Professional Documents

Culture Documents

BRC Series: High Temperature Metal Bellows Seals

BRC Series: High Temperature Metal Bellows Seals

Uploaded by

Dhananjay B KCopyright:

Available Formats

You might also like

- VP - PSV SEA VEGA REV.0 (New Logo) r2Document4 pagesVP - PSV SEA VEGA REV.0 (New Logo) r2Sugiman LayantoNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Flowserve ISC2 - API 682 Compliant Mech SealDocument2 pagesFlowserve ISC2 - API 682 Compliant Mech SealIR fanNo ratings yet

- 1.2.2.gb RCV - Co2 Tank - Carbon Steel - s0000517 G GBDocument1 page1.2.2.gb RCV - Co2 Tank - Carbon Steel - s0000517 G GBDung BuiNo ratings yet

- 40mm Gauge Data Sheet Rev 2 PDFDocument1 page40mm Gauge Data Sheet Rev 2 PDFrosario medinaNo ratings yet

- SMS Swedish Standard Union: Size RangeDocument7 pagesSMS Swedish Standard Union: Size RangeGaurav BedseNo ratings yet

- RBO RBA FansDocument2 pagesRBO RBA FansbeemasundarNo ratings yet

- Dedacciai RanrsDocument1 pageDedacciai Ranrspk50sNo ratings yet

- NSK - HPS Brochure FinalDocument8 pagesNSK - HPS Brochure FinalRicardo PerezNo ratings yet

- Comment - Design of 24 M Comp Girder-R5 FINAL PDFDocument60 pagesComment - Design of 24 M Comp Girder-R5 FINAL PDFNilay Gandhi100% (2)

- Gate Valve Series 371/W371 Open Stem & Yoke (OS&Y) Gate Valves Series 372/W372 Non Rising Stem (NRS) Gate ValvesDocument6 pagesGate Valve Series 371/W371 Open Stem & Yoke (OS&Y) Gate Valves Series 372/W372 Non Rising Stem (NRS) Gate ValvesCinthya Yesenia Cruz MedinaNo ratings yet

- PC Bridge Catalog APB (Adhi Beton)Document7 pagesPC Bridge Catalog APB (Adhi Beton)A Akbar HawardiNo ratings yet

- Figure 740 GRINNELL Rapid Installation Pivot-Bolt (GRIP) Rigid CouplingDocument4 pagesFigure 740 GRINNELL Rapid Installation Pivot-Bolt (GRIP) Rigid CouplingСергей КолесниковNo ratings yet

- Catalogo ISCDocument6 pagesCatalogo ISCAdolfo AriasNo ratings yet

- Presentasi SNI 2017Document43 pagesPresentasi SNI 2017Fransisca WijayaNo ratings yet

- Mechanical-T Bolted Branch Outlets: Carbon Steel Pipe - Hole Cut ProductsDocument8 pagesMechanical-T Bolted Branch Outlets: Carbon Steel Pipe - Hole Cut ProductsAritz BilbaoNo ratings yet

- Brochure - MS - WR - Plansifter Sirius - MPAK - EN - WEB - BID21Document8 pagesBrochure - MS - WR - Plansifter Sirius - MPAK - EN - WEB - BID21Lizandro ParedesNo ratings yet

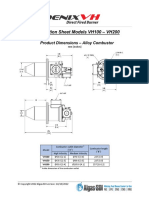

- Spec Sheet PN 57001 Phoenix VH VH100 VH200 3 1Document4 pagesSpec Sheet PN 57001 Phoenix VH VH100 VH200 3 1Jona RochaNo ratings yet

- Bearing Lubrication Quick Reference Guide: Grease CompatibilityDocument4 pagesBearing Lubrication Quick Reference Guide: Grease CompatibilitySamuel PagottoNo ratings yet

- D SeriesDocument2 pagesD SeriesRupesh ParaswarNo ratings yet

- Bagues Bi Matière CSB TPDocument29 pagesBagues Bi Matière CSB TPmid.beNo ratings yet

- Synergy CatalogueDocument8 pagesSynergy CatalogueTino JuNo ratings yet

- 3 Speed Mining Gearbox OverviewDocument1 page3 Speed Mining Gearbox OverviewAndrew KochNo ratings yet

- Boss Connector: Soil and Vent ComponentsDocument1 pageBoss Connector: Soil and Vent ComponentsBoraNo ratings yet

- c907 Gear BronzeDocument2 pagesc907 Gear BronzeMartin JensenNo ratings yet

- R/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: SDD/YMD/R300/STLDocument1 pageR/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: SDD/YMD/R300/STLNagLakshmananNo ratings yet

- SS Side Seal: Balance Air Equipment Plot No: 708-709, Sector-2 IMT, Bawal Haryana-123501Document1 pageSS Side Seal: Balance Air Equipment Plot No: 708-709, Sector-2 IMT, Bawal Haryana-123501Support aeronomNo ratings yet

