Professional Documents

Culture Documents

ASME PTC 30-1991 Air Cooled Heat Exchangers

ASME PTC 30-1991 Air Cooled Heat Exchangers

Uploaded by

ShanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASME PTC 30-1991 Air Cooled Heat Exchangers

ASME PTC 30-1991 Air Cooled Heat Exchangers

Uploaded by

ShanCopyright:

Available Formats

ASME PTC 30-1991 AIR COOLED HEAT EXCHANGERS

W

O

r

T.

N er

O

t-

g

66

--``-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

AIR COPLED HEAT EXCHANGERS ASME PTC 30-1 991

The total tube-side pressure drop is the sum of APf For fully developed turbulent flow (Rei > approx-

and APent. Nozzleandheaderlossesmayneed to be imately 7,000), there areseveralgoodcorrelations

separately considered. available. For general use, the Petukhov-Popov equa-

.The properties used in these equations and those tion,Eq.(D.61,(Ref. [I 311, is regarded as .the most

in the following paragraphs are usually evaluated at accurate but it is not in convenient form for ratioing

the arithmetic mean bulk temperature on the tube changes in velocity, for example,

side, except for pp,,, which is evaluated atthe inside

wall temperature at the point where thefluid reaches

--``-`-`,,`,,`,`,,`---

its arithmetic mean bulk temperature.

D.2.2 Heat Transfer. The appropriate heat transfer

0 correlation to use depends upon whether theflow is

turbulentorlaminar. For laminar flow (Rei c 2100),

many different 'correlations and analytical treatments

have been given in the literature. Reference [ I O ] is

the most comprehensive.and up-to-datesource. The

Hausen equation (Ref. [Ill, [I211 is widely recom- where the subscript t indicates turbulent.

mended in the literature to represent the major ef- Theviscosityratioterm hasbeenadded to the

fects in laminar flow: above equation here. The Moody-Darcy friction fac-

tor, fM,in Eq. (D.6) can be calculated from Eq. (D.3).

TheSieder-Tateequation, Eq. (D.7),Ref.[4], is

usuallyadequate for air cooler applications and is

more convenient for adjustments of tube side con-

0.0668( y)(

y)(

F) ditions:

3.65 +

,+o.o4[ (?)(y)(?)]

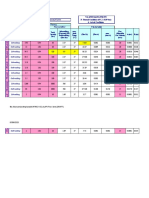

Forwater, Figs. D.2aandD.2btaken from Kern

(Ref.[141),are very easy to use.FiguresD.2aand

.(E)"' (D.5)

D.2bmayberepresented

sional equation:

by the following dimen-

a where fi,,Lis the mean inside heat transfer coeffi-

cientforlaminar flow in atube of length L.

Examination of Eq. (D.5)reveals thatforsmall where (h,),. = I .70 (loo + T ) V;, (D.8b)

L, 6 is proportional to L"/3, where L is the length of

the tube. This is due to the development of an ad-

verse temperature gradientas a resultof the conduc- . ,

and C = 0.911 - 0.429 log,,D, (D&)

tive heat transfer in the fluid. As mentioned above,

various devices may be inserted into the tube in order

to break up this gradient by disturbing the boundary where T is the mean water temperature in "F, V,, the

layer or by fdrcing theflow tobecome turbulent. No tube inside water velocity in feetpersecond,and

general correlations are available for all such devices, Dlthe inside tube diameter in inches.

and specific correlations for eachtype should be ob-

0 tained from thevendorandtheirinterpretation

agreedupon prior to thetest.

The dimensions of hi are then Btu/hr.ft*."F, and h;

is based upon the inside area of the tube.

67

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

0 7 5 9 b 7 0 0083300 5 W

ASME PTC 30-1991 AIR COOLED HEAT EXCHANGERS

For transition flow (2100 < Re, 7,000), no ac- vapor with no liquid present has a quality of 1.00,

curate predictions are possible because of the slow- and a totally condensed stream at its boiling point or

ness with which fully-developed velocity and thermal bubble point has a quality of zero.

profiles are achieved and becauseof the strong effect Estimates can be made of the frictional loss using

of the entrance flow geometry. An estimate can be the work of Martinelli andNelson (Ref. [151). The

made by linearly interpolating between the laminar frictional pressure dropthrough the tube for the con-

flow heat transfercoefficient, ,obtainedfrom Eq. densing flow entering as a saturated vapor(x, = 1.O),

(D.5) and the turbulent flow result, h,, , obtained and exiting at a qualityof x, is found from

from Eq. (D.6) or (D.7)) using the equation: -

i APP,TPF = 43P,,Y (D,10)

h, = KL t (h,,, - 7j;.L I( Re' - 2100

4900 ) where TPF indicates two-phase flow and APp,v is the

pressure dropcalculatedfrom Eq. (D.?) assuming

that theflow is all vapor and no,condensation occurs.

for 2100 c Re,< 7000 0.9) The mean two-phasemultipying factor, P,,,is read

from Fig. D.3 as a function of the exit qualityand the

reduced pressure of the vapor,

Any calculation in this range must be regarded as J

highly uncertain.

--``-`-`,,`,,`,`,,`---

P

P, = - (D.11)

PC,

where P is the absolute pressure of the condensing

D.3 SINGLE COMPONENT CONDENSATION vapor and PCr is the absolute critical pressure of the

D.3.1 GeneralComment. The condensation of a vapor being condensed. P and P,, must be in con-

single (pure) component can usually be considered sistent units, usually psia.

to be carried out at nearlyconstantpressureand The other two pressure effectsthat need to be con-

therefore at nearly constant temperature. However,' sidered in condensation are the momentum and hy-

the details of the condensation process are not fully drostatic contributions. Momentum effects arisefrom

understood, and the correlations correspondinglyare the deceleration of the vapor as it condenses; in prin-

not very precise, Coefficients for condensing steam ciple, this results in a pressure 'recovery. However,

or ammonia are so high (in the absence of non-con- this recovery is usually at least partially offsetby in-

densablegas) that this uncertainty hardly matters.' creased friction losses in the liquid film. ln design, it

-, Howbver,coefficients for other substances(such as is usually conservativeto neglect any pressure recov-

propane or other light and medium hydrocarbons), ery that may occur. However, in analyzing the per-

while generally quite good, may be, comparable to formance of aunit, this pressurerecoverymay

the air side when the area ratio is taken into account. explain, at least partly, why the pressure drop is less

The heat transfer correlations givenbelow are accu- than that expected.

rate enough for most purposes. Prediction of pres-, The hydrostatic pressure effect arises only for ver-

sure drop in two-phase flow is very uncertain; errors tical or inclined tubes. The hydrostatic pressure effect

up to a factor of five are possible. results in an increase in the pressure atthe lowerend

of the tube.compared to a similar horizontal tube.

