Professional Documents

Culture Documents

Work Instruction For Straightness Testing: To Cover CDT TUBE

Work Instruction For Straightness Testing: To Cover CDT TUBE

Uploaded by

Neeraj SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Instruction For Straightness Testing: To Cover CDT TUBE

Work Instruction For Straightness Testing: To Cover CDT TUBE

Uploaded by

Neeraj SinghCopyright:

Available Formats

DOC. NO.

: WI-QA-13

WORK INSTRUCTION FOR STRAIGHTNESS TESTING Rev/dat : 02/17.07.2018

Page no : 1 of 1

1 OBJECTIVE : To maintain the procedure of straightness Testing of Tube

2 SCOPE : To cover CDT TUBE

3 RESPONSIBILITY : Quality Assurance.

Sr. No. ACTIVITY DOC No. RESP.

1 Check the straightness of the tube at the time of machine set up approval QF/QA/CD/03 QA SUPERVISOR

2 After machine set up approval, check the straightness after every two hrs. QA CHECKER

3 Straightness testing procedure - QA CHECKER

3.1 Select the randam sample of 600 mm length from centre of length of tube - QA CHECKER

3.2 Deburing the ends of tube or remove the burs from ends by emery paper - QA CHECKER

3.3 The total tolerance (maximum curvature )of any point in total length of - QA CHECKER

tube is determined by rolling the tube on surface plate and measuring

the curvature with feeler gauge

3.4 Take three readings of curvature deviation with feeler gauge at zero degree - QA CHECKER

o

and three readings at 90 rotation of tube on surface plate

1 st reading - at 10 mm from one end

2 nd reading - at 10 mm from 2nd end

3 rd reading - at centre of tube

3.5 Record the maximum value of six reading taken for curvature deviation in QF/QA/CD/03 QA CHECKER

tube inspection report

4 Acceptance Criteria - QA SUPERVISOR

Tubes shall not deviate from straightness by more then 1/600 of any length

measured at the centre of that length ( IS 3074 : 2005) - QA CHECKER

4.1 Required accuracy criteria for surface plate. QF/QA/08 QA CHECKER

flatness daviation for grade 0 surface plate = 3.5 microns

Calibration error (as per calibarion certificate) = 9.3 microns (say )

Observed value after verification of calibration error.

Observed value450 (say) +3.5 +9.5 = 463 microns

4.2 Accept the lot of observed deviation less than =1 mm (1000 microns) - QA CHECKER

5 Monitor data recorded in tube inspection report and tube inspection report QF/QA/CD/03 QA SUPERVISOR

to be signed

6 Ensure callibration of feeler guage and surface plate QA SUPERVISOR

Prepared By Approved By

You might also like

- Kyocera TA-3051ci 3551ci 4551ci 5551ci Service Manual Rev.6Document1,375 pagesKyocera TA-3051ci 3551ci 4551ci 5551ci Service Manual Rev.6James96% (28)

- UT Procedure Rev.0Document32 pagesUT Procedure Rev.0Goutam Kumar Deb100% (2)

- Non Destructive Testing Procedure UT, RT, MT, PT (ASME)Document63 pagesNon Destructive Testing Procedure UT, RT, MT, PT (ASME)Irvan Maruli100% (2)

- Leak Test Procedure PDFDocument6 pagesLeak Test Procedure PDFanon_456282505100% (3)

- Test Certificate: Ferro Steel SolutionDocument1 pageTest Certificate: Ferro Steel SolutionNeeraj Singh80% (5)

- CB Testing and Commissioning 76-92 PDFDocument17 pagesCB Testing and Commissioning 76-92 PDFVijaya Kumar100% (2)

- List of Critical Spares (Mechanical)Document15 pagesList of Critical Spares (Mechanical)Neeraj SinghNo ratings yet

- Work Experience Reflection Example PDFDocument2 pagesWork Experience Reflection Example PDFChesna Mae Javellana AmanteNo ratings yet

- Steel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Final Inspection of PipesDocument7 pagesSteel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Final Inspection of PipesmahendraNo ratings yet

- 1744 - UT PROCEDURE (For Final) PDFDocument27 pages1744 - UT PROCEDURE (For Final) PDFpvdang8453100% (1)

