Professional Documents

Culture Documents

Report Rollcage

Report Rollcage

Uploaded by

Ajit ShindeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Report Rollcage

Report Rollcage

Uploaded by

Ajit ShindeCopyright:

Available Formats

Documentation for Roll Cage

Refer rule A7.3.1 Failure to meet the deadlines. PG: 8; Rule book revision no: 00

The roll cage design details submission guidelines :

o Complete roll cage only, JPG images in minimum 3 sides (front, side and rear) &

Isometric view.

o Standard 2D drawing softcopy for complete roll cage along with driver-cockpit and

engine compartment. It should clearly show the position of seat, pedal, gear shifter,

fire extinguisher, seat belt, steering, engine, fuel tank, drive shafts.

o Material strength calculation sheet for selection of primary and secondary members

(if it’s other than SAE 1018). It should give Yield strength, Bending Stiffness etc.

o Material test report from college/accredited lab which describes both the chemical

and physical properties. Material report from tube supplier and invoice copy.

o CAE analysis by 3D evaluation method for various impacts in crash /roll over

conditions.

Submission targets :

o Your report in soft copy should be mailed to the zonal leaders assigned from technical

mentor group. (mail id to be mentioned).

o The report should reach on or before 23th of October 2017 by 5pm.

o The reply for the normal design considerations will be provided by lead mentor or

mentor assigned for the respective college. The reply will be given by mail in a week’s

time, before end of the 29th October 2017.

o The feedback on non-compliance need to be corrected and reverted back within 7

days of the feedback. The team needs to submit only the corrected portion and not

the complete file in this case as mentioned above.

o In case of any doubts, you are requested to contact zonal lead mentor or your

assigned mentor.

o By 15th November 2017, teams should target to complete drivable vehicle and make

more validation.

o Non submission of report is considered for case of disqualification and team need

not prepare and participate anymore this year.

Local Technical Inspection Requirements by 01 Jan 18:

o The weld joints and its test reports are to be made available.

o Manufacture proof for the roll cage welding, fixtures and templates made, drawings

used for development and bending of the tubes and photographs for work carried out

are required to be made available.

Note 1: All these reports in original copies are required to be carried at event location as well.

Note 2: Teams participating at IIT-Roper will also need to follow the same timeline for submission of

documents for roll cage design verification. In reality, team should target to complete the buggy on

wheels by 15 Nov 2017 and then continue design validation in the next 2 months. For Roper teams

will get more time for practice and long validation of the buggy in terms of quality& ruggedness.

1 | BAJA SAEINDIA 2018 I Rollcage Document

Baja SAEINDIA Frame Pre-Check &

Template

College Name:

Team ID:

Instructions: -

Part 1) GEOMETRY TEMPLATE

Insert 2D engineering drawings/CAD renderings of your frame in the following standard views: -

1. Front

2. Side

3. Top

4. Isometric X 2 (1 primary + 1 secondary)

The drawings should note the major dimensions and angles required to meet the frame rules

in B7.3 as specified in the below mentioned diagram and as per NOTE* given.

Part 2) DESIGN PRE-CHECK

In this part, insert the following information as a screenshot, photo, or scanned image. Add as

many pages are necessary; please make sure that your information is CLEAR and READABLE!

– Roll Cage Specification Sheet

– You do NOT need to specify the car number or competitions on this pre-check form

– You do NOT need signatures on this pre-check form

– The above two items are needed on the paper copy that you bring to the competition.

– Frame Material Documentation

– Invoice of roll cage material

– Material Test of Certification (Mechanical & Chemical Properties)

Submitting this Document: -

When you are ready to submit this document, print/convert it to PDF format; the maximum

acceptable file size is 10 MB.

Mail the document to bajatechteam@saeindia.org before the specified deadline.

Format: Team ID_Rollcage check sheet (Ex: 18549_Rollcage check sheet)

The Technical Inspection Team will review your submission and mark it as “Accepted” or “Rejected”

on the bajasaeindia forum. Questions or feedback will be provided for rejected submissions.

