Professional Documents

Culture Documents

Software Verification: EXAMPLE IS 456-00 RC-PN-001

Software Verification: EXAMPLE IS 456-00 RC-PN-001

Uploaded by

renzo1221Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Software Verification: EXAMPLE IS 456-00 RC-PN-001

Software Verification: EXAMPLE IS 456-00 RC-PN-001

Uploaded by

renzo1221Copyright:

Available Formats

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

EXAMPLE IS 456-00 RC-PN-001

Slab Punching Shear Design

PROBLEM DESCRIPTION

The purpose of this example is to verify slab punching shear design in SAFE

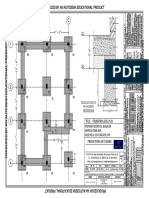

The numerical example is a flat slab that has three 8-m spans in each direction, as

shown in Figure 1.

0.3 m A B C D 0.3 m

8m 8m 8m

0.6 m

4

0.25 m thick flat slab

8m

3

Columns are 0.3 m x 0.9 m

with long side parallel

8m to the Y-axis, typical

2 Concrete Properties

Unit weight = 24 kN/m3

f'c = 30 N/mm2

8m

Y Loading

DL = Self weight + 1.0 kN/m 2

X LL = 4.0 kN/m2

1

0.6 m

Figure 1: Flat Slab for Numerical Example

The slab overhangs beyond the face of the column by 0.15 m along each side of

the structure. The columns are typically 0.3 m x 0.9 m with the long side parallel

to the Y-axis. The slab is typically 0.25 m thick. Thick plate properties are used

for the slab.

The concrete has a unit weight of 24 kN/m3 and a f 'c of 30 N/mm2. The dead load

consists of the self weight of the structure plus an additional 1 kN/m2. The live

load is 4 kN/m2.

EXAMPLE IS 456-00 RC-PN-001 - 1

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

TECHNICAL FEATURES OF SAFE TESTED

Calculation of punching shear capacity, shear stress and D/C ratio.

RESULTS COMPARISON

Table 1 shows the comparison of the punching shear capacity, shear stress ratio

and D/C ratio obtained in SAFE with the punching shear capacity, shear stress

ratio and D/C ratio obtained by the analytical method. They match exactly for

this problem.

Table 1 Comparison of Design Results for Punching

Shear at Grid B-2

Shear Stress Shear Capacity

Method (N/mm2) (N/mm2) D/C ratio

SAFE 1.792 1.141 1.57

Calculated 1.792 1.141 1.57

COMPUTER FILE: IS 456-00 RC-PN-001.FDB

CONCLUSION

The SAFE results show an exact comparison with the independent results.

EXAMPLE IS 456-00 RC-PN-001 - 2

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

HAND CALCULATION

Hand Calculation For Interior Column Using SAFE Method

d 250 26 250 38 2 = 218 mm

Refer to Figure 1.

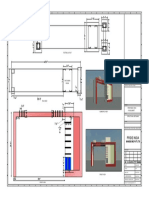

b0 = 518+ 1118 + 1118 + 518 = 3272 mm

518 Note: All dimensions in millimeters

Y

Critical section for

109 150 150 109 punching shear shown

dashed.

A B

Column Side 2

109

Side 1

Side 3

450

X

1118

Center of column is 450

point (x1, y1). Set

this equal to (0,0).

Side 4 109

D C

Figure 2: Interior Column, Grid B-2 in SAFE Model

V2 1

1

0.536

2 900

1

3 300

V3 1

1

0.278

2 300

1

3 900

The coordinates of the center of the column (x1, y1) are taken as (0, 0).

EXAMPLE IS 456-00 RC-PN-001 - 3

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

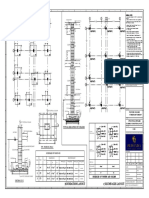

The following table is used for calculating the centroid of the critical section for punching

shear. Side 1, Side 2, Side 3, and Side 4 refer to the sides of the critical section for

punching shear as identified in Figure 2.

Item Side 1 Side 2 Side 3 Side 4 Sum

x2 259 0 259 0 N.A.

y2 0 559 0 559 N.A.