D.3.2 Pressure Drop. Pressure drop calculations in Accounting for this effect requires detailed calcula-

two phase flows in principle require thestep by step tions of the local density of the two-phase mixture

integration of local conditions, coupledwith the heat and is often(conservatively) omitted in condenser

transfer rate to estimate the rate at which the vapor design.

is being condensed. The total pressure effect is the

algebraic sum of the frictional, momentum, ,and hy- D.3.3 Heat Transfer Coefficients

1

drostatic effects, of which the first is usually of the

greatest concern. Animportant parameter is the qual- D.3.3.1 Horizontal Tubes. At low condensing rates

ity ofthe flow, which is defined as the mass flow rate inside horizontal tubes, the condensate flows down

of the vapor phase only, divided by the total mass the wallsof the tubeinto a pool at the bottom of the

flow rate of both vapor andliquid phases. A saturated tube, which then drains by gravity out of the end of

68

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

AIR COOLED HEAT EXCHANGERS 30-1991 ASME PTC

--``-`-`,,`,,`,`,,`---

1 .o 1.5 2 3 4 5 6 7 8 9 1 0

Velocity Through Tubes, ft/sec

GENERAL NOTE: This chart applies only to a tube 0.62 inside diameter kg., 3/4 in. X 16 BWG).

For other diameters, refer to Fig. D.2b.

FIG. D.2a CHART FOR CALCULATINGIN-TUBEHEATTRANSFERCOEFFICIENTS

FOR WATER

69

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

ASME PTC 30-1991 AIR COOLED HEAT EXCHANGERS

1.2

'i *I

ò

5 1.0

U ,

.-

0

CI

E0 0.9

ò

-.o-

"

0.5

O.7.

0.4 0.6 0.7 0.8 0.9 1.0

Inside Diameter of Tube, in.

1.5 2.0

GENERAL NOTE: Multiply the value obtained from Fig. D.2a by the above factor.

. .

FIG, D.2b CORRECTIONFACTORTO FIG. D.2a FOROTHERTUBEDIAMETERS

the tube. Kern's modification (Ref. [I411of Nusselt's and ß is found as a function of I$? in Fig. D.4. The

equation (Ref. 1161) may be used to calculate the Chaddock correlationcorrectsthehorizontaltube

coefficient in this case: Nusselt equation for the relative amount of surface

blanketed by thestratified pool of liquid (through

r i113

which no heat transfer is assumed to occur).

At higher condensing rates, all or a portion of the

L -I

tube may be in annular two-phase flow, in which a

turbulent liquid film covers the entire inner surface

of the tube. A convenient correlation forthis regime

is due to Boyko and Kruzhilin (Ref. [18J).

In this equation, L is the length of the tube and W ,

is the pounds of vapor condensed pertube per hour.

If a U-bend tubeis used, L is the combined lengthof

both straight sections and the U bend.

A more rigorous equation used for low condensing

rates is the Chaddock correlation (Ref. [I 71):

(D.14a)

where, In this equation, G, is the mass velocity of the con-

densing stream

=

r

I

- 5.06 X 10-4

)LrT,,, -7-J"'

D:.75

I

70.142

(D.13b)

L -I

r 1114

where W,, is the pounds of vapor entering each tube.

L J per hour.

70

--``-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

ASNË P T C k 3 0 91 W 0757670 OOA3303 O

AIR COOLED HEAT EXCHANGERS ASME PTC 30-1991

Also, Asthe condensing load increases above the point

at which thecondensate film becomes turbulent

(which occurs when Re, = 4W, l p L P ~ D>2000),

i the

Colburncorrelation (Ref. [20]) becomesvalid.The

Colburn correlation may be represented graphically

as in Fig. D.5 or analytically by Eq. (D.16):

--``-`-`,,`,,`,`,,`---

where x, and x, are the inlet and exil qualities of the where Pr,,p = cp81,pp1*p

kf,P

stream,. 'respectively, For the special and important

case of totalcondensation of asaturatedvapor

stream, the term in brackets in Eq. (D.14a) reduces Again, research is showing that the transitionfrom

to: laminar to turbulent flow is not as abrupt as,sug-

gested by Fig. D.5 and the actual coefficients in the

transition regime are higher than shown for Rei from

(D.14e) perhaps 800 to 3000.

If the condensing load (or moreexactly, the vapor

flow) is sufficientlyhigh, vapor shear effects cause an

The correlationsof Kern and Chaddock are valid at early transition to turbulence in the condensate film

and a sharp increase in the heat transfer coefficient.

0 low vapor flow rates, where gravity dominates the

flow pattern,andareinvalidat high vapor flow rates,

. wherevaporsheardominates.TheBoyko-Kruzhilin

Undertheseconditions,theBoyko-Kruzhilinequa-

tion given above, Eq. (D.14a) et seq., becomes valid.

correlation operates in exactly the opposite fashion. Again, a conservative and simple procedure for esti-

Comparisonof the fundamentalbases for each equa- mating a condensing coefficient for vertical tubes is

tion indicates that the correlationwhich is valid under to calculate the. coefficient by all threeequations,

a given set of conditions gives a higher heat transfer (D.14), (D.15), and (D.161,andselectthe highest

coefficient than the invalid correlation. Therefore, to coefficient.

determine which type of correlation is applicable in D.3.3.3 Inclined Tubes.Very fewdatahavebeen

a given situation, one may calculate the coefficient published on condensation in downward flow inside

by each method and select the higher.value. In the inclined tubes, though proprietary data and correla-

transition region where the correlations cross, the ac-

tions exist. It is reported that the condensing coeffi-

tual coefficients are found to be greater than those

cient increases significantly (compared to a vertical

predicted by either type of correlation. The values of

tube) in a tube which is inclined from 1 deg. to 20

6, calculated by theseequationsaremeanvaluesfor deg. from the vertical. As the inclination moves to-

the entire tube. Calculation of the local values is be-

ward the horizontal, the coefficient changes toward

yond the scope of this standard;Ref. I191 may be

that for a horizontal tube.

consulted as a typical example.

Nilsson (Ref. [21]) has shown that a very slight (1

to 2 deg.) upward inclination in a horizontal tube can

D.3.3.2 Vertical Tubes. Nusselt (Ref. [I611 also ob- cause substantial reduction in the condensation heat

tained an equation for Condensation under laminar transfer coefficient, presumably because of excessive

condensate film conditions in vertical tubes (corre- pooling of the liquid in the lower end of the tube.

spondinggenerally to low condensingrates).This

equation is

D.3,4 Mean Temperature Difference for Saturated

I- 1113

PureComponentCondensation. Themean tem-

perature difference for condensation of a saturated

pure vapor, assuming a constant overall heat transfer

71

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

-ASME P T C * 3 0 91 O759670 0083304 2 '

--``-`-`,,`,,`,`,,`---

ASME PTC 30-1 991 AIR COOLED HEAT EXCHANGERS

6

9

O

II

a

Q

I

t

t- 8 9:

O

72

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

A S I E PTC*30 71 O757670 0083305 4

AIR COOLED HEAT EXCHANGERS ASME PTC 30-1991

O 1 .o0

0.95

0.90

0.85

0.80

ß

0.75

0.70

O. 65

0.60.

