Professional Documents

Culture Documents

Roads - Design Parametrs and Outline Specifications - For Vol II

Roads - Design Parametrs and Outline Specifications - For Vol II

Uploaded by

Tayyabah ZafarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Roads - Design Parametrs and Outline Specifications - For Vol II

Roads - Design Parametrs and Outline Specifications - For Vol II

Uploaded by

Tayyabah ZafarCopyright:

Available Formats

1) LEVELING & GRADING AND ROAD WORKS

Scope of Work

The scope of work includes general leveling and grading of parking areas, depot / stabling yard, Station

and track corridor and design of roads and parking areas. The road works include construction of access

roads from existing roads to the stations, internal roads of depot/ stabling area facility, alternate road

networks due to closure of existing vehicular roads due to development of KCR corridor at designated

points/ stations and the development of motor vehicle parking at particular stations. This shall include all

pavement works and road furniture (road side curb, barriers, traffic signs and pavement markings)

Design Standards

The following design standards or equivalent highly verifiable Chinese Standard shall be adopted for the

design work:

AASHTO - A Policy on Geometric Design of Highway and Streets

AASHTO Design Guide for Pavement Structures 1993

Asphalt Institute Pavement Design Manuals

FHWA Urban Drainage Design Manual

DESIGN PARAMETERS:

General

The KCR shall be developed on the previously defined corridor with third rail as locomotive power

system. The corridor comprises of exclusive loop corridor of approximately 29.7 km and 13.5 km shared

with Pakistan Railways.

Being powered with third rail electrification system, at grade crossing with vehicular roads need to be

barred. Comprehensive traffic diversion plans are to be established which might require construction of

new roads and intersections.

Leveling and Grading Works

The leveling and grading works shall be include depot area/ stabling yard, track corridor fence to fence as

shown in drawings attached in Volume III of this document and all pavement works area i.e. access roads

and parking areas for vehicular traffic to the station. Existing drainage pattern shall be preferably

maintained. The areas shall be sloped to collect storm water drainage in existing nearby water bodies.

Road Works

The corridor passes through highly populated which require access roads to stations and parking.

Parking areas are to be developed based on the demand basis for each station has at least twenty five

(25) slots for cars, a hundred (100) bike parking slots, Ten (10) slots for taxi/ auto parking and two (02)

bus bays.

Design Parameters

The main features of the roads shall meet the following criteria:

Employer’s Requirements Page-1

Geometric Design

Design Vehicle

Single Unit Truck (SU-9 / SU-12)

Length = Varies

Width = 2.44 m

Height = 3.35 - 4.11 m

Design Speed

Access Roads = 50 km/h (maximum)

Parking Areas = 30km/h (maximum)

Roads:

Width of lane = 3.5m (minimum)

Gradient = 6% maximum

Cross Slope = 0.5% (minimum if no longitudinal gradients available)

Roads shall be designed for quick access to and from stations avoiding any unnecessary congestion or

delays of traffic on existing roads due vehicular trips generated for KCR. This shall also take into

consideration the access points of nearby residential and commercial areas.

The road and parking area construction may require land acquisition which shall be a sole responsibility

of the Client and shall be provided to the Contractor free of cost for development works. The area shall

be acquired based on the land demarcated by the Contractor for such use.

Parking areas shall be provided as near to the stations as possible. The design elements of the roads and

pavements shall conform to the relevant design standards enlisted in previous section.

Pavement Design

Design life of road = 20 years

CBR = as per geotechnical investigation results

The Contractor shall study the traffic demand and shall provide adequate pavement structure. All roads

shall be of flexible type with asphalt concrete whereas the parking lots shall be paved with concrete

pavers with minimum pavement thickness as shown in Volume III of this document.