- PARKER 72 - Series-COUPLINGDocument4 pagesPARKER 72 - Series-COUPLINGRajpal SharmaNo ratings yet

- Isv B492RDocument4 pagesIsv B492RdeborazoletNo ratings yet

- dvt550 60hz 22174507Document2 pagesdvt550 60hz 22174507Jesus EstelaNo ratings yet

- DN600 Future Jacking Pipe SocketDocument1 pageDN600 Future Jacking Pipe SocketTayseer Al AbedNo ratings yet

- TurningDocument766 pagesTurningDavid BahenaNo ratings yet

- Spherical Roller Bearings Exq Series NachiDocument8 pagesSpherical Roller Bearings Exq Series Nachijuan gordonNo ratings yet

- A2 MetricDocument1 pageA2 MetricGilang HendraNo ratings yet

- Slotted Spring Pins Design GuideDocument8 pagesSlotted Spring Pins Design GuideHumor 101No ratings yet

- Catalogo Perfil Estrutural Info Tecnicas InglesDocument7 pagesCatalogo Perfil Estrutural Info Tecnicas InglesWagner SilvaNo ratings yet

- R/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: Form Number: QD/177/01Document1 pageR/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: Form Number: QD/177/01cmpuckNo ratings yet

- Diamondspark 52 MC: Seamless Metal-Cored WireDocument2 pagesDiamondspark 52 MC: Seamless Metal-Cored WireDavid RodriguesNo ratings yet

- Metal Cored Wires BÖHLER HL 46 MC BÖHLER HL 51-FD (EN)Document4 pagesMetal Cored Wires BÖHLER HL 46 MC BÖHLER HL 51-FD (EN)lazaroccsNo ratings yet

- p80 Submittal 06 19 PDFDocument1 pagep80 Submittal 06 19 PDFsuhasNo ratings yet

- Sika Waterbars® - MergedDocument5 pagesSika Waterbars® - Mergedmahmoud badrNo ratings yet

- Bar GrillesDocument10 pagesBar GrillesMuhammad RafiuddinNo ratings yet

- Bushan Power Steel PipeDocument16 pagesBushan Power Steel PipeKarthikeyan VisvakNo ratings yet

- GRINNELL Figure 772 Grooved Rigid Coupling 1-1/4 - 24 Inch (DN32 - DN600) Sizes 1/2 Inch (M12) Bolt For 2 - 4 Inch (DN50 - DN100) Sizes General Description Technical DataDocument4 pagesGRINNELL Figure 772 Grooved Rigid Coupling 1-1/4 - 24 Inch (DN32 - DN600) Sizes 1/2 Inch (M12) Bolt For 2 - 4 Inch (DN50 - DN100) Sizes General Description Technical DataСергей КолесниковNo ratings yet

- Technical DataDocument3 pagesTechnical DataLuis Marcelo HinojosaNo ratings yet

- TD 2800e 8PG BW Oct2015Document8 pagesTD 2800e 8PG BW Oct2015Salah GhNo ratings yet

- Cylindrical Fuse Base Detail86Document3 pagesCylindrical Fuse Base Detail86Hendra AwanNo ratings yet

- Repsol Merak VDL PDFDocument1 pageRepsol Merak VDL PDFrandiNo ratings yet

- Quickvic Flexible Coupling For Steel: Carbon Steel Pipe - Grooved CouplingsDocument4 pagesQuickvic Flexible Coupling For Steel: Carbon Steel Pipe - Grooved CouplingsMina MagdyNo ratings yet

- Gandhi Pipes Prez 2020Document24 pagesGandhi Pipes Prez 2020Puneet367No ratings yet

- Caja Reductora - MM - W5200 - 1317200985429Document2 pagesCaja Reductora - MM - W5200 - 1317200985429joroma58No ratings yet

- VITAULICDocument8 pagesVITAULICJoko SchumacherNo ratings yet

- Fig. 810/910 Cast Iron Y-Type: Material Specification Features and BenefitsDocument1 pageFig. 810/910 Cast Iron Y-Type: Material Specification Features and BenefitsMuhamad SuryaNo ratings yet

- Brochure The Precast Concrete Product: BetonDocument9 pagesBrochure The Precast Concrete Product: BetonA Akbar HawardiNo ratings yet

- Actaris Gas Regulators SERusDocument2 pagesActaris Gas Regulators SERushendrik muellerNo ratings yet

- Metso Neles High Performance Valve, Metal Seated Series BWDocument8 pagesMetso Neles High Performance Valve, Metal Seated Series BWjayakumarNo ratings yet