0 0.5 1.0 1.5 2.0 2.5 3.0

*", radians

FIG. D.4 ß AS A FUNCTION FOR I),,, FOR THE CHADDOCK METHOD

coefficient, and constant saturation temperature, is sure existing in the vapor space. In this case, it has

given by: been shown that the above-referenced equationsfor

condensing a saturated vapor adequately predict the

EMTD = LMTD = ,t -G \ (D.17) heat transfer rate on the vapor side, if the saturation

temperature of the vapor is used as the process fluid

temperature in Eq. (D.17). It is necessary to include

c where TSatis thesaturationtemperature of thecon-

densing vapor.

in the heat load the sensible heat of cooling the va-

por,even though its temperature is ignored in cal-

culating the EMTD.

If the sutface is above the saturation temperature,

The EMTD under these conditions is independent

the vapor will cool sensibly by the usual single phase

of flow arrangement. It should be noted that in fact

convectiveprocess until it reaches a temperature

the local condensing coefficients do vary with local

such that the wall does become wet. In principle, it

quality, but the effect on the overall coefficient is

is only necessary to follow the cooling of the vapor

. ordinarily small. Consideration of these effects is in and the wall temperature until the wall reaches sat-

any case beyond the scope of this-document.

uration - temperature and then follow the procedure

given in the previous paragraph.

D.3.5 SuperheatedVapors. A superheatedvapor However, such local vaporcooling calculations are

will condense directly from the superheated stateon tedious because the vaportemperaturechanges

a surface that is even slightly (perhaps 0.01"F)below alongeachtubeand theairtemperature changes

the saturation temperature of the vapor at the pres- across each row of tubes as well as along each tube.

--``-`-`,,`,,`,`,,`---

73

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

ASME PTC*130 I0 7 5 9 6 7 0 008330b b E !

91 .

ASME PTC 30-1991

--``-`-`,,`,,`,`,,`---

74

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

ASME PTC*30 71.W 0757670 0083307 8

AIR COOLED HEAT,EXCHANGERS ASME PTC 30-1991

Reference i221 shows that the heat transfefflux for These calculationsrequirevapor-liquid equilibrium

cooling a superheated vapor must be higher than the and enthalpy calculations that are usually computer-

condensing flux if the wall is to remain dry. Therefore, based and supplied by the customer. Before any con-

if it is assumed that the vapor is desuperheating in clusions can be drawn about the performanceof the

the wet wall regime from the start (using the simple condenser, mutual agreement must be reached be-

procedure given in the first paragraph), the area cal- tween customer and vendor on the validity of these

culated to be required will either be correct (if the calculations.

wall is wet even at the vapor entrance)or conservative (b) Sensibleheattransfereffects(¡.e./ cooling of

(if some portion of the wall is in fact dry). The term the vapor-gas mixture) are always present in multi-

correct means that the calculated area is as close to component condensation in both the vapor-gas and

that actually required as the validity of the correla- liquid phases. The cooling of the vapor-gas mixture

tions permits; conservative means that the calculated tends to be an important and often controlling part

area is larger than would be obtained by a detailed of the heat transfer process.

local

calculation. (c) Mass transfer effects are always presentin mul-

ticomponent condensation. These processes areonly

poorlyunderstoodandmust be treated in a fairly

D.3.6 Subcooling of Condensate, When subcooled arbitrary manner.The specific problem of a single

condensate is required, it is customary to design the condensable vapor with a noncondensable gas can

condenser so that the bottom row or rows of tubes, be handled with some rigor as shown in Ref. [231.

disposed in one or more passes, run full of conden- (d) Physical properties changein both phases, both

sate. The liquid phase heat transfercoefficient canbe as a result of changing compositions and changing

temperatures.

--``-`-`,,`,,`,`,,`---

calculated using the correlations given in para.D.2

and the heat transfer rateby using a corrected LMTD, Usually, careful analysis of multicomponent con-

the correction factors being given in para. 5.5 for the densationproblems (which may includenoncon-

appropriate pass arrangement. densable gases) requires zone-by-zone analysis on a

The averageair temperature leaving the subcooling computer. However, if the condensing temperature

section can be calculated by a heat balance. Without range is relatively small compared to the mean tem-

going to a zone-by-zone analysis (which requires a perature difference, orif only a small amount of con-

computer program for all practical purposes), it is densate is formed,approximatecalculations . of

necessary to assume that the average air temperature sufficient accuracy may be possible (Ref. [24]).

off of the subcooling rowsis equivalent to a uniform In thesecases, the heattransferprocesson the

tube side may be considered to consist of tw6 re-

inlet air temperature to the condensing rows. This is

sistances in series:

of course not the case,and it is usually somewhat

( I ) Sensible heat transfer from the vapor-gas mix-

nonconservative to assume so. In analyzing the per-

ture to the condensate interface,with a typicalvapor-

formance of an existing unit, this factor can be taken

phase heat transfercoefficient h,, calculated from the

.into account qualitatively without a great deal of

correlations in para. D.2, and,

computation.

(2) Convection of the sensible heat from (1) above

e and the latent heat released by condensation at the

interface through the condensate layer, with a con-

densing heat transfer coefficienthi,=.

A combined coefficient forthese two processes on

D.4 MULTICOMPONENT CONDENSATION,

INCLUDING NONCONDENSABLE GASES the condensing side, h, maybecalculatedby Eq.

(D.18a)

There are several special problems associated with

the condensation of a multicomponent mixturenora 1

vapor containing anoncondensable gas. Amongthem h, = (D.18a)

z 1

are the following: -+-

h,,h,

(a) It is necessary for accuratedesign to have a

condensingcurve for the mixture; acondensing where

curve gives the temperature of the condensing mix-

@ ture and the fraction of the flow that has been con- Z= QS"

(D.18b)

densed as a function of the amount of heat removed. Q, + QL+ Qd

75

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

ASME P T C 8 3 0 91 0759670 0083308 T I .

ASME PTC 30-1991 AIR COOLED HEAT EXCHANGERS

Q, is the heat duty required to cool the vapor-gas (c) Reduction in number of tubes in successive

mixture: passes in condensing(andsometimessubcooling)

service in order to maintain high vapor velocity and

condensing coefficients. Note however that uniform

distribution of the two phases among the tubes in

later passescan not be expected, and this can lead

to excessive subcooling in sometubesand incom-

QLis the heat duty required for condensation: plete condensation in others.

