Professional Documents

Culture Documents

Sikarep Microcrete-3 Uw: Antiwashout, Non-Shrink, High Strength Cementitious Micro Concrete For Underwater Repairs

Sikarep Microcrete-3 Uw: Antiwashout, Non-Shrink, High Strength Cementitious Micro Concrete For Underwater Repairs

Uploaded by

Arpan SahaCopyright:

Available Formats

You might also like

- AESTIVA - Service ManualDocument144 pagesAESTIVA - Service ManualVinicius Belchior da Silva100% (4)

- PublicationDocument161 pagesPublicationmbNo ratings yet

- Sikagrout - 228Document3 pagesSikagrout - 228Anonymous T7zEN6iLHNo ratings yet

- Sikagrout - 214 11hsDocument3 pagesSikagrout - 214 11hsBao PhanNo ratings yet

- Sikagrout - 220Document3 pagesSikagrout - 220Rukmana's FamilyNo ratings yet

- Sikarep Microcrete-4: Ready To Use Non-Shrink, Cementitious Micro ConcreteDocument3 pagesSikarep Microcrete-4: Ready To Use Non-Shrink, Cementitious Micro ConcretePankaj KapilNo ratings yet

- sikagrout_-228 (1)Document3 pagessikagrout_-228 (1)jinghuilimNo ratings yet

- Sikagrout - 220Document3 pagesSikagrout - 220wan arifNo ratings yet

- Shrinkage Compensated Cementitious GroutDocument3 pagesShrinkage Compensated Cementitious GroutPramod SinghNo ratings yet

- Sikagrout Deep PourDocument3 pagesSikagrout Deep PourLuis Andrade InsúaNo ratings yet

- Sika Microcrete-217 PDFDocument3 pagesSika Microcrete-217 PDFGianni MenaNo ratings yet

- Sikagrout - 215: Pumpable Shrinkage Compensated Cementitious GroutDocument2 pagesSikagrout - 215: Pumpable Shrinkage Compensated Cementitious GroutKent BasigaNo ratings yet

- Adhesive PDFDocument3 pagesAdhesive PDFsatish chandraNo ratings yet

- Sikagrout - 328Document3 pagesSikagrout - 328Javier TapiaNo ratings yet

- PDS SikaGrout-215P PDFDocument3 pagesPDS SikaGrout-215P PDFDeny PutraNo ratings yet

- Sikagrout 215 M Pds enDocument3 pagesSikagrout 215 M Pds enfikryh_2No ratings yet

- Sikagrout® - 295Document3 pagesSikagrout® - 295Ayman ZakariaNo ratings yet

- Sika® Microcrete®-218: Product Data SheetDocument3 pagesSika® Microcrete®-218: Product Data SheetthowchinNo ratings yet

- Sika PDS E SikaGrout - 214-11Document3 pagesSika PDS E SikaGrout - 214-11khun_kae100% (1)

- Sikagrout - 214: Cementitious, High Early Strength, Non-Shrink, Precision GroutDocument3 pagesSikagrout - 214: Cementitious, High Early Strength, Non-Shrink, Precision Grout7d5b3373No ratings yet

- Sikagrout - 200 PT: Product Data SheetDocument3 pagesSikagrout - 200 PT: Product Data SheetFrancis Hiro LedunaNo ratings yet

- Sikarep® Microcrete-4: Product Data SheetDocument2 pagesSikarep® Microcrete-4: Product Data Sheetsidharthsud28No ratings yet

- Sika GroutDocument3 pagesSika Groutchong pak limNo ratings yet

- PDS Sikacrete 113 PPDocument4 pagesPDS Sikacrete 113 PPKoh HanNo ratings yet

- SdadsadasDocument3 pagesSdadsadasTwink Arcane 9No ratings yet

- Sikagrout -3200 ZaDocument4 pagesSikagrout -3200 ZaKidist AlemayehuNo ratings yet

- TDS Consol Grout 600 MFDocument2 pagesTDS Consol Grout 600 MFPEP GUDANGNo ratings yet

- 2 - Sikacrete-113 PP SA - PDS - GCC - (01-2018) - 1 - 1Document3 pages2 - Sikacrete-113 PP SA - PDS - GCC - (01-2018) - 1 - 1Marimuthu Vijayan100% (2)

- Sikagrout - 214 11Document3 pagesSikagrout - 214 11Thắng HoàngNo ratings yet

- Sikarep Microcrete-4Document4 pagesSikarep Microcrete-4indrajeet4911No ratings yet

- SikaGrout-220 2011-11 - 1 PDFDocument4 pagesSikaGrout-220 2011-11 - 1 PDFRajiv SingalNo ratings yet

