Professional Documents

Culture Documents

Flt93f Ads 4.81.output

Flt93f Ads 4.81.output

Uploaded by

Sherman DesktopOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flt93f Ads 4.81.output

Flt93f Ads 4.81.output

Uploaded by

Sherman DesktopCopyright:

Available Formats

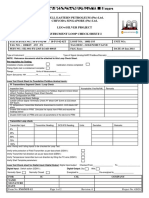

Application Data Sheet (ADS)

1755 La Costa Meadows Drive | San Marcos, California 92078 USA

760-744-6950 Toll Free (US): 800-854-1993 Fax: 760-736-6250

FLT93 F

www.fluidcomponents.com FlexSwitch ™ Insertion for Flow, Level & Temperature

Customer Information

Customer Name & Address: ___________________________________________

P.O. No.:_____________________ Customer Order: ____________________

__________________________________________________________________

Tag Number(s):

__________________________________________________________________

Contact: ___________________________________________________________

Phone: ___________________________ Fax: __________________________

Email: _____________________________________________________________

Control Circuit Jumper Section (Required for Block 12, Codes 3 through W of OIS)

Input Power: c 115 Vac c 230 Vac c 24 Vdc c 24 Vac

Application Matrix Alarm No. 1

(Circle one alarm combination and enter in Blocks 10 - 11 on OIS) Alarm Condition:

c Relay de-energized with low flow, low level (dry), or high temperature

Alarm 1

Gas Liquid Level Temper- Interface c Relay de-energized with high flow, high level (wet), or low temperature

Alarm 2 Flow Flow (Wet/Dry) ature

Contact Configuration: c SPDT

Not required A 0 C0 E0 D0

c DPDT (This selection disables Alarm No. 2)

Gas Flow AA

Alarm No. 2

Liquid Flow

Alarm Condition:

Level (Wet/Dry) AC CC DC

c Relay de-energized with low flow, low level (dry), or high temperature

Interface DD c Relay de-energized with high flow, high level (wet), or low temperature

Temperature AE CE EE DE

Contact Configuration: c SPDT (only)

Instrument Calibration (Required for Block 12, Codes 3 through W of OIS)

Part 1: Process Conditions

AIR

c Primary Flow Media: ______________________________________________ c Secondary Flow Media: ___________________________________________

c Lower Level Media: _______________________________________________ c Upper Level Media: ______________________________________________

c Gas c Liquid c Gas c Liquid

Temperature: c °F c °C Temperature: c °F c °C

10

Minimum __________ 25

Nominal ___________ 40

Maximum__________ Minimum __________ Nominal ___________ Maximum__________

Pressure: c Psig c Bar(g) Pressure: c Psig c Bar(g)

1

Minimum __________ Nominal ___________ Maximum__________ Minimum __________ Nominal ___________ Maximum__________

Part 2: Calibration Conditions - Flow Applications Only

IMPORTANT: FCI calibrates in two medias; choose c Water or c Air

For Temperature Applications Only For Flow Applications Only For Level/Interface Applications Only

Temperature Range 250

Pipe or duct inside diameter: _______________________ Sensing Element Mounting: c Side

c As entered for the primary/lower media in the c inches c mm c Top

“Process Conditions” section above. Pipe Orientation: c horizontal c vertical

Level Rate-of-Change: _____________ c inches/sec

c As entered for the secondary/upper media in the Sensing Element Mounting: c side c top (at sensing element) c mm/sec

“Process Conditions” section above.

Flow Direction: c right to left c left to right

c Other: __________________________________ Interface Rate-of-Change: ___________ c inches//hr

c top to bottom c bottom to top (at sensing element) c mm/hr

Alarm Set Point: No. 1 ______________________

Flow Range: minimum _________ maximum __________

No. 2 ______________________

Nominal Flow Rate: ____________________________ Output Bar Graph: c Required

Analog Output Curve: c Required m/sec

Flow Units: ___________________________________ c Not required

c Not required

Alarm Set Point: No. 1 __________

4.81 No. 2 __________

Note: For vacuum and/or small volume (less than 10 in.3

or 150 cm3 ) process conditions, calibration of the temper- Analog Output Curve (per Block 11 on OIS):

ature output is recommended if the temperature alarm is c Air (see Code 8) c Special (see Code W)

used in combination with a flow or level/interface alarm. c Not required

© Copyright 2014 Fluid Components International LLC. All rights reserved. Subject to change without notice. Order Information Sheet effective 01/2015 Doc. No. 01SA011304 U