2 | BAJA SAEINDIA 2018 I Rollcage Document

Material Specifications –

TABLE 1: DIMENSIONS FOR PRIMARY MEMBERS MATERIAL

Material

Cross section of tube

Thickness

Outer Dimension of tube

Bending Strength

Bending Stiffness

Application in (eg RRH, FLC etc)

TABLE 2: DIMENSIONS FOR SECONDARY MEMBERS MATERIAL

Material

Cross section of tube

Thickness

Outer Dimension of tube

Bending Strength

Bending Stiffness

Application in (eg SIM, FAB etc)

3 | BAJA SAEINDIA 2018 I Rollcage Document

Supporting Calculations (If applicable)

4 | BAJA SAEINDIA 2018 I Rollcage Document

Roll Cage Spec Sheet

5 | BAJA SAEINDIA 2018 I Rollcage Document

Material Invoice: -

6 | BAJA SAEINDIA 2018 I Rollcage Document

Material Certification(s): -

The following document should clearly define the chemical composition of the material used for the

roll cage along with the report from Govt. Approved Laboratory.

7 | BAJA SAEINDIA 2018 I Rollcage Document

Dimensions of roll cage

TABLE 3: DIMENSIONS OF ROLL CAGE

S.N. Description of the rule Dimension Unit

value

1 Inclination of RRH from vertical

2 Width of the RRH, measured at a point 686 mm (27 in.) above the inside

seat bottom is

3 Width of the RRH measured at a point 355.6 mm (14 in.) above the seat

bottom is

4 Length of ALC member is

5 No of diagonal bracing in RRH is

6 The top intersection of the LDB members and the RRH vertical members

is

7 The bottom intersections of the LDB members and the RRH vertical

members is

8 The angle between the LDB members and the RRH vertical members is

9 Points CR and CL of RHO is ____ forward of a point, in the vehicle’s

elevation view defined by the intersection of the RHO members and a

vertical line rising from the after end of the seat.

10 Points CR and CL is ____ lower than the top edge of the template

11 The SIM height above the seat bottom is

12 The angle between the FBMUP and the vertical is

13 Unsupported length of FAB members is

14 The intersection with the FBMUP members measured as a straight-line

distance from centerline to centerline of points C is at ___ (refer fig 25)

15 Attachment of rear bracing with system FAB is at _______ of Point B

(refer fig 25)

TABLE 4: APPLICABLE ONLY FOR BOLTED ROLLCAGE

S.N. Description of the rule Dimension Unit

value

1 Thickness of the flanges used for the joints is

2 Minimum radius of the flange used in tube frame is

3 Maximum gap between the flanges before tightening is

4 Minimum no of bolts in any flange in tube frame is

5 Minimum diameter of the bolt in any flange is

6 The distance between the bolt hole and edge of the flange is

NOTE: - Also fill the above-mentioned roll cage dimensions in the following images in the

boxes specifically designated for each dimension in the roll cage.

8 | BAJA SAEINDIA 2018 I Rollcage Document

Front View

14

8

Show that RRH width > 32

inches at 14 “above seat

Seat surface

9 | BAJA SAEINDIA 2018 I Rollcage Document

Side View

13

15

1 12

11

10 | BAJA SAEINDIA 2018 I Rollcage Document

Top View

NOTE*:-With the above given details, also add details like Max length, Width & Height of vehicle.

Details of Angle between RRH, RHO to FAB/FBM. This details should be added in front, side or top

view where ever they can be conveniently shown.

11 | BAJA SAEINDIA 2018 I Rollcage Document

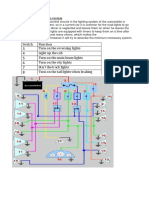

Isometric View

Add 2 images of your roll cage in the isometric view: -

1) Showing the primary members in color coding specified below: -

2) Showing the secondary members in color coding specified below: -

12 | BAJA SAEINDIA 2018 I Rollcage Document

You might also like

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Small Block Chevrolet: Stock and High-Performance RebuildsFrom EverandSmall Block Chevrolet: Stock and High-Performance RebuildsRating: 4 out of 5 stars4/5 (14)

