Professional Documents

Culture Documents

Mold Plates: Mold Base Industries, Inc

Mold Plates: Mold Base Industries, Inc

Uploaded by

oszemCopyright:

Available Formats

You might also like

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Manual Relé DP-25 (Union Switch & Signal Inc.)Document7 pagesManual Relé DP-25 (Union Switch & Signal Inc.)Raphael MuzziNo ratings yet

- Structural SteelDocument61 pagesStructural SteelRohit 89No ratings yet

- SabicDocument46 pagesSabicdhdfh0% (1)

- Aspac Royalloy enDocument7 pagesAspac Royalloy enNugroho Faris SudrajatNo ratings yet

- Rebar Steel Bar Detail For Grade 1Document29 pagesRebar Steel Bar Detail For Grade 1talatzahoorNo ratings yet

- What Is Rebar?: Grades of Rebar in Different CodesDocument9 pagesWhat Is Rebar?: Grades of Rebar in Different CodesSalih MohayaddinNo ratings yet

- 254SMO 性能Document8 pages254SMO 性能yw_oulalaNo ratings yet

- 254SMO 性能Document8 pages254SMO 性能yw_oulalaNo ratings yet

- Y STRAINER FLANGED END 150 Model PDFDocument1 pageY STRAINER FLANGED END 150 Model PDFsajanchaudhariNo ratings yet

- Astm B224Document4 pagesAstm B224DouglasNo ratings yet

- Technical Specifications For ValvesDocument32 pagesTechnical Specifications For ValvesEr Hussain GhadialiNo ratings yet

- Reinforcing Steel BarsDocument17 pagesReinforcing Steel BarsRonald BilogNo ratings yet

- Aalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFDocument3 pagesAalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFganmosesNo ratings yet

- Wire - Rod - Cold C4CDocument10 pagesWire - Rod - Cold C4CGabriel MesquitaNo ratings yet

- Is 1977Document11 pagesIs 1977rahulmechdceNo ratings yet

- BabbittDocument4 pagesBabbitthrsreenathNo ratings yet

- ASME Weld Number Tables - P Number Base & F Number FillerDocument14 pagesASME Weld Number Tables - P Number Base & F Number FillerChris McNairNo ratings yet

- Ch-07 SteelsDocument20 pagesCh-07 SteelsKHUSHI JAIN100% (1)

- API 5CT Material Specfication J55Document1 pageAPI 5CT Material Specfication J55Ivan DNo ratings yet

- Slabbrochure Baosteel PDFDocument36 pagesSlabbrochure Baosteel PDFKetnipha SukwannawitNo ratings yet

- Stainless Steel 202 Material Chemical CompositionDocument3 pagesStainless Steel 202 Material Chemical CompositionLelka2000No ratings yet

- EN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationDocument5 pagesEN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationNaiduNo ratings yet

- WaterfordDocument12 pagesWaterfordCamilo MorenoNo ratings yet

- 4-1. Hy-Lok Tube Fittings (2020)Document76 pages4-1. Hy-Lok Tube Fittings (2020)bernaNo ratings yet

- Gresham Boiler Manufacturing CompanyDocument5 pagesGresham Boiler Manufacturing CompanymuddassirNo ratings yet

- ASTM B881 17 Standard Terminology Relating To Aluminum and Magnesium Alloy ProductsDocument7 pagesASTM B881 17 Standard Terminology Relating To Aluminum and Magnesium Alloy Products오덕환Oh DuckhwanNo ratings yet

- 3.3 Piping Design Criteria Rev 2Document15 pages3.3 Piping Design Criteria Rev 2Maheswaran KurusamyNo ratings yet

- Working With Boron Steel NovDec 2005Document4 pagesWorking With Boron Steel NovDec 2005Hugo MoraisNo ratings yet

- Bulb Flats BrochureDocument12 pagesBulb Flats BrochureVivek GuptaNo ratings yet

- PART 02 (Steel Sections)Document23 pagesPART 02 (Steel Sections)MohamedMostafaNo ratings yet

- Champak Steel & Engineering Co - Champak Steel & Engineering Co - Champak Steel & Engineering CoDocument54 pagesChampak Steel & Engineering Co - Champak Steel & Engineering Co - Champak Steel & Engineering CoHabli MawardiNo ratings yet