You might also like

- Loop Check Sheet TransmitterDocument2 pagesLoop Check Sheet Transmittershanks263100% (2)

- KFM Regler 930M84 - EDocument8 pagesKFM Regler 930M84 - EZia SultanNo ratings yet

- Flow Totalizer08.11.18Document21 pagesFlow Totalizer08.11.18alejocmedNo ratings yet

- APC Dry ContactDocument4 pagesAPC Dry Contactparas99No ratings yet

- See Instrument Loop Test TableDocument6 pagesSee Instrument Loop Test TableJan Richardo GultomNo ratings yet

- Loop Check Sheet Sol ValveDocument2 pagesLoop Check Sheet Sol Valveshanks263100% (1)

- RT8205A RichtekDocument28 pagesRT8205A Richtekเจตนิพิฐ วีระพันธ์ไพบูลย์No ratings yet

- Melt PressDocument10 pagesMelt PressTASNEEM AHMADNo ratings yet

- D Pac-RelayDocument16 pagesD Pac-RelayFatih KargaNo ratings yet

- Ut 1201Document2 pagesUt 1201pathivadasirishNo ratings yet

- Catalogue-CGV-24C-UV-OV Relay-CAT-CGV24C-01Document4 pagesCatalogue-CGV-24C-UV-OV Relay-CAT-CGV24C-01waveengg.coNo ratings yet

- GVI Digital Manual PDFDocument9 pagesGVI Digital Manual PDFAnoirNo ratings yet

- GFlow KUF810 Ultrasonic FlowmeterTechnical Specification RevCDocument9 pagesGFlow KUF810 Ultrasonic FlowmeterTechnical Specification RevCadi michaelNo ratings yet

- NRG Battery Charger Data Sheet MSDDocument6 pagesNRG Battery Charger Data Sheet MSDMohamed SalamaNo ratings yet

- LCD Monitor Power Supply 9940Document12 pagesLCD Monitor Power Supply 9940miltonhmbddsNo ratings yet

- Condition Based Health Monitoring of TransformersDocument3 pagesCondition Based Health Monitoring of Transformerss.selva9566No ratings yet

- Configuration Data Sheet Rosemount 3051 Pressure Transmitter 4 20 Ma Hart en 89456Document6 pagesConfiguration Data Sheet Rosemount 3051 Pressure Transmitter 4 20 Ma Hart en 89456Dramanuss1984No ratings yet

- Regler 930M83 (Gas-Diesel) EDocument8 pagesRegler 930M83 (Gas-Diesel) EOswaldo LeónNo ratings yet

- BC1602K Series VER01Document28 pagesBC1602K Series VER01Jeremiah DayNo ratings yet

- Danfoss Ret2000 Electronic Digital Thermostat Installation Guide 087n644400Document101 pagesDanfoss Ret2000 Electronic Digital Thermostat Installation Guide 087n644400scotlandtravelmanNo ratings yet

- Data - Sheet - Ac - DC - 82a R-1Document6 pagesData - Sheet - Ac - DC - 82a R-1Aashish MoyalNo ratings yet

- Semiconductor Technical Data: L SuffixDocument12 pagesSemiconductor Technical Data: L SuffixSuwandra I Gede PutuNo ratings yet

- HydroKnowz DatasheetDocument17 pagesHydroKnowz DatasheetPrashant JNo ratings yet

- NFPA 110 Compliant NRG Series Battery ChargersDocument2 pagesNFPA 110 Compliant NRG Series Battery ChargersService Brags & Hayes, Inc.No ratings yet

- MeasurIT FCI Application Data Sheet Flow Switch 0903Document1 pageMeasurIT FCI Application Data Sheet Flow Switch 0903cwiejkowskaNo ratings yet

- Datasheet & QAP of TCP - BSDocument8 pagesDatasheet & QAP of TCP - BSAashish MoyalNo ratings yet

- CAT5132Document12 pagesCAT5132khaldonalwafi0No ratings yet

- Choosing The Correct Digipot PrikitiuwsportDocument6 pagesChoosing The Correct Digipot PrikitiuwsportAwal Onggaa SaputraNo ratings yet

- Duran 53300-900-08Document4 pagesDuran 53300-900-08David PazNo ratings yet

- Manual Multimetro Goldstar dm-332 - CalDocument13 pagesManual Multimetro Goldstar dm-332 - Calav100% (2)

