Professional Documents

Culture Documents

ISO 9001 Audit Gap Analysis Checklist

ISO 9001 Audit Gap Analysis Checklist

Uploaded by

saravanan ramkumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ISO 9001 Audit Gap Analysis Checklist

ISO 9001 Audit Gap Analysis Checklist

Uploaded by

saravanan ramkumarCopyright:

Available Formats

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 1 of 54

Audit Date:

Audit Description:

Lead Auditor:

Audit Team Members:

4.1 4.2.1 4.2.2 4.2.3 4.2.4

ISO 9001:2008 Auditable Clauses

5.1 5.2 5.3 5.4.1 5.4.2

(Tick those to be evaluated during this audit)

5.5.1 5.5.2 5.5.3 5.6.1 5.6.2

Each auditor should complete the section of the checklist they have been

assigned by the Quality Manager (Internal audits) or Lead Auditor (external 5.6.3 6.1 6.2.1 6.2.2 6.3

audits) [delete as appropriate]. The auditor may provide additional notes 6.4 7.1 7.2.1 7.2.2 7.2.3

and questions regarding the audit trail for each element in the blank space

on the checklist. 7.3.1 7.3.2 7.3.3 7.3.4 7.3.5

The Quality Manager or Lead Auditor [delete as appropriate] is responsible 7.3.6 7.3.7 7.4.1 7.4.2 7.4.3

for reviewing completed sections of the checklist and to organize all

individual sections into one sequential checklist at the conclusion of the 7.5.1 7.5.2 7.5.3 7.5.4 7.5.5

audit. 7.6 8.1 8.2.1 8.2.2 8.2.3

8.2.4 8.3 8.4 8.5.1 8.5.2

8.5.3

PRODUCT REALIZATION PROCESS EXCLUSIONS

ISO 9001:2008 Permissible Exclusions 7.1 7.2.1 7.2.2 7.2.3 7.3.1

(Tick those applicable, if any) 7.3.2 7.3.3 7.3.4 7.3.5 7.3.6

7.3.7 7.4.1 7.4.2 7.4.3 7.5.1

7.5.2 7.5.3 7.5.4 7.5.5 7.6

Legend

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 2 of 54

A = Opportunity for B = Minor Non- C = Major Non-conformance SQ = Supplementary Question

Improvement conformance

Conformance: Adherence with the requirements of the standard. No major or minor non-conformances found

Opportunity for Improvement A situation or condition of a management system that may be weak, cumbersome, redundant, overly complex, or in

(OFI): some other manner, may, in the opinion of the auditor, offer an opportunity for an organization to improve its current

status.

OFIs do not require any action on the part of the organization; however, the organization should give them serious

consideration in view of the auditor’s knowledge and exposure to similar systems.

An OFI may be an improvement to the management system or could prevent future problems.

Minor Non-conformance: A non-conformity that, based on the judgment and experience of the auditor, is not likely to result in the failure of the

management system or reduce its ability to assure controlled processes or products.

It may be either:

A failure in some part of the supplier's management system relative to a specified requirement.

A single observed lapse in following one item of a company's management system.

Major Non-conformance: The absence (omission, not addressed) or total breakdown (commission, failure, not implemented) of a system to meet a

specified requirement.

A number of minor non-conformities against one requirement can represent a total breakdown of the system and thus

be considered a major non-conformity.

Any non-compliance that would result in the probable shipment of a non-conforming product. Conditions that may result

in the failure of or materially reduce the usability of the products or services for their intended purpose.

A non-compliance that, in the judgment and experience of the auditor, is likely to either to result in the failure of the

management system or to materially reduce its ability to assure controlled processes and products.

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 3 of 54

4.1 General Requirements

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Has the organization established, documented, implemented

1 4.1 and maintained a QMS and continually improved its

effectiveness?

Has the organization identified the processes needed for the

2 4.1a

QMS and their application throughout the organization?

Has the organization determined the sequence and interaction

3 4.1b

of QMS processes?

What are the criteria and methods the organization uses to

4 4.1c ensure that the operation and control of QMS processes are

effective?

Has the organization provided resources and information

5 4.1d needed to support the operation and monitoring of QMS

processes?

Does the organization monitor, measure and analyze QMS

6 4.1e

processes?

Has the organization implemented actions necessary to achieve

7 4.1f planned results and continual improvement of processes

needed for the QMS?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 4 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Are processes needed for the QMS managed by the

8 4.1 organization in accordance with the requirements of ISO

9001:2008?

How does the organization maintain control over outsourced

9 4.1

processes?

Are the necessary controls for outsourced processes that affect

10 4.1 product conformity with requirements identified within the

QMS?

Does organization have adequate control over outsourced

11 4.1

processes to ensure conformity to all customer requirements?

4.2.1 General

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 5 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

1 4.2.1a Does the organization have a documented quality policy?

Does the organization have a set of documented quality

2 4.2.1a

objectives?

3 4.2.1b Does the organization have a quality manual?

Does the organization operate a set of documented

4 4.2.1c

procedures?

Are adequate documents in place to ensure the effective

5 4.2.1d

planning, operation and control of organization’s processes?

Does documentation include the records required by ISO

6 4.2.1d

9001:2008?

4.2.2 Quality Manual

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 6 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Where in the quality manual is the scope of the QMS identified,

1 4.2.2a

including details of and justification for exclusions?