- Sikacrete®-114 PP: Product Data SheetDocument3 pagesSikacrete®-114 PP: Product Data Sheetmm mmNo ratings yet

- Sikagrout 214 11 Pds enDocument3 pagesSikagrout 214 11 Pds ensalma karimahNo ratings yet

- Sika PDS - E - SikaGrout - 214-11Document3 pagesSika PDS - E - SikaGrout - 214-11Dipak BorsaikiaNo ratings yet

- Sikafloor - 3 Quartztop: Coloured Mineral Dry Shake Floor HardenerDocument5 pagesSikafloor - 3 Quartztop: Coloured Mineral Dry Shake Floor Hardenermusiomi2005No ratings yet

- Sika Monotop RDocument3 pagesSika Monotop Rtengok69No ratings yet

- Sikagrout 215 New - Pds en PDFDocument3 pagesSikagrout 215 New - Pds en PDFDeny Anarista SitorusNo ratings yet

- SikaSwell S 2 PDSDocument3 pagesSikaSwell S 2 PDSJohnnyNo ratings yet

- Sikagrout® 215 (New) : Product Data SheetDocument3 pagesSikagrout® 215 (New) : Product Data SheetWan Fikri DarmawanNo ratings yet

- Sikagrout FM - Pds en PDFDocument3 pagesSikagrout FM - Pds en PDFANDI SETIAWANNo ratings yet

- DR - Fixit Pidigrout 10 MDocument3 pagesDR - Fixit Pidigrout 10 MBijaya RaulaNo ratings yet

- Sikagrout - 114Document3 pagesSikagrout - 114YASHICA VAITTIANATHANNo ratings yet

- Sikagrout FMDocument2 pagesSikagrout FMKasyie AbrahamNo ratings yet

- Sikagrout 215 M - Pds en PDFDocument3 pagesSikagrout 215 M - Pds en PDFPrabowo SandiNo ratings yet

- Sikagrout 215 M Pds enDocument3 pagesSikagrout 215 M Pds enAdiprabowo WicaksonoNo ratings yet

- Sikagrout®-215 (New) : Product Data SheetDocument3 pagesSikagrout®-215 (New) : Product Data SheetWahyu MahaendraNo ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 NewPeralatan Divisi3No ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 NewAlex Tri WijayantoNo ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 Newmanuel rgNo ratings yet

- Sikadur®-53: Product Data SheetDocument3 pagesSikadur®-53: Product Data Sheetjet toledoNo ratings yet

- Sikatop - 122: Fibre Reinforce, Polymer Modified Repair MortarDocument2 pagesSikatop - 122: Fibre Reinforce, Polymer Modified Repair MortarJoana Marie Perciano100% (1)

- Sikacrete Floor Level 2011-10-1Document3 pagesSikacrete Floor Level 2011-10-1Shaun WongNo ratings yet

- Sika Raintite: Liquid Membrane Waterproofing SystemDocument2 pagesSika Raintite: Liquid Membrane Waterproofing SystemMoatz HamedNo ratings yet

- Sikadour 212-11Document3 pagesSikadour 212-11saroat moongwattanaNo ratings yet

- SikaEmeriCreteTopping PdsDocument2 pagesSikaEmeriCreteTopping Pdsfvtolosa2022a11No ratings yet

- Sikacrete-114 SADocument46 pagesSikacrete-114 SAinfoNo ratings yet

- Gunite GP 459Document2 pagesGunite GP 459Syed RaziuddinNo ratings yet

- Sika PDS E SikaRep SDocument3 pagesSika PDS E SikaRep Slwin_oo2435No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Intake Structure For Water Supply: Mathanakeerthi S Assistant Professor Civil Engineering Sns College of EngineeringDocument17 pagesIntake Structure For Water Supply: Mathanakeerthi S Assistant Professor Civil Engineering Sns College of EngineeringArpan SahaNo ratings yet

- Well Foundation DesignDocument4 pagesWell Foundation DesignArpan SahaNo ratings yet

- Specification Report Construction of Intake Well, WTP & Clear Water Sump For Ramappa-Godavari (Mangapeta Segment) in Mangapeta Mandal in Mulugu Constituency of Warangal DistrictDocument29 pagesSpecification Report Construction of Intake Well, WTP & Clear Water Sump For Ramappa-Godavari (Mangapeta Segment) in Mangapeta Mandal in Mulugu Constituency of Warangal DistrictArpan SahaNo ratings yet

- Chapter - 1 Preamble, Water Source & Availability and Selection of Water Intake LocationDocument157 pagesChapter - 1 Preamble, Water Source & Availability and Selection of Water Intake LocationArpan SahaNo ratings yet

- Disclosure To Promote The Right To InformationDocument34 pagesDisclosure To Promote The Right To InformationArpan SahaNo ratings yet