- Astm A182 A182m f904lDocument1 pageAstm A182 A182m f904lestimationNo ratings yet

- A394Document6 pagesA394Armando Yarlaque RamosNo ratings yet

- High Performance Austenitic Welded Stainless Tubular ProductDocument2 pagesHigh Performance Austenitic Welded Stainless Tubular ProductGuido RuizNo ratings yet

- Bushing Type For Drilling JigDocument6 pagesBushing Type For Drilling JigAnonymous 5YMOxVQNo ratings yet

- PNS49Document14 pagesPNS49jbcast86No ratings yet

- Heat Treat 2Document5 pagesHeat Treat 2gawaNo ratings yet

- Cold Rolled Steels - AK SteelDocument8 pagesCold Rolled Steels - AK SteelRuben HernandezNo ratings yet

- ASTM A194 Grade 4: Chemical Composition (Carbon Steel)Document1 pageASTM A194 Grade 4: Chemical Composition (Carbon Steel)manikannanNo ratings yet

- bs1452 Grade 250Document2 pagesbs1452 Grade 250Syed Shoaib RazaNo ratings yet

- ASTM A240/A240M Type 316: Chemical Composition (AISI 316 / 1.4401 / UNS S31600)Document1 pageASTM A240/A240M Type 316: Chemical Composition (AISI 316 / 1.4401 / UNS S31600)sasi00027No ratings yet

- Aalco Metals LTD - Aluminium Alloy 6063 0 Extrusions - 160Document3 pagesAalco Metals LTD - Aluminium Alloy 6063 0 Extrusions - 160umar farooqNo ratings yet

- Air DuctsDocument6 pagesAir DuctsmohamedroyaleyeuaeNo ratings yet

- Const PPT (Reinf. Types)Document21 pagesConst PPT (Reinf. Types)Shefali GoswamiNo ratings yet

- Steel Bars, Carbon, Merchant Quality, M-Grades: Standard Specification ForDocument2 pagesSteel Bars, Carbon, Merchant Quality, M-Grades: Standard Specification Forprajakt_pieNo ratings yet

- Steel Dynamics Bar Book Rev 2 New CoverDocument194 pagesSteel Dynamics Bar Book Rev 2 New CoverNina LazuardiNo ratings yet

- Aluminum Alloy Sheet For Corrugated Aluminum PipeDocument3 pagesAluminum Alloy Sheet For Corrugated Aluminum PipeFRANZ RICHARD SARDINAS MALLCONo ratings yet

- PTM Three and Three CatalogueDocument31 pagesPTM Three and Three CatalogueSalvatore ShwNo ratings yet

- Dalsteel Metals Pty Limited Aluminium Alloy 6063 T6 Extrusions 158Document3 pagesDalsteel Metals Pty Limited Aluminium Alloy 6063 T6 Extrusions 158Zac Francis DaymondNo ratings yet

- Generally The Materials Used For Structures Fall Into The Category of A Welded Steel Structure With Castings As Reinforcement in Critical AreasDocument4 pagesGenerally The Materials Used For Structures Fall Into The Category of A Welded Steel Structure With Castings As Reinforcement in Critical AreasbalajimetturNo ratings yet

- Latest Shipbuilding MaterialsDocument9 pagesLatest Shipbuilding MaterialsAnonymous e3ceN15No ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- KanboardDocument292 pagesKanboardoszemNo ratings yet

- Fudan-Corvinus: Double Degree MbaDocument8 pagesFudan-Corvinus: Double Degree MbaoszemNo ratings yet

- The Growing Ecosystem For Egan Fet Power Conversion: PrologueDocument6 pagesThe Growing Ecosystem For Egan Fet Power Conversion: PrologueoszemNo ratings yet

- The Platform Play: How To Operate Like A Tech CompanyDocument8 pagesThe Platform Play: How To Operate Like A Tech CompanyoszemNo ratings yet

- Who Wins in A 5G World VFDocument13 pagesWho Wins in A 5G World VFoszemNo ratings yet

- DesignWest 2013 GaN SeminarDocument88 pagesDesignWest 2013 GaN SeminaroszemNo ratings yet

- How To Design Multi-Kw Converters For Electric Vehicles Part 4 - Power Factor Correction PDFDocument9 pagesHow To Design Multi-Kw Converters For Electric Vehicles Part 4 - Power Factor Correction PDFoszemNo ratings yet