- A Sam: Ultrasonic Inspection ProcedureDocument6 pagesA Sam: Ultrasonic Inspection ProcedureTokoKueAmelaCookis100% (1)

- UT ProcedureDocument14 pagesUT Procedureshifa0% (1)

- General Procedure For Ultrasonic Examination ProcedureDocument28 pagesGeneral Procedure For Ultrasonic Examination ProceduredrakeNo ratings yet

- LNG-80-100937-RA-6065-00023-0000 HT PipingDocument7 pagesLNG-80-100937-RA-6065-00023-0000 HT PipingMohammad AftabNo ratings yet

- Ultrasonic Inspection Procedure For Complete Joint Penetration (CJP) Welds in A T-JointDocument9 pagesUltrasonic Inspection Procedure For Complete Joint Penetration (CJP) Welds in A T-JointPierpaolo AparoNo ratings yet

- Procedure Pneumatic TestDocument4 pagesProcedure Pneumatic TestSalman Khan100% (1)

- Dimensional Control ProcedureDocument12 pagesDimensional Control ProcedureBethel NdifonNo ratings yet

- MSAE014-QC-PRE-035-Quality Procedure For Hydrostatic TestingDocument12 pagesMSAE014-QC-PRE-035-Quality Procedure For Hydrostatic Testingqamar qateebNo ratings yet

- DN Wind Systems India Pvt. LTD.: Ultrasonic Procedure FOR Wind Mill TowerDocument23 pagesDN Wind Systems India Pvt. LTD.: Ultrasonic Procedure FOR Wind Mill TowermaheshNo ratings yet

- Calibration Procedure - Pressure Test Transducers For API Specification 6A ApplicationsDocument5 pagesCalibration Procedure - Pressure Test Transducers For API Specification 6A Applicationsvinsensius rasaNo ratings yet

- Calibration Procedure: 1-PurposeDocument5 pagesCalibration Procedure: 1-PurposeHassan SleemNo ratings yet

- TWI-UT-Forgings Procedure For Level 3Document9 pagesTWI-UT-Forgings Procedure For Level 3willypumphandle_5309100% (1)

- 1463-Q871-1-006 04PG1009 PDFDocument45 pages1463-Q871-1-006 04PG1009 PDFpaolaNo ratings yet

- Welded Pipes Made of Thermomechanically Rolled Materials 7Document1 pageWelded Pipes Made of Thermomechanically Rolled Materials 7qc_531040655No ratings yet

- Procedure For Ultrasonic Examination of Clad PlatesDocument8 pagesProcedure For Ultrasonic Examination of Clad PlatesJYOTI RANJAN BISWALNo ratings yet

- Drift 005Document4 pagesDrift 005tofa01100% (1)

- NDT-SA-SATORP-UT-60, Rev00, Date 15 Aug-2023Document20 pagesNDT-SA-SATORP-UT-60, Rev00, Date 15 Aug-2023Md Abu Hanif RajuNo ratings yet

- QP180 CrimpingDocument8 pagesQP180 Crimpingqualitycontrol3116100% (1)

- Receipt Inspection NS2A4Document11 pagesReceipt Inspection NS2A4islam atifNo ratings yet

- Ut - Bhe Nde Nu 700mw RH RT Rev 00 Latest Ut Procedure 14-02-2014Document17 pagesUt - Bhe Nde Nu 700mw RH RT Rev 00 Latest Ut Procedure 14-02-2014JoelNo ratings yet

- Scope:: Property of "Oil & Gas Inspection Services"Document6 pagesScope:: Property of "Oil & Gas Inspection Services"Asem AbdelazizNo ratings yet

- Item Inspected: CBLT-TPI-00F-186-12623Document16 pagesItem Inspected: CBLT-TPI-00F-186-12623Zulfadli RaniNo ratings yet

- Checklist of Validation of Dy Heat SterilizerDocument8 pagesChecklist of Validation of Dy Heat Sterilizersami2210No ratings yet

- SMS - 603 - UTZ - 001 - Sulzer SPEKTRA Rev.00.pdf (TTD) PDFDocument24 pagesSMS - 603 - UTZ - 001 - Sulzer SPEKTRA Rev.00.pdf (TTD) PDFRosyidi danangNo ratings yet