- Beam SketchDocument3 pagesBeam SketchArpan SahaNo ratings yet

- Effect of Prying Action Forces On Design Method of Rigid Bolted Connections With Circular End PlateDocument17 pagesEffect of Prying Action Forces On Design Method of Rigid Bolted Connections With Circular End PlateArpan SahaNo ratings yet

- Design of Well Foundation - Design-of-Well-FoundationDocument6 pagesDesign of Well Foundation - Design-of-Well-FoundationArpan SahaNo ratings yet

- FDN - SketchDocument1 pageFDN - SketchArpan SahaNo ratings yet

- Typical Slab DesignDocument3 pagesTypical Slab DesignArpan SahaNo ratings yet

- Beam DesignDocument21 pagesBeam DesignArpan SahaNo ratings yet

- StandardDocument1 pageStandardArpan SahaNo ratings yet

- Slab Design:: Two Way Concrete Floor SystemDocument3 pagesSlab Design:: Two Way Concrete Floor SystemArpan SahaNo ratings yet

- Particular Specifications: 1.0 GeneralDocument68 pagesParticular Specifications: 1.0 GeneralArpan SahaNo ratings yet

- Biomems Devices For Drug Delivery: Improved Therapy by DesignDocument9 pagesBiomems Devices For Drug Delivery: Improved Therapy by DesignviviNo ratings yet

- GifDocument1 pageGifWeda MaharaniNo ratings yet

- Assignment 2 DR Azizul PDFDocument4 pagesAssignment 2 DR Azizul PDFjinNo ratings yet

- LipidsDocument22 pagesLipidsMary Grace CaasiNo ratings yet

- Recent Advances in Fragment Molecular Orbital-Based Molecular Dynamics (FMO-MD) SimulationsDocument23 pagesRecent Advances in Fragment Molecular Orbital-Based Molecular Dynamics (FMO-MD) SimulationsRudolf KiraljNo ratings yet

- TrasarDocument22 pagesTrasarM Ahmed LatifNo ratings yet

- NEETriumph PHYSICAL CHEMISTRYDocument133 pagesNEETriumph PHYSICAL CHEMISTRYHiral Mayank ShahNo ratings yet

- MSDS Auramix 300 PDFDocument3 pagesMSDS Auramix 300 PDFkk mishra0% (1)

- Washing Machine: Owner'S ManualDocument76 pagesWashing Machine: Owner'S ManualJohn Jairo Salas SalasNo ratings yet

- Process Description1Document74 pagesProcess Description1mohsen ranjbarNo ratings yet

- Uses and Advantages of CementDocument3 pagesUses and Advantages of CementdominationanalyticsNo ratings yet

- Chapter 11 NotesDocument9 pagesChapter 11 NotesJohnnyMoyaNo ratings yet

- Lect-04-Classification of Igneous Rocks-Microgranites, Micro-Adamellites, and MicrogranodioritesDocument7 pagesLect-04-Classification of Igneous Rocks-Microgranites, Micro-Adamellites, and MicrogranodioritesWai Ateny WaiNo ratings yet

- A DEH PR-5652-001-GB MultiAirPremium BR R6!10!2017 150dpiDocument12 pagesA DEH PR-5652-001-GB MultiAirPremium BR R6!10!2017 150dpitrutleptNo ratings yet

- Kode Pada Pipa&Jenis Tes Pada PipaDocument20 pagesKode Pada Pipa&Jenis Tes Pada Pipadicki100% (1)

- Biology SylDocument50 pagesBiology SylHildegard KanjimiNo ratings yet

- 920-01-643 HWL EN 06.17 WebDocument2 pages920-01-643 HWL EN 06.17 WebMohsenNo ratings yet

- Sandeep NewDocument2 pagesSandeep Newvignesh kumarNo ratings yet

- Calcium Carbonate Ball Mill PDFDocument3 pagesCalcium Carbonate Ball Mill PDFAnonymous yy8In96j0rNo ratings yet

- Reservoir Souring: Reservoir Souring:: Is Prevention Better Than Cure?Document20 pagesReservoir Souring: Reservoir Souring:: Is Prevention Better Than Cure?greg100% (1)

- Provisional Bill: Multi Normal DischargeDocument3 pagesProvisional Bill: Multi Normal Dischargeparth dataNo ratings yet

- ISO - ISO - TC 34 - SC 11 - Animal and Vegetable Fats and OilsDocument10 pagesISO - ISO - TC 34 - SC 11 - Animal and Vegetable Fats and OilsZahid Mahmood0% (1)

- Basics of Micro IrrigationDocument16 pagesBasics of Micro IrrigationJames WilliamsNo ratings yet