- Cross-Roller RingDocument1 pageCross-Roller RingMadhuri RasalNo ratings yet

- Medidor Nivel Magnetico PDFDocument2 pagesMedidor Nivel Magnetico PDFrubenNo ratings yet

- Herc-Alloy 800 Hammerlok - CatDocument1 pageHerc-Alloy 800 Hammerlok - CatAdhe GedeNo ratings yet

- Astm C662Document3 pagesAstm C662정호철No ratings yet

- Brochure - SIL PT BarDocument4 pagesBrochure - SIL PT Barprashant patilNo ratings yet

- User Instructions: Installation Operation Maintenance LDG Gas Powered Heavy-Duty Actuator SeriesDocument32 pagesUser Instructions: Installation Operation Maintenance LDG Gas Powered Heavy-Duty Actuator SeriesDhananjay B KNo ratings yet

- Mechanical Seal Quick Ship: Engineered, Manufactured, Assembled, Tested and Shipped in 72 HoursDocument2 pagesMechanical Seal Quick Ship: Engineered, Manufactured, Assembled, Tested and Shipped in 72 HoursDhananjay B KNo ratings yet

- Bearing LifeDocument3 pagesBearing LifeDhananjay B KNo ratings yet

- Wilcoxon Short Form Catalog-2018Document36 pagesWilcoxon Short Form Catalog-2018Dhananjay B KNo ratings yet

- Renk MaagDocument12 pagesRenk MaagDhananjay B KNo ratings yet

- Oil BleedingDocument3 pagesOil BleedingDhananjay B KNo ratings yet

- IMI Remosa ValvesDocument4 pagesIMI Remosa ValvesDhananjay B KNo ratings yet

- Saudi Aramco Steam Turbine Training CourseDocument45 pagesSaudi Aramco Steam Turbine Training CourseDhananjay B K100% (3)

- Gearbox FailureDocument18 pagesGearbox FailureDhananjay B KNo ratings yet

- Yamaha MT-15 Brochure PDFDocument5 pagesYamaha MT-15 Brochure PDFDhananjay B K100% (2)

- Sinif Ingilizce 8. Unite Calisma Kagidi Test Etkinlik Worksheet FITNESS by Murat DukkanciDocument13 pagesSinif Ingilizce 8. Unite Calisma Kagidi Test Etkinlik Worksheet FITNESS by Murat DukkanciElif yurtsevenNo ratings yet

- Topic 5 AC To AC ConverterDocument53 pagesTopic 5 AC To AC ConverterNorain ZakariaNo ratings yet

- Mormon Sex Slave Tells of Horrific Abuse by Church Leaders - Www-fourwinds10-NetDocument3 pagesMormon Sex Slave Tells of Horrific Abuse by Church Leaders - Www-fourwinds10-NetGovernment-Slave-4-UNo ratings yet

- PRISMA 2020 Flow Diagram For Updated Systematic Reviews Which Included Searches of Databases, Registers and Other SourcesDocument1 pagePRISMA 2020 Flow Diagram For Updated Systematic Reviews Which Included Searches of Databases, Registers and Other SourcesSurya WijayaNo ratings yet

- Department of Education: Republic of The PhilippinesDocument14 pagesDepartment of Education: Republic of The PhilippinesJanna GunioNo ratings yet

- RS 232 Repeater KFD2-FF-Ex2.RS232: FunctionDocument4 pagesRS 232 Repeater KFD2-FF-Ex2.RS232: FunctionEder AlexandreNo ratings yet

- Social and Self Control TheoryDocument2 pagesSocial and Self Control TheoryKarl Amiel EspirituNo ratings yet

- Q Bank Chem MCD Viii 2019Document19 pagesQ Bank Chem MCD Viii 2019hgbv tttbNo ratings yet

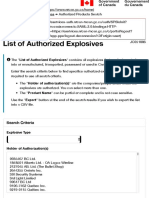

- NRCan's Explosives Eservices - Authorized Products SearchDocument5 pagesNRCan's Explosives Eservices - Authorized Products SearchDiego VilaNo ratings yet

- Railway Accounting: Indian Railway Accounts ServiceDocument5 pagesRailway Accounting: Indian Railway Accounts ServiceAbhijeet AsthanaNo ratings yet

- If I Had A Million Dollars EssayDocument4 pagesIf I Had A Million Dollars Essaygejjavbaf100% (2)

- SavedrecsDocument615 pagesSavedrecsMARIBEL BARBECHONo ratings yet

- 373 PDFDocument6 pages373 PDFIjdra Journal Jitendra BadjatyaNo ratings yet

- REHS4987-02 Replacing Base Edge Assemblies in Large Wheel Loader BucketsDocument19 pagesREHS4987-02 Replacing Base Edge Assemblies in Large Wheel Loader BucketsCarlosNo ratings yet

