Professional Documents

Culture Documents

Abschn 14

Abschn 14

Uploaded by

Vikas NaikOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abschn 14

Abschn 14

Uploaded by

Vikas NaikCopyright:

Available Formats

IV - Part 6 Section 14 A Flares and Cold Vents Chapter 5

GL 2007 Page 14–1

Section 14

Flares and Cold Vents

A. General − communication by portable radio or telephone is

still possible

1. Scope

− public address announcements and acoustic warn-

The following requirements apply to flares and cold ing signals are audible throughout the installation

vents on mobile offshore units and fixed offshore (s)/unit.

installations, used for the safe disposal of hydrocarbon

gases and vapours and other gases associated with This applies in particular to maximum flow condi-

drilling, production and processing of mineral oil and tions.

gas.

Special requirements for sour gas have to be consid- 5. Design

ered according to Section 17, C.

5.1 For safety and environmental reasons the

2. Reference to other rules, regulations and need for flaring shall be minimized.

standards

5.2 In the design of the flare/cold vent system

Designs based on other internationally acknowledged provisions shall be made to avoid:

rules, regulations or standards will be accepted if they

provide an equal degree of safety. − blowback of the flame

Attention is drawn also to governmental regulations − accumulation of liquids in the flare piping

and/or requirements imposed by local authorities.

− carry-over of liquids, e.g. by appropriately sized

3. Orientation, arrangement knock-out drum

3.1 The target of a safe dilution of the released − precipitation of unburnt liquid droplets onto

gas shall be duly considered. For the orientation of the equipment or structure, e.g. by appropriately sized

flare or cold vent relative to the offshore installa- droplet removal systems

tion(s)/unit, careful consideration shall be given to

prevailing wind directions and speeds. − hydrocarbon contamination of air intakes for heat-

ing, ventilation, air condition (HVAC) and com-

bustion air

3.2 In general the flare or cold vent shall be posi-

tioned downwind of any production/process areas and − excessive internal back pressure resulting from

accommodation modules. critical discharge scenarios

3.3 The arrangement of the flare or cold vent − excessive forces due to surge effects on the piping

shall be determined with due regard to unimpeded:

− thermal stresses caused by temperature differences

− helicopter and boat traffic between discharged gas and components of the

− crane boom circles system

− access to boat landings from the water side (ma- − fallout/generation of sludge

rine craft) and from the installation’s/unit’s escape

routes 5.3 The safety arrangements for the flare/cold

vent systems shall be incorporated into the installa-

3.4 Accessibility for maintenance of the flare or tion’s/unit’s Emergency Shut Down (ESD) system, as

vent tip has to be ensured. necessary.

4. Noise 5.4 The hydraulic and thermal capacity of a

flare/cold vent shall be determined on a well defined

Noise produced by flares and cold vents shall at all worst case scenario, taking into account the highest

normally manned locations be within such limits as to possible flow rates, e.g. in a blowdown situation, and

ensure that considering worst case gas composition.

Chapter 5 Section 14 C Flares and Cold Vents IV - Part 6

Page 14–2 GL 2007

5.5 Selection of materials shall be made with due In most cases, structural components and equipment

regard to corrosion and erosion attack. can safely tolerate higher degrees of heat density than

those defined for personnel in Table 14.1. However, if

any items vulnerable to overheating problems are

involved, such as construction materials that have low

B. Flares melting points (for example, aluminium or plastic),

heat-sensitive streams, flammable vapour spaces, or

1. Special requirements electrical equipment, then the effect of radiant heat on

them may need to be evaluated. Thus, special attention

A flare system shall be properly designed with due may be required for helicopter decks made of alumin-

regard to: ium. Structural integrity and operability have to be

maintained, e.g. by thermal insulation.

− complete combustion (smokeless operation to be

ensured by manufacturer) Further consideration shall be given to the thermal

stability of lubricants, e.g. for drilling equipment, and

− flame retention and stability even under surging to the limitation of surface temperatures in hazardous

gas conditions and maximum wind conditions areas.

4. Pilot burner and ignition system

2. Documents for approval

A pilot burner shall be provided in such an arrange-

Documentation on the following shall be submitted for ment to ensure a stable pilot flame under all environ-

review/approval: mental conditions. Means to verify the existence of the

pilot flame and to verify that the pilot burner does

− description of the flare type, materials and manu- ignite the gas flow instantaneous on discharge are

facturer, type of seal required, e.g. installation of flame monitors.