(d) Multiple servicesmay be handled in a.single

Q, = X W p , c o n d (D.

18d) unit, usually with the sections in parallel on the air

flow (side-by-side in the frame). Different tube sizes

and number of rows may be used in each section.

(e) A single row of tubes may be split between two

Q,, is the heat duty required for cooling the con- passes in order to obtain the same number of tubes

densate: in eachpass,e.g., two passes in five rows of tubes.

(0 A row oftubes may contain asingle tube (or at

most a few tubes) servingas a vent condenseroff of

an air removal point and having a differentinlet and

outlet header connection.

Thermal analysis of types a, b, and c can be carried

- out by a procedure similar to that suggested for sub-

wp," an'cl Wp,,are the average weight flow rates of

vapor and condensate in the condensingprocess, and cooling sections above, and with the same caution

Wp,condis the amount of vapor actually condensed. upon assuming the air inlet temperature to the upper

rows of tubes to be uniform.

Type d can be analyzed straightforwardly foreach

section if the air flow and exit air temperature for

D.5 UNUSUAL PASSARRANGEMENTS each section are measured.

Type e can .be analyzedreasonablycloselyby

For. avariety of reasons,unusualpassarrange- straightforward methods, using the actual numberof

ments of various kinds are often used in air cooled

tubes in each pass for tube-side calculations and ig-

exchangers, The following examples may be cited:

noring the usually slight imbalance in the air tem-

(a) Reduction in number of tubes in successive

perature profile caused by the split pass or passes.

passes,used in cooling viscous liquids in order to

Type f poses no serious problems on the air side

increase thevelocity and maintainturbulent flow

since only a few tubes are involved.The analysis-in-

conditions. side the tube can be carried out by the methods of

(b) Using enhancement devices in one or more of para, D.4 or Ref. [231.

the last passes for the same purpose.

76

--``-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

A S I E P T C * 3 O 71 E O757670 0083307 1

--``-`-`,,`,,`,`,,`---

AIR COOLED HEAT EXCHANGERS ASME PTC 30-1991

APPENDIX E - FOULING

E,1 Theexchangerdesignerincorporates a heat should preferablybe performed in the clean condition

transfer fouling resistance to account for the accu- on bóth air-side and tube-sideto minimize the effects

mulations of layers of resistive material on the heat of fouling since fouling cánnot be reliably predicted.

transfer surfacesas the exchanger operates. Thefoul- The fouling resistances used to interpret the test re-

ing resistance is also known as fouling factor, dirt fac- sults shall be agreed upon by the parties to the test

tor, and dirt film. The fouling resistance occurs on prior to the start of the test, see para. 3.2(j).

both the air-side and the process-side heat transfer

surfaces. Unfortunately,. the existing technologydoes

not provide a dependable analytical method for ac- E.3 the influence of foulingon the overall heat trans-

curate prediction of fouling. The purchaser normally fer coefficientwill vary accordingto the relative-mag-

depends on experience in similar services to select nitudes of the fouling resistances and the clean heat

and specify the design fouling resistances. transferresistances. For example, a closed-circuit

treated'water coolermight have a low tube-side foul-

ing resistance of 0.0005 hr.ft*-"F/Btu referencedto the

E,2 Fouling presentduringthe test affects the air-side inside surface. Thismight be approximately5 percent

and process-side heat transfer coefficients and flow of the total heat transfer resistance. In comparison,

pressure drops. Fouling of the air-side surface may this resistancefor aheavy oil cooler might be 0.003

occur from the depositionof air-borne materials such hr.ft2-"F/Btuwhich might be over 20 percent of the

as dust, organic material, seeds, and insects, or from total heat transfer resistance, making a clean condi-

corrosion. It is impossible to accurately predict the tion for testing relatively more important.

effect of such deposits and they must be removed

prior to testing. Fouling of the inside surface of the

tubes is dependent upon the fouling and corrosion E.4 For additionai information on fouling the reader

characteristics of the fluidin the tubes.Testing may refer to Ref. [25].

77

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

'ASME PTC*3O 91 H 0757670 0083310 8 E

AIR COOLED HEAT EXCHANGERS ASME PTC 30-1991

APPENDIX F - RECIRCULATION OF AIR

F.1 Advkse wind conditions, faulty design, or poor be basically the same as for a test conducted when

orientation of the ACHE with respect to adjacent there is no air recirculation or contamination. How-

structures may cause hot air to recirculate into the ever, entering air temperatures may be far from uni-

O unit. The resultantelevation of enteringairtemper- form. Temperature variations at a given measurement

0 ature above ambient will reduce the capacity of the

ACHE. Simitayly, contämination of the entering air by

hot air from extraneous heat sources, such as heaters,

station and/or variationsfrom station to station, cou-

pled with variations in air velocity, may require an

abnormaliy large number of measurement stations,

boilers, or heat exchangers, will have a detrimental and may necessitate coincident measurement of tem-

effect on capacity. perature and air flow at each station.

F.2 Since the performance evaluation procedures de- F.3 A detailed survey should be made just prior to

scribed by this Code are based on entering rather than the test, and agreement reachedby theparties to the

ambient air, the-recirculation and/or contamination test on the number andlocation of measurements to

described abovewill not necessarily havea significant be taken to ensure the desired level of accuracy.

effect op the performance capabirity of the ACHE. The

results of a test conducted while the entering air tem- F.4 For more information on this subject the reader

perature is well above ambient, but uniform, should is referred to Refs. [27] through 1361.

(I,

--``-`-`,,`,,`,`,,`---

V

79

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

ASME P T C * 3 Ö 91 0759670 008331L T

AIR COOLED HEAT EXCHANGERS ASME PTC 30-1991

APPENDIX G - REFERENCES

[I 1 FieldTesting of Air-CooledHeatExchangers, [I41Kern, D. Q., Process Heat Transfer, McGraw-Hill

Chemical Engineering Progress, July 1960. Book Company, New York (1950).

[2]Flow of Fluids Through Valves, Fittìngs, and Pipe [I 51 Martinelli, R. C., and Nelson, D. B., Trans. ASME

- Crane Co., Technical Paper No. 410, 1978. 70,695, (1948).

[3]Fundamentals of Pipe Flow, R. P. Benedict, Wiley, [I61 Nusselt,W.,Zeits. VDI 60, 541, 569(I916).

-1980. Also cited in Refs. 161 and [91.

[4]Sieder, E. N., andTate,G. E., Ind. Eng.Chem., [I 71 Chaddock, J. B., Refrig.Eng.65,No. 4, 36

28, 1429 (1936). (1957).