OUTLINE SPECIFICATIONS:

Granular Sub-base Course

All sub-base material shall be free from dirt, organic matter, shale or other deleterious matter and shall be

of such quality that it will bind readily to form a firm, stable sub-base. Material for sub-base shall consist of

well-graded gravel with sand and silt, conforming to the following requirements:

AASHTO Sieve Percent Passing

3 in. (75 mm) 100

# 10 (2 mm) 20 - 100

# 40 (0.45 mm) 5 - 60

# 200 0-8

Employer’s Requirements Page-2

All sub-base aggregate shall conform to the following physical requirements.

Liquid Limit (AASHTO T-89) 25 maximum

Plasticity Index (AASHTO T-90) 6 maximum

Sand Equivalent (AASHTO T-176) 25 minimum

Loss by Abrasion (AASHTO T-96) 40 maximum

California Bearing Ratio (CBR)

(at 100% compaction as per ASTM D-1557 or > 30

AASHTO T-180 method ‘D’)

Aggregate Base Course

All aggregates for base course shall consist of clean, tough, durable, sharp angle fragments free of any

excess of thin or elongated pieces and reasonably free of soft, disintegrated or decomposed stone, dirt or

other deleterious matter. Crushed gravel or stone fragments for base courses shall consist of the product

obtained by crushing gravel shall conform to the following grading requirements:

AASHTO Sieve Percent Passing

2 in. (50.8 mm) 100

1 1/2 in.(38.1 mm) 35 - 70

1 in. (25.4 mm) 0 - 15

1/2 in. (12.7 mm) 0- 5

Fine materials for base course shall be quarry screenings or natural material and of suitable binding

quality as approved by the Engineer. The material shall be free from foreign or organic matter, dirt, shale,

clay and clay lumps, or other deleterious matter and shall conform to the following requirements:

AASHTO Sieve Percent Passing

3/8 in. (9.5 mm) 100

#4 85 - 100

# 100 10 - 30

Plasticity Index (AASHTO T-90) 6 maximum

Sand Equivalent (AASHTO T-176) 30 minimum

The combined material shall consist of a mixture of all aggregate uniformly graded from coarse to fine to

conform to the following gradation requirements:

AASHTO Sieve Percent Passing

2 in. (50.8 mm) 100

1 1/2 in.(38.1 mm) 60 - 90

1 in. (25.4 mm) 42 - 77

3/4 in. (19.0 mm) 35 - 70

1/2 in. (12.7 mm) 25 - 60

#4 15 - 40

# 10 10 - 26

# 40 5 - 15

# 200 2-9

All base course aggregates shall conform to the following physical requirements:

Employer’s Requirements Page-3

Loss of Sodium Sulfate Soundness

Test (AASHTO 104) 10% maximum

Loss of Magnesium Sulfate Soundness

Test (AASHTO 104) 12% maximum

Loss by Abrasion Test (AASHTO T-96) 40% maximum

Thin and Elongated Pieces, by Weight

(larger than 25 mm, thickness less 5%

than 1/5 length)

Friable Particles (AASHTO T-112) 0.25% maximum

Bituminous Binder Course

Aggregates

Aggregates for "Bituminous Binder Course" shall consist of coarse aggregates, fine aggregates, and filler

material, if required, all complying with the following requirements:

Gradation

When tested according to AASHTO T-11 and AASHTO T-27, the combined mineral aggregate shall

conform to the following grading:

AASHTO Sieve Class A Class B

Size Percent Passing Percent Passing

1½ in. 100 100

1 in. 100 80 - 100

3/4 in. 80 –100 70 - 90

3/8 in. 60 - 80 55 - 75

No. 4 45 – 65 44 - 62

No. 10 30 – 50 33 - 48

No. 40 15 - 32 16 - 27

No. 200 3 - 10 3 - 10

Gradation of mineral filler shall be:

Sieve Percent Passing

(By Weight)

No. 30 (0.600 mm) 100

No. 50 (0.300 mm) 95 - 100

No. 200 (0.075 mm) 70 - 100

Physical Requirement

The combined mineral aggregate shall meet the quality requirements specified in section "Aggregate

Base Course" and in addition shall conform to the following physical requirements.