− description of operating and safety philosophy In order to start and maintain a flame, an ignition

with regard to flaring system shall be provided capable of remote operation,

so that neither personnel nor ignite controls can be

− process flow sheet affected by detrimental heat radiation.

− piping and instrumentation diagrams (PIDs) in- 5. Safety arrangements

cluding safety facilities, flare collecting headers

and flare utilities 5.1 Provision shall be made to prevent the ingress

of air into the flare system and possible formation of

− design of vessels, e.g. scrubbers, knock-out drums explosive atmosphere at low flow rates. This may be

achieved by providing a continuous purge gas system

− radiation calculations (flare study) for hot flares or equivalent.

respectively dispersion study for cold vents

5.2 Suitably arranged alarms for reception at a

− plans for thermal shielding, insulation and protec- manned control station shall be provided for the flare

tion of structure and pressurized equipment, as far system, e.g.:

as necessary

− pilot flame out

− plans of provision and location of heat shields for

personnel escape routes, as far as necessary − low pressures in the gas line or pilot gas line

− levels in scrubbers/knock-out drums

3. Thermal radiation levels

Pilot flame monitors are to be located such that heat

The intensity and distribution of thermal radiation radiation from the flare does not render them inoper-

shall be calculated by using an appropriate method in able.

order to cover the entire operating range of the flare.

5.3 Where drain pumps for scrubbers/knock-out

Maximum exposure levels for personnel as given in

drums are provided, their operation shall be automatic.

Table 14.1 shall not be exceeded unless special protec-

tive measures are taken. Solar radiation shall be taken

into account. For example, solar radiation levels of 0,7

to 0,8 kW/m² have been recorded for the southern C. Cold Vents

North Sea.

1. Special requirements

Special attention may be required regarding protection

for elevated working environments, such as cranes, The approval of cold vents follows, to the applicable

helicopter decks, drilling derricks, etc. extent, the same procedure as for flares.

IV - Part 6 Section 14 C Flares and Cold Vents Chapter 5

GL 2007 Page 14–3

A cold vent system shall be properly designed with Provision of a flame arrester shall be considered on a

due regard to dispersion to ensure that neither explo- vent system wherever a permanent or long-standing

sive nor toxic gas mixtures may be created in the relief is intended to be made from the vent system.

installation/unit under the given environmental condi-

tions. 3. Discharge of toxic and/or corrosive va-

pours

2. Accidental ignition Where toxic and/or corrosive gases are to be dis-

charged through a vent, their concentration shall be

A snuffing system or equivalent shall be provided to such that it does not create a safety hazard for per-

immediately extinguish the flame in case of acciden- sonnel. The safe disposal of substances having toxic

tal ignition of the gases. or corrosive properties may require chemical treat-

For such cases protective measures for personnel and ment prior to their discharge into the atmosphere.

equipment may be required, depending upon their See also Chapter 2 – Mobile Offshore Units, Section

distance from the flame. 1, C.4.6.2.4

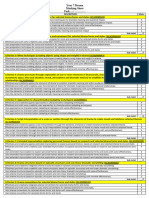

Table 14.1 Recommended total design radiation

Permissible design level (K)

British Thermal Conditions

Kilowatt/m2

Units/hour/foot2

Heat intensity on structures and areas where operators are not

5000 15,77 likely to be performing duties and where shelter from radiant

heat is available (e.g. behind equipment)

Value of K at design flare release at any location to which

people have access (e.g. at grade below flare or at a service

3000 9,46

platform of a nearby tower); exposure should be limited to a

few seconds, sufficient to escape only

Heat intensity in areas where emergency actions lasting up to 1

2000 6,31 minute may be required by personnel without shielding but

with appropriate clothing

Heat intensity in areas where emergency actions lasting up to

1000 4,73 several minutes may be required by personnel without

shielding but with appropriate clothing

Value of K at any location where personnel with appropriate

500 1,58

clothing may be continuously exposed

Remarks:

1. On towers or other elevated structures where rapid escape is not possible, ladders shall be provided on

the side away from the flare, so the structure can provide some shielding when K is grater than 2000

BTU/hour/ft2 (6,31 kW/m2)

2. Solar radiation contribution varies by geographical location and is generally in the range of 250 to 330

BTU/hour/ft2 (0,79 to 1,04 kW/m2)

You might also like

- Year 7 Drama Marking SheetDocument2 pagesYear 7 Drama Marking Sheetruthdoyle76No ratings yet

- Robert Potter - Tony Binns - Jennifer A. Elliott - Etienne Nel - David W. Smith - Geographies of Development - An Introduction To Development Studies-Routledge (2018)Document662 pagesRobert Potter - Tony Binns - Jennifer A. Elliott - Etienne Nel - David W. Smith - Geographies of Development - An Introduction To Development Studies-Routledge (2018)Andreas100% (1)