- Adjustable Frequency DriveDocument1 pageAdjustable Frequency DriveAhmed SayedNo ratings yet

- Group21 4Document25 pagesGroup21 4Luis OliveroNo ratings yet

- Test Report CT Supervision Relay MVTP31 End Client: Sec-EoaDocument2 pagesTest Report CT Supervision Relay MVTP31 End Client: Sec-EoaHumayun Ahsan100% (1)

- Product Description Diesel Engine Fire Pump Controller FTA1100Document2 pagesProduct Description Diesel Engine Fire Pump Controller FTA1100Gerardo Muñoz UrbinaNo ratings yet

- Red670 AcceptanceDocument12 pagesRed670 AcceptancewazakifyNo ratings yet

- Ds203 User'S Manual: Screen ParametersDocument16 pagesDs203 User'S Manual: Screen Parametersjuan carlosNo ratings yet

- WAI1000 Regulator Tester Operating InstructionsDocument84 pagesWAI1000 Regulator Tester Operating InstructionsRoman KlimesNo ratings yet

- 1073 01 Wai A5 Te ML Wai1000 Operating InstructionsDocument104 pages1073 01 Wai A5 Te ML Wai1000 Operating InstructionsErasmo Israel Garcia Ochoa100% (1)

- Earth Leakage Monitoring Relay: BenefitsDocument8 pagesEarth Leakage Monitoring Relay: BenefitsShiaTVfanNo ratings yet

- DM74LS574 Octal D Flip-Flop With TRI-STATE Outputs: General DescriptionDocument6 pagesDM74LS574 Octal D Flip-Flop With TRI-STATE Outputs: General DescriptionnooorNo ratings yet

- lxc900 VDocument1 pagelxc900 VGaurav MahajanNo ratings yet

- TPIC46L01 DatasheetDocument23 pagesTPIC46L01 DatasheetWarr SteelNo ratings yet

- Bill Reader Matrix AftDocument15 pagesBill Reader Matrix AftAlberto VillarNo ratings yet

- Mod RelayDocument1 pageMod RelaySkvkNo ratings yet

- UTG-3010G Series: (Smart) Digital Electric Displacer Type Liquid Level Transmitter / Controller With HART CommunicationDocument3 pagesUTG-3010G Series: (Smart) Digital Electric Displacer Type Liquid Level Transmitter / Controller With HART CommunicationazitaggNo ratings yet

- DiSi Flash MemoryDocument8 pagesDiSi Flash MemoryAhmedNo ratings yet

- DiSi Flash MemoryDocument8 pagesDiSi Flash MemoryFERNSNo ratings yet

- DS CII AlarmDocument4 pagesDS CII AlarmKevin KuanNo ratings yet

- Tm162vca6 SpecDocument23 pagesTm162vca6 SpecMarius FerdyNo ratings yet

- DS 4013 Rev-0Document4 pagesDS 4013 Rev-0Dinesh RajNo ratings yet

- LD7523 PDFDocument18 pagesLD7523 PDFAmalio MamaniNo ratings yet

- Protection Features:: (Adityaseries) (Preliminary)Document11 pagesProtection Features:: (Adityaseries) (Preliminary)deccanelec100% (1)

- CXCI Cordex 2v0 Quick RefDocument2 pagesCXCI Cordex 2v0 Quick RefGuillermo OvelarNo ratings yet

- KL 620 PDFDocument151 pagesKL 620 PDFFidaa JaafrahNo ratings yet

- Check List For The Commissioning of DTS SystemDocument2 pagesCheck List For The Commissioning of DTS SystemmohammadNo ratings yet

- SAT 110V 25A DC ChargerDocument9 pagesSAT 110V 25A DC ChargerAzhar RimaNo ratings yet

- Manual GMDSS040906 ENDocument16 pagesManual GMDSS040906 ENmilen65No ratings yet

- TC and CG Terminal CircuitDocument6 pagesTC and CG Terminal CircuitYomar NegronNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Technical Proposal For Cryogenic Nitrogen GeneratorDocument28 pagesTechnical Proposal For Cryogenic Nitrogen Generatora.faramarziNo ratings yet

- Determination of The Friction Factor in Small PipesDocument6 pagesDetermination of The Friction Factor in Small PipessundarNo ratings yet

- 07 Initial SULFUR RECOVERY UNIT Startup Valve Checklist REV 1Document33 pages07 Initial SULFUR RECOVERY UNIT Startup Valve Checklist REV 1Muhammad IrfanNo ratings yet