L 1118 518 1118 518 b0 = 3272

d 218 218 218 218 N.A.

Ld 243724 112924 243724 112924 713296

Ldx2 63124516 0 63124516 0 0

Ldy2 0 63124516 0 63124516 0

x3

Ldx 2

0

0 mm

Ld 713296

y3

Ldy 2

0

0 mm

Ld 713296

The following table is used to calculate IXX, IYY and IXY. The values for IXX, IYY and IXY

are given in the "Sum" column.

Item Side 1 Side 2 Side 3 Side 4 Sum

L 1118 518 1118 518 N.A.

d 218 218 218 218 N.A.

x2 x3 259 0 259 0 N.A.

y2 y3 0 559 0 559 N.A.

Parallel to Y-Axis X-axis Y-Axis X-axis N.A.

Equations 5b, 6b, 7 5a, 6a, 7 5b, 6b, 7 5a, 6a, 7 N.A.

IXX 2.64E+10 3.53E+10 2.64E+10 3.53E+10 1.23E+11

IYY 1.63E+10 2.97E+09 1.63E+10 2.97E+09 3.86E+10

IXY 0 0 0 0 0

From the SAFE output at Grid B-2:

VU = 1126.498 kN

V2 MU2 = 25.725 kN-m

V3 MU3 = 14.272 kN-m

EXAMPLE IS 456-00 RC-PN-001 - 4

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

At the point labeled A in Figure 2, x4 = 259 and y4 = 559, thus:

1126.498 103 25.725 10 3.86 10 559 0 0 259 0

6 10

vU

3272 218 1.23 1011 3.86 1010 0 2

14.272 106 1.23 1011 259 0 0 559 0

1.23 1011 3.86 1010 0 2

vU = 1.5793 0.1169 0.0958 = 1.3666 N/mm2 at point A

At the point labeled B in Figure 2, x4 = 259 and y4 = 559, thus:

1126.498 103 25.725 10 3.86 10 559 0 0 259 0

6 10

vU

3272 218 1.23 1011 3.86 1010 0 2

14.272 106 1.23 1011 259 0 0 559 0

1.23 1011 3.86 1010 0 2

vU = 1.5793 0.1169 + 0.0958 =1.5582 N/mm2 at point B

At the point labeled C in Figure 2, x4 = 259 and y4 = 559, thus:

1126.498 103 25.725 10 3.86 10 559 0 0 259 0

6 10

vU

3272 218 1.23 1011 3.86 1010 0 2

14.272 106 1.23 1011 259 0 0 559 0

1.23 1011 3.86 1010 0 2

vU = 1.5793 + 0.1169 + 0.0958 = 1.792 N/mm2 at point C

At the point labeled D in Figure 2, x4 = 259 and y4 = 559, thus:

1126.498 103 25.725 10 3.86 10 559 0 0 259 0

6 10

vU

3272 218 1.23 1011 3.86 1010 0 2

14.272 106 1.23 1011 259 0 0 559 0

1.23 1011 3.86 1010 0 2

vU = 1.5793 + 0.1169 0.0958 = 1.6004 N/mm2 at point D

Point C has the largest absolute value of vu, thus vmax = 1.792 N/mm2

EXAMPLE IS 456-00 RC-PN-001 - 5

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 4

The shear capacity is calculated based on the minimum of the following three limits:

ks = 0.5 + c 1.0 = 0.833 (IS 31.6.3.1)

c = 0.25 = 1.127 N/mm 2

(IS 31.6.3.1)

vc = ks c= 1.141 N/mm2 (IS 31.6.3.1)

CSA 13.3.4.1 yields the smallest value of vc = 1.141 N/mm2, and thus this is the shear

capacity.

vU 1.792

Shear Ratio 1.57

vc 1.141

EXAMPLE IS 456-00 RC-PN-001 - 6

You might also like

- Post-Tensioned Slab Design ExampleDocument9 pagesPost-Tensioned Slab Design ExampleLaura ManolacheNo ratings yet

