Professional Documents

Culture Documents

Testing: Why Valve Adjustment

Testing: Why Valve Adjustment

Uploaded by

ankit71989Copyright:

Available Formats

You might also like

- Chevrolet 327 V8 Engine Rebuild ManualDocument120 pagesChevrolet 327 V8 Engine Rebuild ManualAlissa Davis0% (1)

- Buxton-IOM TEST PUMP S10G-M THRU S30G-M TestUnits IOM rvB1 2Document16 pagesBuxton-IOM TEST PUMP S10G-M THRU S30G-M TestUnits IOM rvB1 2Wayne100% (2)

- Wom ValvesDocument11 pagesWom ValvesRio IndokniveziaNo ratings yet

- Plunger Pump ManualDocument23 pagesPlunger Pump Manualgovindharajalu75% (4)

- API Plan 53-Accumulator Bladder ChargingDocument11 pagesAPI Plan 53-Accumulator Bladder Chargingsumantabal_uceNo ratings yet

- Weber ManualDocument28 pagesWeber ManualMedardo SilvaNo ratings yet

- Operation 1Document9 pagesOperation 1Wbamlak AshebrNo ratings yet

- Group 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument7 pagesGroup 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyPriscila RodriguesNo ratings yet

- Assignment 5Document7 pagesAssignment 5Sharizada KanapiyevaNo ratings yet

- QFC Valve ManualDocument27 pagesQFC Valve ManualLeandro100% (1)

- Precharge Kit 5000PSI PDFDocument2 pagesPrecharge Kit 5000PSI PDFmetal_dung2No ratings yet

- Bop - Inspection and TestingDocument53 pagesBop - Inspection and TestingAustin AsuquoNo ratings yet

- Air Operated Hydraulic Presses Instuction and Parts List For Models 6-225 6-425 6-250 6-450 6-275 6-475 6-650 6-850Document11 pagesAir Operated Hydraulic Presses Instuction and Parts List For Models 6-225 6-425 6-250 6-450 6-275 6-475 6-650 6-850grantNo ratings yet

- LwsDocument36 pagesLwscrni rokoNo ratings yet

- Troubleshooting The Divider Block SystemDocument3 pagesTroubleshooting The Divider Block SystemMarcus MorganNo ratings yet

- Group 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument8 pagesGroup 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddydioneslealNo ratings yet

- Group 4 Tests and AdjustmentsDocument6 pagesGroup 4 Tests and AdjustmentsTaha RdmanNo ratings yet

- CAV Pintaux Injection Nozzle RebuildDocument6 pagesCAV Pintaux Injection Nozzle RebuildDanny DanNo ratings yet

- Group 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument8 pagesGroup 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyREMZONANo ratings yet

- Pompa Pneumatica LOCOPUMPDocument10 pagesPompa Pneumatica LOCOPUMPAngelica DragulescuNo ratings yet

- Chiller Testing Procedure Rev 1Document15 pagesChiller Testing Procedure Rev 1Ali AimranNo ratings yet

- 6.37 Combi Bop ManualDocument23 pages6.37 Combi Bop ManualDEATH ASSASSIN GAMERNo ratings yet

- Beamex PGL Manual ENGDocument16 pagesBeamex PGL Manual ENGbiotech666No ratings yet

- Bladder Accummulators InspectionsDocument7 pagesBladder Accummulators InspectionsJamin S. PanderajaNo ratings yet

- Procedure Manual: Ball Valve Hydro TestDocument5 pagesProcedure Manual: Ball Valve Hydro Testnima_h10No ratings yet

- Installation of A Solid Shaft DriverDocument11 pagesInstallation of A Solid Shaft Driverrizal_mufidNo ratings yet

- Cessna®: Service/Parts ManualDocument7 pagesCessna®: Service/Parts ManualFranco PugaNo ratings yet

- TrevitestingDocument23 pagesTrevitestingworkedoutagainNo ratings yet

- Sur - Flo Turbine MeterDocument40 pagesSur - Flo Turbine MeterCheng HuangNo ratings yet

- Appendix C: Test and Test Solutions: 051-62G1-C02 Set Up A 150-TPH Crusher Plant Evaluation (TE1)Document7 pagesAppendix C: Test and Test Solutions: 051-62G1-C02 Set Up A 150-TPH Crusher Plant Evaluation (TE1)Lo Shun FatNo ratings yet