- WP TimingSyncLTE-TDD LTE-A PDFDocument9 pagesWP TimingSyncLTE-TDD LTE-A PDFoszemNo ratings yet

- InTech-Antennas For AutomobilesDocument16 pagesInTech-Antennas For AutomobilesoszemNo ratings yet

- Minterms PDFDocument5 pagesMinterms PDFoszemNo ratings yet

- Hybrid Fuel Cell Power System For Submersible ApplicationsDocument2 pagesHybrid Fuel Cell Power System For Submersible ApplicationsoszemNo ratings yet

- Training CircularDocument20 pagesTraining CircularSasidhar KatariNo ratings yet

- Thesis Final QuestionnaireDocument2 pagesThesis Final QuestionnaireJarby Vann CapitoNo ratings yet

- Design of Buried Rigid Pipes: StandardsDocument26 pagesDesign of Buried Rigid Pipes: StandardsVarun VermaNo ratings yet

- XyzDocument2 pagesXyzaomltNo ratings yet

- History of SteelDocument79 pagesHistory of SteelChrissa100% (2)

- Defining SponsorshipDocument102 pagesDefining SponsorshipShaun Whatling100% (1)

- Cheat Codes For Pokemon Mystery Dungeon - Explorers of Time On Nintendo DS - Codejunkies US4Document2 pagesCheat Codes For Pokemon Mystery Dungeon - Explorers of Time On Nintendo DS - Codejunkies US4degraded 4resterNo ratings yet

- CORESTIC - 8 (Red) : The ProductDocument1 pageCORESTIC - 8 (Red) : The ProductVikrant KhavateNo ratings yet

- CBH-22-304 Plain Washer Din 434 M12, 16 SelfDocument2 pagesCBH-22-304 Plain Washer Din 434 M12, 16 SelfqualityNo ratings yet

- DDA ReportDocument78 pagesDDA ReporturvashiakshayNo ratings yet

- Controllogix FestoDocument43 pagesControllogix FestoEdwin Ramirez100% (1)

- Form 3Document1 pageForm 3rjvydv0No ratings yet

- BROC MP0 MP0R 902-010 en PDFDocument8 pagesBROC MP0 MP0R 902-010 en PDFJesus De la RosaNo ratings yet

- CFAINTB - Prepare For Interpreting AssignmentsDocument2 pagesCFAINTB - Prepare For Interpreting Assignmentsenrique aNo ratings yet

- Industrial Vacuum: Hose, Tools and AccessoriesDocument12 pagesIndustrial Vacuum: Hose, Tools and AccessoriesedgardomichligNo ratings yet

- ElastomerDocument3 pagesElastomersiswoutNo ratings yet

- 11 Cathay Pacific Steel Corp. v. CADocument16 pages11 Cathay Pacific Steel Corp. v. CAkimNo ratings yet

- Republic V FNCBDocument6 pagesRepublic V FNCBMp Cas100% (1)

- Unveiling Creative Advertising: Top Ad Agencies in Delhi NCR - APPPL COMBINEDocument2 pagesUnveiling Creative Advertising: Top Ad Agencies in Delhi NCR - APPPL COMBINEsairam.appplNo ratings yet

- Defining Your Idea, Product, And/Or Service (1) : Osong Fabrice MakiaDocument1 pageDefining Your Idea, Product, And/Or Service (1) : Osong Fabrice Makiangoufor atemafacNo ratings yet

- Technology and Livelihood Education: Quarter 1 - Module 4: Food ProcessingDocument22 pagesTechnology and Livelihood Education: Quarter 1 - Module 4: Food ProcessingLIEZEL SERONDO75% (4)

- 02-09-2022 Lista Unificada Completa MonoDocument26 pages02-09-2022 Lista Unificada Completa MonoCarlos Jose MorenoNo ratings yet

- Increment - Information DocumentDocument5 pagesIncrement - Information DocumentRavi Rai MarwahNo ratings yet

- Digital Marketing Strategy and Marketing Mix UploadDocument39 pagesDigital Marketing Strategy and Marketing Mix UploadAmisha LalNo ratings yet

- Oracle® Accounts Receivable Deductions Settlement: Implementation Guide Release 12.2Document108 pagesOracle® Accounts Receivable Deductions Settlement: Implementation Guide Release 12.2yadavdevenderNo ratings yet