Where does the quality manual contain or reference the

2 4.2.2b documented procedures established for the QMS?

Where does the quality manual include a description of the

3 4.2.2c

interaction between the processes of the QMS?

4.2.3 Control of Documents

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Does the organization operate an establish document control

1 4.2.3

procedure? (If yes, proceed with questions 22 to 28)

Does the document control procedure define the controls

2 4.2.3a

needed to approve documents for adequacy prior to issue?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 7 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Does the document control procedure define the controls

3 4.2.3b needed to review and update as necessary and re-approve

documents?

Does the document control procedure define the controls

4 4.2.3c needed to ensure that changes and the current revision status

of documents are identified?

Does the document control procedure define the controls

5 4.2.3d needed to ensure that relevant versions of applicable

documents are available at points of use?

Does the document control procedure define the controls

6 4.2.3e needed to ensure that documents remain legible and readily

identifiable?

Does the document control procedure define the controls

7 4.2.3f needed to ensure that documents of external origin are

identified and their distribution controlled?

Does the document control procedure define the controls

needed to prevent the unintended use of obsolete documents,

8 4.2.3g

and to apply suitable identification to them if they are retained

for any purpose?

4.2.4 Control of Records

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 8 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Do records exist that provide evidence of conformity to

1 4.2.4 requirements and of the effective operation of the QMS?

(Should be reviewed throughout the audit)

Does the organization have a documented procedure defining

2 4.2.4 the controls needed for the identification, storage, protection,

retrieval, retention time and disposition of records?

Are records legible, readily identifiable and retrievable? (Should

3 4.2.4

be reviewed throughout the audit)

Have the record requirements been reviewed to ensure

4 4.2.4

conformance with contractual and customer requirements?

5 Management Responsibility

5.1 Management Commitment

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 9 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Does the organization communicate the importance of meeting

1 5.1a

customer, statutory and regulatory requirements?

2 5.1b Does the organization have an established quality policy?

3 5.1c Are the quality objectives established by top management?

4 5.1d Does top management conduct management reviews?

Does top management ensure the availability of resources to

5 5.1e

support and continually improve the QMS?

5.2 Customer Focus

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 10 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Does top management ensure that customer requirements are

1 5.2

determined and met?

5.3 Quality Policy

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

1 5.3a Is the quality policy appropriate to the organization?

Does the quality policy include a commitment to continually

2 5.3b

improve the effectiveness of the QMS?

Does the quality policy provide a framework to establish and

3 5.3c

review quality objectives?

Is the quality policy communicated effectively throughout the

4 5.3d

organisation?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 11 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

5 5.3e Is the quality policy reviewed to confirm suitability?

5.4 Planning

5.4.1 Quality Objectives

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Has top management established quality objectives at relevant

1 5.4.1

functions and levels within the organization?

2 5.4.1 Are the quality objectives measurable?

3 5.4.1 Are the quality objectives consistent with quality policy?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 12 of 54

5.4.2 Quality Management System Planning

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Is the planning of the QMS consistent with the organisation’s

1 5.4.2a quality objectives and general requirements of ISO 9001:2008

(Clause 4.1)?

Does the organization ensure that the integrity of the QMS is

2 5.4.2b maintained when changes to the QMS are planned and

implemented?

5.5 Responsibility, Authority and Communication

5.5.1 Responsibility and Authority

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Has the organization defined and communicated responsibility

1 5.5.1

and authority? (e.g. organizational chart)

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 13 of 54

5.5.2 Management Representative

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

1 5.5.2 Does the organization have a Management Representative?

Does the Management Representative have responsibility and

2 5.5.2a authority to ensure that processes needed for the QMS are

established, implemented and maintained?

Does the Management Representative have responsibility and

3 5.5.2b authority to report to top management on the performance of

the QMS and any need for improvement?

Does the Management Representative have responsibility and

4 5.5.2c authority to ensure the promotion of awareness of customer

requirements throughout the organization?

5.5.3 Internal Communication

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 14 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Is information regarding the effectiveness of the QMS

1 5.5.3

communicated within the organization?

2 SQ If yes, how is the effectiveness of the QMS communicated?

5.6 Management Review

5.6.1 General

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

1 5.6.1 Does top management undertake management review?

Are the records of management reviews maintained in

2 5.6.1

accordance with Clause 4.2.4?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 15 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

3 SQ What is the frequency of management reviews?

4 SQ What sort of information is reviewed in management reviews?

Please show me what records are available from the most

5 SQ

recent management review?

5.6.2 Review Input

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

1 5.6.2a Does the review process consider the results of audits?

2 5.6.2b Does the review process consider customer feedback?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 16 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Does the review process consider process performance and

3 5.6.2c

product conformity?

Does the review process consider the status of the corrective

4 5.6.2d

and preventive actions?

Does the review process follow up actions from previous

5 5.6.2e

management reviews?

Does the review process consider changes that could affect the

6 5.6.2f

QMS?

Does the review process make recommendations for

7 5.6.2g

improvement?

5.6.3 Review Output

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Do the outputs of the review process include decisions and

1 5.6.3a actions concerning the improvement of the effectiveness of the

QMS and its processes?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 17 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Do the outputs of the review process include decisions and

2 5.6.3b actions concerning the improvement of product related

customer requirements?

Do the outputs of the review process include decisions and

3 5.6.3c

actions concerning the resource requirements?