- Group 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument7 pagesGroup 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyREMZONA0% (1)

- Group 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument16 pagesGroup 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyPriscila RodriguesNo ratings yet

- Accumulator and Bop Test ProceduresDocument7 pagesAccumulator and Bop Test Proceduresyefersson morales lopezNo ratings yet

- DHDA Pump Operating InstructionsDocument5 pagesDHDA Pump Operating InstructionsAbd.Buhari Abd.GalimNo ratings yet

- Single Line Installation and System Startup/trouble Shooting Bulletin SL-300Document4 pagesSingle Line Installation and System Startup/trouble Shooting Bulletin SL-300Torres Toledo JttNo ratings yet

- Diaphragm & Bladder Expansion Tank Installation ProceduresDocument2 pagesDiaphragm & Bladder Expansion Tank Installation ProceduresronnienatividadNo ratings yet

- Liquid Ring Vacuum Pumps Intial Start Up ProceduresDocument3 pagesLiquid Ring Vacuum Pumps Intial Start Up ProceduresFA Ay100% (3)

- Fuel Valve: See Chapter 900-1Document14 pagesFuel Valve: See Chapter 900-1Subramoniam MarineNo ratings yet

- PistonDocument5 pagesPistonAna Paula Maia LimaNo ratings yet

- Choke Maintnance PDFDocument42 pagesChoke Maintnance PDFbtrasla9023No ratings yet

- Hydro Test ProceduresDocument10 pagesHydro Test Proceduresazimr157100% (2)

- JLA Safety Valve Test BenchDocument4 pagesJLA Safety Valve Test Benchjromero_rpgNo ratings yet

- Installation and MaintenanceDocument4 pagesInstallation and MaintenanceHugoh Kansirgi DavidNo ratings yet

- Maintenance Working Hours Flow For Gas TurbineDocument7 pagesMaintenance Working Hours Flow For Gas TurbineHilmi HanoinNo ratings yet

- AIB - GVS - 20 Bomba de VacioDocument11 pagesAIB - GVS - 20 Bomba de VacioRico GonzalezNo ratings yet

- Autoclave Harvey 5000Document16 pagesAutoclave Harvey 5000Cesar Alfonso Saldivar MontoyaNo ratings yet

- Maintenance and Repair of Fuel Suppply, Lubrication and Cooling System Fuel Pump TestingDocument12 pagesMaintenance and Repair of Fuel Suppply, Lubrication and Cooling System Fuel Pump TestingAdarsh AnilNo ratings yet

- Gate Valve Installation Operation & Maintenance ManualDocument5 pagesGate Valve Installation Operation & Maintenance ManualViba Fluid ControlNo ratings yet

- WaterWorker Vertical Well Tank Installation ManualDocument12 pagesWaterWorker Vertical Well Tank Installation ManualS100% (1)

- Bristol CompresoresDocument31 pagesBristol CompresoresBairon jaramilloNo ratings yet

- Group 3 Tests and AdjustmentsDocument7 pagesGroup 3 Tests and Adjustmentsmãi bên emNo ratings yet

- Valvework Usa. Model M MSGDocument7 pagesValvework Usa. Model M MSGLuis Enrique RicoNo ratings yet

- CAD Operation-BasicDocument27 pagesCAD Operation-Basicnds2006sNo ratings yet

- Olaer Charging KitDocument4 pagesOlaer Charging KitA.m. Senthil KumarNo ratings yet

- Vacuum Test Procedure PDFDocument2 pagesVacuum Test Procedure PDFDanilo de JurasNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Intermittent Gas Lift Is An Artificial Lift Technique That Has BeenDocument4 pagesIntermittent Gas Lift Is An Artificial Lift Technique That Has Beenankit71989No ratings yet

- Flow Coefficient Test ProcedureDocument2 pagesFlow Coefficient Test Procedureankit71989No ratings yet

- 3.10 Temperature Taps 3.10.1 General: As-Lift Valve Probe TestDocument1 page3.10 Temperature Taps 3.10.1 General: As-Lift Valve Probe Testankit71989No ratings yet