Sand Equivalent

(AASHTO T-176) determined after

all processing minimum except

for addition of asphalt binder: 45 minimum

Employer’s Requirements Page-4

Plasticity Index (AASHTO T-90) 6 maximum

Loss of Marshall Stability by

Submerging specimens in water

at 60oC for twenty four (24) hours

as compared to stability measured

after submersion in water at 60oC

for twenty (20) minutes: 25% maximum

Job-Mix

The job mix formula combining the aggregates and bitumen (grade 60-70 penetration) shall be provided

by the Contractor.

Bituminous Wearing Course

Aggregates

Aggregates for "Bituminous Wearing Course" shall consist of coarse aggregates, fine aggregates, and

filler material if required, all complying with the following requirements.

Gradation requirements of mineral filler:

Sieve Percentage Passing

(By Weight)

No. 30 (0.600 mm) 100

No. 50 (0.300 mm) 95 - 100

No. 200 (0.075 mm) 70 - 100

Sand Equivalent (AASHTO T-176)

determined after all processing except

for addition of asphalt binder : 45 minimum

Plasticity index (AASHTO T-90) 3 maximum

Loss of Marshall Stability by

submerging specimens in water

at 60o C for twenty-four (24) hours

as compared to stability measured

after submersion in water at 60o C

for twenty (20) minutes. 25% maximum

When tested according to AASHTO T-11 and AASHTO T-27 the combined aggregate shall conform to

the following gradings:

AASHTO Sieve Size Percent Passing

¾ in. 100

½ in. 80 - 95

3/8 in. -

Employer’s Requirements Page-5

No. 4 48 - 62

No. 10 32 - 45

No. 40 16 - 26

No. 80 8 - 18

No. 200 4-8

Job-Mix

The job mix formula combining the aggregates and bitumen (grade 60-70 penetration) shall be provided

by the Contractor.

Traffic Marking and Pavement Studs

a) Standards and Codes:

Sponsor Number Subject

AASHTO M - 237 Epoxy Resin Adhesive for Bonding Traffic

Markers to Hardened Concrete

AASHTO M - 247 Glass Beads Used in Traffic Paint

ASTM D - 1214 Sieve Analysis of Glass Spheres

FS TT-B-1325 Bead, (Glass Spheres) Retro- reflective

FS TT-P-110 Paint, Traffic Black (Non- reflectorized)

Traffic signs, road markings and pavement studs shall also be in accordance with the

requirements of international standards.

b) Aggregate :

The aggregate shall consist of light coloured silica sand, calcite, quartz, calcined flint, or other

material approved by the Engineer.

c) Pigment and Extender

White Material

The pigment shall be titanium dioxide complying with the requirements of Type A (anatase) or

Type R (rutile) of BS-1851.

Yellow Materials

Sufficient suitable yellow pigment shall be substituted for all or part of the titanium dioxide to

comply with the other requirements of this specification.

All Materials

The extender shall normally be whiting (i.e. calcium carbonate prepared from natural chalk)

complying with the requirements of BS-1795. The manufacturer may substitute lithopone

complying with the requirement of BS-296 for any or all of the whiting.

Binder

Employer’s Requirements Page-6

The binder shall consist of synthetic hydrocarbon resin, or, with the approval of the Engineer, gun

or wood resin, plasticized with mineral oil.

Testing

The samples shall be prepared and tested in accordance with B.S. Specification 3262 (1976)

appendix A to H at stages:

a) At the manufacturer's plant.

b) After it has been re-melted by the road application contractor.