- Death RoadDocument12 pagesDeath RoadRodrigo Salgueiro LlanosNo ratings yet

- Demonizing Drugmakers: The Political Assault On The Pharmaceutical Industry, Cato Policy Analysis No. 475Document56 pagesDemonizing Drugmakers: The Political Assault On The Pharmaceutical Industry, Cato Policy Analysis No. 475Cato InstituteNo ratings yet

- Valuing The Suitable Agro-Industrial Wastes For Cultivation of P. Platypus and P. EousDocument4 pagesValuing The Suitable Agro-Industrial Wastes For Cultivation of P. Platypus and P. EousDinesh Babu PugalenthiNo ratings yet

- Divergent Plate BoundaryDocument4 pagesDivergent Plate BoundaryGreg ManNo ratings yet

- Homeostasis Case StudyDocument3 pagesHomeostasis Case Studyapi-332887331No ratings yet

- Chapter 6 Food Handlers Safety HygieneDocument20 pagesChapter 6 Food Handlers Safety HygieneIrish MalabananNo ratings yet

- TYPHOIDDocument13 pagesTYPHOIDnaceyjj33No ratings yet

- Lec5 - Geotechnical Investigation Reports and Foundation Recommendations-Scope For Improvement-ExamplesDocument20 pagesLec5 - Geotechnical Investigation Reports and Foundation Recommendations-Scope For Improvement-ExamplesrohitNo ratings yet

- Cell DivisionDocument50 pagesCell Divisionbknishad100% (2)

- Bombas SumergiblesDocument79 pagesBombas SumergiblesInstinct_brNo ratings yet

- Chapter 15 IMSMDocument42 pagesChapter 15 IMSMjthemansmith1No ratings yet

- Nanoscience 2 PDFDocument388 pagesNanoscience 2 PDFSergio ArturoNo ratings yet

- A La Carte MenuDocument1 pageA La Carte Menuhappy frankensteinNo ratings yet

- YttrrtDocument9 pagesYttrrtImad AghilaNo ratings yet

- Speaking Listening 1Document3 pagesSpeaking Listening 1fara dias safrinaNo ratings yet

BRC Series: High Temperature Metal Bellows Seals

BRC Series: High Temperature Metal Bellows Seals

Uploaded by

Dhananjay B KOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BRC Series: High Temperature Metal Bellows Seals

BRC Series: High Temperature Metal Bellows Seals

Uploaded by

Dhananjay B KCopyright:

Available Formats

BRC Series

High temperature

metal bellows seals

BRC Series edge-welded metal bellows seals are exceptionally

robust and designed to seal high-temperature hydrocarbons, heat

transfer fluids and severe services in refineries and hydrocarbon

processing plants. The BRC series is fully compliant with

API 682/ISO 21039 Type C requirements and features thick-plate

Alloy 718 bellows convolutions for superior corrosion resistance.

Features and Benefits

• Rugged construction throughout makes BRC seals the

toughest and most reliable metal bellows mechanical seals

for difficult refinery pump services.

Operating Parameters

• Bellows diaphragm thicknesses start at 0.010 in. (0.25 mm)

Pressure Up to 300 psi (20.7 bar)

on small sizes and extend to 0.012 in. (0.30 mm) for the

industry’s strongest bellows, capable of long-term chemical Temperature -100°F to 800°F

exposure and low-stress performance. (-73°C to 427°C)

Specific Gravity 0.45 and higher

• Alloy 718 bellows and end adapters satisfy NACE MR0103

and have the highest resistance to stress-cracking corrosion Surface Speed Up to 75 ft/sec (23 m/sec)

in sulfuric-laced environments at high temperature.

Shaft Sizes 0.983 to 6.000 inches

(25 to 152.4 mm)

• Mounted in a flexible graphite ring to avoid shrink-fit

distortions, the silicon carbide rotating face sustains

a stable, flat sealing surface for reliable, low-leakage

performance. Materials of Construction

Bellows Assembly Alloy 718 / 316 Stainless Steel

• Seal face combinations of carbon against silicon carbide or Alloy 718

or carbide against carbide are matched with the service

conditions from heavy hydrocarbons to light products Rotating Face Silicon Carbide

including some solids. Stationary Face Carbon or Silicon Carbide

• Configurable with rotating or stationary bellows, BRC Gaskets Flexible Graphite

seals include a steam purge baffle under the stationary Metal Parts 316 Stainless Steel or

components to eliminate coking and prolong clean Alloy 718

operation.