- DcDesk 2000 - Revision HistoryDocument21 pagesDcDesk 2000 - Revision HistoryVasile GurezNo ratings yet

- Tropical Homes, Inc. vs. National Housing Authority - 1Document4 pagesTropical Homes, Inc. vs. National Housing Authority - 1PNP MayoyaoNo ratings yet

- Control Unit Cerberus FIT FC360 - Addressable Fire Control PanelsDocument2 pagesControl Unit Cerberus FIT FC360 - Addressable Fire Control PanelsMarco LaanNo ratings yet

- Solved - For The Three-Bus System Whose Ybus Is Given, Calculate...Document6 pagesSolved - For The Three-Bus System Whose Ybus Is Given, Calculate...ZabeehullahmiakhailNo ratings yet

Mold Plates: Mold Base Industries, Inc

Mold Plates: Mold Base Industries, Inc

Uploaded by

oszemOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mold Plates: Mold Base Industries, Inc

Mold Plates: Mold Base Industries, Inc

Uploaded by

oszemCopyright:

Available Formats

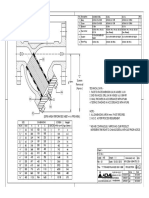

Mold Plates

Mold Plates

Mold Base Industries, Inc.

QUALITY MOLD PLATES MBI # 4 STEEL-FREE GENERAL

MEET CUSTOMERS’ NEEDS MACHINING STAINLESS CHARACTERISTICS

MBI offers a full line of exceptional mold HOLDER BLOCK STEEL MBI #4 Steel is a chromium alloy

plates, clamping plates, ejector plates Holder blocks made from MBI’s pre- which is supplied in the hardened

and spacer blocks in virtually any size up hardened stainless have excellent and tempered condition.

to 40" x 60", all furnished in the same machinability, uniform hardness and MBI #4 Steel is characterized by:

high quality steel grades used in our superior resistance to corrosion, caused ✔ Excellent machinability.

mold sets. Whether you need precision by engineering resins and humid ✔ Good corrosion resistance.

ground plates, semi-finished ground or working or storage conditions. Lower ✔ Uniform hardness in all dimensions.

raw plates, MBI has the materials and production costs are also achieved ✔ Good indentation resistance.

machining services required to meet through greater heat transfer These properties combine to

your needs. We realize our customers from corrosion-free water produce a steel with outstanding

demand quality, and we strive to meet channels. MBI’s pre- production performance.

those demands. hardened stainless The practical benefits of good

Since 1972 MBI has been dedicated to holder block is corrosion resistance in a holder

serving our customers’ needs by offering an AISI 420F steel are:

superior mold plates, custom mold bases (modified) steel pre-heat ✔ Lower mold maintenance costs,

and self-lube components, all at competi- treated to 340 HB for superior quality. e.g., molds stored or operated in humid

tive prices. "Stainless bases are today considered conditions require no special protection.

Our standard grade steels #1 (ASTM A- standard by MBI." ✔ Lower production costs since water

36), #2 (AISI 4130), #3 (modified P-20), cooling channels are unaffected by cor-

#4 (stainless steel holder block) and our rosion, ensuring consistent cycle time.

specialties, such as H-13 and aluminum,

STEEL SPECIFICATIONS

deliver quality products to our customers. (1, 2, 3 and 4 are in stock; other grades are available)

MBI MBI MBI MBI

STEEL SPECIFICATIONS TYPE

No. 1

ASTM

No. 2

MODIFIED

No. 3

MODIFIED

No. 4

STAINLESS

MBI uses only high quality steels in A-36 AISI P-20 STEEL

4130 HOLDER BLOCK

their mold bases and plate items. This HARDNESS 262/321 262/321 340 BRINELL

BHN BHN 37 RC (AVERAGE)

assures reliable mold performance

BASIC ANALYSIS % % % %

whether it be the Basic Number 1, 2, 3 CARBON C .25 MAX .27/.33 .24/.35 0.33

MANGANESE MN .80/1.20 .90/1.30 .75/1.00 1.35

or 4 steels or the specialties such as PHOSPHORUS P .04 MAX .035 MAX .025 MAX ------

H-13, stainless or aluminum. The SULFUR S .05 MAX .04 MAX .005 MAX 0.12

SILICON SI .40 MAX .15/.40 .15/.40 0.35

moldmaker and end user can be CHROMIUM CR ------ .60/.90 .90/1.20 16.7

MOLYBDENUM MO ------ .15/.25 .45/.65 ------

assured of the quality of these steels.