The following properties shall be checked:

o Softening Point

o Colour and Luminance

o Heat Stability

o Flow Resistance

o Skid Resistance

Traffic Signs

The Traffic Signs shall be designed for size, message and installation as per Manual on Uniform

Traffic Control Devices (MUTCD) standards

Sign Materials

Sign materials shall be

a) Aluminium Alloy Sheets: Aluminium alloy sheets shall conform to ASTM B 209, 6061-T6 aluminium,

degreased and alodine-treated, 3 mm thick, unless otherwise noted on the plans.

b) Steel Sheets: Steel sheets shall conform to the requirements of the "Specifications for Cold-Rolled

Carbon Steel Sheets, Commercial Quality," ASTM A-366, 16 gauge thick unless otherwise noted on

the plans.

c) Stainless Steel Bolts, Washers and Self-Locking Nuts: These items shall conform to ASTM A- 276,

chromium-nickel grade. Minimum yield 2,110 kilograms per square centimeter.

d) Vulcanized Fibre Washers: Fibre washers shall conform to ASTM D-710, grey, commercial grade,

when shown on the plans.

e) Hard Rubber Washers

f) Nylon and Neoprene Fittings: Nylon and/or neoprene washers, spacers, sleeves etc.

g) Reflective Sheeting

Precast Cement Concrete Fair Faced Curb Stone and Gutter Blocks

Cement concrete fair faced finished curb stones/gutter block/edge block shall be fair face and precast

using cement-concrete Class ‘C’, conforming to the requirements as stipulated in the section "Plain and

Employer’s Requirements Page-7

Reinforced Cement Concrete". The formwork shall conform to the requirements as stipulated in the

section "Formwork".

Excavation shall be made to the required depth and the base upon which the kerb or combination of kerb

and gutter is to be set shall be compacted to a minimum density of ninety (90) percent of the maximum

dry density as determined by AASHTO T-191 Method.

Employer’s Requirements Page-8

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- (B) OGUNDOKUN ROUTE SURVEY PROJECT REPORT-1Document56 pages(B) OGUNDOKUN ROUTE SURVEY PROJECT REPORT-1Bode Olabode67% (3)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Peterbilt Model 387 Operators ManualDocument188 pagesPeterbilt Model 387 Operators Manualruivieira1275% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pavement Manegement System in DPWHDocument22 pagesPavement Manegement System in DPWHElvin G. Tactac100% (1)

- Design Report For Water Works Roads and DrainageDocument6 pagesDesign Report For Water Works Roads and DrainageTayyabah ZafarNo ratings yet

- Form of Financial Bid (Letter of Offer)Document13 pagesForm of Financial Bid (Letter of Offer)Tayyabah ZafarNo ratings yet

- Chapter 4 Drainage DesignDocument34 pagesChapter 4 Drainage DesignTayyabah ZafarNo ratings yet

- Guidelines For Road Safety Engineering Part 2 PDFDocument89 pagesGuidelines For Road Safety Engineering Part 2 PDFTayyabah ZafarNo ratings yet

- Bituminous Soft Fibre BoardDocument1 pageBituminous Soft Fibre BoardTayyabah ZafarNo ratings yet

- Parallel-Flow Drum-Mix Plants: SectionDocument33 pagesParallel-Flow Drum-Mix Plants: SectionTayyabah ZafarNo ratings yet

- BBIA Landside Infrastructure Final Design ReportDocument167 pagesBBIA Landside Infrastructure Final Design ReportTayyabah ZafarNo ratings yet

- Hot-Mix Asphalt Laydown and CompactionDocument50 pagesHot-Mix Asphalt Laydown and CompactionTayyabah ZafarNo ratings yet

- Operational Areas of Karachi PortDocument8 pagesOperational Areas of Karachi PortTayyabah ZafarNo ratings yet

- Guidelines For Road Safety Engineering Part 2 PDFDocument89 pagesGuidelines For Road Safety Engineering Part 2 PDFTayyabah ZafarNo ratings yet

- Mangapapa School : Year 4 Learning Neighbourhood Museum VisitDocument2 pagesMangapapa School : Year 4 Learning Neighbourhood Museum Visitapi-226349289No ratings yet