[5]Briggs, D. E., and Young, E. H., Convection Heat [I81 Boyko, L. D.,andKruzhilin,G. N., Int. J. Heat

Transfer and Pressure Drop of Air Flowing Across Tri- Mass Trfr. 70, 361 (1967).

angular Pitch Banks of Finned Tubes, AIChE, August [I91 Travis, D. P., Baron, A. B., andRohsenow,W.

1962. M., MIT Rept. No. DSR 72591 -74 (1971 1.

[61Ward, D.J., and Young, E. H., Heat Transfer and r201 Colburn, A. P., Trans. AlChE 30, 170 (1934).

Pressure Drop of Air in Forced Convection Across Tri-

angular Pitch Banks of Finned Tubes, Chemical Engi- [21]Nilsson, S . N.,Paper 2.32, Proc. Xlll Int. Cong.

neering Symposium Series No. 29, Vol. 55, 1959. Refrig., Washington, DC (1971),

[7]Gardner, K. A., Efficiency of ExtendedSurface, 1221Bell, K. J., Chem. Eng. Prog. 68, No. 7,81 (1972).

ASME Transactions Paper 1945,Vol. 67. [231 Colburn, A. P., andHougen, O. A., Ind. Eng.

[8]Moody, L. F., Trans. ASME 66, 671 (1944). Chem. 26, 1186, (1934).

--``-`-`,,`,,`,`,,`---

[9]Blasius, H., Forschg. Arb. h g -Wes. No. 131,Ber- r241 Bell, K.J., and Chaly, M.A., AlChE Symp. Series

lin (1913).Cited in Schlicting, H., BoundaryLayer 69, NO. 131, 72-79 (1972).

Theory, 7th ed., McGraw-Hill Book Co., New York [25]Kakac, S., Bergles, A.E., and Mayinger, G., Heat

(I979). Exchangers: Thermal-Hydraulic Fundamentals and De-

[I O] Shah, R. K., and London, A. L., Advances in Heat sign, McGraw-Hill, and Hemisphere Publishing Corp.

Transfer, Supplement1: Laminar Flow Forced Convec- (I 9811.

tion in Ducts, Academic Press, New York (1978). i261 TubularExchangerManufacturersAssociation,

[Il]Hausen,H., VDlZ Beih. Verfahrenstech. 4. 91 Standards of TEMA, latest edition.

(1943).Cited in Ref. [12]. L271 Gunter, A. Y., and Shipes, K. V., “Hot Air Recir-

1121 Jakob, M., Heat Transfer, J. W: Wiley and Sons, culation .by Air Coolers,”AlChE TwelfthNational

New York, Vol. 1 (1949). Heat Transfer Conference, AIChE-ASME, Tulsa,Okla-

homa, August 15-1 8, 1971.

[I31 Petukhov, B. S., and Popov, V. N., Teplofiz. Vy-

sok. Temperature 7, No. 1 (1963).Also discussed by 1281 Collins, G. F., andMathews, R. T., “Climatic

B. S, Petukhov in Advances In Heat Transfer, Vol. 6, Considerations in Design of Air Cooled HeatExchan-

O Hartnett, J. P., and Irvine, T. F., Jr. Eds., Academic

Press, New York (1970).

gers,“Paper 59-A-255,December 4, 1959,

Meeting ASME.

Annual

81

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

ASME P T C U 3 0 7.1 m O757670 8083332 I m i

ASME PTC 30-1991 AIR COOLED HEAT EXCHANGERS

1291CoolingTower InstituteTechnical Subcommittee [34] Haldridge, E. S., and Reed, B. H., ”Pressure Dis-

No, 2: “Recirculation,” C T I Bulletin PFM-110, 1958. tribution on Buildings,” Department of Army, Con-

Also PFM-11OA, Appendix to PFM-11O. tract No. DA-18-064 CML77,August1956,Texas

Engineering Experiment Station, Texas A & M.

[30] Schmidt, W., “Calculations of Distribution of

Smokeand

Waste

Gases in the Atmosphere,” 1351 Haldridge, E. S., and Reed, B. H., “Pressure Dis-

-

Gesundheits Ing. Vol 49, 1926, pp. 425-426. tribution on Buildings-ReportNo. 2,” Department of

Army, Contract No. DA-18-064 CML77, August

[31] Sutton, O. G., “A Theory of Eddy Diffusion in 1956,

Texas

Engineering

Experiment

Station,

the Atmosphere,“ Proc. Roy. Society (London) Ser. A Texas A & M.

Vol. 135, 1932, PP. 143-1 65.

[36] Kosten, C. J., Morgan, J. I., Burns, J. M., and

1321 Bailey,A., and Vincent,N.D. G., “Wind Pressure Curlett, P. L., “OperatingExperienceandPerform-

on Building Including Effects on Adjacent Building,” anceTesting of theWorlds Largest Air Cooled

Journal Institution of Civil Engineer, March 1943, Condenser,” April 27-29,1981,AmericanPower

PP. 243-275. Conference, Chicago, Illinois.

[33] Dryden, H. L., and Hill, C. C., “Wind Pressures

on Structures,” Scientific Papers of Bureau of Stan-

dards, Vol. 20, 1926, p. 697.

--``-`-`,,`,,`,`,,`---

82

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

COMPLETE LlSTlNC OF ASME PERFORMANCE TEST CODES

PTC 1 - General Instructions ....................,...............................I986

PTC 2 - Definitions and Values ..........,......................................1980

(R1985)

PTC 3.1 - Diesel and Burner Fuels ......,.,......,...............................I958

.,

(RI985)

PTC 3.2 - Solid Fuels ,.......,..,...........,..,......,...,........,...............I954

(R1 984)

- Gaseous Fuels ..,.. ..,......,.,......,.,...,,.........,...,...........,1969

--``-`-`,,`,,`,`,,`---

PTC 3,3

(R1 985)

PTC 4.1 - Steam-Generating Units (With 1968 and

1969 Addenda) .. .............. .....,................................I964

(R1 985)

Diagram for Testing of a Steam Generator,

Fig. 1 (Pad of 100)

Heat Balance of a Steam Generator,

Fig. 2 (Pad of 100)

PTC 4.la - ASME Test Form for Abbreviated EfficiencyTest -

Summary Sheet (Pad of 100) ......... .... . ......,........,.......I964

, , ,

PTC 4.1b - ASME Test for Abbreviated EfficiencyTest -

Calculation Sheet (Pad of 100) ........................ ..............1964

PTC 4.2 - . . ........ . ....... ...... .......,......,......,...I969

Coal Pulverizers , , , , ,, ,

(R1 985)

PTC 4.3 - Air Heaters ...... ... ............... ......... ..........................I968

(RI 985)

PTC 4.4 - Gas Turbine HeatRecovery Steam Generators........................I981

(RI 987)

PTC 5 - ReciprocatingSteam Engines ..................,.......................I949

PTC 6 - Steam Turbines .... ....................,......,............,............1976

(R1 982)