- Ms For Hyrdo Pneumatic Testing of Spherical TANKS (730-TK-03 A/B & C) A-CON-PRO-730-38939Document15 pagesMs For Hyrdo Pneumatic Testing of Spherical TANKS (730-TK-03 A/B & C) A-CON-PRO-730-38939Ramzi ZoghlamiNo ratings yet

- Helium Leak Testing Procedure-Heat ExchangerDocument5 pagesHelium Leak Testing Procedure-Heat ExchangerDanielNo ratings yet

- Pipe Specimen For Aut Calibration Selection Thickness Survey & Laminations Checks Rev c1.Document12 pagesPipe Specimen For Aut Calibration Selection Thickness Survey & Laminations Checks Rev c1.EdAlmNo ratings yet

- Collapse Tests of Pipe Casing and Tubing: February 2000Document10 pagesCollapse Tests of Pipe Casing and Tubing: February 2000Ankit LonareNo ratings yet

- CB Testing and Commissioning 76-92Document17 pagesCB Testing and Commissioning 76-92Vijaya KumarNo ratings yet

- A-Qac-Pro-730-38930 Rev ADocument10 pagesA-Qac-Pro-730-38930 Rev ARamzi ZoghlamiNo ratings yet

- P4a-MT-103, Rev.3Document67 pagesP4a-MT-103, Rev.3Hatem RagabNo ratings yet

- Ultrasonic Test Procedure1Document8 pagesUltrasonic Test Procedure1MHDNo ratings yet

- Ultrasonic TestDocument11 pagesUltrasonic TestHarry DobleNo ratings yet

- 05 Ultrasonic Test Procedure 500405Document11 pages05 Ultrasonic Test Procedure 500405Sefa KasapogluNo ratings yet

- 13 - Exhibit D Hydro. Test. Cross Country PLDocument12 pages13 - Exhibit D Hydro. Test. Cross Country PLMoaatazz NouisriNo ratings yet

- UT ProcedureDocument6 pagesUT ProcedureMurali YNo ratings yet

- Saep 1146Document8 pagesSaep 1146Ronanki RaviNo ratings yet

- J1525-HW3-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW3-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- J1525-HW1-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW1-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- A 531 - A 531M - 91 R01 - Qtuzms9bntmxtqDocument5 pagesA 531 - A 531M - 91 R01 - Qtuzms9bntmxtqAdrian GonzalezNo ratings yet

- Ultrasonic Test Procedure AWS D1.1 (NDE Procedure For Structure)Document26 pagesUltrasonic Test Procedure AWS D1.1 (NDE Procedure For Structure)Taufik SantosoNo ratings yet

- Ebs1 Aaaa00 Saqa Prqa 0006Document10 pagesEbs1 Aaaa00 Saqa Prqa 0006SERT-QA/QC- BUZNo ratings yet

- LEAK TEST PROCEDURE - Copy 2Document2 pagesLEAK TEST PROCEDURE - Copy 2Ahmed AlaaNo ratings yet

- Hardness Test Procedure: 1 of 8 DE3511.006/EDocument8 pagesHardness Test Procedure: 1 of 8 DE3511.006/Esalman1111aNo ratings yet

- LEAK TEST PROCEDURE - Copy 2Document2 pagesLEAK TEST PROCEDURE - Copy 2Ahmed AlaaNo ratings yet

- LEAK TEST PROCEDURE - Copy 2Document2 pagesLEAK TEST PROCEDURE - Copy 2Ahmed AlaaNo ratings yet

- Procedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesDocument10 pagesProcedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesJonathan Espinoza MejiaNo ratings yet

- Testing UMTS: Assuring Conformance and Quality of UMTS User EquipmentFrom EverandTesting UMTS: Assuring Conformance and Quality of UMTS User EquipmentNo ratings yet

- Fine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlFrom EverandFine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlNo ratings yet

- UMTS Performance Measurement: A Practical Guide to KPIs for the UTRAN EnvironmentFrom EverandUMTS Performance Measurement: A Practical Guide to KPIs for the UTRAN EnvironmentNo ratings yet