- As CaCo3 Alkalinity-Worked ExamplesDocument2 pagesAs CaCo3 Alkalinity-Worked ExamplesSivakumar NagarathinamNo ratings yet

- Ateco Dome Assembly ManualDocument45 pagesAteco Dome Assembly Manualtran chan100% (1)

- Ring Tank Guidelines 123Document39 pagesRing Tank Guidelines 123Vikram VijayNo ratings yet

- Oisd 118Document27 pagesOisd 118Priyanka RazdanNo ratings yet

- PDS To PDMS Conversion DemoDocument27 pagesPDS To PDMS Conversion DemoshahidNo ratings yet

- Figure 1: Coordinate of Plant LocationDocument11 pagesFigure 1: Coordinate of Plant LocationJonathon John100% (1)

- Carbon Molecular Sieve DataDocument6 pagesCarbon Molecular Sieve DataShashank RaiNo ratings yet

- Reservior Skid Assl Qap AlfaDocument1 pageReservior Skid Assl Qap AlfaajmainNo ratings yet

- Binh Nen Khi 3000 Lit-Rk Project-23122015Document1 pageBinh Nen Khi 3000 Lit-Rk Project-23122015Van DiepNo ratings yet

- Minutes of Meeting SMPV GCR Review With AnnexDocument22 pagesMinutes of Meeting SMPV GCR Review With AnnexNishant ThakurNo ratings yet

- Pe11-3021-Doc-p100 - Rev 0 Control PhilosophyDocument3 pagesPe11-3021-Doc-p100 - Rev 0 Control PhilosophyrkNo ratings yet

- Foster Adhesive: Technical Data SheetDocument2 pagesFoster Adhesive: Technical Data SheetMounir BoutaghaneNo ratings yet

- Profile Engr. Owais Manzoor (Lead Metallurgist) : International AffiliationDocument6 pagesProfile Engr. Owais Manzoor (Lead Metallurgist) : International AffiliationOwais Manzoor MalikNo ratings yet

- Design of Firewater Network For A Typical Onshore Gas Processing PlantDocument9 pagesDesign of Firewater Network For A Typical Onshore Gas Processing PlantAsis AriadiNo ratings yet

- Alloy 20, UNS N08020, Carpenter 20, 20Cb-3, Incoloy Alloy 20Document1 pageAlloy 20, UNS N08020, Carpenter 20, 20Cb-3, Incoloy Alloy 20osto72No ratings yet

- Oil Tank 750 m3Document15 pagesOil Tank 750 m3Lutfi AndreansyahNo ratings yet

- Dry Bulk Storage Tank SpecificationDocument7 pagesDry Bulk Storage Tank SpecificationMohamed Mostafa IbrahimNo ratings yet

- CODEX Transport of Fats and OilsDocument15 pagesCODEX Transport of Fats and OilsDwayne A PunchNo ratings yet

- Refining Industry - Vapor Recovery Unit (VRU)Document2 pagesRefining Industry - Vapor Recovery Unit (VRU)Nicolae VisanNo ratings yet

- Cad Weld MSDSDocument5 pagesCad Weld MSDSKatari Murthy NaiduNo ratings yet

- Callidus Flares Brochure PDFDocument5 pagesCallidus Flares Brochure PDFNurul Atiqah Ahmad KamalNo ratings yet

- 2017 Failure-Rates PDFDocument102 pages2017 Failure-Rates PDFcrd1990No ratings yet

- Glass Flake SpecDocument7 pagesGlass Flake Speckvramanan_1No ratings yet

- Double Deck - Floating RoofDocument7 pagesDouble Deck - Floating RoofDhia SlamaNo ratings yet

- VaconoDocument16 pagesVaconoLassadNo ratings yet

- Hart - 2014 - A Review of Technologies For Transporting Heavy Crude Oil and Bitumen Via Pipelines PDFDocument10 pagesHart - 2014 - A Review of Technologies For Transporting Heavy Crude Oil and Bitumen Via Pipelines PDFAbraham SilesNo ratings yet

- Pressure - Vacuum Relief Valve - Part 1Document10 pagesPressure - Vacuum Relief Valve - Part 1winarnobNo ratings yet

- Compressed Gases and Cryogenic Fluids CodeDocument5 pagesCompressed Gases and Cryogenic Fluids Codesudarshan jalluriNo ratings yet

