20971

30240 4.4816e-002 20911

33840 4.5009e-002 20863

36000 4.5066e-002 20837

Table – Heat Flux variation for polyurethane

Fig.- Heat Flux VS Time Fig. -Directional heat flux VS Time

IJCRTICGT029 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 219

www.ijcrt.org © 2017 IJCRT | International Conference Proceeding ICGTETM Dec 2017 | ISSN: 2320-2882

IJCRT Publish Paper record is available at DOI: http://doi.one/10.1727/IJCRT.17149

Fig. -Thermal Error VS Time

RESULT FOR GLASS FIBRE

Time VS Cumulative Iteration Heat Flux VS Time

Hence for Glass Fibre insulation material Heat Flux variations are :

Time (s) Minimum (w/m²) Maximum (w/m²)

360 3.5395e-003 4717.8

720 1.6334e-003 8169

1800 4.6912e-004 13380

5040 5.9342e-003 17865

8640 2.4175e-002 19317

12240 5.1937e-002 19729

15840 5.4985e-002 19800

19440 5.7368e-002 19575

23040 5.9005e-002 19679

IJCRTICGT029 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 220

www.ijcrt.org © 2017 IJCRT | International Conference Proceeding ICGTETM Dec 2017 | ISSN: 2320-2882

IJCRT Publish Paper record is available at DOI: http://doi.one/10.1727/IJCRT.17149

26640 6.0162e-002 19596

30240 6.0939e-002 19520

33840 6.1449e-002 19453

36000 6.1599e-002 19416

Table - for Glass Fibre insulation material Heat Flux variations

Hence for Glass Fibre insulation material temperature variations are :

Time (s) Minimum (°c) Maximum (°c)

360 58.703 79.575

720 44.841 80.757

1800 21.802 79.495

5040 -0.40305 75.998

8640 -8.6942 75.978

12240 -11.756 75.983

15840 -12.93 75.869

19440 -13.357 75.776

23040 -13.472 75.629

26640 -13.456 75.461

30240 -13.338 75.267

33840 -13.229 75.055

36000 -13.245 74.922

Table - Glass Fibre insulation material temperature variations

IJCRTICGT029 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 221

www.ijcrt.org © 2017 IJCRT | International Conference Proceeding ICGTETM Dec 2017 | ISSN: 2320-2882

IJCRT Publish Paper record is available at DOI: http://doi.one/10.1727/IJCRT.17149

Fig Directional heat flux VS Time for Glasswool Fig. -Thermal Error VS Time for Glasswool

Fig. Heat Flux VS Time for Glasswool

RESULT FOR ROCKWOOL

Object Temp Temp Temp Temp Temp Temp Temp Temp

Name Global Global (°c) 1 2 3 4 5

Max Min (°c) (°c) (°c) (°c) (°c)

(°c) (°c)

Min 74.393 -9.7959 68.746 68.719 68.768 68.727 63.7 62.739

Max 76.61 54.968 75.674 75.675 75.679 75.665 75.175 74.992

Table Temperature variation for Rockwool

IJCRTICGT029 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 222

www.ijcrt.org © 2017 IJCRT | International Conference Proceeding ICGTETM Dec 2017 | ISSN: 2320-2882

IJCRT Publish Paper record is available at DOI: http://doi.one/10.1727/IJCRT.17149

Fig.-Total Heat Flux VS Time for Rockwool Fig. Directional Heat Flux VS Time for Rockwool

Fig Thermal Error VS Time for Rockwool

VI. CONCLUSIONS

Polyurethane, Glass wool and Rockwool insulation make a significant contribution to maintain temperature inside solar hot water

storage tank. As changing insulation material in solar hot water storage tank its performance observed with ANSYS software.

Different performance parameter such as night heat losses and temperature variation observed for Polyurethane, Glass wool and

Rockwool insulation material. Form analysis it is observed that Polyurethane is most efficient thermal insulation. Polyurethane

reduces night heat loss and maintains highest temperature in solar water hot water tank than Glass wool & Rockwool. It concluded

that there are some aspects which altered while changing insulation materials simultaneously.

Temperature: Highest temperature occurred at Polyurethane, by then Glass fibre and last one at Rockwool.

Heat Flux: There are night heat losses occurred due to heat flux, thermal error as it also goes decreasing from Polyurethane, Glass

fibre and Rockwool.

Life: Among the three insulations, life of Solar Water Storage Tank with insulation of Polyurethare is more than Glass wool and

Rockwool.

IJCRTICGT029 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 223

www.ijcrt.org © 2017 IJCRT | International Conference Proceeding ICGTETM Dec 2017 | ISSN: 2320-2882

IJCRT Publish Paper record is available at DOI: http://doi.one/10.1727/IJCRT.17149

ACKNOWLEDGMENT

Authors are thankful to the SSBT`s, College of Engineering and Technology, Bambhori, Jalgaon for providing library facility. The

authors would like to thank the staff and colleagues for useful discussions.