- Anchor Bolt DesignDocument2 pagesAnchor Bolt Designmassive85No ratings yet

- Design of Two Way Slab - ACI Coefficient Method Using Mathcad PrimeDocument3 pagesDesign of Two Way Slab - ACI Coefficient Method Using Mathcad PrimeYan YanNo ratings yet

- CSA A23.3 DeflectionsDocument11 pagesCSA A23.3 Deflections700spymaster007No ratings yet

- Corbel Design - ACI 318 PDFDocument2 pagesCorbel Design - ACI 318 PDFnishchint100% (12)

- Base Plate BiaxilDocument26 pagesBase Plate BiaxilvijaystructuralNo ratings yet

- "Shear-End-Pl-13" - Beam End Connection Using Shear End PlatesDocument16 pages"Shear-End-Pl-13" - Beam End Connection Using Shear End PlatesArdXkillerNo ratings yet

- Requirement of DrawingDocument1 pageRequirement of DrawingMohammed SumerNo ratings yet

- Epson 3800 3880 SMDocument306 pagesEpson 3800 3880 SMIon IonutNo ratings yet

- Reinforcing Bar Development and Splice Lengths ACI 318-11Document8 pagesReinforcing Bar Development and Splice Lengths ACI 318-11lucianduNo ratings yet

- Two Way Slab DesignDocument35 pagesTwo Way Slab DesignMarc Kalfat100% (1)

- RC Design Aci318m 19 v4.0Document43 pagesRC Design Aci318m 19 v4.0Mohammed HanafiNo ratings yet

- Design Slab On GradeDocument14 pagesDesign Slab On GradeKio ChopperNo ratings yet

- Design of Reinforced Concrete Shear WallDocument15 pagesDesign of Reinforced Concrete Shear WallAnonymous nwByj9L0% (1)

- ACI Section Crack Width ControlDocument6 pagesACI Section Crack Width ControlImaduddin KhajaNo ratings yet

- General Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Document14 pagesGeneral Input:-: Moment & Shear Strength Design of Rectangular RC According ACI318M-08Maharajan McsNo ratings yet

- ACI 318-14 RC Shear Wall Design - Short Walls PDFDocument9 pagesACI 318-14 RC Shear Wall Design - Short Walls PDFHuzil FernandezNo ratings yet

- ACI 318M-11 RC Beam Ledge Design - v0.01 - 2017-10-11Document12 pagesACI 318M-11 RC Beam Ledge Design - v0.01 - 2017-10-11taw1021966m100% (1)

- Plate Results and Design ForcesDocument10 pagesPlate Results and Design Forcesthirumalaichettiar100% (1)

- Footing Design Result-RcdcDocument360 pagesFooting Design Result-RcdcJoseph Cloyd L. LamberteNo ratings yet

- Punching Shear Check For Slabs - ACI 318-08Document4 pagesPunching Shear Check For Slabs - ACI 318-08sopnanairNo ratings yet

- Fence Calculation FinalDocument200 pagesFence Calculation FinalMohamed HassanNo ratings yet

- ACI-14 Beam Ledge Design v1.0Document6 pagesACI-14 Beam Ledge Design v1.0Raymund Dale P. BallenasNo ratings yet

- Corbel Design Spreadsheet To ACI318Document6 pagesCorbel Design Spreadsheet To ACI318LAU TONo ratings yet

- Slab DesignDocument10 pagesSlab DesignKeeperNo ratings yet

- POLEFDNDocument10 pagesPOLEFDNcklconNo ratings yet

- Shear Wall With Boundary ElementDocument4 pagesShear Wall With Boundary ElementArnel DodongNo ratings yet

- Precast Dowel ConnectionDocument1 pagePrecast Dowel ConnectionmathuNo ratings yet

- Masonry Wall Design at Horizontal Bending, Based On ACI 530-05 Input Data & Design SummaryDocument1 pageMasonry Wall Design at Horizontal Bending, Based On ACI 530-05 Input Data & Design Summaryazamislam726537No ratings yet

- Concrete Column Design Based On ACI 318-19: Input Data & Design SummaryDocument3 pagesConcrete Column Design Based On ACI 318-19: Input Data & Design Summaryجميل عبد الله الحماطيNo ratings yet