PTC 6A - Appendix Ato Test Code for Steam Turbines

(With 1958 Addenda) ...............,,......,.......................1982

PTC 6 - Guidance for Evaluation of Measurement Uncertainty

Report in Performance Tests of Steam Turbines .........................,..I985

PTC 6 s - Procedures for Routine Performance Tests

Report of Steam Turbines ...............,....................,..............I988

PTC 6.1 - Interim Test Code for an Alternative Procedure

for Testing Steam Turbines ...........,......... ...,.............,...I984

PTC 6 on Steam Turbines- Interpretations 1977-1983

PTC 7 - Reciprocating Steam-Driven Displacement Pumps...............,....1949

(R1 969)

PTC 7.1 - Displacement Pumps ............................,...............,......I962

(R1969)

PTC 8.2 - Centrifugal Pumps .. ..........,......,.......,.................,......,1990

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

ASME P T C * 3 0 71 W 0757670 QQB3314 5

PTC 9 .Displacement Compressors. Vacuum Pumps and

Blowers(With 1972 Errata) ......................................... 1970

(R1 985)

PTC IO - CompressorsandExhausters .......................................... 1965

(RI 986)

PTC 11 - Fans ..................................................................... 1984

PTC 12.1 - Closed Feedwater Heaters .............................................. 1978

(RI 987)

PTC 12.2 - Steam-Condensing Apparatus .......................................... 1983

PTC 12.3 - Deaerators .............................................................. 1977

(R1984)

PTC 14 - EvaporatingApparatus ................................................. 1970

(RI985)

PTC 16 - Gas Producers and Continuous Gas Generators ...................... 1958

(RI 985)

PTC 17 - Reciprocating Internal-combustion Engines ........................... 1973

(R1985)

PTC 18 - HydraulicPrimeMovers ................................................ 1949

PTC 18.1 - Pumping Mode of Pump/Turbines ..................................... 1978

(R1 984)

PTC 19.1 - MeasurementUncertainty ............................................. 1985

PTC 19.2 - Pressure Measurement ................................................. 1987

PTC 19.3 - TemperatureMeasurement ............................................. 1974

(R1 986)

PTC 19.5 - Application, Part II of Fluid Meters: Interim Supplement

on Instruments and Apparatus ...................................... 1972

PTC 19.5.1 - WeighingScales ........................................................ 1964

PTC 19.6 - Electrical Measurements in Power Circuits ............................ 1955

PTC 19.7 - Measurement of Shaft Power ........................................... 1980

PT% 19 8 - Measurement of Indicated Horsepower ............................... 1970

(R1 985)

PTC 19.1O - Flue and Exhaust Gas Analyses ........................................ 1981

PTC 19.11 - Water and Steam in the Power Cycle (Purity and Quality,

Lead Detection and Measurement) ................................. 1970

PTC 19.12 - Measurement of Time .................................................. 1958

PTC 19.1 3 - Measurement of Rotary Speed ......................................... 1961

PTC 19.14 - LinearMeasurements .................................................. 1958

PTC 19.16 - Density Determinations of Solids and Liquids ........................ 1965

PTC 19.1 7 - Determination of the Viscosity of Liquids ............................. 1965

PTC 19.22 - Digital Systems Techniques ............................................ 1986

PTC 19.23 - Guidance Manual for Model Testing .................................. 1980

(RI 985)

PTC 20.1 - Speed and Load Governing Systems for Steam

Turbine-Generator Units .............................................. 1977

' (R1988)

PTC 20.2 - Overspeed Trip Systems for Steam TurbineGenerator

Units ................................................................. 1965

(RI 986)

PTC 20.3 - Pressure Control Systems Used on Steam

Turbine-Generator Units ............................................. 1970

(R1979)

--``-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

PTC 21 .Dust Separating Apparatus ............................................. 1941

PTC 22 - Gas Turbine Powér Plants .............................................. 1985

PTC 23 - Atmospheric Water Cooling Equipment ............................... 1986

PTC 23.1 - Spray Cooling Systems ................................................. 1983

. PTC24 - .Ejectors ................................................................. 1976

(R1982)

PTC 25.3 - Safety and Relief Valves ................................................ 1988

PTC 26 - Speed-Governing Systems for Internal Combustion

€ngine-Generator Units .............................................. 1962

PTC 28 - Determining the Properties of Fine Particulate Matter ................1965

(R1985)

PTC 29 - Speed Governing Systems for Hydraulic

.............................................

Turbine-Generator Units 1965

(RI 985)

PTC 30 - Air Cooled Heat. Exchangers ........................................... 1991

PTC 31 - Ion Exchange Equipment ............................................... 1973

(R1 985)

PTC 32.1 - Nuclear Steam Supply Systems ........................................ 1969

(R1985)

PTC 32.2 - Methods of Measuring the Performance of Nuclear

Reactor Fuel in Light Water Reactors ............................... 1979

(R1986)

PTC 33 - Large Incinerators ...................................................... 1978

(R1 985)

PTC 33a - Appendix to PTC 33-1978 - ASME Form for

Abbreviated Incinerator Efficiency Test

(Form PTC 33a-1980) ............................................... 1980

(R1 987)

PTC 36 - Measurement of Industrial Sound ..................................... 1985

PTC 38 - Determiningthe Concentration of Particulate

Matter in a Gas Stream .........1.................................... 1980

(RI985)

PTC 39.1 - Condensate Removal Devices for Steam Systems .................... 1980

(RI 985)

PTC 42 - Wind Turbines .......................................................... 1988

The Philosophy of Power Test Codes and Their Development

--``-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

¡ASME P T C r 3 0 9L E 0759b70 0 0 8 3 3 L b 9

~

A complete list of all Performance Test Codes appsars

at the end of this book.

While providing for exhaustive

tests, these Codes are so d r a w n

thatselectedpartsmay be used

for tests of limited scope,

This document is printed

o n 50% recycled paper.

50% RECOVERED PAPER MATERIAL

means paper waste generated after the

completion of the papermaking

process, such as postconsumer

materials, text books, envelopes,

--``-`-`,,`,,`,`,,`---

bindery waste, printing waste, cutting

and converting waste, butt rolls,

obsolete inventories, and rejected

unused stock.

