Professional Documents

Culture Documents

Description and Application: 80%ar - 20%CO EN ISO 17632-A-T 42 4 M M 3 H5 AWS A5.18 E70C-6M

Description and Application: 80%ar - 20%CO EN ISO 17632-A-T 42 4 M M 3 H5 AWS A5.18 E70C-6M

Uploaded by

MaheshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Description and Application: 80%ar - 20%CO EN ISO 17632-A-T 42 4 M M 3 H5 AWS A5.18 E70C-6M

Description and Application: 80%ar - 20%CO EN ISO 17632-A-T 42 4 M M 3 H5 AWS A5.18 E70C-6M

Uploaded by

MaheshCopyright:

Available Formats

MX-A100

80%Ar - 20%CO2

EN ISO 17632-A-T 42 4 M M 3 H5

AWS A5.18 E70C-6M

Description and Application

MX-A100 has a high percentage of metal powders in its core which provide many advantages over solid wire, such as high

recovery together with high deposition rate. The deposition rate is often as much as 20% or more than that of solid wires, due to

superior weldability enabling the use of higher welding currents. This wire operates with a very stable smooth arc giving very little

spatter and deep penetration. Slag removal between runs is not necessary because this wire produces almost no silicate slag.

Thanks to its good arc re-striking characteristics combined with excellent wire feeding properties,

this wire is an ideal choice for robotic or other kinds of mechanized welding applications.

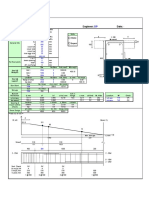

Recommended Parameter Range, for flat position

Volt WFS (m/min)

44 28 Wire stick-out

42 26 1.0 mmØ: 20mm

40 24

1.2 mmØ: 20mm

38 Ø 22

36 mm 20 1.4 mmØ: 20mm

1.6

34 18 1.6 mmØ: 25mm

32 16

mØ

Ø

30 14

m

m

m

28 1.4 12

0

1.

26 10

24 8

22 6

20 4

18 Ø 2

mm

1.2

50 100 150 200 250 300 350 400 450 Amp. 50 100 150 200 250 300 350 400 450 Amp.

Note: The above parameter ranges are intended for Ar+CO2. More voltage is necessary for 100 % CO2.

Typical Chemical Analysis (wt. %)

C Si Mn P S Ni Cr Mo

0.05 0.63 1.58 0,017 0.011 - - -

Typical Mechanical Properties

Re(MPa) Rm(MPa) A5(%) CV(J)-30ºC CV(J)-40ºC

450 550 33 102 89

Guarantee min.420 500~640 min.20 min.47 min.47

Example of Diffusible hydrogen content: 2.8 [ml/100g]

Welding Positions

Approvals

LR DNV GL BV ABS R.M.R.S Others

4YS H5 IV YMS H5 SA4YM HHH 4YSA H5 4YMS H5 TÜV, DB, RINA

13 The original since 1968

You might also like

- Acqua Tedela Pump Series - 1Document22 pagesAcqua Tedela Pump Series - 1Janzzen CrudaNo ratings yet

- CBL Interpretation Chart PDFDocument1 pageCBL Interpretation Chart PDFReza Alfiano100% (1)

- D3529 17300 2Document1 pageD3529 17300 2stinkzNo ratings yet

- IIW - Welding DefectsDocument31 pagesIIW - Welding Defectsvarundevil87No ratings yet

- Continuous Hot-Dip Galvanized Steel Bars For Concrete ReinforcementDocument5 pagesContinuous Hot-Dip Galvanized Steel Bars For Concrete Reinforcementmohammed karasnehNo ratings yet

- Chem Lab Report 12 Lum Antar12Document4 pagesChem Lab Report 12 Lum Antar12Nor Ashikin Ismail50% (2)

- Metalworking - Mines, Forges & FoundriesDocument22 pagesMetalworking - Mines, Forges & FoundriesThe 18th Century Material Culture Resource Center100% (4)

- GMAW Welding GuideDocument96 pagesGMAW Welding GuideJUAN VASCONo ratings yet

- Description and Application: 80%ar - 20%CO EN ISO 17632-A-T 42 2 B M 1 H5 AWS A5.20 E71T-5M-JDocument1 pageDescription and Application: 80%ar - 20%CO EN ISO 17632-A-T 42 2 B M 1 H5 AWS A5.20 E71T-5M-JChikadibia OkoroNo ratings yet