- Script Creation For A 2D Airfoil Meshing Using ICEM CFD On ANSYSDocument30 pagesScript Creation For A 2D Airfoil Meshing Using ICEM CFD On ANSYSSungki JungNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- #08207A: Customer Satisfaction - Sunroof Water Leak - Install Drain Tube Extensions - (Sep 15, 2008)Document12 pages#08207A: Customer Satisfaction - Sunroof Water Leak - Install Drain Tube Extensions - (Sep 15, 2008)lamping_ap100% (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- 11126-574002-EAT342 Hydraulically Powered Block Lifter INT MODERATED PDFDocument8 pages11126-574002-EAT342 Hydraulically Powered Block Lifter INT MODERATED PDFsaqibNo ratings yet

- Design Index PDC PDFDocument2 pagesDesign Index PDC PDFrdos14No ratings yet

- Toca NGTC Build Manual 01-02-12Document22 pagesToca NGTC Build Manual 01-02-12Periclesleite100% (1)

- Mech Design 2 - JEDR Assignment and Quiz Autumn 2019Document20 pagesMech Design 2 - JEDR Assignment and Quiz Autumn 2019Saurabh GuptaNo ratings yet

- Gauge StandardsDocument12 pagesGauge StandardsHector Martinez100% (1)

- Ijet V5i1p24Document10 pagesIjet V5i1p24SakthiNo ratings yet

- Johnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Metal Stamping Dies - Gage Standards December, 2012Document31 pagesJohnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Metal Stamping Dies - Gage Standards December, 2012Anonymous 7ZTcBnNo ratings yet

- Drawing StandardsDocument12 pagesDrawing StandardsAgung Bayu100% (1)

- ME465 - Major Course Project - Fall 2019Document2 pagesME465 - Major Course Project - Fall 2019Abdul BariNo ratings yet

- Grant Prideco Rotary Shoulder HandbookDocument112 pagesGrant Prideco Rotary Shoulder Handbookrlk2806No ratings yet

- 212 Asb 08 130Document7 pages212 Asb 08 130Walberto PachecoNo ratings yet

- Baja SAE Tech Inspection Sheet 2014-2015Document12 pagesBaja SAE Tech Inspection Sheet 2014-2015FoureyeddjNo ratings yet

- Sae J58-2015Document9 pagesSae J58-2015levanhuongNo ratings yet

- 6719-Design Report For Abutments A 1 & A2-BR 5 (R1) PDFDocument29 pages6719-Design Report For Abutments A 1 & A2-BR 5 (R1) PDFHasantha PereraNo ratings yet

- Observation On Design and Drawing of Widening Box Culverts (Straight & Skew) and Miscellaneous Drawings Reg LTR DT - 31-07-2020Document14 pagesObservation On Design and Drawing of Widening Box Culverts (Straight & Skew) and Miscellaneous Drawings Reg LTR DT - 31-07-2020Vikas SharmaNo ratings yet

- Pile Driving Guidelines: EquipmentDocument5 pagesPile Driving Guidelines: EquipmentSean CrossNo ratings yet

- Aerospace Assembly Task REF - DEFDocument9 pagesAerospace Assembly Task REF - DEFazeem sheikhNo ratings yet

- Stress Analysis of GRP - GRE - FRP Piping System Using Caesar II - What Is PipingDocument23 pagesStress Analysis of GRP - GRE - FRP Piping System Using Caesar II - What Is PipingHazimNo ratings yet

- Me 8381 Lab ManualDocument36 pagesMe 8381 Lab ManualMohanraj SubramaniNo ratings yet

- Engine Design ProjectDocument1 pageEngine Design ProjectHenry SantosNo ratings yet

- Protastructure Design Guide Beam Column Joint Shear Design Nbci 2016Document14 pagesProtastructure Design Guide Beam Column Joint Shear Design Nbci 2016chong fung yunNo ratings yet

- ME5013 Assignment Section A-2014 PDFDocument5 pagesME5013 Assignment Section A-2014 PDFJanLuiz2015No ratings yet

- Department of Structural Engineering University of California San DiegoDocument6 pagesDepartment of Structural Engineering University of California San DiegomimiNo ratings yet

- 2 - Technical Specification - 66 KV C R PANELS - R4Document71 pages2 - Technical Specification - 66 KV C R PANELS - R4gohilnarendra100% (1)