REFERENCES

[1] G.N.Kulkarni Optimization of solar water heating systems through water replenishment Energy Conversion and Management 50

(2009) pg 837–846

[2] P. Armstrong*, D. Ager, I. Thompson, M. McCulloch Improving the energy storage capability of hot water tanks through wall

material specification Energy 78 (2014) 128-140

[3] Kulkarni G.N. Kedare SB, Bandyopadhyay S. Determination of design space and optimization of solar water heating systems.

Solar Energy 2007;81(8):958–68.

[4] Jianhua Fan, Simon Furbo, Hongqiang Yue Development of a hot water tank simulation program with improved prediction of

thermal stratification in the tank Energy Procedia 70 ( 2015) 193 – 202.

[5] Kulkarni G.N. Kedare SB, Bandyopadhyay S. Design of solar thermal systems utilizing pressurized hot water Solar Energy 82

(2008) 686–699

[6] Ryan M. Dickinson,*, Cynthia A. Cruickshank, Stephen J. Harrison The effect of discharge configurations on the thermal

behaviour of a multi-tank storage system Energy Procedia 30 ( 2012 ) 215 – 224

[7] Shuhong Li,*, Yongxin Zhang, Kai Zhang, Xianliang Li, Yang Li, Xiaosong Zhang Study on performance of storage tanks in

solar water heater system in charge and discharge progress Energy Procedia 48 ( 2014 ) 384 – 393

[8] Wenfeng Gao, Tao Liu, Wenxian Lin, Chuanxu Luo Numerical Study on Mixing Characteristics of hot Water inside the Storage

Tank of a Solar System with Different Inlet Velocities of the Supply Cold Water Procedia Environmental Sciences 11 (2011) 1153 –

1163

[9] Yoram L. Shabtay, John R.H. Black Compact hot water storage systems combining copper tube with high conductivity graphite

and phase change materials SHC 2013, International Conference on Solar Heating and Cooling for Buildings and Industry September

23-25, 2013, Freiburg, Germany

[10] Sharma A, Tyagi VV, Chen CR, Buddhi D, Review of Thermal Energy Storage with Phase Change Materials and Applications,

Renewable and Sustainable Energy Reviews 2009; 13:318 – 345.

[11] H. P. Garg, J Prakash Solar Energy Fundamental and Application First Revised Edition, Tata McGraw-Hill.

[12] S. P. Sukhatme, J. K. Nayak Solar Energy Principle of Thermal Collection and Storage third edition The McGraw-Hill

Companies.

[13] Dr. D S Deshmukh, Mr. M.V.Raolani and Mr. M.V. Kulkarni, “Design Considerations for Solar Water Heating System

Techniques: A Critical Review” organized by Shram Sadhana Bombay Trust’s College of Engineering & Technology, Bambhori,

Jalgaon,.International Conference on Advances in Energy Technology on March29, 2013.

[14] Mahesh V. Kulkarni, Dr. Dheeraj S. Deshmukh and Dipak C. Talele, “Solar Water Heater Collector Testing Methodology” at

International Conference on Sustainable Development 2014, organized by S.S.B.T.’s, College of Engineering & Technology,

Bambhori, Jalgaon, on dated 25th- 26th February 2014

[15] Mr. M.V. Kulkarni, and Dr. D.S. Deshmukh, “Improving Efficiency of Solar Water Heater Using Phase Change Materials” in

Pratibha: International Journal of Science, Spirituality, Business and Technology (IJSSBT), ISSN (Print) 2277-7261 and ISSN (on-

line):2278-3857, Page No. 39- 44, Volume 3, No.1, Dec., 2014.

[16] M.V. Kulkarni, Dr. D.S. Deshmukh published a research paper entitled - Design of Experiment for Solar Water Heater

Performance Analysis‖ in Pratibha: International Journal of Science, Spirituality, Business and Technology (IJSSBT), ISSN (Print)

2277-7261 and ISSN (on-line):2278-3857, Page No. 55- 60, Volume 3, No.2, June

IJCRTICGT029 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 224

www.ijcrt.org © 2017 IJCRT | International Conference Proceeding ICGTETM Dec 2017 | ISSN: 2320-2882

IJCRT Publish Paper record is available at DOI: http://doi.one/10.1727/IJCRT.17149

[16] M.V. Kulkarni, Dr. D.S. Deshmukh published a research paper entitled - Investigation of Storage Tank Performance Using Phase

Change Material in a Solar Water Heating System in Pratibha: International Journal of Science, Spirituality, Business and Technology

(IJSSBT), ISSN (Print) 2277-7261 and ISSN (on-line):2278-3857, Page No. 24-29, Volume 4, No.1, November, 2015.