- Estimate Summary: Change Order Cont. Sales TaxDocument2 pagesEstimate Summary: Change Order Cont. Sales TaxFaizal Sattu100% (1)

- Installation Procedure For TowerDocument4 pagesInstallation Procedure For TowerRachel FloresNo ratings yet

- 9 Seperation DistancesDocument26 pages9 Seperation DistancesmetaslaNo ratings yet

- WMS or Procedure For FireproofingDocument13 pagesWMS or Procedure For FireproofingRodelio RemoNo ratings yet

- Diagram Alir Fluida 3 Fasa: Gas Dehydrator Gas Scrubber X-MastreeDocument1 pageDiagram Alir Fluida 3 Fasa: Gas Dehydrator Gas Scrubber X-Mastree'Aditz Nento S'No ratings yet

- 03-M-U-300819 Installation Instruction For Cold Box of Air Separation PlantDocument40 pages03-M-U-300819 Installation Instruction For Cold Box of Air Separation PlantmahmoudNo ratings yet

- 9686-6130-MS-000-0002 - B2 - MS Tank Construction. - ApprovedDocument23 pages9686-6130-MS-000-0002 - B2 - MS Tank Construction. - ApprovedANIL PLAMOOTTIL100% (1)

- Shop Inspection Requirements and Inspection and Testing Sequence For Tank ComponentsDocument4 pagesShop Inspection Requirements and Inspection and Testing Sequence For Tank ComponentsdurraaiNo ratings yet

- Bawana BOQDocument28 pagesBawana BOQSasi Kiran VundamatlaNo ratings yet

- E 09 GP 008 Vendor Contractor Work Package Management Process-2019Document21 pagesE 09 GP 008 Vendor Contractor Work Package Management Process-2019John KalvinNo ratings yet

- Tank Fabrication & ErectionDocument72 pagesTank Fabrication & ErectionPramod GrNo ratings yet

- Xiangshui Chemical Factory's ExplosionDocument21 pagesXiangshui Chemical Factory's ExplosionnajihahNo ratings yet

- QCF316 Cold Insulation Inspection Report For Vessel / MachineryDocument1 pageQCF316 Cold Insulation Inspection Report For Vessel / MachineryminhnnNo ratings yet

- B2020-TDC-SR-006 Shell Rolling R0Document2 pagesB2020-TDC-SR-006 Shell Rolling R0Ramalingam PrabhakaranNo ratings yet

- Pyrolsyis ppt-1Document15 pagesPyrolsyis ppt-1Aswin MNo ratings yet

- Compressor Drive Engine Power CalculatorDocument2 pagesCompressor Drive Engine Power CalculatorJoshi DhvanitNo ratings yet

- 7T04-CS-00-TS-018 R01 Project Specificationfor Cleaning Reequirements For Piping SystemsDocument9 pages7T04-CS-00-TS-018 R01 Project Specificationfor Cleaning Reequirements For Piping Systemsel_sharkawy2011100% (1)

- Mostostalex - Sprinkler TanksDocument8 pagesMostostalex - Sprinkler TanksVanja Ivkovic100% (1)

- GAPS Guidelines: Electrostatic PrecipitatorsDocument4 pagesGAPS Guidelines: Electrostatic PrecipitatorsAsad KhanNo ratings yet

- Oil SpillDocument31 pagesOil SpillArthur James De TorresNo ratings yet

- V1.1 Sizing Thermal Mass Flow Meter SizingDocument8 pagesV1.1 Sizing Thermal Mass Flow Meter SizingThori MFMNo ratings yet

- 4th Edition ChecklistsDocument10 pages4th Edition ChecklistsYuber Rodriguez HNo ratings yet

- Technical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoDocument27 pagesTechnical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoIdung ChristopherNo ratings yet

- Interconnecting Pipe Rack - TF1-PRK-510Document68 pagesInterconnecting Pipe Rack - TF1-PRK-510Khac Hoang PhamNo ratings yet

- Renderoc TGDocument2 pagesRenderoc TGMansoor Ali50% (2)

- Besmm4f PDFDocument2 pagesBesmm4f PDFGodwin JohnNo ratings yet

- Method Statement For Repair Deethanizer Reflux Pump - CommentsDocument5 pagesMethod Statement For Repair Deethanizer Reflux Pump - CommentsRahmat HidayatNo ratings yet

- CNC Oxyacetylene Flame Cutting MachineDocument12 pagesCNC Oxyacetylene Flame Cutting MachineNaman JoharNo ratings yet