- Surface Imperfection Type Result RemarksDocument3 pagesSurface Imperfection Type Result Remarksankit71989No ratings yet

- Well Physical ParameterDocument1 pageWell Physical Parameterankit71989No ratings yet

- Plug Valve ManualDocument1 pagePlug Valve Manualankit71989100% (1)

- Project Conception and Appraisal - Lect IIIDocument27 pagesProject Conception and Appraisal - Lect IIIankit71989No ratings yet

- Project TimeDocument1 pageProject Timeankit71989No ratings yet

- Project ResourcesDocument26 pagesProject Resourcesankit71989No ratings yet

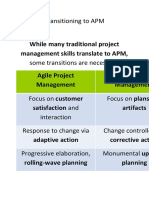

- Transitioning To APM: While Many Traditional Project Management Skills Translate To APMDocument2 pagesTransitioning To APM: While Many Traditional Project Management Skills Translate To APMankit71989No ratings yet

- Shortening Project DurationDocument1 pageShortening Project Durationankit71989No ratings yet

- Reliability: Performing Its Intended Function For A Stated Period of Time Under Certain SpecifiedDocument12 pagesReliability: Performing Its Intended Function For A Stated Period of Time Under Certain Specifiedankit71989No ratings yet

- PERT Time EstimatesDocument1 pagePERT Time Estimatesankit71989No ratings yet

- Mutually Exclusive EventsDocument1 pageMutually Exclusive Eventsankit71989No ratings yet

- Inferential StatsDocument2 pagesInferential Statsankit71989No ratings yet

Testing: Why Valve Adjustment

Testing: Why Valve Adjustment

Uploaded by

ankit71989Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Testing: Why Valve Adjustment

Testing: Why Valve Adjustment

Uploaded by

ankit71989Copyright:

Available Formats

TESTING

Refer API 6A latest edition for testing procedures. Prior to pressure testing, valves

adjustment is to be carried out.

Valve adjustment method

a. Close the plug and apply hydrostatic pressure less than equal to 50% of the full

working pressure.

b. Bleed off the pressure by opening the plug.

c. Tighten the adjusting nut to the correct torque (Typically the adjusting nut will tighten

at least another 90 degrees).

d. Repeat the procedure for the other side to complete valve adjustments,

Valve adjustments require that plug must be settled into the inserts by differential

pressure. The differential hydrostatic pressure forces are many times greater than the

force applied by the adjusting nut alone.

WHY VALVE ADJUSTMENT

a. To remove excess grease from the space between plug and inserts.

b. For reliable valve performance.

What may happen if valve is not adjusted:-

In case the valve is not adjusted, the fit between plug and inserts will be loosened after the

first seat test. This results in unreliable seal energizing for further testing.

STORAGE

a. Draining after testing: - all equipments should be drained and lubricated after testing

and prior to storage.

b. All components and assemblies should be cleaned of dirt, oil, metal particles and

other contaminants.

You might also like

- Chevrolet 327 V8 Engine Rebuild ManualDocument120 pagesChevrolet 327 V8 Engine Rebuild ManualAlissa Davis0% (1)

- Buxton-IOM TEST PUMP S10G-M THRU S30G-M TestUnits IOM rvB1 2Document16 pagesBuxton-IOM TEST PUMP S10G-M THRU S30G-M TestUnits IOM rvB1 2Wayne100% (2)

- Wom ValvesDocument11 pagesWom ValvesRio IndokniveziaNo ratings yet

- Plunger Pump ManualDocument23 pagesPlunger Pump Manualgovindharajalu75% (4)

- API Plan 53-Accumulator Bladder ChargingDocument11 pagesAPI Plan 53-Accumulator Bladder Chargingsumantabal_uceNo ratings yet

- Weber ManualDocument28 pagesWeber ManualMedardo SilvaNo ratings yet

- Operation 1Document9 pagesOperation 1Wbamlak AshebrNo ratings yet

- Group 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument7 pagesGroup 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyPriscila RodriguesNo ratings yet

- Assignment 5Document7 pagesAssignment 5Sharizada KanapiyevaNo ratings yet

- QFC Valve ManualDocument27 pagesQFC Valve ManualLeandro100% (1)