- James Walker o Ring GuideDocument32 pagesJames Walker o Ring Guidecvishwas1159No ratings yet

- Se TLPC TN 3746 Gi Bolts Spec PQRDocument13 pagesSe TLPC TN 3746 Gi Bolts Spec PQRMl JainNo ratings yet

- Ni 2366Document8 pagesNi 2366marguepaNo ratings yet

- DS-1 Volume 4 Addendum PDFDocument15 pagesDS-1 Volume 4 Addendum PDFMuhammad Bilal KhattakNo ratings yet

- A Regular ASME Design Checklist - Deconeq Engineering GroupDocument3 pagesA Regular ASME Design Checklist - Deconeq Engineering GroupAmit SharmaNo ratings yet

- Metals Stamping GlobalDocument40 pagesMetals Stamping GlobalMostafa Abd El AlemNo ratings yet

- Manipallavan SS 2014 - ModDocument36 pagesManipallavan SS 2014 - ModmanipallavanNo ratings yet

- Reuse and Salvage Guidelines - Specifications For Crankshafts in 3000 To 3400 and D-Series EnginesDocument38 pagesReuse and Salvage Guidelines - Specifications For Crankshafts in 3000 To 3400 and D-Series EnginesJuan Pujol100% (2)

- 181103-CCECC-MAX-DCRP-BR-18-F-0439 Resubmission of Method Statment For Cast-in-Place Concrete Pilot Piles Construciton (500mm Dia. & 600mm Dia) For Stations & BuildingsDocument69 pages181103-CCECC-MAX-DCRP-BR-18-F-0439 Resubmission of Method Statment For Cast-in-Place Concrete Pilot Piles Construciton (500mm Dia. & 600mm Dia) For Stations & BuildingsArman ShohelNo ratings yet

- Requirement Specifications For A Painting RobotDocument8 pagesRequirement Specifications For A Painting RobotMunzir ZafarNo ratings yet

- Semester 1 ERP System Skills Exam December 2022Document6 pagesSemester 1 ERP System Skills Exam December 2022armaan ryanNo ratings yet

- 2009 Bendix Ppap Requirements Guidelines Rev 1-9-2009Document60 pages2009 Bendix Ppap Requirements Guidelines Rev 1-9-2009BussborgNo ratings yet

- Tata Motors Case StudyDocument35 pagesTata Motors Case StudyGokulraju Rangasamy100% (2)

- PQC Design Tunnel PTLGDocument31 pagesPQC Design Tunnel PTLGrao shoaibNo ratings yet

- Automotive Trims Design - Advanced Structures IndiaDocument7 pagesAutomotive Trims Design - Advanced Structures IndiaMuthu KumarNo ratings yet

- Gasket CalculatorDocument24 pagesGasket Calculatorवैभव धुरीNo ratings yet

- MCC Design GuideDocument53 pagesMCC Design GuideOmar YoushimatzNo ratings yet

- Converting Design To PrototypeDocument4 pagesConverting Design To PrototypeRrdbjdNo ratings yet

- Stress Analysis of GRP GRE FRP Piping System Using Caesar IIDocument5 pagesStress Analysis of GRP GRE FRP Piping System Using Caesar IIiaftNo ratings yet

- Universidad de Oriente SEF 2009Document5 pagesUniversidad de Oriente SEF 2009DevilSzexNo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Document19 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Mohamed AtefNo ratings yet

- James Walker - O RingsDocument32 pagesJames Walker - O RingsJaime OroNo ratings yet

- Performance-Based Road Maintenance Contracts in the CAREC RegionFrom EverandPerformance-Based Road Maintenance Contracts in the CAREC RegionNo ratings yet

- Engineering Service Revenues World Summary: Market Values & Financials by CountryFrom EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- Springs Heavy Gauge World Summary: Market Values & Financials by CountryFrom EverandSprings Heavy Gauge World Summary: Market Values & Financials by CountryNo ratings yet

- Japan Car Database by Teoalida SAMPLEDocument50 pagesJapan Car Database by Teoalida SAMPLEJayath BogahawatteNo ratings yet

- Port User Manual BahrainDocument107 pagesPort User Manual BahrainJavier Alejandro Calbun LetelierNo ratings yet