C D

BRC Seal

Standard design

with threaded

bellows adapter

A

B

C1 D

BRCH Seal

Optional design

with bolted

bellows adapter

A

B

Dimensional Data inches millimeters

Seal A B C C1 D Seal A B C C1 D

Size Min Max Min Min Min Size Min Max Min Min Min

1680 2.449 0.983 2.281 1.969 3.469 1680 62.2 25.0 57.9 50.0 88.1

1812 2.668 1.108 2.625 2.313 3.563 1812 67.8 28.1 66.7 58.7 90.5

2027 2.887 1.170 2.688 2.376 3.688 2027 73.3 29.7 68.3 60.3 93.7

2125 2.950 1.358 2.688 2.376 3.688 2125 74.9 34.5 68.3 60.3 93.7

2250 3.137 1.420 2.875 2.563 3.688 2250 79.7 36.1 73.0 65.1 93.7

2375 3.137 1.545 2.531 2.219 3.719 2375 79.7 39.2 64.3 56.3 94.5

2500 3.316 1.670 2.844 2.532 3.688 2500 84.2 42.4 72.2 64.3 93.7

2687 3.559 1.795 2.844 2.532 3.781 2687 90.4 45.6 72.2 64.3 96.0

2750 3.575 1.983 2.781 2.469 3.844 2750 90.8 50.4 70.6 62.7 97.6

3000 3.952 2.170 3.125 2.813 4.063 3000 100.4 55.1 79.4 71.4 103.2

3250 4.200 2.420 3.125 2.813 4.063 3250 106.7 61.5 79.4 71.4 103.2

3500 4.481 2.670 3.125 2.813 4.063 3500 113.8 67.8 79.4 71.4 103.2

3750 4.699 2.920 3.188 2.876 4.063 3750 119.4 74.2 81.0 73.0 103.2

4000 5.028 3.108 3.594 3.282 4.063 4000 127.7 78.9 91.3 83.4 103.2

4250 5.342 3.358 3.375 3.063 4.063 4250 135.7 85.3 85.7 77.8 103.2

4812 5.875 3.858 3.563 3.251 4.063 4812 149.2 98.0 90.5 82.6 103.2

5500 6.803 4.483 3.563 3.251 4.156 5500 172.8 113.9 90.5 82.6 105.6

6750 7.875 6.000 3.625 3.313 3.125 6750 200.0 152.4 92.1 84.1 79.4

FSD142eng REV 11/08 Printed in USA

USA and Canada

Kalamazoo, Michigan USA

To find your local Flowserve representative

Telephone: 1 269 381 2650

and find out more about Flowserve Corporation visit Telefax: 1 269 382 8726

www.flowserve.com

Europe, Middle East, Africa

Essen, Germany

Telephone: 49 201 31937-0

Telefax: 49 201 2200-561

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Asia Pacific

Flowserve product is designed to perform its intended function safely during its useful life. However, the purchaser or user of Flowserve

products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial service Singapore

conditions. Although Flowserve can provide general guidelines, it cannot provide specific data and warnings for all possible applications. The

purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance

Telephone: 65 6544 6800

of Flowserve products. The purchaser/user should read and understand the Installation Instructions included with the product, and train its Telefax: 65 6214 0541

employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes

only and should not be considered certified or as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to

Latin America

be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve is Mexico City

continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to

change without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation Telephone: 52 55 5567 7170

at any one of its worldwide operations or offices.

Telefax: 52 55 5567 4224

© 2008 Flowserve Corporation

You might also like

- VP - PSV SEA VEGA REV.0 (New Logo) r2Document4 pagesVP - PSV SEA VEGA REV.0 (New Logo) r2Sugiman LayantoNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Flowserve ISC2 - API 682 Compliant Mech SealDocument2 pagesFlowserve ISC2 - API 682 Compliant Mech SealIR fanNo ratings yet

- 1.2.2.gb RCV - Co2 Tank - Carbon Steel - s0000517 G GBDocument1 page1.2.2.gb RCV - Co2 Tank - Carbon Steel - s0000517 G GBDung BuiNo ratings yet

- 40mm Gauge Data Sheet Rev 2 PDFDocument1 page40mm Gauge Data Sheet Rev 2 PDFrosario medinaNo ratings yet

- SMS Swedish Standard Union: Size RangeDocument7 pagesSMS Swedish Standard Union: Size RangeGaurav BedseNo ratings yet

- RBO RBA FansDocument2 pagesRBO RBA FansbeemasundarNo ratings yet

- Dedacciai RanrsDocument1 pageDedacciai Ranrspk50sNo ratings yet

- NSK - HPS Brochure FinalDocument8 pagesNSK - HPS Brochure FinalRicardo PerezNo ratings yet

- Comment - Design of 24 M Comp Girder-R5 FINAL PDFDocument60 pagesComment - Design of 24 M Comp Girder-R5 FINAL PDFNilay Gandhi100% (2)

- Gate Valve Series 371/W371 Open Stem & Yoke (OS&Y) Gate Valves Series 372/W372 Non Rising Stem (NRS) Gate ValvesDocument6 pagesGate Valve Series 371/W371 Open Stem & Yoke (OS&Y) Gate Valves Series 372/W372 Non Rising Stem (NRS) Gate ValvesCinthya Yesenia Cruz MedinaNo ratings yet