- Filled Composite ColumnDocument1 pageFilled Composite ColumnLloyd R. PonceNo ratings yet

- Development Length ACI 318-14 v2.0Document5 pagesDevelopment Length ACI 318-14 v2.0Raymund Dale P. BallenasNo ratings yet

- One Way SlabDocument7 pagesOne Way Slabsidiq7No ratings yet

- ACI 350-06 & ACI224R-01 Rec Sec Flexural Crack Width Control Rev00 07-Sep-2013Document7 pagesACI 350-06 & ACI224R-01 Rec Sec Flexural Crack Width Control Rev00 07-Sep-2013Muhammad Imran ZafarNo ratings yet

- Design of Anchor Reinforcement in Concrete Pedestals (ASCE - ACI 318-08)Document12 pagesDesign of Anchor Reinforcement in Concrete Pedestals (ASCE - ACI 318-08)Cesar Rojas100% (1)

- Corbel DesignDocument2 pagesCorbel Designsidiq7No ratings yet

- AISC Design Guide 1 Table 3.2 PDFDocument1 pageAISC Design Guide 1 Table 3.2 PDFamine ayari100% (1)

- Base Plate Anchor Bolt DesignDocument8 pagesBase Plate Anchor Bolt DesignnoneofyourbusineesNo ratings yet

- Flat SlabDocument69 pagesFlat Slabmukhlesh100% (1)

- ACI Punching Shear Reinforcement DesignDocument6 pagesACI Punching Shear Reinforcement DesignRaymund Dale P. BallenasNo ratings yet

- Beam Anal FinalDocument144 pagesBeam Anal FinalFeigyl MiroNo ratings yet

- CFD Aci 318 14 - 1Document15 pagesCFD Aci 318 14 - 1tailieuxaydung2019100% (1)

- Development - Splice Lengths (ACI)Document4 pagesDevelopment - Splice Lengths (ACI)yasirjurabaNo ratings yet

- 4 Analysis and Design of Steel Deck - Concrete Composite SlabsDocument112 pages4 Analysis and Design of Steel Deck - Concrete Composite SlabsLê Ngọc-Hà100% (2)

- Design of Composite BeamDocument7 pagesDesign of Composite BeamMohammed SumerNo ratings yet

- Design of Steel ShedDocument164 pagesDesign of Steel ShedKilaru HareeshNo ratings yet

- Foundation-Base Fixed or Pin in Modelling of StructureDocument2 pagesFoundation-Base Fixed or Pin in Modelling of StructureThiha Kyaw100% (1)

- F1. SCT - SN-Steel Formwork Design - GTG BEAM FORMWORKDocument32 pagesF1. SCT - SN-Steel Formwork Design - GTG BEAM FORMWORKshihabNo ratings yet

- SAFE 200407 Presentation Allow Uplift AnalysisDocument7 pagesSAFE 200407 Presentation Allow Uplift AnalysisCSEC Uganda Ltd.No ratings yet

- Ecc Boundary Wall - (143004) Type 1 Rev1Document10 pagesEcc Boundary Wall - (143004) Type 1 Rev1mathuNo ratings yet

- ACI Design AidsDocument60 pagesACI Design AidsNabeel Sheikh100% (1)

- Basic Design Parameters:: Loads: 1Document5 pagesBasic Design Parameters:: Loads: 1Timo SchenkoNo ratings yet

- RC Design - ACIDocument41 pagesRC Design - ACIAbebe WoldeNo ratings yet

- Aci 318-14 RC-PN-001Document6 pagesAci 318-14 RC-PN-001Bunkun15No ratings yet

- ACI 318-14 RC-PN Example 001Document6 pagesACI 318-14 RC-PN Example 001Novin KamyabNo ratings yet

- Rebars Splice and Column RebarDocument11 pagesRebars Splice and Column RebarIrfan KhanNo ratings yet

- Software Verification: Example 10Document5 pagesSoftware Verification: Example 10Haytham ZaghloulNo ratings yet