6 Resource Management

6.1 Provision of Resources

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 18 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Has the organization provided the necessary resources to

1 6.1.1a implement and maintain the QMS and continually improve its

effectiveness?

Has the organization provided the necessary resources to

2 6.1.1b

ensure that customer requirements are met?

6.2 Human Resources

6.2.1 General

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Does the organization ensure that personnel have the

1 6.2.1

necessary competence to ensure product conformity?

6.2.2 Competence, Training & Awareness

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 19 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Does the organization determine the necessary education,

1 6.2.2a training, skills and experience for people performing work

affecting product quality?

Does the organization initiate training or other actions to

2 6.2.2b

achieve the necessary level of competence?

Does the organization evaluate the effectiveness of training or

3 6.2.2c

other actions taken?

Does the organization ensure that personnel are aware of the

4 6.2.2d

relevance and importance of their activities?

Does the organization ensure that personnel are aware of how

5 6.2.2d

they contribute to the achievement of the quality objectives?

Does the organization maintain training records in accordance

7 6.2.2e

with Clause 4.2.4?

6.3 Infrastructure

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 20 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Has the organization identified any shortcomings in its

1 6.3

infrastructure and is it taking appropriate action?

Are the buildings, workspace and utilities appropriate for the

2 6.3a

organization product or service?

Is process equipment (including computer software)

3 6.3b

appropriate for the organization’s product or service?

Are support services (e.g. transport, communications, and

4 6.3c waste disposal) appropriate for the organization’s product or

service?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 21 of 54

6.4 Work Environment

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Is the work environment appropriate for achieving product or

1 6.4

service requirements?

2 6.4 Is safety and protective equipment provided where necessary?

3 6.4 Are workstations set out ergonomically?

4 6.4 Are kitchen and toilet facilities adequate?

5 6.4 Are heat, humidity, light levels and airflow controllable?

Are factors affecting hygiene, cleanliness, noise, vibration and

6 6.4

pollution controllable?

Has the organization identified any shortcomings and is it

7 6.4

taking appropriate action?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 22 of 54

7 Product Realization

Question No.

Clause Ref.

Finding

Audit Evidence/Comment

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Has the organization excluded itself from the requirements of

1 7

the Product Realization process?

Has the organization justified any permissible exclusion in the

2 7

relevant section of the quality manual?

7.1 Planning & Product Realization

Question No.

Clause Ref.

Finding

Audit Evidence/Comment

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

1 7.1 Have the processes needed for product realization identified?

Is the planning of product realization consistent with the

2 7.1

requirements of the other processes of the QMS?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 23 of 54

Question No.

Clause Ref.

Finding

Audit Evidence/Comment

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Has the organisation determined quality objectives for its

3 7.1a

products?

Has the organisation identified processes, documents and

4 7.1b

resources required by specific products?

Has the organisation identified methods for verification,

5 7.1c validation, monitoring and inspection and test activities to meet

acceptance criteria?

Has the organisation determined what records are needed to

6 7.1d provide evidence that requirements for specific products have

been met?

Is there an identifiable output from the planning process, in an

7 7.1e

appropriate format in accordance with 4.2.4?

7.2 Customer-related Processes

7.2.1 Determination of Requirements Related to the Product

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 24 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Has the organisation determined product requirements prior to

1 7..2

commitment to supply?

Customer’s specified requirements, delivery, warranty and

2 7.2.1a

service?

3 7.2.1b Requirements necessary for the product’s intended use?

4 7.2.1c Statutory and regulatory requirements?

5 7.2.1d Any additional requirements determined by the organisation?

7.2.2 Review of Requirements Related to the Product

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 25 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Does the organization undertake a review to ensure that the

1 7.2.2 organization has the ability to meet requirements before

committing to supply product?

Does the organization ensure that product requirements are

2 7.2.2a

defined and reviewed before committing to supply product?

Does the organization ensure that contract or order

3 7.2.2b requirements differing from those previously expressed are

resolved before committing to supply product?

Does the organization ensure that it has the ability to meet the

4 7.2.2c

defined requirements?

Can you show me records of the product requirement review

5 SQ

results and actions resulting from them?

When customers don’t have documented requirements, how do

6 SQ

you confirm their requirements before accepting orders?

When product requirements are changed, how do you ensure

7 SQ that relevant documents are changed and that relevant

personnel are made aware of the changes?

7.2.3 Customer Satisfaction

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 26 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Has the organization implemented effective arrangements for

1 7.2.3a

communicating product information?

Has the organization implemented effective arrangements for

2 7.2.3b

communicating enquiries?

Has the organization implemented effective arrangements for

3 7.2.3b communicating contracts or order handling including

amendments?

Has the organization implemented effective arrangements for

4 7.2.3c

communicating customer feedback?

Has the organization implemented effective arrangements for

5 7.2.3c

communicating customer complaints?

7.3 Design & Development

7.3.1 Design & Development Planning

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 27 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Have stages of design and development been determined for

1 7.3.1a

the product?

Are requirements for review, verification and validation defined

2 7.3.1b

for each stage?

Is validation completed prior to delivery or use, where

3 7.3.1b

practical?

4 7.3.1c Are responsibilities for design and development defined?

Is there effective communication between different members or

5 7.3.1

groups in the design team?

Is planning output updated as appropriate as the design and

6 7.3.1

development progresses?