- PC Bridge Catalog APB (Adhi Beton)Document7 pagesPC Bridge Catalog APB (Adhi Beton)A Akbar HawardiNo ratings yet

- Figure 740 GRINNELL Rapid Installation Pivot-Bolt (GRIP) Rigid CouplingDocument4 pagesFigure 740 GRINNELL Rapid Installation Pivot-Bolt (GRIP) Rigid CouplingСергей КолесниковNo ratings yet

- Catalogo ISCDocument6 pagesCatalogo ISCAdolfo AriasNo ratings yet

- Presentasi SNI 2017Document43 pagesPresentasi SNI 2017Fransisca WijayaNo ratings yet

- Mechanical-T Bolted Branch Outlets: Carbon Steel Pipe - Hole Cut ProductsDocument8 pagesMechanical-T Bolted Branch Outlets: Carbon Steel Pipe - Hole Cut ProductsAritz BilbaoNo ratings yet

- Brochure - MS - WR - Plansifter Sirius - MPAK - EN - WEB - BID21Document8 pagesBrochure - MS - WR - Plansifter Sirius - MPAK - EN - WEB - BID21Lizandro ParedesNo ratings yet

- Spec Sheet PN 57001 Phoenix VH VH100 VH200 3 1Document4 pagesSpec Sheet PN 57001 Phoenix VH VH100 VH200 3 1Jona RochaNo ratings yet

- Bearing Lubrication Quick Reference Guide: Grease CompatibilityDocument4 pagesBearing Lubrication Quick Reference Guide: Grease CompatibilitySamuel PagottoNo ratings yet

- D SeriesDocument2 pagesD SeriesRupesh ParaswarNo ratings yet

- Bagues Bi Matière CSB TPDocument29 pagesBagues Bi Matière CSB TPmid.beNo ratings yet

- Synergy CatalogueDocument8 pagesSynergy CatalogueTino JuNo ratings yet

- 3 Speed Mining Gearbox OverviewDocument1 page3 Speed Mining Gearbox OverviewAndrew KochNo ratings yet

- Boss Connector: Soil and Vent ComponentsDocument1 pageBoss Connector: Soil and Vent ComponentsBoraNo ratings yet

- c907 Gear BronzeDocument2 pagesc907 Gear BronzeMartin JensenNo ratings yet

- R/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: SDD/YMD/R300/STLDocument1 pageR/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: SDD/YMD/R300/STLNagLakshmananNo ratings yet

- SS Side Seal: Balance Air Equipment Plot No: 708-709, Sector-2 IMT, Bawal Haryana-123501Document1 pageSS Side Seal: Balance Air Equipment Plot No: 708-709, Sector-2 IMT, Bawal Haryana-123501Support aeronomNo ratings yet

- PARKER 72 - Series-COUPLINGDocument4 pagesPARKER 72 - Series-COUPLINGRajpal SharmaNo ratings yet

- Isv B492RDocument4 pagesIsv B492RdeborazoletNo ratings yet

- dvt550 60hz 22174507Document2 pagesdvt550 60hz 22174507Jesus EstelaNo ratings yet

- DN600 Future Jacking Pipe SocketDocument1 pageDN600 Future Jacking Pipe SocketTayseer Al AbedNo ratings yet

- TurningDocument766 pagesTurningDavid BahenaNo ratings yet

- Spherical Roller Bearings Exq Series NachiDocument8 pagesSpherical Roller Bearings Exq Series Nachijuan gordonNo ratings yet

- A2 MetricDocument1 pageA2 MetricGilang HendraNo ratings yet

- Slotted Spring Pins Design GuideDocument8 pagesSlotted Spring Pins Design GuideHumor 101No ratings yet

- Catalogo Perfil Estrutural Info Tecnicas InglesDocument7 pagesCatalogo Perfil Estrutural Info Tecnicas InglesWagner SilvaNo ratings yet

- R/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: Form Number: QD/177/01Document1 pageR/F - 300Lb Rating Medium Duty 'Y'-Type Strainer: Form Number: QD/177/01cmpuckNo ratings yet

- Diamondspark 52 MC: Seamless Metal-Cored WireDocument2 pagesDiamondspark 52 MC: Seamless Metal-Cored WireDavid RodriguesNo ratings yet

- Metal Cored Wires BÖHLER HL 46 MC BÖHLER HL 51-FD (EN)Document4 pagesMetal Cored Wires BÖHLER HL 46 MC BÖHLER HL 51-FD (EN)lazaroccsNo ratings yet

- p80 Submittal 06 19 PDFDocument1 pagep80 Submittal 06 19 PDFsuhasNo ratings yet