- Reinforcing Bar Development and Splice Lengths Per ACI 318-05Document8 pagesReinforcing Bar Development and Splice Lengths Per ACI 318-05cengizNo ratings yet

- PAEC2016 - Rect. Beam Analysis Using ACI 318-14Document24 pagesPAEC2016 - Rect. Beam Analysis Using ACI 318-14Sayavi Nicole Sayavi NickNo ratings yet

- JLG X 430 - Arrivals SlabCalcs - GOODDocument29 pagesJLG X 430 - Arrivals SlabCalcs - GOODKailin JuNo ratings yet

- ACI-350 P-M Interaction 2.1Document17 pagesACI-350 P-M Interaction 2.1Franklyn P. GenoveNo ratings yet

- Rebars (318-05)Document2 pagesRebars (318-05)Yan Naung KoNo ratings yet

- Solid Slab Inspection ChecklistsDocument2 pagesSolid Slab Inspection ChecklistsMohammed SumerNo ratings yet

- A B C D E F G A': Ground FloorplanDocument1 pageA B C D E F G A': Ground FloorplanMohammed SumerNo ratings yet

- South - PPT - PPT HydDocument6 pagesSouth - PPT - PPT HydMohammed SumerNo ratings yet

- 2016-FL3030说明书50m臂长最后版-2016 11 3 PDFDocument96 pages2016-FL3030说明书50m臂长最后版-2016 11 3 PDFMohammed SumerNo ratings yet

- Jdivision Name: Find I NextDocument2 pagesJdivision Name: Find I NextMohammed SumerNo ratings yet

- Eng - Khalil&mr - Basem With Majid Hilal AgreementDocument7 pagesEng - Khalil&mr - Basem With Majid Hilal AgreementMohammed SumerNo ratings yet

- Yahoo Mail - Hello and Thank You From DAT!Document2 pagesYahoo Mail - Hello and Thank You From DAT!Mohammed SumerNo ratings yet

- Khalfan Final All (30.aug.2016) - Model - pdf5Document1 pageKhalfan Final All (30.aug.2016) - Model - pdf5Mohammed SumerNo ratings yet

- TABLE: Load Combinations Name Load Case/Combo Scale Factor Type AutoDocument27 pagesTABLE: Load Combinations Name Load Case/Combo Scale Factor Type AutoMohammed SumerNo ratings yet

- Khalfan Final All (30.aug.2016) - Model - pdf1Document1 pageKhalfan Final All (30.aug.2016) - Model - pdf1Mohammed SumerNo ratings yet

- Flat Slab Design To Bs8110-Part 1-1997Document23 pagesFlat Slab Design To Bs8110-Part 1-1997sskamalakannanNo ratings yet

- Design of Composite BeamDocument7 pagesDesign of Composite BeamMohammed SumerNo ratings yet

- Analysis of Stress-Strain and DeflectionDocument12 pagesAnalysis of Stress-Strain and DeflectionMohammed SumerNo ratings yet

- Johnson Lifts SpecsDocument4 pagesJohnson Lifts SpecsMohammed Sumer60% (5)

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductMohammed SumerNo ratings yet

- T8@7"C/C 4 T12: Schedule of FootingsDocument1 pageT8@7"C/C 4 T12: Schedule of FootingsMohammed SumerNo ratings yet

- Soil Test For Hospital BuildingDocument8 pagesSoil Test For Hospital BuildingMohammed SumerNo ratings yet

- Foundation Details For Boundary Wall Lake TownDocument1 pageFoundation Details For Boundary Wall Lake TownMohammed SumerNo ratings yet

- Entrance ArchDocument1 pageEntrance ArchMohammed SumerNo ratings yet

- Column & Footing LayoutDocument1 pageColumn & Footing LayoutMohammed SumerNo ratings yet

- Macro Chapter 7Document12 pagesMacro Chapter 7Mary Jane PelaezNo ratings yet

- CESCCommunityProjectPlan Brgy - MacarioDaconDocument6 pagesCESCCommunityProjectPlan Brgy - MacarioDaconKennedy BalmoriNo ratings yet