7.3.2 Design & Development Inputs

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 28 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Are records of design inputs maintained in accordance with

1 7.3.2

Clause 4.2.4?

2 7.3.2a Are requirements defined for function and performance?

3 7.3.2b Are applicable statutory and regulatory requirements defined?

4 7.3.2c Is information to be used from previous designs defined?

Are other requirements essential for design and development

5 7.3.2d

adequately defined?

Are design inputs reviewed for adequacy to confirm that they

6 7.3.2

are complete, unambiguous and not in conflict?

7.3.3 Design & Development Outputs

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 29 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Do the outputs meet input requirements for design and

1 7.3.3a

development?

Do the outputs provide information required for purchasing,

2 7.3.3b

production and service provision?

Do the outputs contain or reference product acceptance

3 7.3.3c

criteria?

Do outputs specify characteristics for the product’s safe and

4 7.3.3d

proper use?

7.3.4 Design & Development Review

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 30 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Have design and development reviews taken place (involving

1 7.3.4 representatives of all relevant functions) in accordance with the

design and development plan?

Do participants in design reviews include representatives of

2 7.3.4 functions concerned with the design development stage being

reviewed?

Are records of reviews available in accordance with Clause

3 7.3.4

4.2.4?

Can the organization confirm that the results of design and

4 7.3.4a

development have been evaluated?

5 7.3.4b Were problems identified and were actions taken for resolution?

7.3.5 Design & Development Verification

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 31 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Has verification been completed in accordance with the design

1 7.3.5 and development plan to confirm that design and development

outputs meet requirements of inputs?

Are records maintained of the results of verification and any

2 7.3.5

necessary actions in accordance with Clause 4.2.4?

7.3.6 Design & Development Validation

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Has validation been completed in accordance with the design

1 7.3.6 and development plan to confirm that the product is suitable

for its specified application or intended use?

Are records maintained of the results of validation and any

2 7.3.6

necessary actions in accordance with Clause 4.2.4?

7.3.7 Control of Design & Development Changes

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 32 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Have changes been reviewed to evaluate their effect on

1 7.3.7

constituent parts and on product already delivered?

2 7.3.7 Have changes been approved prior to implementation?

3 7.3.7 Have changes been appropriately verified and validated?

Are records maintained of the results of change reviews and

4 7.3.7

any necessary actions in accordance with Clause 4.2.4?

7.4 Purchasing

7.4.1 Purchasing Process

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 33 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Are verification requirements appropriate for the product’s

1 7.4.1

application?

Are suppliers evaluated and selected (in accordance with

2 7.4.1 established criteria) on the basis of their ability to meet

specified requirements?

Are suppliers periodically re-evaluated in accordance with

3 7.4.1

established criteria?

Are records maintained of the results of supplier evaluations in

4 7.4.1

accordance with Clause 4.2.4?

7.4.2 Purchasing Information

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 34 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Does purchasing information adequately describe the product

1 7.4.2

to be purchased?

Does purchasing information adequately describe the

2 7.4.2a requirements for approval of product, procedures and

equipment?

Does purchasing information adequately describe the

3 7.4.2b

requirements for qualification of personnel?

Does purchasing information adequately describe quality

4 7.4.2c

management system requirements?

Does the organisation ensure that purchasing information is

5 7.4.2

adequate prior to issue to the supplier?

7.4.3 Verification of Purchased Product

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 35 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Is purchased product verified in accordance with specified

1 7.4.3

requirements?

Does purchasing information contain details of any verification

2 7.4.3

to be performed at the supplier’s premises?

7.5 Product & Service Provision

7.5.1 Control of Production & Service Provision

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Is required information available to describe product

1 7.5.1a

characteristics?

2 7.5.1b Are necessary work instructions available?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 36 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

3 7.5.1c Is suitable equipment available?

4 7.5.1d Are required monitoring and measuring devices available?

Are required monitoring and measuring devices used in

5 7.5.1e

accordance with work instructions and/or the quality plan?

Are requirements for release, delivery and post delivery

6 7.5.1f

activities implemented?

7.5.2 Validation Processes for Production & Service Provision

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 37 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Is production or provision of service which cannot be verified by

1 7.5.2a subsequent monitoring or measuring adequately validated to

demonstrate that planned results are being achieved?

2 7.5.2b Are criteria defined for review and approval of the processes?

3 7.5.2c Are personnel qualified and is equipment approved?

Are required records maintained in accordance with Clause

4 7.5.2d

4.2.4?

5 7.5.2e Is the time interval for process re-validation defined?

Does validation demonstrate the ability of the process to

6 7.5.2f

achieve planned results?

7.5.3 Identification & Traceability

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 38 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Is product identification and traceability required to be

1 7.5.3

maintained throughout production (for any products)?

Is inspection and test status adequately defined maintained

2 7.5.3

throughout production?

If traceability is a requirement are records of unique

3 7.5.3 identification of the product available in accordance with

Clause 4.2.4?

7.5.4 Customer Property

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Does the organisation adequately identify, verify, protect and

1 7.5.4

safeguard customer property?

2 7.5.4 Is the customer’s intellectual property controlled?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 39 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Are records maintained of any loss or damage to customer

3 7.5.4

property in accordance with Clause 4.2.4?

7.5.5 Preservation of Product

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Are components adequately identified, handled, packaged,

1 7.5.5

stored and protected prior to use?