VANADIUM V ------ .02 MIN .04 MIN ------

PROPERTIES OF # 4 STEEL

IMPACT STRENGTH

Approximate values; samples taken from a round bar,

1" diameter. Hardness: 340 Brinell

The practical benefits of the excellent machinability are: Testing temperature: Izod KU

0 0

✔ Lower mold production costs (due to less wear of the 68 F (20 C) ft./lbs. Joules

Impact strength 28 30

cutting edges on the milling and drilling tools) and increased

cutting speed can be used giving shorter machining time. TENSILE STRENGTH

Approximate values; samples taken from a round bar,

APPLICATIONS 1" diameter. Hardness: 340 Brinell

Testing temperature: p.s.i. t.s.i. N/mm2

MBI #4 Steel is primarily intended for holders and bolsters for 0 0

68 F (20 C)

plastic and rubber molds. It provides a completely stainless Tensile strength (Rm) 164000 73.2 1130

mold with high corrosion resistance. Yield strength (Rp 0.2) 134000 59.9 925

Reduction of area (Z%) 32.0

Elongation (A10%) 8.0

HEAT TREATMENT

MBI #4 Steel is intended for use in the as-delivered condition,

MILLING

Carbide tools and Rough Finish

i.e., hardened and tempered to 340 Brinell, 37 Rc (Average). high speed steel tools milling milling

Depth of cut (t) in min. 0.08 max. 0.08

MACHINING mm min. 0.2 max. 0.2

MBI #4 Steel greatly improves machinability compared to Carbide tools

ISO machining group P30 – P40 P10 – P20

conventional AISI 420 steels hardened and tempered to 37 Cutting speed (v) f.p.m. 230 – 330 295 – 380

Rc. With most steelmakers standardizing on sulfur content of m/min. 15 – 30 20 – 35

High speed steel tools

.012 to .015 percent, machinability of these materials is now Cutting speed (v) f.p.m. 50 – 100 65 – 115

significantly improved. m/min. 15 – 30 20 – 35

DRILLING

Depth of hole

Diameter 2xD 6xD 8xD 10xD

in/mm rpm/feed (rev. mm/in)

.08 .06 .05 .04

0.16/4 1720/ 1435/ 1310/ 1190/

.003 .003 .002 .002

.14 .11 .08 .07

0.32/8 1080/ 900/ 820/ 740/

.006 .004 .003 .003

.25 .19 .15 .12

0.64/16 570/ 475/ 435/ 395/

.019 .008 .006 .005

.29 .22 .17 .15

1.0/25 370/ 310/ 285/ 260/

.012 .009 .007 .006

Chip removal is recommended when depth of hole is > 4 x DIA.

Flush cooling should be used.

Mold Base Industries, Inc.

7450 & 7501 Derry Street • Harrisburg, PA 17111-5230

Telephone: 800-241-6656

Manufacturing FAX: 717-564-2250 • Office FAX: 717-564-7705

Internet: www.moldbase.com E-mail: sales@moldbase.com

Mold Base Industries, Inc.

7450 & 7501 Derry Street

Harrisburg, PA 17111-5230

Telephone: 800-241-6656

Manufacturing FAX: 717-564-2250

Office FAX: 717-564-7705

Internet: www.moldbase.com

E-mail: sales@moldbase.com

Made with Quality in the USA

You might also like

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Manual Relé DP-25 (Union Switch & Signal Inc.)Document7 pagesManual Relé DP-25 (Union Switch & Signal Inc.)Raphael MuzziNo ratings yet

- Structural SteelDocument61 pagesStructural SteelRohit 89No ratings yet

- SabicDocument46 pagesSabicdhdfh0% (1)

- Aspac Royalloy enDocument7 pagesAspac Royalloy enNugroho Faris SudrajatNo ratings yet

- Rebar Steel Bar Detail For Grade 1Document29 pagesRebar Steel Bar Detail For Grade 1talatzahoorNo ratings yet