- Description and Application: 100%CO /80%ar - 20%CO EN ISO 17632-A-T 46 3 P C/M 1 H5 AWS A5.20 E71T-1C/1M,-9C/9MDocument1 pageDescription and Application: 100%CO /80%ar - 20%CO EN ISO 17632-A-T 46 3 P C/M 1 H5 AWS A5.20 E71T-1C/1M,-9C/9Mamit singhNo ratings yet

- Description and Application: 80%ar - 20%co en Iso 18276-A-T 62 5 Mn1Nimo P M 2 H5 Aws A5.29 E101T1-GmDocument1 pageDescription and Application: 80%ar - 20%co en Iso 18276-A-T 62 5 Mn1Nimo P M 2 H5 Aws A5.29 E101T1-GmAmit SinghNo ratings yet

- 44 DW-309MoLPDocument1 page44 DW-309MoLPamit singhNo ratings yet

- Description and Application: 80%ar - 20%CO / 100%CO EN ISO 17633-A T 19 9 L P C1/M21 1 AWS A5.22 E308LT1-1/4 EN 1.4316Document1 pageDescription and Application: 80%ar - 20%CO / 100%CO EN ISO 17633-A T 19 9 L P C1/M21 1 AWS A5.22 E308LT1-1/4 EN 1.4316amit singhNo ratings yet

- Act 2-21Document4 pagesAct 2-21CYNDRILLE JOHN BRAGATNo ratings yet

- Proportional Hydraulic Bank: Electrical SpecificationsDocument1 pageProportional Hydraulic Bank: Electrical SpecificationsJaime Basquez PaccoNo ratings yet

- P-1100 A-B CurveDocument1 pageP-1100 A-B CurveRakesh WinmeenNo ratings yet

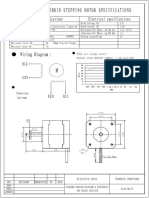

- High Torque Hybrid Stepping Motor Spe Cificatio NSDocument2 pagesHigh Torque Hybrid Stepping Motor Spe Cificatio NSYadira GonzalezNo ratings yet

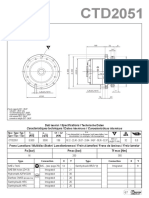

- 2mod09 Specifiche EngDocument1 page2mod09 Specifiche EngYosmell Fritzan Paz UrbizagasteguiNo ratings yet

- PUMP SERIES For FiltrationDocument22 pagesPUMP SERIES For FiltrationKaye TrishaNo ratings yet

- 27-00-001 AVK Fire Hydrant Dry Barrel - 25-12-2017Document2 pages27-00-001 AVK Fire Hydrant Dry Barrel - 25-12-2017Imtiyaz KhanNo ratings yet

- 21BCM0099 VL2021220107215 Ast01Document2 pages21BCM0099 VL2021220107215 Ast01amitheserathinasamyNo ratings yet

- ssMOD10 v101 eDocument1 pagessMOD10 v101 eRomain CAFFONo ratings yet

- 4Document6 pages4Irina BesliuNo ratings yet

- Avk High Pressure, 250 Psi, Dry Barrel Fire Hydrant 27/00: UL/FM Approved, Modern Type 001Document3 pagesAvk High Pressure, 250 Psi, Dry Barrel Fire Hydrant 27/00: UL/FM Approved, Modern Type 001Mohamed FathiNo ratings yet

- sh460 20160718 LCN7700 FinLRDocument2 pagessh460 20160718 LCN7700 FinLRJo HydeNo ratings yet

- Second Floor Girder Design: GRID 3 (BEAM 39-49) (Left Section)Document4 pagesSecond Floor Girder Design: GRID 3 (BEAM 39-49) (Left Section)CYNDRILLE JOHN BRAGATNo ratings yet

- Scanjet Tank Cleaning Equipment: Key FeaturesDocument2 pagesScanjet Tank Cleaning Equipment: Key FeaturesИван КоротковNo ratings yet

- Scanjet Datasheet SC30T 2016-02Document2 pagesScanjet Datasheet SC30T 2016-02moe_htwe_1No ratings yet

- Curvas de Operacion A 60 HZ: N 3450 RPMDocument1 pageCurvas de Operacion A 60 HZ: N 3450 RPMLuis RaymundoNo ratings yet

- Manual New Hidden FixationsDocument2 pagesManual New Hidden FixationsjosepNo ratings yet

- Doc 01 RO 20210722134755Document2 pagesDoc 01 RO 20210722134755alex7vnNo ratings yet