Are finished products adequately identified, handled, packaged,

2 7.5.5

stored and protected prior to delivery?

7.6 Control of Monitoring & Measuring Equipment

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 40 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Are monitoring and measuring devices required by the QMS

1 7.6

controlled?

Is each device calibrated or verified at specified intervals (or

2 7.6a prior to use) against measurement standards traceable to

national or international standards?

Where no such standards exist is the basis of calibration or

3 7.6a

verification defined?

Is each device adjusted or re-adjusted as necessary (in

4 7.6b

accordance with manufacturer’s instructions)?

Is each device identified to enable calibration status to be

5 7.6c

determined?

Is each device safeguarded from adjustment, which would

6 7.6d

invalidate the measurement result?

Is each device protected from damage or deterioration during

7 7.6e

handling, maintenance or storage?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 41 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Is the validity of previous results assessed and appropriate

8 7.6 action taken, when a device is found not to conform to

requirements?

Are records of the results of calibration and verification

9 7.6

maintained in accordance with Clause 4.2.4?

When computer software is used in the monitoring and

10 7.6

measuring equipment is it validated prior to initial use?

When computer software is used in the monitoring and

11 7.6

measuring equipment is it re-confirmed as necessary?

8.0 Measurement, Analysis & Improvement

8.1 General

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 42 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Has the organization implemented appropriate measurement,

1 8.1a analysis and improvement processes needed to demonstrate

product conformity?

Has the organization implemented appropriate measurement,

2 8.1b analysis and improvement processes needed to ensure

conformity of the QMS

Has the organization implemented appropriate measurement,

3 8.1c analysis and improvement processes needed to continually

improve the effectiveness of the QMS?

Does the organization apply statistical techniques and

4 8.1

determine the extent of their use?

8.2 Monitoring & Measurement

8.2.1 Customer Satisfaction

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 43 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

1 8.2.1 Does the organization monitor customer satisfaction?

Does the organization use this information in accordance with

2 8.2.1

defined methods?

8.2.2 Audit

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Is there a documented procedure which defines responsibility

1 8.2.2

and requirements for planning and conducting audits?

Is there a documented procedure which defines responsibility

2 8.2.2

and requirements for reporting audit results?

Is there an audit programme in place defining audit criteria,

3 8.2.2

scope, frequency and methods?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 44 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

4 8.2.2 Are records of audits maintained?

5 8.2.2 Do audit records confirm that audits were conducted?

Do audit records confirm that audits were conducted in

6 8.2.2

accordance with the audit schedule?

Were appropriate follow up actions taken to eliminate non-

7 8.2.2

conformances and their root cause?

8 8.2.2 Were the results of any follow up actions verified?

Are effective methods used to monitor (and measure if

9 8.2.2

applicable) the processes of the QMS and the organisation?

Do the results confirm that they are capable of achieving

10 8.2.2

planned results?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 45 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

If planned results are not achieved has appropriate action been

11 8.2.2

taken?

8.2.3 Monitoring & Measurement of Processes

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Are effective methods used to monitor and measure the

1 8.2.3

processes of the QMS and the organisation?

Do the results confirm that the processes are capable of

2 8.2.3

achieving planned results?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 46 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

If planned results are not achieved has appropriate action been

3 8.2.3

taken?

8.2.4 Monitoring & Measurement of Product

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Are product characteristics measured to confirm that product

1 8.2.4

requirements are met?

Do monitoring and measuring activities take place at

2 8.2.4

predetermined stages during the product realization process?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 47 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Are records of evidence of conformity with acceptance criteria

3 8.2.4

maintained in accordance with Clause 4.2.4?

Are records that indicate authorized release of a product to the

4 8.2.4

next stage available?

Do arrangements exist to ensure that a product is not released

5 8.2.4

until the all requirements have been met

Do arrangements exist to ensure that if a product must be

6 8.2.4

released prior satisfying the requirements, is it approved?

8.3 Control on Non-conforming Product

Question No.

Clause Ref.

Finding

Audit Evidence/Comment

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Is there a documented procedure which describes how non-

1 8.3

conforming product is dealt with?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 48 of 54

Question No.

Clause Ref.

Finding

Audit Evidence/Comment

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Is there a documented procedure which describes the

2 8.3 identification of non-conformities and actions to prevent

unintended use or delivery?

Is there a documented procedure which describes the

3 8.3 necessary responsibility and authority for dealing with non-

conforming product?

Is there a documented procedure which describes methods of

4 8.3

dealing with non-conforming product?

Is there a documented procedure which describes the action to

5 8.3

be taken if non-conformity is detected after delivery?

Are there records of action taken following identification of a

6 8.3

non-conformity maintained in accordance with Clause 4.2.4?

Do the records detail any re-work undertaken to eliminate the

7 8.3

detected non-conformity?

Do the records detail methods and criteria for re-verification to

8 8.3

demonstrate conformity?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 49 of 54

Question No.

Clause Ref.

Finding

Audit Evidence/Comment

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Do the records detail acceptances under concession by a

9 8.3

relevant authority?

Do the records detail if non-conforming products were

10 8.3

withdrawn from intended use?

8.4 Analysis of Data

Question No.

Clause Ref.