- ControTrace Installation Checklist PipeDocument1 pageControTrace Installation Checklist PipeEnoch TwumasiNo ratings yet

- 1ef 110mec 1MH DS 060610 - BDocument204 pages1ef 110mec 1MH DS 060610 - Bاحمد شوقي عمارNo ratings yet

- Section 4 Electrical InstallationsDocument6 pagesSection 4 Electrical InstallationsJ T Mendonça SantosNo ratings yet

- F101-1 Client Information Form and ApprovalDocument4 pagesF101-1 Client Information Form and ApprovalgoyalpramodNo ratings yet

- Earth SpecificationDocument20 pagesEarth SpecificationMohammad Hafiz MahadzirNo ratings yet

- Al Boury Oil FieldDocument11 pagesAl Boury Oil FieldSherif MohammedNo ratings yet

- The Relationship Between Dimensions of Love, Personality, and Relationship LengthDocument11 pagesThe Relationship Between Dimensions of Love, Personality, and Relationship LengthjuaromerNo ratings yet

- Contoh Skrip Rakaman AudioDocument2 pagesContoh Skrip Rakaman AudioconankoayNo ratings yet

- Quest Test 6 Wave Phenomena KEYDocument7 pagesQuest Test 6 Wave Phenomena KEYHa ViNo ratings yet

- Nepal National Building Code: Draft Final NBC 205: 2012Document52 pagesNepal National Building Code: Draft Final NBC 205: 2012Sudan ShresthaNo ratings yet

- Report RubricsDocument2 pagesReport Rubricsswaggerz95No ratings yet

- RFQ-97 For Supply of Biscuit & Soap-2Document1 pageRFQ-97 For Supply of Biscuit & Soap-2Prodip Debnath NayanNo ratings yet

- Exercise Oracle Forms 6i TrainingDocument5 pagesExercise Oracle Forms 6i TrainingFarooq Shahid100% (1)

- Assignment 6 Solar ERGY 420Document14 pagesAssignment 6 Solar ERGY 420Mostafa Ahmed ZeinNo ratings yet

- Bread Board - Transformer - PCB - Soldering - LectureDocument31 pagesBread Board - Transformer - PCB - Soldering - Lectureananyautkarsh140904No ratings yet

- Ds Futro s700Document6 pagesDs Futro s700Lougan LuzNo ratings yet

- Mick Thomson's Guitars and GearDocument10 pagesMick Thomson's Guitars and GearAleksandar LjubinkovicNo ratings yet

- Is Codes ListDocument37 pagesIs Codes Listmoondonoo7No ratings yet

- Detailed Lesson Plan in ICT ExcelDocument5 pagesDetailed Lesson Plan in ICT ExcelColleen Vender100% (3)

- Forex Survival GuideDocument22 pagesForex Survival Guidevikki2810No ratings yet

- Interactive Physics ManualDocument13 pagesInteractive Physics ManualMarciano SantamaríaNo ratings yet

- Earth Dams Foundation & Earth Material InvestigationDocument111 pagesEarth Dams Foundation & Earth Material Investigationmustafurade1No ratings yet

- Jeanette Novakovich Formal ResumeDocument4 pagesJeanette Novakovich Formal ResumeJ'etté NovakovichNo ratings yet

- Brkarc-2350 - 2014Document128 pagesBrkarc-2350 - 2014Sarah AnandNo ratings yet

- Jetblue Airways: A New BeginningDocument25 pagesJetblue Airways: A New BeginningHesty Tri BudihartiNo ratings yet

- Item Wise Rate TenderDocument5 pagesItem Wise Rate TenderB-05 ISHA PATELNo ratings yet

- Assessing Sleep Quality of Shs StudentsDocument10 pagesAssessing Sleep Quality of Shs StudentsDian HernandezNo ratings yet

- Mathematics: Quarter 1 - Module 8: Division of Whole Numbers by Decimals Up To 2 Decimal PlacesDocument34 pagesMathematics: Quarter 1 - Module 8: Division of Whole Numbers by Decimals Up To 2 Decimal PlacesJohn Thomas Satimbre100% (1)

- Moral Stories - Situated Reasoning About Norms, Intents, Actions, and Their Consequences 2012.15738Document21 pagesMoral Stories - Situated Reasoning About Norms, Intents, Actions, and Their Consequences 2012.15738Zhu XUNo ratings yet

- Os Past Papers' Solutions 2017Document4 pagesOs Past Papers' Solutions 2017zainab tehreemNo ratings yet

- R Reference Manual Volume 1Document736 pagesR Reference Manual Volume 1PH1628No ratings yet