ISBN #O-7918-2073-4 C00057

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

You might also like

- Cooling Towers Information PackageDocument25 pagesCooling Towers Information Packagemdawg467No ratings yet

- Harmonic VibrationsDocument17 pagesHarmonic VibrationsIan MannNo ratings yet

- GROB 76pages PDFDocument76 pagesGROB 76pages PDFRaine LopezNo ratings yet

- 0048 Vivem175enDocument110 pages0048 Vivem175enArmando MaloneNo ratings yet

- Analysis and Enhancement of Hydraulic Ram Pump Using Computational Fluid Dynamics (CFD)Document25 pagesAnalysis and Enhancement of Hydraulic Ram Pump Using Computational Fluid Dynamics (CFD)IJIRSTNo ratings yet

- Design and Control of Condensate-Throttling ReboilersDocument12 pagesDesign and Control of Condensate-Throttling ReboilersForcus onNo ratings yet

- ACTUATORSDocument6 pagesACTUATORSMohamed Arriff100% (1)

- Flue Gas Heat Recovery in Power Plants, Part IIIDocument6 pagesFlue Gas Heat Recovery in Power Plants, Part IIIknsaravanaNo ratings yet

- See Sheet API-2000: Normal Venting Liquid Movement Thermal EffectDocument33 pagesSee Sheet API-2000: Normal Venting Liquid Movement Thermal EffecthhvgNo ratings yet

- Subsonic Ejector RamjetDocument99 pagesSubsonic Ejector Ramjetmarco20874No ratings yet

- FT-C ManualDocument80 pagesFT-C ManualnitantharaniNo ratings yet

- EPA 2015-Assessment - of - Non-Egu - Nox - Emission - Controls - and - Appendices - A - B PDFDocument192 pagesEPA 2015-Assessment - of - Non-Egu - Nox - Emission - Controls - and - Appendices - A - B PDFVuToanThangNo ratings yet

- Themodynamic Model Selection For CHEMCADDocument19 pagesThemodynamic Model Selection For CHEMCADratnakar patharkarNo ratings yet

- Basic of Refrigeration ProcessDocument29 pagesBasic of Refrigeration Process한준희No ratings yet

- Is 10496 - Specification For Feed Water, Boiler Water and Condensate For High Pressure BoilersDocument38 pagesIs 10496 - Specification For Feed Water, Boiler Water and Condensate For High Pressure BoilersSumit KaushikNo ratings yet

- Ethylene Dichloride ManufacturerDocument5 pagesEthylene Dichloride Manufacturerbarus goldenNo ratings yet

- CECO Environmental - Separation&Filtration - Upstream & Midstream - YPFB 3-26-2024Document54 pagesCECO Environmental - Separation&Filtration - Upstream & Midstream - YPFB 3-26-2024Ecosuministros ColombiaNo ratings yet

- Flue Gas Heat Recovery in Power Plants, Part IIDocument11 pagesFlue Gas Heat Recovery in Power Plants, Part IIknsaravana100% (1)

- Optimizing A Large Vessel Separator DesignDocument9 pagesOptimizing A Large Vessel Separator DesignmctimlimNo ratings yet

- Dynamics Model of Fire Tube Shell BoilerDocument10 pagesDynamics Model of Fire Tube Shell BoilerViro AkahanNo ratings yet

- Jet Pump Technical DataDocument11 pagesJet Pump Technical DataIdelia Cutipa Yauri100% (1)

- DesuperheaterDocument4 pagesDesuperheaterNaama RahavNo ratings yet

- Orbit Article Molecular Sieve Dehydration Switching ValvesDocument12 pagesOrbit Article Molecular Sieve Dehydration Switching ValvesPasquale Sessa0% (1)

- The Curious Behavior of Homogeneous Azeotropic Distillation-Implications For Entrainer SelectionDocument20 pagesThe Curious Behavior of Homogeneous Azeotropic Distillation-Implications For Entrainer SelectionkarimifarhadNo ratings yet

- Single and Multistage Steam Jet Ejectors: TorinoDocument12 pagesSingle and Multistage Steam Jet Ejectors: TorinoSuman SenapatiNo ratings yet

- Autoignition Temperature Measurements of Hydrogen MixturesDocument7 pagesAutoignition Temperature Measurements of Hydrogen MixturesAlly EnemmyNo ratings yet

- Chapter 1 Refrigeration CycleDocument19 pagesChapter 1 Refrigeration CycleMira FazziraNo ratings yet

- Refrigeration (Kylteknik) : 2. Vapour-Compression Refrigeration ProcessesDocument36 pagesRefrigeration (Kylteknik) : 2. Vapour-Compression Refrigeration ProcessesiJeng RalluNo ratings yet

- Unesco - Eolss Sample Chapters: Vacuum Creating EquipmentDocument7 pagesUnesco - Eolss Sample Chapters: Vacuum Creating Equipmentahmed nawaz100% (1)

- Amistco Mist Eliminator - Installation GuideDocument16 pagesAmistco Mist Eliminator - Installation GuidetmtoroNo ratings yet

- Aqueous Solubility of Inorganic Compounds at Various TemperaturesDocument9 pagesAqueous Solubility of Inorganic Compounds at Various TemperaturesterrorfordNo ratings yet

- Steam Air Ejector Performance and Its Dimensional ParametersDocument296 pagesSteam Air Ejector Performance and Its Dimensional ParametersGuru Raja Ragavendran NagarajanNo ratings yet

- HEI Tech Sheet 110Document15 pagesHEI Tech Sheet 110Suganya LokeshNo ratings yet

- Valve Test Pressures Common Grades PDFDocument1 pageValve Test Pressures Common Grades PDFvaliullahNo ratings yet

- A D B C: Steam Ejector Hybrid Systems in The Chemical IndustryDocument4 pagesA D B C: Steam Ejector Hybrid Systems in The Chemical IndustryAjiNo ratings yet

- Design of Condenser & ReboilerDocument39 pagesDesign of Condenser & ReboilerSyahmiNo ratings yet

- Packed Bed ColumnDocument14 pagesPacked Bed ColumnUmar DrazNo ratings yet

- Heat Tracing Basics - SLIDES-HRM-300410Document31 pagesHeat Tracing Basics - SLIDES-HRM-300410Chirag ShahNo ratings yet

- Cascade Refrigeration SystemDocument2 pagesCascade Refrigeration SystemHsein WangNo ratings yet

- Compounding of Steam TurbineDocument2 pagesCompounding of Steam TurbinejaihogoluNo ratings yet

- Steam Trap TesterDocument4 pagesSteam Trap TesterISMAEL RAMIREZNo ratings yet

- 837 1Document7 pages837 1azlanNo ratings yet

- Assignment I: Mahima Baid (220CH1630) Aayush Chaturvedi (220CH1162)Document9 pagesAssignment I: Mahima Baid (220CH1630) Aayush Chaturvedi (220CH1162)MAHIMA BAIDNo ratings yet

- Steam Turbines FundamentalsDocument51 pagesSteam Turbines Fundamentalssevero97100% (2)

- 1a.calibration of OrificemeterDocument7 pages1a.calibration of OrificemeterArjun P PNo ratings yet

- Improve Flaring OperationsDocument4 pagesImprove Flaring Operationsaa dd qqNo ratings yet

- Vertical Thermosyphon ReboilersDocument9 pagesVertical Thermosyphon ReboilersLucianoNo ratings yet