Finding

Audit Evidence/Comment

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Are data collected and analyzed to demonstrate the suitability

1 8.4 and effectiveness of the QMS and to evaluate where continual

improvement of its effectiveness can be made?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 50 of 54

Question No.

Clause Ref.

Finding

Audit Evidence/Comment

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Does the analysis of data include information relating to

2 8.4

customer satisfaction?

Does the analysis of data include information relating to the

3 8.4

conformity to product requirements?

Does the analysis of data include information relating to

4 8.4

characteristics and trends of processes and products?

Does the analysis of data include information relating to

5 8.4

improvement opportunities and preventive action?

Does the analysis of data include information relating to

6 8.4

suppliers?

8.5 Improvement

8.5.1 Continual Improvement

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 51 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Does the organisation continually improve the effectiveness of

1 8.5.1

the QMS through use of the quality policy?

Does the organisation continually improve the effectiveness of

2 8.5.1

the QMS through use of quality objectives?

Does the organisation continually improve the effectiveness of

3 8.5.1

the QMS through use of audit results?

Does the organisation continually improve the effectiveness of

4 8.5.1

the QMS through use of data analysis?

Does the organisation continually improve the effectiveness of

5 8.5.1

the QMS through use of corrective and preventive action?

Does the organisation continually improve the effectiveness of

6 8.5.1

the QMS through use of management reviews?

8.5.2 Corrective Action

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 52 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Is there a documented procedure which describes how

1 8.5.2

corrective action is undertaken?

Do corrective actions records identify and address root

2 8.5.2

cause(s)?

3 8.5.2 Are actions taken appropriate to the severity of the problem?

Does the corrective action procedure define the requirements

4 8.5.2a for the review of non-conformities (including customer

complaints)?

Does the corrective action procedure define the requirements

5 8.5.2d

for the review of determining the causes of non-conformities?

Does the corrective action procedure define the requirements

6 8.5.2c for evaluating the need for action to ensure that non-

conformities do not recur?

Does the corrective action procedure define the requirements

7 8.5.2d

for determining and implementing action needed?

Does the corrective action procedure define the requirements

8 8.5.2e

for the records of the results of action taken?

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 53 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Does the corrective action procedure define the requirements

9 8.5.2f

for reviewing the effectiveness of corrective actions taken?

Have corrective actions been implemented in accordance with

10 8.5.2

the documented procedure?

8.5.3 Preventive Action

Auditor Name (print): Initials: Date:

Tranzone

ISO 9001:2008 Audit & Gap Analysis Checklist Version 1

(This checklist may be used for internal or external auditing purposes).

Page 54 of 54

Question No.

Clause Ref.

Finding

Audit Evidence

Audit Question NO

YES N.B. Provide references to documentation

A B C

where necessary

Does the preventive action procedure define the requirements

1 8.5.3a

for determining causes of potential non-conformities?

Does the preventive action procedure define the requirements

2 8.5.3b for evaluating whether action needs to be taken to prevent

occurrence?

Does the preventive action procedure define the requirements

3 8.5.3c for determining what action is required and ensuring that it is

implemented?

Does the preventive action procedure define the requirements

4 8.5.3d for maintaining records (in accordance with Clause 4.2.4) of the

results of action taken?

Does the preventive action procedure define the requirements

5 8.5.3e

for reviewing preventive action taken?

Has preventive action been implemented in accordance with

6 8.5.3

the documented procedure?

Auditor Name (print): Initials: Date:

You might also like

- 144 SQRRDocument19 pages144 SQRRcaptainamerica201390% (20)

- Pharmacy Statistics Midterms - Hypothesis TestingDocument41 pagesPharmacy Statistics Midterms - Hypothesis TestingKaguraNo ratings yet

- ISO 9001 2015 Mock AuditDocument15 pagesISO 9001 2015 Mock AuditMadan R HonnalagereNo ratings yet

- Audit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19From EverandAudit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19No ratings yet

- Ethics Code ConductDocument9 pagesEthics Code ConductSurabhi SrivastavaNo ratings yet

- Apply Quality StandardsDocument71 pagesApply Quality StandardsDavid PolaoNo ratings yet

- 1.1. Management Review InputDocument3 pages1.1. Management Review InputCok Mayun WidyatmikaNo ratings yet

- Audit Planning TechniquesDocument12 pagesAudit Planning TechniquesRahul KadamNo ratings yet

- How To Set The ISMS ScopeDocument15 pagesHow To Set The ISMS ScopeDomijones ManaloNo ratings yet

- How Can ISO 13485 Clause 7.4, Purchasing, Enhance ProcurementDocument3 pagesHow Can ISO 13485 Clause 7.4, Purchasing, Enhance ProcurementPavan MujawdiyaNo ratings yet

- Introduction To ISO 9001 2015Document11 pagesIntroduction To ISO 9001 2015chrisNo ratings yet

- Food Safety Auditing PDFDocument20 pagesFood Safety Auditing PDFYashini BhuguthNo ratings yet

- A5.1 Objectives - v1Document5 pagesA5.1 Objectives - v1Jerome MamauagNo ratings yet

- Leave AttendancepolicyDocument9 pagesLeave AttendancepolicyVishal MandowaraNo ratings yet

- SQF Code Edition 7.2 Checklist FinalDocument387 pagesSQF Code Edition 7.2 Checklist FinalGrace Cheng0% (1)