- Emm Heat Treatment Process QuizDocument3 pagesEmm Heat Treatment Process QuizNarinder Kumar67% (6)

- Foamed Concrete: Potential Application in Thermal InsulationDocument6 pagesFoamed Concrete: Potential Application in Thermal InsulationJr Rameez RajaNo ratings yet

- 1116 Usp 32 Microbiological Evaluation of Clean Rooms and Other Controlled EnvironmentsDocument29 pages1116 Usp 32 Microbiological Evaluation of Clean Rooms and Other Controlled EnvironmentsMauricio Dimaté CamargoNo ratings yet

- HB 0934 002 1090331 HB QA Cador Pathogen Mini 1214 WWDocument40 pagesHB 0934 002 1090331 HB QA Cador Pathogen Mini 1214 WWcarlosNo ratings yet

- Corvine Chemicals & Pharmaceuticals LTD.: Training For The Production of SODIUM AZIDEDocument3 pagesCorvine Chemicals & Pharmaceuticals LTD.: Training For The Production of SODIUM AZIDENiraNo ratings yet

Sikarep Microcrete-3 Uw: Antiwashout, Non-Shrink, High Strength Cementitious Micro Concrete For Underwater Repairs

Sikarep Microcrete-3 Uw: Antiwashout, Non-Shrink, High Strength Cementitious Micro Concrete For Underwater Repairs

Uploaded by

Arpan SahaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sikarep Microcrete-3 Uw: Antiwashout, Non-Shrink, High Strength Cementitious Micro Concrete For Underwater Repairs

Sikarep Microcrete-3 Uw: Antiwashout, Non-Shrink, High Strength Cementitious Micro Concrete For Underwater Repairs

Uploaded by

Arpan SahaCopyright:

Available Formats

Product Data Sheet

Edition 01/01/2014

Identification no:

02 02 01 01 006 0 000000

®

SikaRep Microcrete-3 UW

SikaRep® Microcrete-3 UW

(Formerly known as SikaRep® Microcrete-3)

Antiwashout, non-shrink, high strength cementitious micro

concrete for underwater repairs

Construction

®

SikaRep Microcrete-3 UW is a factory design, pourable/ pumpable, non-shrink anti

Product wash repair concrete with selected cement, aggregate and other chemicals.

Recommended water only to be added at site.

Description

®

Uses SikaRep Microcrete-3 UW is mainly recommended for the repair of damaged

concrete structures for damp wet and submerged condition.

Bridge Columns

Pier

Pile caps

Quay Pillars

Retaining wall in splash zone / submerged condition

It is also recommended for grouting of large gaps.

®

For larger pockets of voids SikaRep Microcrete-3UW can be added with 8 mm

down aggregate in the ratio of 2:1

®

Characteristics / SikaRep Microcrete-3 UW has the following advantages :

Advantages Shrinkage compensation

Anti wash property

Low porosity

High bond strength

High early strength

Chloride free

Durability

Product Data

Form

Appearance / Colour Grey powder

Packaging 30 kg bag

Storage

Storage Conditions / 6 months from date of production if stored properly in undamaged and unopened,

Shelf-Life original sealed packaging, in dry conditions at temperatures between +5°C and

+40°C. Protect from moisture, direct sunlight and frost.

1 SikaRep® Microcrete -3 1/3

Technical Data

Bulk Density 1.30 kg/l at 27 ºC

pH Value 11 - 13.5 when mixed with water (ready to pour).

Mechanical / Physical

Properties

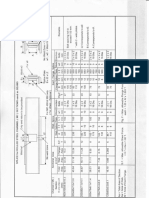

Compressive Strength Ambient temperature: +30°C (According to ASTM C 109* , 70mm Cube)

1 day 3 days 7 days 28 days

2 2 2 2

~20 N/mm ~35 N/mm ~45 N/mm ~55 N/mm

*Test were conducted stimulating site conditions by casting cubes under water

Flexural Strength Ambient temperature: +30°C (According to ASTM C 293-79)

7 days 28 days

2 2

~6.5 N/mm ~8 N/mm

2

Pullout bond strength ~6 N/mm at water: powder ratio 0.18 at 0.025mm slip at 28 days (Used 12mm

dia TMT bar) (According to IS:2770(Part-1)-1967)

Setting Time

Ambient temperature: +30°C (According to ASTM C 403)

Initial Setting Time (minutes) ~250

Final Setting Time (minutes) ~450

System

Information

Application Details

3

Consumption/Dosage 2200 kg/m

At water: powder ratio 0.19

Substrate Quality Substrate must be clean and sound. All loose material must be removed.

Substrate Preparation Substrates that are permanently immersed should be cleaned by suitable means.