- Precharge Kit 5000PSI PDFDocument2 pagesPrecharge Kit 5000PSI PDFmetal_dung2No ratings yet

- Bop - Inspection and TestingDocument53 pagesBop - Inspection and TestingAustin AsuquoNo ratings yet

- Air Operated Hydraulic Presses Instuction and Parts List For Models 6-225 6-425 6-250 6-450 6-275 6-475 6-650 6-850Document11 pagesAir Operated Hydraulic Presses Instuction and Parts List For Models 6-225 6-425 6-250 6-450 6-275 6-475 6-650 6-850grantNo ratings yet

- LwsDocument36 pagesLwscrni rokoNo ratings yet

- Troubleshooting The Divider Block SystemDocument3 pagesTroubleshooting The Divider Block SystemMarcus MorganNo ratings yet

- Group 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument8 pagesGroup 3 Tests and Adjustments: 1 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddydioneslealNo ratings yet

- Group 4 Tests and AdjustmentsDocument6 pagesGroup 4 Tests and AdjustmentsTaha RdmanNo ratings yet

- CAV Pintaux Injection Nozzle RebuildDocument6 pagesCAV Pintaux Injection Nozzle RebuildDanny DanNo ratings yet

- Group 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument8 pagesGroup 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyREMZONANo ratings yet

- Pompa Pneumatica LOCOPUMPDocument10 pagesPompa Pneumatica LOCOPUMPAngelica DragulescuNo ratings yet

- Chiller Testing Procedure Rev 1Document15 pagesChiller Testing Procedure Rev 1Ali AimranNo ratings yet

- 6.37 Combi Bop ManualDocument23 pages6.37 Combi Bop ManualDEATH ASSASSIN GAMERNo ratings yet

- Beamex PGL Manual ENGDocument16 pagesBeamex PGL Manual ENGbiotech666No ratings yet

- Bladder Accummulators InspectionsDocument7 pagesBladder Accummulators InspectionsJamin S. PanderajaNo ratings yet

- Procedure Manual: Ball Valve Hydro TestDocument5 pagesProcedure Manual: Ball Valve Hydro Testnima_h10No ratings yet

- Installation of A Solid Shaft DriverDocument11 pagesInstallation of A Solid Shaft Driverrizal_mufidNo ratings yet

- Cessna®: Service/Parts ManualDocument7 pagesCessna®: Service/Parts ManualFranco PugaNo ratings yet

- TrevitestingDocument23 pagesTrevitestingworkedoutagainNo ratings yet

- Sur - Flo Turbine MeterDocument40 pagesSur - Flo Turbine MeterCheng HuangNo ratings yet

- Appendix C: Test and Test Solutions: 051-62G1-C02 Set Up A 150-TPH Crusher Plant Evaluation (TE1)Document7 pagesAppendix C: Test and Test Solutions: 051-62G1-C02 Set Up A 150-TPH Crusher Plant Evaluation (TE1)Lo Shun FatNo ratings yet

- Group 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument7 pagesGroup 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyREMZONA0% (1)

- Group 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument16 pagesGroup 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyPriscila RodriguesNo ratings yet

- Accumulator and Bop Test ProceduresDocument7 pagesAccumulator and Bop Test Proceduresyefersson morales lopezNo ratings yet

- DHDA Pump Operating InstructionsDocument5 pagesDHDA Pump Operating InstructionsAbd.Buhari Abd.GalimNo ratings yet

- Single Line Installation and System Startup/trouble Shooting Bulletin SL-300Document4 pagesSingle Line Installation and System Startup/trouble Shooting Bulletin SL-300Torres Toledo JttNo ratings yet

- Diaphragm & Bladder Expansion Tank Installation ProceduresDocument2 pagesDiaphragm & Bladder Expansion Tank Installation ProceduresronnienatividadNo ratings yet

- Liquid Ring Vacuum Pumps Intial Start Up ProceduresDocument3 pagesLiquid Ring Vacuum Pumps Intial Start Up ProceduresFA Ay100% (3)

- Fuel Valve: See Chapter 900-1Document14 pagesFuel Valve: See Chapter 900-1Subramoniam MarineNo ratings yet