- Sika Waterbars® - MergedDocument5 pagesSika Waterbars® - Mergedmahmoud badrNo ratings yet

- Bar GrillesDocument10 pagesBar GrillesMuhammad RafiuddinNo ratings yet

- Bushan Power Steel PipeDocument16 pagesBushan Power Steel PipeKarthikeyan VisvakNo ratings yet

- GRINNELL Figure 772 Grooved Rigid Coupling 1-1/4 - 24 Inch (DN32 - DN600) Sizes 1/2 Inch (M12) Bolt For 2 - 4 Inch (DN50 - DN100) Sizes General Description Technical DataDocument4 pagesGRINNELL Figure 772 Grooved Rigid Coupling 1-1/4 - 24 Inch (DN32 - DN600) Sizes 1/2 Inch (M12) Bolt For 2 - 4 Inch (DN50 - DN100) Sizes General Description Technical DataСергей КолесниковNo ratings yet

- Technical DataDocument3 pagesTechnical DataLuis Marcelo HinojosaNo ratings yet

- TD 2800e 8PG BW Oct2015Document8 pagesTD 2800e 8PG BW Oct2015Salah GhNo ratings yet

- Cylindrical Fuse Base Detail86Document3 pagesCylindrical Fuse Base Detail86Hendra AwanNo ratings yet

- Repsol Merak VDL PDFDocument1 pageRepsol Merak VDL PDFrandiNo ratings yet

- Quickvic Flexible Coupling For Steel: Carbon Steel Pipe - Grooved CouplingsDocument4 pagesQuickvic Flexible Coupling For Steel: Carbon Steel Pipe - Grooved CouplingsMina MagdyNo ratings yet

- Gandhi Pipes Prez 2020Document24 pagesGandhi Pipes Prez 2020Puneet367No ratings yet

- Caja Reductora - MM - W5200 - 1317200985429Document2 pagesCaja Reductora - MM - W5200 - 1317200985429joroma58No ratings yet

- VITAULICDocument8 pagesVITAULICJoko SchumacherNo ratings yet

- Fig. 810/910 Cast Iron Y-Type: Material Specification Features and BenefitsDocument1 pageFig. 810/910 Cast Iron Y-Type: Material Specification Features and BenefitsMuhamad SuryaNo ratings yet

- Brochure The Precast Concrete Product: BetonDocument9 pagesBrochure The Precast Concrete Product: BetonA Akbar HawardiNo ratings yet

- Actaris Gas Regulators SERusDocument2 pagesActaris Gas Regulators SERushendrik muellerNo ratings yet

- Metso Neles High Performance Valve, Metal Seated Series BWDocument8 pagesMetso Neles High Performance Valve, Metal Seated Series BWjayakumarNo ratings yet

- Cross-Roller RingDocument1 pageCross-Roller RingMadhuri RasalNo ratings yet

- Medidor Nivel Magnetico PDFDocument2 pagesMedidor Nivel Magnetico PDFrubenNo ratings yet

- Herc-Alloy 800 Hammerlok - CatDocument1 pageHerc-Alloy 800 Hammerlok - CatAdhe GedeNo ratings yet

- Astm C662Document3 pagesAstm C662정호철No ratings yet

- Brochure - SIL PT BarDocument4 pagesBrochure - SIL PT Barprashant patilNo ratings yet

- User Instructions: Installation Operation Maintenance LDG Gas Powered Heavy-Duty Actuator SeriesDocument32 pagesUser Instructions: Installation Operation Maintenance LDG Gas Powered Heavy-Duty Actuator SeriesDhananjay B KNo ratings yet

- Mechanical Seal Quick Ship: Engineered, Manufactured, Assembled, Tested and Shipped in 72 HoursDocument2 pagesMechanical Seal Quick Ship: Engineered, Manufactured, Assembled, Tested and Shipped in 72 HoursDhananjay B KNo ratings yet

- Bearing LifeDocument3 pagesBearing LifeDhananjay B KNo ratings yet

- Wilcoxon Short Form Catalog-2018Document36 pagesWilcoxon Short Form Catalog-2018Dhananjay B KNo ratings yet

- Renk MaagDocument12 pagesRenk MaagDhananjay B KNo ratings yet

- Oil BleedingDocument3 pagesOil BleedingDhananjay B KNo ratings yet

- IMI Remosa ValvesDocument4 pagesIMI Remosa ValvesDhananjay B KNo ratings yet

- Saudi Aramco Steam Turbine Training CourseDocument45 pagesSaudi Aramco Steam Turbine Training CourseDhananjay B K100% (3)

- Gearbox FailureDocument18 pagesGearbox FailureDhananjay B KNo ratings yet

- Yamaha MT-15 Brochure PDFDocument5 pagesYamaha MT-15 Brochure PDFDhananjay B K100% (2)