Non-immersed or intermittently immersed substrates can also be prepared using

these techniques. Depending on the circumstances, scrabbling or bush hammering

®

may be appropriate. In view of the fluid nature of SikaRep Microcrete-3, all

shuttering must be leakproof. This can be achieved using foam rubber sealing strips

at the edges.

Application

Instructions

Mixing Water : Powder = 0.18 to 0.19 by weight (5.4 l to 5.7 l water per 30 kg

bag)dependent on the desired flow.

Mixing Time 5 minutes minimum

Mixing Tool Mix powder by mechanically powered mixer or drum type concrete mixer. Ensure

that the machine capacity and the number of operators are adequate to enable

grouting to be carried out as a continuous operation.

®

Put around 80 to 90% of required water in the mixing drum, followed by SikaRep

Microcrete-3 UW and then add the balance water.

Do not mix more material, which cannot be used within Pot Life. DO NOT ADD

EXTRA WATER.

2 SikaRep® Microcrete -3 UW 2/3

Application Method / The mixed material shall be placed within 20 minutes of mixing to gain full benefit of

Tools the expansion process. Continuous material flow is required and the material

shouldbe poured or pumped through a flexible tube, minimum diameter 50mm, to

the lowest point in the form. At the start of the operation, the material flow should be

restricted in order to avoid any water entrapment. The bottom of the tube may be

raised as necessary to reduce any back pressure but should not be raised above

the level of the material

®

SikaRep Microcrete-3 UW may be placed in thicknesses upto 80mm in one pour

when placed above water. When placed under water, the heat sink effect in this

environment permits thicknesses upto 150mm to be placed. For thicker sections

upto 200mm above water and 400mm under water, it is necessary to fill out

®

SikaRep Microcrete-3 UW underwater micro concrete using a clean, rounded and

well graded aggregate in the size range from 2mm upto 8mm. The quantity of

®

aggregate added should not exceed 1 part aggregate to 1 part SikaRep

Microcrete-3 UW by weight. For such mixes a concrete mixer must be used.

Unrestrained surface area should be kept to a minimum.

Curing Details Curing will not be required in intermittently or totally submerged situations.

However, when cast above water, all exposed surfaces should be thoroughly cured.

Construction

Cleaning of Tools Clean all tools and application equipment with water immediately after use.

Hardened / cured material can only be removed mechanically.

Notes on Application / Curing will not be required in intermittently or totally submerged situations.

Limitations However, when cast above water, all exposed surfaces should be thoroughly cured.

®

For additional technical information on SikaRep Microcrete-3 UW or other products

contact the technical services department.

Value Base All technical data stated in this Product Data Sheet are based on laboratory tests.

Actual measured data may vary due to circumstances beyond our control.

Health and Safety For information and advice on the safe handling, storage and disposal of chemical

products, users shall refer to the most recent Material Safety Data Sheet containing

Information physical, ecological, toxicological and other safety-related data.

Legal Notes The information, and, in particular, the recommendations relating to the application

and end-use of Sika products, are given in good faith based on Sika's current

knowledge and experience of the products when properly stored, handled and

applied under normal conditions in accordance with Sika’s recommendations. In

practice, the differences in materials, substrates and actual site conditions are such

that no warranty in respect of merchantability or of fitness for a particular purpose,

nor any liability arising out of any legal relationship whatsoever, can be inferred

either from this information, or from any written recommendations, or from any other

advice offered. The user of the product must test the product’s suitability for the

intended application and purpose. Sika reserves the right to change the properties

of its products. The proprietary rights of third parties must be observed. All orders

are accepted subject to our current terms of sale and delivery. Users must always

refer to the most recent issue of the local Product Data Sheet for the product

concerned, copies of which will be supplied on request.

Sika India Pvt. Ltd. Phone +91 33 2447 2448/2449

Commercial Complex II Telefax +91 33 2468 8688/2665

620, Diamond Harbour Road www. sika.in

Kolkata, 700 034, India info@in.sika.com

3 SikaRep® Microcrete -3 UW 3/3

You might also like

- AESTIVA - Service ManualDocument144 pagesAESTIVA - Service ManualVinicius Belchior da Silva100% (4)

- PublicationDocument161 pagesPublicationmbNo ratings yet

- Sikagrout - 228Document3 pagesSikagrout - 228Anonymous T7zEN6iLHNo ratings yet

- Sikagrout - 214 11hsDocument3 pagesSikagrout - 214 11hsBao PhanNo ratings yet

- Sikagrout - 220Document3 pagesSikagrout - 220Rukmana's FamilyNo ratings yet

- Sikarep Microcrete-4: Ready To Use Non-Shrink, Cementitious Micro ConcreteDocument3 pagesSikarep Microcrete-4: Ready To Use Non-Shrink, Cementitious Micro ConcretePankaj KapilNo ratings yet