- What Is Rebar?: Grades of Rebar in Different CodesDocument9 pagesWhat Is Rebar?: Grades of Rebar in Different CodesSalih MohayaddinNo ratings yet

- 254SMO 性能Document8 pages254SMO 性能yw_oulalaNo ratings yet

- 254SMO 性能Document8 pages254SMO 性能yw_oulalaNo ratings yet

- Y STRAINER FLANGED END 150 Model PDFDocument1 pageY STRAINER FLANGED END 150 Model PDFsajanchaudhariNo ratings yet

- Astm B224Document4 pagesAstm B224DouglasNo ratings yet

- Technical Specifications For ValvesDocument32 pagesTechnical Specifications For ValvesEr Hussain GhadialiNo ratings yet

- Reinforcing Steel BarsDocument17 pagesReinforcing Steel BarsRonald BilogNo ratings yet

- Aalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFDocument3 pagesAalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFganmosesNo ratings yet

- Wire - Rod - Cold C4CDocument10 pagesWire - Rod - Cold C4CGabriel MesquitaNo ratings yet

- Is 1977Document11 pagesIs 1977rahulmechdceNo ratings yet

- BabbittDocument4 pagesBabbitthrsreenathNo ratings yet

- ASME Weld Number Tables - P Number Base & F Number FillerDocument14 pagesASME Weld Number Tables - P Number Base & F Number FillerChris McNairNo ratings yet

- Ch-07 SteelsDocument20 pagesCh-07 SteelsKHUSHI JAIN100% (1)

- API 5CT Material Specfication J55Document1 pageAPI 5CT Material Specfication J55Ivan DNo ratings yet

- Slabbrochure Baosteel PDFDocument36 pagesSlabbrochure Baosteel PDFKetnipha SukwannawitNo ratings yet

- Stainless Steel 202 Material Chemical CompositionDocument3 pagesStainless Steel 202 Material Chemical CompositionLelka2000No ratings yet

- EN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationDocument5 pagesEN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationNaiduNo ratings yet

- WaterfordDocument12 pagesWaterfordCamilo MorenoNo ratings yet

- 4-1. Hy-Lok Tube Fittings (2020)Document76 pages4-1. Hy-Lok Tube Fittings (2020)bernaNo ratings yet

- Gresham Boiler Manufacturing CompanyDocument5 pagesGresham Boiler Manufacturing CompanymuddassirNo ratings yet

- ASTM B881 17 Standard Terminology Relating To Aluminum and Magnesium Alloy ProductsDocument7 pagesASTM B881 17 Standard Terminology Relating To Aluminum and Magnesium Alloy Products오덕환Oh DuckhwanNo ratings yet

- 3.3 Piping Design Criteria Rev 2Document15 pages3.3 Piping Design Criteria Rev 2Maheswaran KurusamyNo ratings yet

- Working With Boron Steel NovDec 2005Document4 pagesWorking With Boron Steel NovDec 2005Hugo MoraisNo ratings yet

- Bulb Flats BrochureDocument12 pagesBulb Flats BrochureVivek GuptaNo ratings yet

- PART 02 (Steel Sections)Document23 pagesPART 02 (Steel Sections)MohamedMostafaNo ratings yet

- Champak Steel & Engineering Co - Champak Steel & Engineering Co - Champak Steel & Engineering CoDocument54 pagesChampak Steel & Engineering Co - Champak Steel & Engineering Co - Champak Steel & Engineering CoHabli MawardiNo ratings yet

- Astm A182 A182m f904lDocument1 pageAstm A182 A182m f904lestimationNo ratings yet

- A394Document6 pagesA394Armando Yarlaque RamosNo ratings yet

- High Performance Austenitic Welded Stainless Tubular ProductDocument2 pagesHigh Performance Austenitic Welded Stainless Tubular ProductGuido RuizNo ratings yet

- Bushing Type For Drilling JigDocument6 pagesBushing Type For Drilling JigAnonymous 5YMOxVQNo ratings yet

- PNS49Document14 pagesPNS49jbcast86No ratings yet

- Heat Treat 2Document5 pagesHeat Treat 2gawaNo ratings yet

- Cold Rolled Steels - AK SteelDocument8 pagesCold Rolled Steels - AK SteelRuben HernandezNo ratings yet