- PistonDocument5 pagesPistonAna Paula Maia LimaNo ratings yet

- Choke Maintnance PDFDocument42 pagesChoke Maintnance PDFbtrasla9023No ratings yet

- Hydro Test ProceduresDocument10 pagesHydro Test Proceduresazimr157100% (2)

- JLA Safety Valve Test BenchDocument4 pagesJLA Safety Valve Test Benchjromero_rpgNo ratings yet

- Installation and MaintenanceDocument4 pagesInstallation and MaintenanceHugoh Kansirgi DavidNo ratings yet

- Maintenance Working Hours Flow For Gas TurbineDocument7 pagesMaintenance Working Hours Flow For Gas TurbineHilmi HanoinNo ratings yet

- AIB - GVS - 20 Bomba de VacioDocument11 pagesAIB - GVS - 20 Bomba de VacioRico GonzalezNo ratings yet

- Autoclave Harvey 5000Document16 pagesAutoclave Harvey 5000Cesar Alfonso Saldivar MontoyaNo ratings yet

- Maintenance and Repair of Fuel Suppply, Lubrication and Cooling System Fuel Pump TestingDocument12 pagesMaintenance and Repair of Fuel Suppply, Lubrication and Cooling System Fuel Pump TestingAdarsh AnilNo ratings yet

- Gate Valve Installation Operation & Maintenance ManualDocument5 pagesGate Valve Installation Operation & Maintenance ManualViba Fluid ControlNo ratings yet

- WaterWorker Vertical Well Tank Installation ManualDocument12 pagesWaterWorker Vertical Well Tank Installation ManualS100% (1)

- Bristol CompresoresDocument31 pagesBristol CompresoresBairon jaramilloNo ratings yet

- Group 3 Tests and AdjustmentsDocument7 pagesGroup 3 Tests and Adjustmentsmãi bên emNo ratings yet

- Valvework Usa. Model M MSGDocument7 pagesValvework Usa. Model M MSGLuis Enrique RicoNo ratings yet

- CAD Operation-BasicDocument27 pagesCAD Operation-Basicnds2006sNo ratings yet

- Olaer Charging KitDocument4 pagesOlaer Charging KitA.m. Senthil KumarNo ratings yet

- Vacuum Test Procedure PDFDocument2 pagesVacuum Test Procedure PDFDanilo de JurasNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Intermittent Gas Lift Is An Artificial Lift Technique That Has BeenDocument4 pagesIntermittent Gas Lift Is An Artificial Lift Technique That Has Beenankit71989No ratings yet

- Flow Coefficient Test ProcedureDocument2 pagesFlow Coefficient Test Procedureankit71989No ratings yet

- 3.10 Temperature Taps 3.10.1 General: As-Lift Valve Probe TestDocument1 page3.10 Temperature Taps 3.10.1 General: As-Lift Valve Probe Testankit71989No ratings yet

- Surface Imperfection Type Result RemarksDocument3 pagesSurface Imperfection Type Result Remarksankit71989No ratings yet

- Well Physical ParameterDocument1 pageWell Physical Parameterankit71989No ratings yet

- Plug Valve ManualDocument1 pagePlug Valve Manualankit71989100% (1)

- Project Conception and Appraisal - Lect IIIDocument27 pagesProject Conception and Appraisal - Lect IIIankit71989No ratings yet

- Project TimeDocument1 pageProject Timeankit71989No ratings yet

- Project ResourcesDocument26 pagesProject Resourcesankit71989No ratings yet

- Transitioning To APM: While Many Traditional Project Management Skills Translate To APMDocument2 pagesTransitioning To APM: While Many Traditional Project Management Skills Translate To APMankit71989No ratings yet

- Shortening Project DurationDocument1 pageShortening Project Durationankit71989No ratings yet

- Reliability: Performing Its Intended Function For A Stated Period of Time Under Certain SpecifiedDocument12 pagesReliability: Performing Its Intended Function For A Stated Period of Time Under Certain Specifiedankit71989No ratings yet

- PERT Time EstimatesDocument1 pagePERT Time Estimatesankit71989No ratings yet

- Mutually Exclusive EventsDocument1 pageMutually Exclusive Eventsankit71989No ratings yet

- Inferential StatsDocument2 pagesInferential Statsankit71989No ratings yet