- sikagrout_-228 (1)Document3 pagessikagrout_-228 (1)jinghuilimNo ratings yet

- Sikagrout - 220Document3 pagesSikagrout - 220wan arifNo ratings yet

- Shrinkage Compensated Cementitious GroutDocument3 pagesShrinkage Compensated Cementitious GroutPramod SinghNo ratings yet

- Sikagrout Deep PourDocument3 pagesSikagrout Deep PourLuis Andrade InsúaNo ratings yet

- Sika Microcrete-217 PDFDocument3 pagesSika Microcrete-217 PDFGianni MenaNo ratings yet

- Sikagrout - 215: Pumpable Shrinkage Compensated Cementitious GroutDocument2 pagesSikagrout - 215: Pumpable Shrinkage Compensated Cementitious GroutKent BasigaNo ratings yet

- Adhesive PDFDocument3 pagesAdhesive PDFsatish chandraNo ratings yet

- Sikagrout - 328Document3 pagesSikagrout - 328Javier TapiaNo ratings yet

- PDS SikaGrout-215P PDFDocument3 pagesPDS SikaGrout-215P PDFDeny PutraNo ratings yet

- Sikagrout 215 M Pds enDocument3 pagesSikagrout 215 M Pds enfikryh_2No ratings yet

- Sikagrout® - 295Document3 pagesSikagrout® - 295Ayman ZakariaNo ratings yet

- Sika® Microcrete®-218: Product Data SheetDocument3 pagesSika® Microcrete®-218: Product Data SheetthowchinNo ratings yet

- Sika PDS E SikaGrout - 214-11Document3 pagesSika PDS E SikaGrout - 214-11khun_kae100% (1)

- Sikagrout - 214: Cementitious, High Early Strength, Non-Shrink, Precision GroutDocument3 pagesSikagrout - 214: Cementitious, High Early Strength, Non-Shrink, Precision Grout7d5b3373No ratings yet

- Sikagrout - 200 PT: Product Data SheetDocument3 pagesSikagrout - 200 PT: Product Data SheetFrancis Hiro LedunaNo ratings yet

- Sikarep® Microcrete-4: Product Data SheetDocument2 pagesSikarep® Microcrete-4: Product Data Sheetsidharthsud28No ratings yet

- Sika GroutDocument3 pagesSika Groutchong pak limNo ratings yet

- PDS Sikacrete 113 PPDocument4 pagesPDS Sikacrete 113 PPKoh HanNo ratings yet

- SdadsadasDocument3 pagesSdadsadasTwink Arcane 9No ratings yet

- Sikagrout -3200 ZaDocument4 pagesSikagrout -3200 ZaKidist AlemayehuNo ratings yet

- TDS Consol Grout 600 MFDocument2 pagesTDS Consol Grout 600 MFPEP GUDANGNo ratings yet

- 2 - Sikacrete-113 PP SA - PDS - GCC - (01-2018) - 1 - 1Document3 pages2 - Sikacrete-113 PP SA - PDS - GCC - (01-2018) - 1 - 1Marimuthu Vijayan100% (2)

- Sikagrout - 214 11Document3 pagesSikagrout - 214 11Thắng HoàngNo ratings yet

- Sikarep Microcrete-4Document4 pagesSikarep Microcrete-4indrajeet4911No ratings yet

- SikaGrout-220 2011-11 - 1 PDFDocument4 pagesSikaGrout-220 2011-11 - 1 PDFRajiv SingalNo ratings yet

- Sikacrete®-114 PP: Product Data SheetDocument3 pagesSikacrete®-114 PP: Product Data Sheetmm mmNo ratings yet

- Sikagrout 214 11 Pds enDocument3 pagesSikagrout 214 11 Pds ensalma karimahNo ratings yet

- Sika PDS - E - SikaGrout - 214-11Document3 pagesSika PDS - E - SikaGrout - 214-11Dipak BorsaikiaNo ratings yet

- Sikafloor - 3 Quartztop: Coloured Mineral Dry Shake Floor HardenerDocument5 pagesSikafloor - 3 Quartztop: Coloured Mineral Dry Shake Floor Hardenermusiomi2005No ratings yet

- Sika Monotop RDocument3 pagesSika Monotop Rtengok69No ratings yet

- Sikagrout 215 New - Pds en PDFDocument3 pagesSikagrout 215 New - Pds en PDFDeny Anarista SitorusNo ratings yet

- SikaSwell S 2 PDSDocument3 pagesSikaSwell S 2 PDSJohnnyNo ratings yet

- Sikagrout® 215 (New) : Product Data SheetDocument3 pagesSikagrout® 215 (New) : Product Data SheetWan Fikri DarmawanNo ratings yet