- HR87H7893Document1 pageHR87H7893Neeraj SinghNo ratings yet

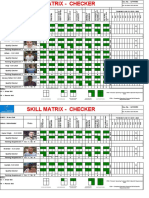

- A. Customer Oriented ProcessesDocument8 pagesA. Customer Oriented ProcessesNeeraj SinghNo ratings yet

- Recruitment of Upper Division Clerk (Udc), Stenographer (Steno.) and Multi-Tasking Staff (MTS) in EsicDocument4 pagesRecruitment of Upper Division Clerk (Udc), Stenographer (Steno.) and Multi-Tasking Staff (MTS) in EsicNeeraj SinghNo ratings yet

- Programmes Details For Academic Session 2020-21 Shri Vishwakarma Skill University, HaryanaDocument3 pagesProgrammes Details For Academic Session 2020-21 Shri Vishwakarma Skill University, HaryanaNeeraj SinghNo ratings yet

- The Punjab Excise Act, 1914Document56 pagesThe Punjab Excise Act, 1914Neeraj SinghNo ratings yet

- Acts Excise ThePunjabExciseAct 1914.pdfDocument26 pagesActs Excise ThePunjabExciseAct 1914.pdfNeeraj SinghNo ratings yet

- Objective SheetDocument13 pagesObjective SheetNeeraj SinghNo ratings yet

- NC'S Remarks Target Date: Internal Quality Audit (Iqa) Check SheetDocument1 pageNC'S Remarks Target Date: Internal Quality Audit (Iqa) Check SheetNeeraj SinghNo ratings yet

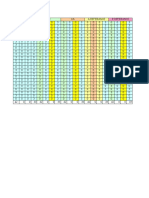

- Attribute MSA FormatDocument5 pagesAttribute MSA FormatNeeraj SinghNo ratings yet

- Need To Improve The Cleanness, Layout of Plant Floor With Each Process IdentificationDocument7 pagesNeed To Improve The Cleanness, Layout of Plant Floor With Each Process IdentificationNeeraj SinghNo ratings yet

- Skill Matrix Mill No.-4Document6 pagesSkill Matrix Mill No.-4Neeraj SinghNo ratings yet

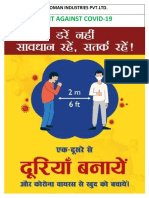

- Standard Guideline For Carrying Out Operation During and After COVID19 Lockdown Version 02Document28 pagesStandard Guideline For Carrying Out Operation During and After COVID19 Lockdown Version 02Neeraj SinghNo ratings yet

- What Is Communication ?Document7 pagesWhat Is Communication ?Neeraj SinghNo ratings yet

- Mill No.02: R P Oil Consumption %Document4 pagesMill No.02: R P Oil Consumption %Neeraj SinghNo ratings yet

- CMD Home Sector 10 FaridabadDocument3 pagesCMD Home Sector 10 FaridabadNeeraj SinghNo ratings yet

- CLL Training Schedule 13 To 29 April 2020Document2 pagesCLL Training Schedule 13 To 29 April 2020Neeraj SinghNo ratings yet

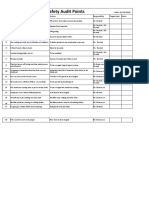

- Tata Safety Audit Points: SR - No. Observation Points Actions Responsibility Targate Date StatusDocument2 pagesTata Safety Audit Points: SR - No. Observation Points Actions Responsibility Targate Date StatusNeeraj SinghNo ratings yet

- Before: Rubber Mat On Loading Plateform of Loading TruckDocument1 pageBefore: Rubber Mat On Loading Plateform of Loading TruckNeeraj SinghNo ratings yet

- 22nd Annual Report - FY 2016-17 PDFDocument133 pages22nd Annual Report - FY 2016-17 PDFNeeraj SinghNo ratings yet

- Safe Make Distance InduDocument1 pageSafe Make Distance InduNeeraj SinghNo ratings yet

- Action Plan For Dent ControlDocument2 pagesAction Plan For Dent ControlNeeraj SinghNo ratings yet

- 11 Request - Letter - For - Proposal - For - Workshop - Industrial - SafetyDocument1 page11 Request - Letter - For - Proposal - For - Workshop - Industrial - SafetyNeeraj SinghNo ratings yet