- Ica220 72MDocument1 pageIca220 72MAlexander ZulqarnainNo ratings yet

- Wte - Brochure - ENG 12Document1 pageWte - Brochure - ENG 12Docu CenterNo ratings yet

- Manual de Instalacao TLC 60Document2 pagesManual de Instalacao TLC 60Fabio MachadoNo ratings yet

- Aircraft Structures Iii: Tutorial No 1: Sectional PropertiesDocument4 pagesAircraft Structures Iii: Tutorial No 1: Sectional PropertiesOmkarNo ratings yet

- Baumer MTRM Series Hall Sensors Datasheet 02 11 15 2487Document2 pagesBaumer MTRM Series Hall Sensors Datasheet 02 11 15 2487Edoardo RuggeriNo ratings yet

- Davis Shirtliff Manual 2015Document328 pagesDavis Shirtliff Manual 2015Tonui JohnNo ratings yet

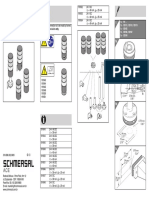

- Navodila Za Montažo / Fitting Instructions 2SS15N Navodila Za Montažo / Fitting Instructions 2SS15NDocument1 pageNavodila Za Montažo / Fitting Instructions 2SS15N Navodila Za Montažo / Fitting Instructions 2SS15NFahrudin BajramovicNo ratings yet

- Amico Flow MeterDocument2 pagesAmico Flow MeterAhlan kpNo ratings yet

- Concrete Beam Design (CSA A23.1-94)Document2 pagesConcrete Beam Design (CSA A23.1-94)marijean catuiraNo ratings yet

- Powrquad Serie 20 Esquemas HidraulicosDocument28 pagesPowrquad Serie 20 Esquemas Hidraulicoslark_No ratings yet

- BBS 25.02.23-01.06.2023-YlpDocument26 pagesBBS 25.02.23-01.06.2023-YlpsalauddinNo ratings yet

- SCC LV Cable - Thermal SC RatingDocument1 pageSCC LV Cable - Thermal SC RatingRenato AbalosNo ratings yet

- Mu Dia of Bar Mu Ast Fy FCK Spacing 905.1580914 B D D Ast mm2Document2 pagesMu Dia of Bar Mu Ast Fy FCK Spacing 905.1580914 B D D Ast mm2PrakashNo ratings yet

- Forza Za Door Installation Guide Fd30-60 PDFDocument20 pagesForza Za Door Installation Guide Fd30-60 PDFMaríaPaula CheheidNo ratings yet

- Sheet - 7Document1 pageSheet - 7nalanliyanage008No ratings yet

- Ce221 Tute8sol PDFDocument10 pagesCe221 Tute8sol PDFTech StarNo ratings yet

- Catalog Iso 21287 Series Cci Aventics en 6907740Document198 pagesCatalog Iso 21287 Series Cci Aventics en 6907740nada chahbounNo ratings yet

- Example - Transformed Sections Fig. 1: A y A yDocument1 pageExample - Transformed Sections Fig. 1: A y A yThabiso MotalingoaneNo ratings yet

- Mhda Hollow Ceiling AnchorDocument1 pageMhda Hollow Ceiling AnchorMohammed AnwarNo ratings yet

- CN 32-250Document1 pageCN 32-250Sachin ParasharNo ratings yet

- Composite Girder BridgeDocument1 pageComposite Girder BridgeTeddie B. YapNo ratings yet

- Catalogue Wheel Track and Pump Drives - Protetto PDFDocument1 pageCatalogue Wheel Track and Pump Drives - Protetto PDFkaribean007No ratings yet

- Motorav m25n 1 eDocument1 pageMotorav m25n 1 eNikNo ratings yet

- Motorav m25n 1 e PDFDocument1 pageMotorav m25n 1 e PDFNikNo ratings yet

- AMICO Induk BrosurDocument2 pagesAMICO Induk Brosurdzikri nur hNo ratings yet

- C1 CalcDocument1 pageC1 CalcJayar Valloyas MendietaNo ratings yet

- Multi-Parameter - Multi-Gas Mass Flow MeterDocument6 pagesMulti-Parameter - Multi-Gas Mass Flow MeterJulio David Vilca PizarroNo ratings yet

- Curva Flygt HS 5100 MT 3 431-Tuberia 4 PulgDocument5 pagesCurva Flygt HS 5100 MT 3 431-Tuberia 4 PulgAlbert ChacoNo ratings yet