- Sinif Ingilizce 8. Unite Calisma Kagidi Test Etkinlik Worksheet FITNESS by Murat DukkanciDocument13 pagesSinif Ingilizce 8. Unite Calisma Kagidi Test Etkinlik Worksheet FITNESS by Murat DukkanciElif yurtsevenNo ratings yet

- Topic 5 AC To AC ConverterDocument53 pagesTopic 5 AC To AC ConverterNorain ZakariaNo ratings yet

- Mormon Sex Slave Tells of Horrific Abuse by Church Leaders - Www-fourwinds10-NetDocument3 pagesMormon Sex Slave Tells of Horrific Abuse by Church Leaders - Www-fourwinds10-NetGovernment-Slave-4-UNo ratings yet

- PRISMA 2020 Flow Diagram For Updated Systematic Reviews Which Included Searches of Databases, Registers and Other SourcesDocument1 pagePRISMA 2020 Flow Diagram For Updated Systematic Reviews Which Included Searches of Databases, Registers and Other SourcesSurya WijayaNo ratings yet

- Department of Education: Republic of The PhilippinesDocument14 pagesDepartment of Education: Republic of The PhilippinesJanna GunioNo ratings yet

- RS 232 Repeater KFD2-FF-Ex2.RS232: FunctionDocument4 pagesRS 232 Repeater KFD2-FF-Ex2.RS232: FunctionEder AlexandreNo ratings yet

- Social and Self Control TheoryDocument2 pagesSocial and Self Control TheoryKarl Amiel EspirituNo ratings yet

- Q Bank Chem MCD Viii 2019Document19 pagesQ Bank Chem MCD Viii 2019hgbv tttbNo ratings yet

- NRCan's Explosives Eservices - Authorized Products SearchDocument5 pagesNRCan's Explosives Eservices - Authorized Products SearchDiego VilaNo ratings yet

- Railway Accounting: Indian Railway Accounts ServiceDocument5 pagesRailway Accounting: Indian Railway Accounts ServiceAbhijeet AsthanaNo ratings yet

- If I Had A Million Dollars EssayDocument4 pagesIf I Had A Million Dollars Essaygejjavbaf100% (2)

- SavedrecsDocument615 pagesSavedrecsMARIBEL BARBECHONo ratings yet

- 373 PDFDocument6 pages373 PDFIjdra Journal Jitendra BadjatyaNo ratings yet

- REHS4987-02 Replacing Base Edge Assemblies in Large Wheel Loader BucketsDocument19 pagesREHS4987-02 Replacing Base Edge Assemblies in Large Wheel Loader BucketsCarlosNo ratings yet

- Death RoadDocument12 pagesDeath RoadRodrigo Salgueiro LlanosNo ratings yet

- Demonizing Drugmakers: The Political Assault On The Pharmaceutical Industry, Cato Policy Analysis No. 475Document56 pagesDemonizing Drugmakers: The Political Assault On The Pharmaceutical Industry, Cato Policy Analysis No. 475Cato InstituteNo ratings yet

- Valuing The Suitable Agro-Industrial Wastes For Cultivation of P. Platypus and P. EousDocument4 pagesValuing The Suitable Agro-Industrial Wastes For Cultivation of P. Platypus and P. EousDinesh Babu PugalenthiNo ratings yet

- Divergent Plate BoundaryDocument4 pagesDivergent Plate BoundaryGreg ManNo ratings yet

- Homeostasis Case StudyDocument3 pagesHomeostasis Case Studyapi-332887331No ratings yet

- Chapter 6 Food Handlers Safety HygieneDocument20 pagesChapter 6 Food Handlers Safety HygieneIrish MalabananNo ratings yet

- TYPHOIDDocument13 pagesTYPHOIDnaceyjj33No ratings yet

- Lec5 - Geotechnical Investigation Reports and Foundation Recommendations-Scope For Improvement-ExamplesDocument20 pagesLec5 - Geotechnical Investigation Reports and Foundation Recommendations-Scope For Improvement-ExamplesrohitNo ratings yet

- Cell DivisionDocument50 pagesCell Divisionbknishad100% (2)

- Bombas SumergiblesDocument79 pagesBombas SumergiblesInstinct_brNo ratings yet

- Chapter 15 IMSMDocument42 pagesChapter 15 IMSMjthemansmith1No ratings yet

- Nanoscience 2 PDFDocument388 pagesNanoscience 2 PDFSergio ArturoNo ratings yet

- A La Carte MenuDocument1 pageA La Carte Menuhappy frankensteinNo ratings yet

- YttrrtDocument9 pagesYttrrtImad AghilaNo ratings yet

- Speaking Listening 1Document3 pagesSpeaking Listening 1fara dias safrinaNo ratings yet