- Case Study of CLassic Vehicle Oriented Planning Analysis of RadburnDocument60 pagesCase Study of CLassic Vehicle Oriented Planning Analysis of RadburnJosielynNo ratings yet

- Previsedpayyanur Project Report Town HallDocument24 pagesPrevisedpayyanur Project Report Town HallNidhi JhabakNo ratings yet

- (22403) Rbe Microproject-2Document11 pages(22403) Rbe Microproject-2saikrishnamithapalli053No ratings yet

- Down at The Depot - American Railroad Stations From 1831 To 1920 (Trains)Document328 pagesDown at The Depot - American Railroad Stations From 1831 To 1920 (Trains)nevena_milinovic50% (2)

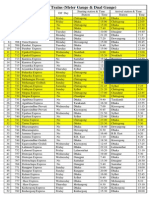

- Table 31Document7 pagesTable 31Jann KongNo ratings yet

- Account SummaryDocument304 pagesAccount SummaryJeddah0% (1)

- Hornby HR1977 Locomotive Lubrication and Maintenance ChartDocument4 pagesHornby HR1977 Locomotive Lubrication and Maintenance ChartJohn GasparNo ratings yet

- LWBDocument64 pagesLWBDerick CorreaNo ratings yet

- (Exceeding Event Expectations) Events Management: Company NameDocument17 pages(Exceeding Event Expectations) Events Management: Company NameGenelene BalinadoNo ratings yet

- Baja SuspensionDocument9 pagesBaja SuspensionImbran Sheriff100% (2)

- Social Science SQP - 2015-16 - Set 2 MSDocument10 pagesSocial Science SQP - 2015-16 - Set 2 MSArshad JamilNo ratings yet

- Chamarajanagara Bus TimingDocument4 pagesChamarajanagara Bus Timingதளபதி கோபி கோவைNo ratings yet

- Simulation of Antilock Braking SystemDocument4 pagesSimulation of Antilock Braking Systemankush_laxmanNo ratings yet

- Tesla Owners ManualDocument115 pagesTesla Owners Manualalsimon2038100% (1)

- Eddh (Hamburg) R (15jan16) PDFDocument63 pagesEddh (Hamburg) R (15jan16) PDFnabatmanNo ratings yet

- Reigate & Banstead BC Sept 2009Document12 pagesReigate & Banstead BC Sept 2009parkingeconomicsNo ratings yet

- Tadano GT 550e 2 - O1 1eDocument214 pagesTadano GT 550e 2 - O1 1eMuhammad100% (12)

- Counter ListDocument8 pagesCounter Listprashanthnarayanappa31No ratings yet

- Adani Hgiel 1139 STR MJB 207+740 TP 01 R0Document1 pageAdani Hgiel 1139 STR MJB 207+740 TP 01 R0as8877422No ratings yet

- Concrete Mix Design Calculations - Water Cement Ratio and Optimum Cement Content and Ideal Aggregate PropotionsDocument6 pagesConcrete Mix Design Calculations - Water Cement Ratio and Optimum Cement Content and Ideal Aggregate PropotionsGemunu WilsonNo ratings yet

- TPD Report On Downtown ProtestsDocument107 pagesTPD Report On Downtown ProtestsKOLD News 13No ratings yet

- ProfileDocument32 pagesProfileBINAY KUMARNo ratings yet

- Custom Truck One Source To Display Load King Trailers at EUFMCDocument2 pagesCustom Truck One Source To Display Load King Trailers at EUFMCPR.comNo ratings yet

- Saxon Woods MapDocument1 pageSaxon Woods Mapelextranjero7023No ratings yet

- DO 41 - Noted DefectsDocument17 pagesDO 41 - Noted DefectsJay RickNo ratings yet

- Updated Schedule of Bangladesh Railway (22 October 2014) PDFDocument4 pagesUpdated Schedule of Bangladesh Railway (22 October 2014) PDFTaufiqulIslaamNo ratings yet