- Project Methodology For Summer InternshipDocument2 pagesProject Methodology For Summer InternshipabhijitnadangeNo ratings yet

- Pont Dalle en Béton Armé (Solid Slab Bridge) I. Hypothèse StructureDocument5 pagesPont Dalle en Béton Armé (Solid Slab Bridge) I. Hypothèse Structureken koemhongNo ratings yet

- Phylon Freight Bulk Freighter/BFF-1 Series (Modified)Document1 pagePhylon Freight Bulk Freighter/BFF-1 Series (Modified)Dan ChristensenNo ratings yet

- Dry Port eDocument59 pagesDry Port eBakalcha mediaNo ratings yet

- Car Filter Price MannDocument36 pagesCar Filter Price MannB Sathish BabuNo ratings yet

- Biển BáoDocument9 pagesBiển BáoThanh ThanhNo ratings yet

- A STUDY OF BARGE HULL FOMS - Robert Taggart 1956Document20 pagesA STUDY OF BARGE HULL FOMS - Robert Taggart 1956Fernando Raúl LADINONo ratings yet

- 10 1 1 554 2000Document7 pages10 1 1 554 2000Amir Ali JanbakhshNo ratings yet

- Raveling in Road Projects Causes and Remedies BY ASSOCIATEDINFODocument8 pagesRaveling in Road Projects Causes and Remedies BY ASSOCIATEDINFOSuryavenkat RaghavanNo ratings yet

- Forklift Operator ManualDocument23 pagesForklift Operator ManualCris SuyamNo ratings yet

- Atis SentencesDocument3 pagesAtis Sentences이지수(사범대학 교육공학과)No ratings yet

- PKK88EDocument2 pagesPKK88EDody NovriansyahNo ratings yet

- Flight Controls: System Normal Secondary DirectDocument5 pagesFlight Controls: System Normal Secondary Directdr.wasni100% (1)

- V3.sia1 - .25.analysis and Design Updation of Aerial Monocable Ropeway Conveyors For Eliminating Recurring Failures and DowntimesDocument12 pagesV3.sia1 - .25.analysis and Design Updation of Aerial Monocable Ropeway Conveyors For Eliminating Recurring Failures and DowntimesTarunNo ratings yet

- The Battle of The HydaspesDocument4 pagesThe Battle of The HydaspesvademecumdevallyNo ratings yet

- Location RECCE: London E1 4LJDocument6 pagesLocation RECCE: London E1 4LJsimiNo ratings yet

- Part Number Retrieval: A Part Number and A Price May Be Changed Without A Preliminary AnnouncementDocument1 pagePart Number Retrieval: A Part Number and A Price May Be Changed Without A Preliminary AnnouncementMiguel CerdaNo ratings yet

- Girt7012 Iss 1Document70 pagesGirt7012 Iss 1Teklu Abebe WoldeNo ratings yet

- Automotive Lighting SystemDocument4 pagesAutomotive Lighting SystemWilson Acosta Liñan100% (1)

- Jet EngineDocument8 pagesJet EngineJustin CebrianNo ratings yet

- Normal Procedures 737-NgDocument101 pagesNormal Procedures 737-NgAllan Mucken100% (1)

- Report GurdeepDocument42 pagesReport GurdeepRitesh Agrawal100% (1)

- Ballast Water Treatment Using Electrochemical Disinfection TechnologyDocument233 pagesBallast Water Treatment Using Electrochemical Disinfection TechnologySupun KariyawasamNo ratings yet

- D2Z India - Industry Assessment - Product LandscapeDocument26 pagesD2Z India - Industry Assessment - Product LandscapeSidharth MaheshNo ratings yet

- VFR TripkitDocument94 pagesVFR TripkitAndres HeisterkampNo ratings yet

- Genral Final With New Questions To READDocument83 pagesGenral Final With New Questions To READRobin HillsonNo ratings yet

- New Double Coin TBR CatelogueDocument55 pagesNew Double Coin TBR CatelogueJose Andres Jimenez CasallasNo ratings yet

- Impact of Digital Technology On Urban SpacesDocument7 pagesImpact of Digital Technology On Urban SpacesJacksonNo ratings yet