- Faqs Udi SystemDocument6 pagesFaqs Udi SystemvadiNo ratings yet

- Clause 8 - ExplanationDocument33 pagesClause 8 - Explanations_agali2413No ratings yet

- MDSAP AU P0008.006 - Audit Time - Determination - 0424 Posted FINALDocument15 pagesMDSAP AU P0008.006 - Audit Time - Determination - 0424 Posted FINALHARESH NIRMALNo ratings yet

- Documents and Records: Presented By: Cardia FourieDocument52 pagesDocuments and Records: Presented By: Cardia FourieWael SaeedNo ratings yet

- Basics of Quality ManagementDocument14 pagesBasics of Quality ManagementWiki Waqas100% (1)

- QMS Training Guide Prep. Based On.... Clause 6 HAM. 19.15ECDocument17 pagesQMS Training Guide Prep. Based On.... Clause 6 HAM. 19.15ECKenate MergaNo ratings yet

- What Is A Document?: Tips On ISO 9001 Quality Management System DocumentationDocument5 pagesWhat Is A Document?: Tips On ISO 9001 Quality Management System DocumentationMohammad Jaid AlamNo ratings yet

- 3rd ISO 90012015 Internal Audit ReportDocument40 pages3rd ISO 90012015 Internal Audit Reportmohammed kurkuruNo ratings yet

- Auditing (3Rd Party)Document7 pagesAuditing (3Rd Party)Neil Buyco VillamorNo ratings yet

- Achieving Quality Production: Textbook, Chapter 19 (PG 235-239)Document4 pagesAchieving Quality Production: Textbook, Chapter 19 (PG 235-239)Vincent ChurchillNo ratings yet

- The Biggest Internal Audit Challenges in The Next Five YearsDocument3 pagesThe Biggest Internal Audit Challenges in The Next Five YearsBagusNo ratings yet

- Supplier Evaluation The First Step in Effective SoDocument4 pagesSupplier Evaluation The First Step in Effective SoShatender kumar Kumar100% (1)

- Q M S (QMS) : Uality Anagement YstemDocument37 pagesQ M S (QMS) : Uality Anagement YstemDaud AliNo ratings yet

- 01 ISO 9001-2015 Transition Checklist C 01 Rev ADocument4 pages01 ISO 9001-2015 Transition Checklist C 01 Rev Avikkas vermaNo ratings yet

- QSP 8.1 Marketing (Preview)Document4 pagesQSP 8.1 Marketing (Preview)Centauri Business Group Inc.No ratings yet

- Audit Client SurveyDocument1 pageAudit Client Surveytaufik_ahmad_4No ratings yet

- The APIC Audit ProgrammeDocument19 pagesThe APIC Audit ProgrammeshdphNo ratings yet

- The Control of Hazardous Energy (Lockout/Tagou T)Document27 pagesThe Control of Hazardous Energy (Lockout/Tagou T)talhabctianNo ratings yet

- Win More Tenders With ISO Management SystemsDocument3 pagesWin More Tenders With ISO Management SystemsDavid100% (2)

- Isr 13485 Delta ChecklistDocument11 pagesIsr 13485 Delta ChecklistMs. ThuNo ratings yet

- Mini Quality ManualDocument7 pagesMini Quality Manualwici2915No ratings yet

- My Accounts: Download The ExnessDocument1 pageMy Accounts: Download The ExnessInt’l Joshy NiceNo ratings yet

- QMS Deployment Kickoff CoveDocument16 pagesQMS Deployment Kickoff CoveAliNo ratings yet

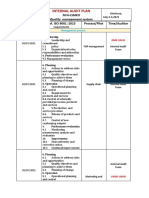

- Internal Audit Plan: Day Ref. ISO 9001:2015 Process/Pilot Time/AuditorDocument3 pagesInternal Audit Plan: Day Ref. ISO 9001:2015 Process/Pilot Time/AuditorPFENo ratings yet

- Food Label Guide FDADocument132 pagesFood Label Guide FDAStephanie AngkaNo ratings yet

- Clause Based ChecklistDocument9 pagesClause Based ChecklistLim Kim YookNo ratings yet

- Quality Manual Policy ObjectivesDocument4 pagesQuality Manual Policy ObjectivesMemories & Moments Payel & Swastik100% (1)

- 31-290917 Internal Audit ReportDocument3 pages31-290917 Internal Audit ReportDanny HuntNo ratings yet

- Welcome To Presentation By: Knowledge SeekersDocument39 pagesWelcome To Presentation By: Knowledge Seekersfaraazxbox1No ratings yet

- ISO 13485 PurchasingDocument5 pagesISO 13485 PurchasingSubhashNo ratings yet

- CapA by HopeDocument31 pagesCapA by HopeAtul R. VekariyaNo ratings yet

- Quality AuditsDocument15 pagesQuality AuditsPrachi PandeyNo ratings yet

- Quality Manual: For Carolina Precision Manufacturing, LLC IndexDocument27 pagesQuality Manual: For Carolina Precision Manufacturing, LLC IndexhjgajjarNo ratings yet

- Best Practice Quality Policy StatementsDocument3 pagesBest Practice Quality Policy StatementsdanielsasikumarNo ratings yet

- How To Create An Process Flowchart: White PaperDocument5 pagesHow To Create An Process Flowchart: White Papermardirad0% (1)

- SOP 20-005 Sampling InspectionDocument9 pagesSOP 20-005 Sampling InspectionsushmaxNo ratings yet