- ASTM A194 Grade 4: Chemical Composition (Carbon Steel)Document1 pageASTM A194 Grade 4: Chemical Composition (Carbon Steel)manikannanNo ratings yet

- bs1452 Grade 250Document2 pagesbs1452 Grade 250Syed Shoaib RazaNo ratings yet

- ASTM A240/A240M Type 316: Chemical Composition (AISI 316 / 1.4401 / UNS S31600)Document1 pageASTM A240/A240M Type 316: Chemical Composition (AISI 316 / 1.4401 / UNS S31600)sasi00027No ratings yet

- Aalco Metals LTD - Aluminium Alloy 6063 0 Extrusions - 160Document3 pagesAalco Metals LTD - Aluminium Alloy 6063 0 Extrusions - 160umar farooqNo ratings yet

- Air DuctsDocument6 pagesAir DuctsmohamedroyaleyeuaeNo ratings yet

- Const PPT (Reinf. Types)Document21 pagesConst PPT (Reinf. Types)Shefali GoswamiNo ratings yet

- Steel Bars, Carbon, Merchant Quality, M-Grades: Standard Specification ForDocument2 pagesSteel Bars, Carbon, Merchant Quality, M-Grades: Standard Specification Forprajakt_pieNo ratings yet

- Steel Dynamics Bar Book Rev 2 New CoverDocument194 pagesSteel Dynamics Bar Book Rev 2 New CoverNina LazuardiNo ratings yet

- Aluminum Alloy Sheet For Corrugated Aluminum PipeDocument3 pagesAluminum Alloy Sheet For Corrugated Aluminum PipeFRANZ RICHARD SARDINAS MALLCONo ratings yet

- PTM Three and Three CatalogueDocument31 pagesPTM Three and Three CatalogueSalvatore ShwNo ratings yet

- Dalsteel Metals Pty Limited Aluminium Alloy 6063 T6 Extrusions 158Document3 pagesDalsteel Metals Pty Limited Aluminium Alloy 6063 T6 Extrusions 158Zac Francis DaymondNo ratings yet

- Generally The Materials Used For Structures Fall Into The Category of A Welded Steel Structure With Castings As Reinforcement in Critical AreasDocument4 pagesGenerally The Materials Used For Structures Fall Into The Category of A Welded Steel Structure With Castings As Reinforcement in Critical AreasbalajimetturNo ratings yet

- Latest Shipbuilding MaterialsDocument9 pagesLatest Shipbuilding MaterialsAnonymous e3ceN15No ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- KanboardDocument292 pagesKanboardoszemNo ratings yet

- Fudan-Corvinus: Double Degree MbaDocument8 pagesFudan-Corvinus: Double Degree MbaoszemNo ratings yet

- The Growing Ecosystem For Egan Fet Power Conversion: PrologueDocument6 pagesThe Growing Ecosystem For Egan Fet Power Conversion: PrologueoszemNo ratings yet

- The Platform Play: How To Operate Like A Tech CompanyDocument8 pagesThe Platform Play: How To Operate Like A Tech CompanyoszemNo ratings yet

- Who Wins in A 5G World VFDocument13 pagesWho Wins in A 5G World VFoszemNo ratings yet

- DesignWest 2013 GaN SeminarDocument88 pagesDesignWest 2013 GaN SeminaroszemNo ratings yet

- How To Design Multi-Kw Converters For Electric Vehicles Part 4 - Power Factor Correction PDFDocument9 pagesHow To Design Multi-Kw Converters For Electric Vehicles Part 4 - Power Factor Correction PDFoszemNo ratings yet

- WP TimingSyncLTE-TDD LTE-A PDFDocument9 pagesWP TimingSyncLTE-TDD LTE-A PDFoszemNo ratings yet

- InTech-Antennas For AutomobilesDocument16 pagesInTech-Antennas For AutomobilesoszemNo ratings yet

- Minterms PDFDocument5 pagesMinterms PDFoszemNo ratings yet

- Hybrid Fuel Cell Power System For Submersible ApplicationsDocument2 pagesHybrid Fuel Cell Power System For Submersible ApplicationsoszemNo ratings yet

- Training CircularDocument20 pagesTraining CircularSasidhar KatariNo ratings yet

- Thesis Final QuestionnaireDocument2 pagesThesis Final QuestionnaireJarby Vann CapitoNo ratings yet