- Sikagrout FM - Pds en PDFDocument3 pagesSikagrout FM - Pds en PDFANDI SETIAWANNo ratings yet

- DR - Fixit Pidigrout 10 MDocument3 pagesDR - Fixit Pidigrout 10 MBijaya RaulaNo ratings yet

- Sikagrout - 114Document3 pagesSikagrout - 114YASHICA VAITTIANATHANNo ratings yet

- Sikagrout FMDocument2 pagesSikagrout FMKasyie AbrahamNo ratings yet

- Sikagrout 215 M - Pds en PDFDocument3 pagesSikagrout 215 M - Pds en PDFPrabowo SandiNo ratings yet

- Sikagrout 215 M Pds enDocument3 pagesSikagrout 215 M Pds enAdiprabowo WicaksonoNo ratings yet

- Sikagrout®-215 (New) : Product Data SheetDocument3 pagesSikagrout®-215 (New) : Product Data SheetWahyu MahaendraNo ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 NewPeralatan Divisi3No ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 NewAlex Tri WijayantoNo ratings yet

- Sikagrout - 215 NewDocument3 pagesSikagrout - 215 Newmanuel rgNo ratings yet

- Sikadur®-53: Product Data SheetDocument3 pagesSikadur®-53: Product Data Sheetjet toledoNo ratings yet

- Sikatop - 122: Fibre Reinforce, Polymer Modified Repair MortarDocument2 pagesSikatop - 122: Fibre Reinforce, Polymer Modified Repair MortarJoana Marie Perciano100% (1)

- Sikacrete Floor Level 2011-10-1Document3 pagesSikacrete Floor Level 2011-10-1Shaun WongNo ratings yet

- Sika Raintite: Liquid Membrane Waterproofing SystemDocument2 pagesSika Raintite: Liquid Membrane Waterproofing SystemMoatz HamedNo ratings yet

- Sikadour 212-11Document3 pagesSikadour 212-11saroat moongwattanaNo ratings yet

- SikaEmeriCreteTopping PdsDocument2 pagesSikaEmeriCreteTopping Pdsfvtolosa2022a11No ratings yet

- Sikacrete-114 SADocument46 pagesSikacrete-114 SAinfoNo ratings yet

- Gunite GP 459Document2 pagesGunite GP 459Syed RaziuddinNo ratings yet

- Sika PDS E SikaRep SDocument3 pagesSika PDS E SikaRep Slwin_oo2435No ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Intake Structure For Water Supply: Mathanakeerthi S Assistant Professor Civil Engineering Sns College of EngineeringDocument17 pagesIntake Structure For Water Supply: Mathanakeerthi S Assistant Professor Civil Engineering Sns College of EngineeringArpan SahaNo ratings yet

- Well Foundation DesignDocument4 pagesWell Foundation DesignArpan SahaNo ratings yet

- Specification Report Construction of Intake Well, WTP & Clear Water Sump For Ramappa-Godavari (Mangapeta Segment) in Mangapeta Mandal in Mulugu Constituency of Warangal DistrictDocument29 pagesSpecification Report Construction of Intake Well, WTP & Clear Water Sump For Ramappa-Godavari (Mangapeta Segment) in Mangapeta Mandal in Mulugu Constituency of Warangal DistrictArpan SahaNo ratings yet

- Chapter - 1 Preamble, Water Source & Availability and Selection of Water Intake LocationDocument157 pagesChapter - 1 Preamble, Water Source & Availability and Selection of Water Intake LocationArpan SahaNo ratings yet

- Disclosure To Promote The Right To InformationDocument34 pagesDisclosure To Promote The Right To InformationArpan SahaNo ratings yet

- Beam SketchDocument3 pagesBeam SketchArpan SahaNo ratings yet

- Effect of Prying Action Forces On Design Method of Rigid Bolted Connections With Circular End PlateDocument17 pagesEffect of Prying Action Forces On Design Method of Rigid Bolted Connections With Circular End PlateArpan SahaNo ratings yet

- Design of Well Foundation - Design-of-Well-FoundationDocument6 pagesDesign of Well Foundation - Design-of-Well-FoundationArpan SahaNo ratings yet

- FDN - SketchDocument1 pageFDN - SketchArpan SahaNo ratings yet

- Typical Slab DesignDocument3 pagesTypical Slab DesignArpan SahaNo ratings yet

- Beam DesignDocument21 pagesBeam DesignArpan SahaNo ratings yet

- StandardDocument1 pageStandardArpan SahaNo ratings yet

- Slab Design:: Two Way Concrete Floor SystemDocument3 pagesSlab Design:: Two Way Concrete Floor SystemArpan SahaNo ratings yet