- Mouser TestsectionDocument33 pagesMouser TestsectionalltheloveintheworldNo ratings yet

- 130-87 InstructionsDocument7 pages130-87 InstructionsAlex GarciaNo ratings yet

- SR-36-01-01 HAZOP TOR Rehman Production FacilityDocument30 pagesSR-36-01-01 HAZOP TOR Rehman Production FacilityMuhammad.Saim100% (1)

- Kohima Nagaland LBDocument1 pageKohima Nagaland LBIndia TreadingNo ratings yet

- Sewing Skills Checklist PDFDocument44 pagesSewing Skills Checklist PDFyemkem100% (1)

- Structural and Literary DevicesDocument40 pagesStructural and Literary Devicesapi-237159930No ratings yet

- Carbohydrates Lecture Bio024Document17 pagesCarbohydrates Lecture Bio024mike angelo albacieteNo ratings yet

- English3 Q2 Mod2 TensesOfTheVerb V3Document33 pagesEnglish3 Q2 Mod2 TensesOfTheVerb V3Johanna Zandra MariaNo ratings yet

- (A) Design - Introduction To Transformer DesignDocument16 pages(A) Design - Introduction To Transformer DesignZineddine BENOUADAHNo ratings yet

- Module 1 What Is Geography and TourismDocument22 pagesModule 1 What Is Geography and TourismLeanne Abegail EstabilloNo ratings yet

- Business Presentation YAKULTDocument12 pagesBusiness Presentation YAKULTJosuaNo ratings yet

- Unit-6 Patterns of Industrialisation PDFDocument12 pagesUnit-6 Patterns of Industrialisation PDFNavdeep SinghNo ratings yet

- Uccx732X Dual 4-A Peak High-Speed Low-Side Power-Mosfet DriversDocument38 pagesUccx732X Dual 4-A Peak High-Speed Low-Side Power-Mosfet DriversTeles SilvaNo ratings yet

- Delhi Public School, Greater Noida Pre-Mid Term Exam Class X Mathematics SESSION 2020-21 Set 1 MM: 40 Time: 1.5 Hours InstructionsDocument3 pagesDelhi Public School, Greater Noida Pre-Mid Term Exam Class X Mathematics SESSION 2020-21 Set 1 MM: 40 Time: 1.5 Hours InstructionsAnishikaNo ratings yet

- Tax System SriLankaDocument44 pagesTax System SriLankamandarak7146No ratings yet

- AAB2000C1Document11 pagesAAB2000C1marcos morillo0% (1)

- Catalogo ColonneDocument140 pagesCatalogo Colonneapi-18378576No ratings yet

- A. Title of Experiment B. Date and Time of Experiment: Wednesday, 10Document15 pagesA. Title of Experiment B. Date and Time of Experiment: Wednesday, 10LichaNo ratings yet

- Electronics Cooling: Mechanical Power Engineering DeptDocument22 pagesElectronics Cooling: Mechanical Power Engineering DeptneilNo ratings yet

- Rotorcraft Aerodynamics: Muhammad Abdullah Tahir 180101034 Aero 17 (A)Document15 pagesRotorcraft Aerodynamics: Muhammad Abdullah Tahir 180101034 Aero 17 (A)Abdullah CheemaNo ratings yet

- CWAG Rectangular CoordinatesDocument52 pagesCWAG Rectangular CoordinatesRolando MerleNo ratings yet

- ManvantaraDocument3 pagesManvantaraafterragnarokNo ratings yet

- Pablocastillo PDFDocument44 pagesPablocastillo PDFPabloNo ratings yet

- Case 621F, 721F Tier 4 Wheel Loader AxelDocument15 pagesCase 621F, 721F Tier 4 Wheel Loader AxelJose CarmonaNo ratings yet

- Gds Manual Flo2d ProDocument182 pagesGds Manual Flo2d ProbycmNo ratings yet

- SSP 604 - Audi 30l v6 Tdi Biturbo Engine EngDocument23 pagesSSP 604 - Audi 30l v6 Tdi Biturbo Engine Engfrancois.garcia31100% (1)