- Annexure 1 SMDocument13 pagesAnnexure 1 SMNeeraj SinghNo ratings yet

- CDGC Public API Postman CollectionDocument6 pagesCDGC Public API Postman Collectionchetan sharmaNo ratings yet

- C Xpert Calibration PI - US Version PrintDocument48 pagesC Xpert Calibration PI - US Version Printtha_ansNo ratings yet

- APIprintableDocument447 pagesAPIprintableServando RodoNo ratings yet

- Catapult ProjectDocument19 pagesCatapult Projectapi-270861823No ratings yet

- INMVD-101 ACS 1000 Medium Voltage Drive-Operation and Maintenance-Rev-ADocument1 pageINMVD-101 ACS 1000 Medium Voltage Drive-Operation and Maintenance-Rev-AMohamed DNo ratings yet

- Evaluation of The Maintenance OrganizationDocument4 pagesEvaluation of The Maintenance Organizationagmas katanaNo ratings yet

- Employee Monitoring and Management System Using GPS and AndroidDocument5 pagesEmployee Monitoring and Management System Using GPS and AndroidAnonymous kw8Yrp0R5r100% (1)

- Legal Issues With ERP - One ChapterDocument3 pagesLegal Issues With ERP - One Chapterqwery3672No ratings yet

- (Data Sheet) hm70 Evo - v1.00 - Rev1 - 20210316.semnatDocument24 pages(Data Sheet) hm70 Evo - v1.00 - Rev1 - 20210316.semnatalsaiedismaelNo ratings yet

- Testing Procedure For Shaft Voltage and Discharges Using A Fluke 190-204 ScopeMeterDocument41 pagesTesting Procedure For Shaft Voltage and Discharges Using A Fluke 190-204 ScopeMeterHari Krishna.MNo ratings yet

- Colonial Topographies of Internet Infrastructure The Sedimented and Linked Networks of The TelegrapDocument16 pagesColonial Topographies of Internet Infrastructure The Sedimented and Linked Networks of The TelegrapIrma Setya NingrumNo ratings yet

- Thyristor Testing Using Vom: Assignment No. 2Document6 pagesThyristor Testing Using Vom: Assignment No. 2Noriel DomdomNo ratings yet

- Capital Budgeting ProjectDocument69 pagesCapital Budgeting ProjectKeleti Santhosh50% (2)

- Advanced Vehicle Control SystemDocument55 pagesAdvanced Vehicle Control Systemgetjohnmilton100% (1)

- PEGO Ecp300expertvd7 enDocument44 pagesPEGO Ecp300expertvd7 enkimolosNo ratings yet

- Datasheet RS485 Shield Rev B EN PDFDocument5 pagesDatasheet RS485 Shield Rev B EN PDFJason CarrNo ratings yet

- Its 2011Document359 pagesIts 2011BogdanAncaNo ratings yet

- Megatrends Shopping Reinvented and Generation ZDocument39 pagesMegatrends Shopping Reinvented and Generation ZPazirish Z. MirzaNo ratings yet

- How To Find TC Packets Source On Huawei Switch PDFDocument2 pagesHow To Find TC Packets Source On Huawei Switch PDFHussein DhafanNo ratings yet

- Construction LawDocument12 pagesConstruction Lawermias asalifNo ratings yet

- GRC WhitepaperDocument32 pagesGRC WhitepaperVikas BhanNo ratings yet

- Unit 2: Networking: Lesson (02) System TypesDocument20 pagesUnit 2: Networking: Lesson (02) System TypesPasindu ChamadithNo ratings yet

- Imds Recommendation 001 General StructureDocument30 pagesImds Recommendation 001 General Structureyoussef achourNo ratings yet

- Mettler Full CatalogDocument128 pagesMettler Full CatalogAhmet KaraNo ratings yet

- Mindray Z6 Z5 SVMDocument179 pagesMindray Z6 Z5 SVMkritonNo ratings yet

- Janitza Manual UMG508 enDocument100 pagesJanitza Manual UMG508 enOchoa Para La BandaNo ratings yet

- 2829 11-4 TenderBulletin ADocument136 pages2829 11-4 TenderBulletin Apalama1No ratings yet

- Power Supply (SPS PCB) Theory of OperationDocument5 pagesPower Supply (SPS PCB) Theory of OperationSv KoNo ratings yet