- Linear PotentiometerDocument1 pageLinear Potentiometerjohanra2608No ratings yet

- Pump GAD For Vertical TurbineDocument9 pagesPump GAD For Vertical TurbineVijay Rama RajuNo ratings yet

- General Information: 2.1. ConcreteDocument3 pagesGeneral Information: 2.1. ConcreteGeloNo ratings yet

- Electrical SystemDocument18 pagesElectrical SystemEm sulistioNo ratings yet

- 步进电机详细参数资料Document13 pages步进电机详细参数资料Andy YouQuanTexNo ratings yet

- 1 Piece Ball Valves FeaturesDocument4 pages1 Piece Ball Valves FeaturesKok WaiNo ratings yet

- Review Paper On Hard Facing Processes and MaterialsDocument4 pagesReview Paper On Hard Facing Processes and MaterialsJaveed A. KhanNo ratings yet

- Heat Treatment of SteelsDocument18 pagesHeat Treatment of SteelsRajeev SaiNo ratings yet

- Lathe Cutting TipsDocument51 pagesLathe Cutting TipsDavid KeighleyNo ratings yet

- Apple Conflict Free MineralsDocument15 pagesApple Conflict Free MineralsMikey CampbellNo ratings yet

- MQ-3 Datasheet SensorDocument2 pagesMQ-3 Datasheet SensorAfif AR100% (1)

- Piping Works Daily ReportDocument19 pagesPiping Works Daily ReportGomathyselviNo ratings yet

- A Comparative Research On Corrosion Behavior of A Standard, Crack-Free and Duplex Hard Chromium CoatingsDocument6 pagesA Comparative Research On Corrosion Behavior of A Standard, Crack-Free and Duplex Hard Chromium CoatingsKarthi SundarNo ratings yet

- 206 CoffingCatalog SCR - Hoist CatalogueDocument60 pages206 CoffingCatalog SCR - Hoist CatalogueSajidNo ratings yet

- European Steel and Alloy Grades: X90Crmov18 (1.4112)Document2 pagesEuropean Steel and Alloy Grades: X90Crmov18 (1.4112)farshid KarpasandNo ratings yet

- APV Plug Valve CatalogueDocument40 pagesAPV Plug Valve CatalogueVeerapandianNo ratings yet

- Galvanic Corrosion: January 1958Document3 pagesGalvanic Corrosion: January 1958TrầnHữuHòaNo ratings yet

- FSW Technical HandbookDocument27 pagesFSW Technical HandbookAnand Kumar MandalNo ratings yet

- Zamzam Manually Water Drilling Micro Enterprises PLC Company Address Is Goro Gutu Woreda Boroda TownDocument2 pagesZamzam Manually Water Drilling Micro Enterprises PLC Company Address Is Goro Gutu Woreda Boroda TownAhmed TofikNo ratings yet

- Volume-7. Essential Knowledge Required For Design and Manufacturing of Hydraulic PressesDocument62 pagesVolume-7. Essential Knowledge Required For Design and Manufacturing of Hydraulic PressesQ.S. Khan100% (5)

- Lec3-Stir Casting& Squeeze CastingDocument16 pagesLec3-Stir Casting& Squeeze Castingguru prasad50% (2)

- Products Fittings Tube Bite Type Fittings For Jis Ks (Jul (1) - 2000)Document54 pagesProducts Fittings Tube Bite Type Fittings For Jis Ks (Jul (1) - 2000)J_BKoNo ratings yet

- Amd Tutorial Me Cadcam 2017Document5 pagesAmd Tutorial Me Cadcam 2017rip111176No ratings yet

- Progress Lighting Commercial Catalog 1977Document100 pagesProgress Lighting Commercial Catalog 1977Alan Masters100% (1)

- Hacksaw BladeDocument12 pagesHacksaw BladeShankar GNo ratings yet

- Keedex Price Book - 2015Document12 pagesKeedex Price Book - 2015Security Lock DistributorsNo ratings yet

- Eil Spec For PmiDocument8 pagesEil Spec For Pmisachinchavan1981No ratings yet

- Unequal Angles ... BS 4-11971 (Superseded by BS 4 1993 DimDocument3 pagesUnequal Angles ... BS 4-11971 (Superseded by BS 4 1993 DimJagdish ChhuganiNo ratings yet

- Asme Section II A Sa-376 Sa-376mDocument10 pagesAsme Section II A Sa-376 Sa-376mAnonymous GhPzn1xNo ratings yet