- Pecb Iso 13485 Lead Auditor Exam Preparation GuideDocument15 pagesPecb Iso 13485 Lead Auditor Exam Preparation GuiderberrospiNo ratings yet

- Technical Bulletin: ISO 9001:2015 - Introducing The ChangesDocument5 pagesTechnical Bulletin: ISO 9001:2015 - Introducing The ChangesAlfredo MárquezNo ratings yet

- Audit Start Up: Involved, Must Not Be Sent in Any Form To Outsiders) )Document14 pagesAudit Start Up: Involved, Must Not Be Sent in Any Form To Outsiders) )MehakKapoorNo ratings yet

- Medical Device Regulation MDR 2017 745 Mindmap ENDocument2 pagesMedical Device Regulation MDR 2017 745 Mindmap ENsab100% (1)

- Non Conforming Product Management: Quality Systems ManualDocument5 pagesNon Conforming Product Management: Quality Systems ManualSalman SheikhNo ratings yet

- ISO 9001 Auditing Practices Group Draft Guidance OnDocument4 pagesISO 9001 Auditing Practices Group Draft Guidance OnStandardsmanNo ratings yet

- Secrets of Surviving A Quality Audit: TimingDocument9 pagesSecrets of Surviving A Quality Audit: TimingmhnofuenteNo ratings yet

- Stage 1 Audit ReportDocument3 pagesStage 1 Audit ReportALOKE GANGULYNo ratings yet

- Dual Mass FlywheelDocument2 pagesDual Mass FlywheelZimekNo ratings yet

- Product Specification: AUO Confidential For STAR Internal Use Only On 2014/04/15Document32 pagesProduct Specification: AUO Confidential For STAR Internal Use Only On 2014/04/15Yunianto ObloNo ratings yet

- Full Download Fundamentals of Human Resource Management 5th Edition Noe Test BankDocument35 pagesFull Download Fundamentals of Human Resource Management 5th Edition Noe Test Bankflautistimpend.bkjv100% (43)

- ZN 414Document8 pagesZN 414hidalgobNo ratings yet

- 90ZV-2 Function & StructureDocument499 pages90ZV-2 Function & StructureKawasaki100% (1)

- New Grad FSR Program Description - DomesticDocument3 pagesNew Grad FSR Program Description - DomesticrmdoucetNo ratings yet

- Article IDocument8 pagesArticle IMuhammad Nuril Wahid FauziNo ratings yet

- Lesson PlanDocument6 pagesLesson PlanMegan ResslerNo ratings yet

- BiodiversityDocument20 pagesBiodiversityA.B SathyaNo ratings yet

- Rev2Document3 pagesRev2Deyvi Osmar Zegarra VillenaNo ratings yet

- Major VFP Encryption Update - SweetPotato Software BlogDocument8 pagesMajor VFP Encryption Update - SweetPotato Software BlogAntonio BeltránNo ratings yet

- Background of The StudyDocument3 pagesBackground of The Studyarnistina malbasNo ratings yet

- Introduction To Humanities: Taleb - Eli@skylineuniversity - Ac .AeDocument8 pagesIntroduction To Humanities: Taleb - Eli@skylineuniversity - Ac .AeAmjad khanNo ratings yet

- Applied Business Unit 2 CourseworkDocument7 pagesApplied Business Unit 2 Courseworkykzdmfajd100% (2)

- A24CE Rev 109Document43 pagesA24CE Rev 109Boeing.smart2298No ratings yet

- Overdispersion Models and EstimationDocument20 pagesOverdispersion Models and EstimationJohann Sebastian ClaveriaNo ratings yet

- Research Template 2023Document24 pagesResearch Template 2023examreviewer9No ratings yet

- Reservoir Fluids Day 4Document57 pagesReservoir Fluids Day 4Bella cedricNo ratings yet

- Engineering Management KNR 4553 / KNL 4603: Topic 3 - PlanningDocument23 pagesEngineering Management KNR 4553 / KNL 4603: Topic 3 - PlanningrpjongNo ratings yet

- Final Design Review ChecklistDocument3 pagesFinal Design Review ChecklisttnchsgNo ratings yet

- Shallow Water Acoustic Networks Full ReportDocument26 pagesShallow Water Acoustic Networks Full ReportSimmi JoshiNo ratings yet

- SHARP-mxm350n M350u m450n M450uDocument12 pagesSHARP-mxm350n M350u m450n M450uIoas IodfNo ratings yet

- A Critical Review of Urban LivabilityDocument18 pagesA Critical Review of Urban LivabilityEdwin SilvaNo ratings yet

- Philips Problem Solving - PRIDE - Poster Deck v02Document11 pagesPhilips Problem Solving - PRIDE - Poster Deck v02Vanita GanthadeNo ratings yet

- O Ring Viton Vs NitrileDocument3 pagesO Ring Viton Vs NitrileIrfanmaulana ardiansyahNo ratings yet

- The English Paragraph: What Is A Paragraph?Document6 pagesThe English Paragraph: What Is A Paragraph?Khin Maung HtweNo ratings yet

- Ebrahim 2016Document31 pagesEbrahim 2016Afrizal DanaNo ratings yet

- Literary Reading Through A Biographical ContextDocument1 pageLiterary Reading Through A Biographical ContexthaydeeNo ratings yet