- Instrument Junction Box Schedule Sadad North Early Development Facility (Edf) Project - Package 1Document2 pagesInstrument Junction Box Schedule Sadad North Early Development Facility (Edf) Project - Package 1Javeria NazNo ratings yet

- Compressible-Fluid Dynamics: Philip A. ThompsonDocument7 pagesCompressible-Fluid Dynamics: Philip A. ThompsonmazharalipakNo ratings yet

- Bernolii EquationDocument5 pagesBernolii EquationEsra BelhajNo ratings yet

- Hypress Compressor For VSP (Vertical Seismic Profile) JobDocument103 pagesHypress Compressor For VSP (Vertical Seismic Profile) JobIAN.SEMUTNo ratings yet

- Flowfit CYA251: Technical InformationDocument12 pagesFlowfit CYA251: Technical InformationAngelica BarbaraNo ratings yet

- 28-501-Dd-C-Sub-Dr-012-1 (Sheet 1 of 5)Document1 page28-501-Dd-C-Sub-Dr-012-1 (Sheet 1 of 5)smazNo ratings yet

- Lectures 1 To 3 PDFDocument34 pagesLectures 1 To 3 PDFdev burmanNo ratings yet

- Selection of Condensers and Chillers: Systems & Components (India) Pvt. LTDDocument34 pagesSelection of Condensers and Chillers: Systems & Components (India) Pvt. LTDRASHEED YUSUFNo ratings yet

- Vacuum Cleaners Catalogue 2020 DYNAVAC 1Document8 pagesVacuum Cleaners Catalogue 2020 DYNAVAC 1Anonymous eq5zSUNo ratings yet

- Air VelocityDocument10 pagesAir VelocityMorkechoNo ratings yet

- Lec 13Document5 pagesLec 13Ghazy alshyalNo ratings yet

- Dial Thermometer DatasheetDocument1 pageDial Thermometer DatasheetmikeylesNo ratings yet

- Data Sheet For Debutanizer Air CoolerDocument5 pagesData Sheet For Debutanizer Air CoolerMohamed hamza souissiNo ratings yet

- N° 5642-1470-HDD-ME-0004: Sheet 1 Data Sheet Check ValvesDocument3 pagesN° 5642-1470-HDD-ME-0004: Sheet 1 Data Sheet Check ValvesEA MQNo ratings yet

- PPE Exit Exam ReviewerDocument48 pagesPPE Exit Exam ReviewerJamiel CatapangNo ratings yet

- Atomrobot Catalogue Atom Vacuum GeneratorDocument4 pagesAtomrobot Catalogue Atom Vacuum GeneratorVahid KarimiNo ratings yet

- LinkedIn-Pump Vendor Data Sheet and Curve PDFDocument9 pagesLinkedIn-Pump Vendor Data Sheet and Curve PDFBehnaz Motamed100% (1)

- Gaz AkışkanlıGüçÇevrimleriDocument31 pagesGaz AkışkanlıGüçÇevrimleriAlper EmekNo ratings yet

- Sample CoolerDocument2 pagesSample CoolerKrishna KumarNo ratings yet

- Soni Me Dy XhamaDocument2 pagesSoni Me Dy Xhamabora sulatiNo ratings yet

- C-102 Azeotropic Distillation ColumnDocument43 pagesC-102 Azeotropic Distillation ColumnVishnuboy VishnuNo ratings yet

- ASME Performance Test CodesDocument2 pagesASME Performance Test CodesPrabhakar KattulaNo ratings yet

- Equipment Delivery Erection Schedule-PCB Project 1Document1 pageEquipment Delivery Erection Schedule-PCB Project 1K.praveenNo ratings yet

- Cavitation in Reciprocating PumpsDocument4 pagesCavitation in Reciprocating PumpsEhab Attia SelimNo ratings yet

- Analizer SymbolReport-070529 92516AMDocument5 pagesAnalizer SymbolReport-070529 92516AMs.mladinNo ratings yet

- MC20005 WHP WI P 0116 Sampling Connection Datasheet WI - Rev.D1Document8 pagesMC20005 WHP WI P 0116 Sampling Connection Datasheet WI - Rev.D1nguyenmainamNo ratings yet

- Ammonia MEB Final PDFDocument30 pagesAmmonia MEB Final PDFMANU BTech MCA Third YearNo ratings yet