[17] M.V. Kulkarni, Dr. D.S. Deshmukh, Dr S.P.Shekhawat, Dr I.D.Patil published a research paper entitled – “Solar Water Heating

System Using Innovative Flat Plate Collector and Storage Volume” in International Journal of Innovative Research in Science,

Engineering and Technology (IJIRSET), ISSN (Print) 2347 – 6710 and ISSN (on-line): 2319 - 8753, Page No. 570-577, Volume 6,

Special Issue 1, January 2017

IJCRTICGT029 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 225

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- Erwin Panofsky - Early Netherlandish Painting - Its Origins and Character by Erwin Panofsky (1966, Harvard University Press) PDFDocument632 pagesErwin Panofsky - Early Netherlandish Painting - Its Origins and Character by Erwin Panofsky (1966, Harvard University Press) PDFDaniel Pinna100% (3)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Vernacular Architecture of JaisalmerDocument25 pagesVernacular Architecture of Jaisalmervijay meena100% (3)

- Design and Operating Parameter f2Document8 pagesDesign and Operating Parameter f2maheshNo ratings yet

- Ecm Unit I MCQDocument5 pagesEcm Unit I MCQmahesh100% (1)

- VGADocument40 pagesVGAmaheshNo ratings yet

- Unit 1Document18 pagesUnit 1maheshNo ratings yet

- Study Thermal Stratification Analysis of Solar Water Heating SystemsDocument6 pagesStudy Thermal Stratification Analysis of Solar Water Heating SystemsmaheshNo ratings yet

- Checklist - Clearing & Grubbing 201Document20 pagesChecklist - Clearing & Grubbing 201LakshithaGonapinuwalaWithanageNo ratings yet

- Axonometric ProjectionDocument6 pagesAxonometric ProjectionSivaram NayakNo ratings yet

- Toilet DesignDocument7 pagesToilet DesignShah PrachiNo ratings yet

- Roman Architecture: History of Architecture - IvDocument48 pagesRoman Architecture: History of Architecture - IvMaria MohanNo ratings yet

- Indian Standard: Methods of Sampling and Analysis of ConcreteDocument46 pagesIndian Standard: Methods of Sampling and Analysis of Concretehari6krishnanNo ratings yet

- ETTINGER Spacers CatalogueDocument71 pagesETTINGER Spacers CatalogueMihhail KoltsovNo ratings yet

- Stair CaseDocument2 pagesStair CasevanacharlabobbyNo ratings yet

- LSMW C1D MassuserDocument7 pagesLSMW C1D MassuserAnish ChattopadhyayNo ratings yet

- Hand Book: Delhi Development AuthorityDocument58 pagesHand Book: Delhi Development AuthorityKanika AggarwalNo ratings yet

- MeterView 4 Users Manual v420Document75 pagesMeterView 4 Users Manual v420Star UetNo ratings yet

- Email Config PDFDocument5 pagesEmail Config PDFAnonymous YUDAcRNo ratings yet

- Storage Protocol PerfDocument6 pagesStorage Protocol PerfrichardgeelenNo ratings yet

- International CatalogDocument128 pagesInternational CatalogDavid HicksNo ratings yet

- Black and White (And A Bit in Between) by Celerie Kemble - ExcerptDocument22 pagesBlack and White (And A Bit in Between) by Celerie Kemble - ExcerptCrown Publishing Group0% (2)

- CCNA R&S-Scaling NetworksDocument1 pageCCNA R&S-Scaling NetworksEmily Owen0% (1)

- Computer Application in Business With Tally ERP9 P Rizwan AhmedDocument14 pagesComputer Application in Business With Tally ERP9 P Rizwan AhmedRizwan Ahmed100% (1)

- Mughal Garden: by - Ganpati Prasad Gupta B. Planning, Sem-VDocument10 pagesMughal Garden: by - Ganpati Prasad Gupta B. Planning, Sem-VGanpati Prasad GuptaNo ratings yet

- Comparison of Pipe Flow EquationsDocument6 pagesComparison of Pipe Flow EquationsJohn HarkenNo ratings yet

- Ass Mtech QBDocument12 pagesAss Mtech QBravirainbowNo ratings yet

- Acoustic EnclosureDocument11 pagesAcoustic EnclosurempwasaNo ratings yet

- Function of OrnamentationDocument13 pagesFunction of OrnamentationsyafrilamirmuhammadNo ratings yet

- How To Use Mail Merge in Microsoft WordDocument15 pagesHow To Use Mail Merge in Microsoft WordAvegail MantesNo ratings yet

- Early British Trackways - Alfred WatkinsDocument82 pagesEarly British Trackways - Alfred Watkinsoftaran100% (6)

- Pic Programer RCDDocument8 pagesPic Programer RCDvikixxxNo ratings yet

- The Leaning Tower of PisaDocument4 pagesThe Leaning Tower of PisaGrace TranNo ratings yet

- UML DiagramsDocument12 pagesUML DiagramsKannan DeenadayalanNo ratings yet

- TEC 312319 MET DoR 001 (Method Statement For Dewatering Works) (K)Document7 pagesTEC 312319 MET DoR 001 (Method Statement For Dewatering Works) (K)Aryaa ArrNo ratings yet

- GEZE Installation Instructions en 808460Document28 pagesGEZE Installation Instructions en 808460PiotrNo ratings yet