- Particular Specifications: 1.0 GeneralDocument68 pagesParticular Specifications: 1.0 GeneralArpan SahaNo ratings yet

- Biomems Devices For Drug Delivery: Improved Therapy by DesignDocument9 pagesBiomems Devices For Drug Delivery: Improved Therapy by DesignviviNo ratings yet

- GifDocument1 pageGifWeda MaharaniNo ratings yet

- Assignment 2 DR Azizul PDFDocument4 pagesAssignment 2 DR Azizul PDFjinNo ratings yet

- LipidsDocument22 pagesLipidsMary Grace CaasiNo ratings yet

- Recent Advances in Fragment Molecular Orbital-Based Molecular Dynamics (FMO-MD) SimulationsDocument23 pagesRecent Advances in Fragment Molecular Orbital-Based Molecular Dynamics (FMO-MD) SimulationsRudolf KiraljNo ratings yet

- TrasarDocument22 pagesTrasarM Ahmed LatifNo ratings yet

- NEETriumph PHYSICAL CHEMISTRYDocument133 pagesNEETriumph PHYSICAL CHEMISTRYHiral Mayank ShahNo ratings yet

- MSDS Auramix 300 PDFDocument3 pagesMSDS Auramix 300 PDFkk mishra0% (1)

- Washing Machine: Owner'S ManualDocument76 pagesWashing Machine: Owner'S ManualJohn Jairo Salas SalasNo ratings yet

- Process Description1Document74 pagesProcess Description1mohsen ranjbarNo ratings yet

- Uses and Advantages of CementDocument3 pagesUses and Advantages of CementdominationanalyticsNo ratings yet

- Chapter 11 NotesDocument9 pagesChapter 11 NotesJohnnyMoyaNo ratings yet

- Lect-04-Classification of Igneous Rocks-Microgranites, Micro-Adamellites, and MicrogranodioritesDocument7 pagesLect-04-Classification of Igneous Rocks-Microgranites, Micro-Adamellites, and MicrogranodioritesWai Ateny WaiNo ratings yet

- A DEH PR-5652-001-GB MultiAirPremium BR R6!10!2017 150dpiDocument12 pagesA DEH PR-5652-001-GB MultiAirPremium BR R6!10!2017 150dpitrutleptNo ratings yet

- Kode Pada Pipa&Jenis Tes Pada PipaDocument20 pagesKode Pada Pipa&Jenis Tes Pada Pipadicki100% (1)

- Biology SylDocument50 pagesBiology SylHildegard KanjimiNo ratings yet

- 920-01-643 HWL EN 06.17 WebDocument2 pages920-01-643 HWL EN 06.17 WebMohsenNo ratings yet

- Sandeep NewDocument2 pagesSandeep Newvignesh kumarNo ratings yet

- Calcium Carbonate Ball Mill PDFDocument3 pagesCalcium Carbonate Ball Mill PDFAnonymous yy8In96j0rNo ratings yet

- Reservoir Souring: Reservoir Souring:: Is Prevention Better Than Cure?Document20 pagesReservoir Souring: Reservoir Souring:: Is Prevention Better Than Cure?greg100% (1)

- Provisional Bill: Multi Normal DischargeDocument3 pagesProvisional Bill: Multi Normal Dischargeparth dataNo ratings yet

- ISO - ISO - TC 34 - SC 11 - Animal and Vegetable Fats and OilsDocument10 pagesISO - ISO - TC 34 - SC 11 - Animal and Vegetable Fats and OilsZahid Mahmood0% (1)

- Basics of Micro IrrigationDocument16 pagesBasics of Micro IrrigationJames WilliamsNo ratings yet

- Emm Heat Treatment Process QuizDocument3 pagesEmm Heat Treatment Process QuizNarinder Kumar67% (6)

- Foamed Concrete: Potential Application in Thermal InsulationDocument6 pagesFoamed Concrete: Potential Application in Thermal InsulationJr Rameez RajaNo ratings yet

- 1116 Usp 32 Microbiological Evaluation of Clean Rooms and Other Controlled EnvironmentsDocument29 pages1116 Usp 32 Microbiological Evaluation of Clean Rooms and Other Controlled EnvironmentsMauricio Dimaté CamargoNo ratings yet

- HB 0934 002 1090331 HB QA Cador Pathogen Mini 1214 WWDocument40 pagesHB 0934 002 1090331 HB QA Cador Pathogen Mini 1214 WWcarlosNo ratings yet

- Corvine Chemicals & Pharmaceuticals LTD.: Training For The Production of SODIUM AZIDEDocument3 pagesCorvine Chemicals & Pharmaceuticals LTD.: Training For The Production of SODIUM AZIDENiraNo ratings yet