- Design of Buried Rigid Pipes: StandardsDocument26 pagesDesign of Buried Rigid Pipes: StandardsVarun VermaNo ratings yet

- XyzDocument2 pagesXyzaomltNo ratings yet

- History of SteelDocument79 pagesHistory of SteelChrissa100% (2)

- Defining SponsorshipDocument102 pagesDefining SponsorshipShaun Whatling100% (1)

- Cheat Codes For Pokemon Mystery Dungeon - Explorers of Time On Nintendo DS - Codejunkies US4Document2 pagesCheat Codes For Pokemon Mystery Dungeon - Explorers of Time On Nintendo DS - Codejunkies US4degraded 4resterNo ratings yet

- CORESTIC - 8 (Red) : The ProductDocument1 pageCORESTIC - 8 (Red) : The ProductVikrant KhavateNo ratings yet

- CBH-22-304 Plain Washer Din 434 M12, 16 SelfDocument2 pagesCBH-22-304 Plain Washer Din 434 M12, 16 SelfqualityNo ratings yet

- DDA ReportDocument78 pagesDDA ReporturvashiakshayNo ratings yet

- Controllogix FestoDocument43 pagesControllogix FestoEdwin Ramirez100% (1)

- Form 3Document1 pageForm 3rjvydv0No ratings yet

- BROC MP0 MP0R 902-010 en PDFDocument8 pagesBROC MP0 MP0R 902-010 en PDFJesus De la RosaNo ratings yet

- CFAINTB - Prepare For Interpreting AssignmentsDocument2 pagesCFAINTB - Prepare For Interpreting Assignmentsenrique aNo ratings yet

- Industrial Vacuum: Hose, Tools and AccessoriesDocument12 pagesIndustrial Vacuum: Hose, Tools and AccessoriesedgardomichligNo ratings yet

- ElastomerDocument3 pagesElastomersiswoutNo ratings yet

- 11 Cathay Pacific Steel Corp. v. CADocument16 pages11 Cathay Pacific Steel Corp. v. CAkimNo ratings yet

- Republic V FNCBDocument6 pagesRepublic V FNCBMp Cas100% (1)

- Unveiling Creative Advertising: Top Ad Agencies in Delhi NCR - APPPL COMBINEDocument2 pagesUnveiling Creative Advertising: Top Ad Agencies in Delhi NCR - APPPL COMBINEsairam.appplNo ratings yet

- Defining Your Idea, Product, And/Or Service (1) : Osong Fabrice MakiaDocument1 pageDefining Your Idea, Product, And/Or Service (1) : Osong Fabrice Makiangoufor atemafacNo ratings yet

- Technology and Livelihood Education: Quarter 1 - Module 4: Food ProcessingDocument22 pagesTechnology and Livelihood Education: Quarter 1 - Module 4: Food ProcessingLIEZEL SERONDO75% (4)

- 02-09-2022 Lista Unificada Completa MonoDocument26 pages02-09-2022 Lista Unificada Completa MonoCarlos Jose MorenoNo ratings yet

- Increment - Information DocumentDocument5 pagesIncrement - Information DocumentRavi Rai MarwahNo ratings yet

- Digital Marketing Strategy and Marketing Mix UploadDocument39 pagesDigital Marketing Strategy and Marketing Mix UploadAmisha LalNo ratings yet

- Oracle® Accounts Receivable Deductions Settlement: Implementation Guide Release 12.2Document108 pagesOracle® Accounts Receivable Deductions Settlement: Implementation Guide Release 12.2yadavdevenderNo ratings yet

- DcDesk 2000 - Revision HistoryDocument21 pagesDcDesk 2000 - Revision HistoryVasile GurezNo ratings yet

- Tropical Homes, Inc. vs. National Housing Authority - 1Document4 pagesTropical Homes, Inc. vs. National Housing Authority - 1PNP MayoyaoNo ratings yet

- Control Unit Cerberus FIT FC360 - Addressable Fire Control PanelsDocument2 pagesControl Unit Cerberus FIT FC360 - Addressable Fire Control PanelsMarco LaanNo ratings yet

- Solved - For The Three-Bus System Whose Ybus Is Given, Calculate...Document6 pagesSolved - For The Three-Bus System Whose Ybus Is Given, Calculate...ZabeehullahmiakhailNo ratings yet