- 5 Steam Boiler FeedwaterDocument16 pages5 Steam Boiler FeedwaterCristhian Garcia Villarroel100% (1)

- Chapter 4 Heat Exchangers With High-Finned Trufin TubesDocument0 pagesChapter 4 Heat Exchangers With High-Finned Trufin TubesManuel ArroyoNo ratings yet

- 2016 - Dividing Wall Column Technology - Recent Developments and Challenges, Olujic - PPT MONTZDocument22 pages2016 - Dividing Wall Column Technology - Recent Developments and Challenges, Olujic - PPT MONTZudaybhatkandeNo ratings yet

- Controlling Heat ExchangersDocument11 pagesControlling Heat ExchangersgermanaponteNo ratings yet

- Refrig JT Plant Brochures - SNC - Valerus - Recd 20170623Document4 pagesRefrig JT Plant Brochures - SNC - Valerus - Recd 20170623johnNo ratings yet

- Kettle Reboilers Chemical Engineering Design Ray SinnoyDocument6 pagesKettle Reboilers Chemical Engineering Design Ray SinnoyFederico BogettiNo ratings yet

- Municipal Solid Waste to Energy Conversion Processes: Economic, Technical, and Renewable ComparisonsFrom EverandMunicipal Solid Waste to Energy Conversion Processes: Economic, Technical, and Renewable ComparisonsNo ratings yet

- 0379 7112 (80) 90009 0Document10 pages0379 7112 (80) 90009 0MihaNo ratings yet

- Design of Water-To-Air Gravity-Assisted Heat Pipe Heat Exchanger Bahar and F. MoztarzadehDocument11 pagesDesign of Water-To-Air Gravity-Assisted Heat Pipe Heat Exchanger Bahar and F. MoztarzadehMarius BrănoaeaNo ratings yet

- Wellbore Heat Loss in Production and Injection Wells, JPT Forum, 1979, 3 PGDocument3 pagesWellbore Heat Loss in Production and Injection Wells, JPT Forum, 1979, 3 PGjoselosse desantosNo ratings yet

- SPE-16904-PA Simulation of Downhole Heater Phenomena in Production WellboreDocument4 pagesSPE-16904-PA Simulation of Downhole Heater Phenomena in Production WellboreraifelmbNo ratings yet

- Limitations On Gas Turbine Performance Imposed by Large Turbine Cooling FlowsDocument8 pagesLimitations On Gas Turbine Performance Imposed by Large Turbine Cooling FlowsSickPinguNo ratings yet

- Energy Loses in Pipes PDFDocument6 pagesEnergy Loses in Pipes PDFAlexander MugabeNo ratings yet

- Multilevel 5 Step Cascaded Sine Wave Inverter CircuitDocument1 pageMultilevel 5 Step Cascaded Sine Wave Inverter CircuitStefan CorneaNo ratings yet

- Density& Specific GravityDocument23 pagesDensity& Specific Gravitynoahngoma41No ratings yet

- Problems 1-3Document3 pagesProblems 1-3raistlinNo ratings yet

- STPS20H 100CTDocument7 pagesSTPS20H 100CTManuel G Medina LopezNo ratings yet

- Graphing Changes in Motion Power PointDocument15 pagesGraphing Changes in Motion Power Pointbronxtube.ytNo ratings yet

- Thermal Diffusivity - Wikipedia, The Free EncyclopediaDocument3 pagesThermal Diffusivity - Wikipedia, The Free EncyclopediaygraoNo ratings yet

- Formula Rio PotenciaDocument2 pagesFormula Rio PotenciaKELY PILCONo ratings yet

- Student Exploration: Free-Fall LaboratoryDocument2 pagesStudent Exploration: Free-Fall LaboratoryAryan PatelNo ratings yet

- MRTS-3 (Paper With Solution)Document35 pagesMRTS-3 (Paper With Solution)semofederationNo ratings yet

- Answer Key Chapter 9Document6 pagesAnswer Key Chapter 9linNo ratings yet

- High Speed Fuses: Section ContentsDocument20 pagesHigh Speed Fuses: Section ContentsStefania MilitaruNo ratings yet

- Powerelectronics in Power System (QB)Document9 pagesPowerelectronics in Power System (QB)T.l. SelvamNo ratings yet

- PG Brainstormer - 4c (Electromagnetism) 635452000703671915Document6 pagesPG Brainstormer - 4c (Electromagnetism) 635452000703671915shivamgarg18No ratings yet

- Separator Sizing SpreadsheetDocument40 pagesSeparator Sizing SpreadsheetWalid Ben Husein100% (2)

- Eurogia Call Keynote Speech Hydrogen Rev.1Document18 pagesEurogia Call Keynote Speech Hydrogen Rev.1Antônio MatheusNo ratings yet

- Quincke'S Method: Magnetic Susceptibility: Aim of The ExperimentDocument4 pagesQuincke'S Method: Magnetic Susceptibility: Aim of The ExperimentAryan VermaNo ratings yet

- 16 MM Push Buttons: Selector Switch OperatorsDocument3 pages16 MM Push Buttons: Selector Switch OperatorsC Y M Machinery SacNo ratings yet

- Problem 11Document6 pagesProblem 11Elbrent Paul M ObedencioNo ratings yet

- Moving Coil GalvanometerDocument5 pagesMoving Coil GalvanometerAshok PradhanNo ratings yet

- Bs 6724 Copper Conductor Multi Core Swa LSZH Basec 0 6 1 KV CableDocument5 pagesBs 6724 Copper Conductor Multi Core Swa LSZH Basec 0 6 1 KV Cabletony6868No ratings yet

- Moment of Inertia Examples With SolutionsDocument14 pagesMoment of Inertia Examples With SolutionsCE PassajNo ratings yet

- Study of R-L-C Series CircuitDocument8 pagesStudy of R-L-C Series Circuitr21745566No ratings yet

- EE301 Lesson 25 AC Power and PWR TriangleDocument27 pagesEE301 Lesson 25 AC Power and PWR TriangleAli AkbarNo ratings yet

- Week 51 Listrik 2021Document28 pagesWeek 51 Listrik 2021Ari PurnamaNo ratings yet

- Experiment No. 1 Aggregate Impact Value Test: FormulaDocument20 pagesExperiment No. 1 Aggregate Impact Value Test: FormulaObaid RaufNo ratings yet

- Flyrock Control PDFDocument13 pagesFlyrock Control PDFCamila Contreras Carrasco100% (1)

- Daikin Ireland Residential Pricelist 2023 InteractiveDocument102 pagesDaikin Ireland Residential Pricelist 2023 InteractiveManuel José Sánchez GarcíaNo ratings yet

- Lab 5 Bernouli TheoremDocument5 pagesLab 5 Bernouli TheoremismailNo ratings yet