Professional Documents

Culture Documents

Hilti Expansion General Notes

Hilti Expansion General Notes

Uploaded by

ZABIHULLAH SAFIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hilti Expansion General Notes

Hilti Expansion General Notes

Uploaded by

ZABIHULLAH SAFICopyright:

Available Formats

GENERAL NOTES FOR POST-INSTALLED ANCHORS

1) EXCEPT WHERE INDICATED ON THE DRAWINGS, POST-INSTALLED ANCHORS SHALL

CONSIST OF THE FOLLOWING ANCHOR TYPES AS PROVIDED BY HILTI, INC. CONTACT HILTI

AT (800) 879-8000 FOR PRODUCT RELATED QUESTIONS.

a) ANCHORAGE TO CONCRETE

i) ADHESIVE ANCHORS FOR CRACKED AND UNCRACKED CONCRETE USE:

(1) ADHESIVES FOR USE:

(a) HILTI HIT-HY 200 SAFE SET SYSTEM WITH HILTI HIT-Z ROD PER ICC ESR-3187

(b) HILTI HIT-HY 200 SAFE SET SYSTEM WITH HILTI HOLLOW DRILL BIT AND

VACUUM WITH HAS THREADED ROD PER ICC ESR-3187

(c) HILTI HIT-RE 500v3 SAFE SET SYSTEM WITH HILTI HOLLOW DRILL BIT AND

VACUUM WITH HAS THREADED ROD PER ICC ESR-3814

(d) HILTI HIT-RE 500v3 SAFE SET SYSTEM WITH HILTI ROUGHENING TOOL (HIT

RT) WITH HAS THREADED ROD PER ICC ESR-3814 FOR DIAMOND CORED

HOLES

(2) STEEL ELEMENTS FOR USE WITH ADHESIVE:

(a) HILTI HAS-V-36 GRADE 36 CARBON STEEL ROD

(b) HILTI HAS-E-55 GRADE 55 CARBON STEEL ROD

(c) HILTI HAS-B-105 GRADE 105 CARBON STEEL ROD

(d) HILTI HAS-R-304 STAINLESS STEEL ROD

(e) HILTI HAS-R-316 STAINLESS STEEL ROD

(f) HILTI HIT-Z ROD (WITH HY 200 ONLY)

ii) MEDIUM DUTY MECHANICAL ANCHORS FOR CRACKED AND UNCRACKED CONCRETE

USE:

(1) HILTI KWIK HUS EZ AND KWIK HUS EZ-I SCREW ANCHOR SAFE SET SYSTEM

WITH HOLLOW DRILL BIT AND VACUUM PER ICC ESR-3027

(2) HILTI KWIK BOLT-TZ EXPANSION ANCHOR SAFE SET SYSTEM WITH HOLLOW

DRILL BIT AND VACUUM AND SI-AT-A22 TOOL WITH ADAPTIVE TORQUE FOR

APPLICABLE SIZES PER ICC ESR-1917

(3) HILTI KWIK BOLT 3 EXPANSION ANCHOR SAFE SET SYSTEM WITH HOLLOW

DRILL BIT AND VACUUM AND SI-AT-A22 TOOL WITH ADAPTIVE TORQUE FOR

APPLICABLE SIZES (UNCRACKED CONCRETE ONLY) PER ICC ESR-2302

iii) HEAVY DUTY MECHANICAL ANCHORS FOR CRACKED AND UNCRACKED CONCRETE

USE:

(1) HILTI HDA UNDERCUT ANCHORS PER ICC ESR 1546

(2) HILTI HSL-3 EXPANSION ANCHORS PER ICC ESR 1545

b) REBAR DOWELING INTO CONCRETE

i) ADHESIVE ANCHORS FOR CRACKED AND UNCRACKED CONCRETE USE:

(1) HILTI HIT-HY 200 SAFE SET SYSTEM WITH HILTI HOLLOW DRILL BIT AND VACUUM

WITH CONTINUOUSLY DEFORMED REBAR PER ICC ESR-3187

(2) HILTI HIT-HY 500v3 SAFE SET SYSTEM WITH HILTI HOLLOW DRILL BIT AND

VACUUM WITH CONTINUOUSLY DEFORMED REBAR PER ICC ESR-3814

(3) HILTI HIT-RE 500v3 SAFE SET SYSTEM WITH HILTI ROUGHENING TOOL (HIT RT)

WITH CONTINUOUSLY DEFORMED REBAR PER ICC ESR-3814 IN DIAMOND CORED

HOLES

c) ANCHORAGE TO SOLID GROUTED MASONRY

i) ADHESIVE ANCHORS USE:

(1) HILTI HIT-HY 270 SAFE SET SYSTEM WITH HILTI HOLLOW DRILL BIT AND VACUUM

PER ICC ESR-4143

(2) STEEL ANCHOR ELEMENT SHALL BE HILTI HAS CONTINUOUSLY THREADED ROD

OR CONTINUOUSLY DEFORMED STEEL REBAR

ii) MECHANICAL ANCHORS USE:

(1) HILTI KWIK BOLT-3 EXPANSION ANCHOR PER ICC ESR 1385

d) ANCHORAGE TO HOLLOW / MULTI-WYTHE MASONRY

i) ADHESIVE ANCHORS USE:

(1) HILTI HIT-HY 270 SAFE SET SYSTEM WITH HILTI HOLLOW DRILL BIT AND VACUUM

PER ICC ESR-4143.

(2) STEEL ANCHOR ELEMENT SHALL BE HILTI HAS CONTINUOUSLY THREADED ROD

OR CONTINUOUSLY DEFORMED STEEL REBAR

(3) THE APPROPRIATE SIZE SCREEN TUBE SHALL BE USED PER ADHESIVE

MANUFACTURER’S PRINTED INSTALLATION INSTRUCTIONS

2) ANCHOR CAPACITY USED IN DESIGN SHALL BE BASED ON THE TECHNICAL DATA

PUBLISHED BY HILTI OR OTHER SUCH METHOD AS APPROVED BY THE STRUCTURAL

ENGINEER OF RECORD. SUBSTITUTION REQUESTS FOR ALTERNATE PRODUCTS OR

DRILLING METHODS MUST BE APPROVED IN WRITING BY THE STRUCTURAL ENGINEER OF

RECORD PRIOR TO USE. CONTRACTOR SHALL PROVIDE CALCULATIONS DEMONSTRATING

THAT THE SUBSTITUTED PRODUCT MEETS OR EXCEEDS THE PERFORMANCE CAPACITIES

OF THE SPECIFIED PRODUCT. SUBSTITUTIONS WILL BE EVALUATED BY THEIR HAVING AN

ICC ESR SHOWING COMPLIANCE WITH THE RELEVANT BUILDING CODE FOR SEISMIC USES,

LOAD RESISTANCE, INSTALLATION CATEGORY, AND/OR AVAILABILITY OF COMPREHENSIVE

INSTALLATION INSTRUCTIONS. ADHESIVE ANCHOR EVALUATION WILL ALSO CONSIDER

CREEP, IN-SERVICE TEMPERATURE, AND INSTALLATION TEMPERATURE.

3) USE OF DIAMOND CORE BIT WITH ROUGHENING TOOL FOR ANCHOR HOLES REQUIRES

APPROVAL FROM ENGINEER OF RECORD PRIOR TO DRILLING. UNLESS OTHERWISE SHOWN

IN THE DRAWINGS, ALL HOLES SHALL BE DRILLED PERPENDICULAR TO THE CONCRETE

SURFACE.

4) INSTALL ANCHORS PER THE MANUFACTURER’S PRINTED INSTALLATION INSTRUCTIONS, AS

INCLUDED IN THE ANCHOR PACKAGING.

5) OVERHEAD ADHESIVE ANCHORS MUST BE INSTALLED USING THE HILTI PROFI PISTON PLUG

SYSTEM.

6) THE CONTRACTOR SHALL ARRANGE AN ANCHOR MANUFACTURER’S REPRESENTATIVE TO

PROVIDE ONSITE INSTALLATION TRAINING FOR ALL ANCHOR PRODUCTS SPECIFIED. THE

STRUCTURAL ENGINEER OF RECORD MUST RECEIVE DOCUMENTED CONFIRMATION THAT

ALL PERSONNEL WHO INSTALL ANCHORS ARE TRAINED PRIOR TO THE COMMENCEMENT

OF ANCHOR INSTALLATION.

7) ANCHOR CAPACITY IS DEPENDENT UPON SPACING BETWEEN ADJACENT ANCHORS AND

PROXIMITY OF ANCHORS TO EDGE OF CONCRETE. INSTALL ANCHORS IN ACCORDANCE

WITH SPACING AND EDGE CLEARANCES INDICATED ON THE DRAWINGS.

8) EXISTING REINFORCING BARS IN THE CONCRETE STRUCTURE MAY CONFLICT WITH

SPECIFIC ANCHOR LOCATIONS. UNLESS NOTED ON THE DRAWINGS THAT THE BARS CAN

BE CUT, THE CONTRACTOR SHALL REVIEW THE EXISTING STRUCTURAL DRAWINGS AND

SHALL UNDERTAKE TO LOCATE THE POSITION OF THE REINFORCING BARS AT THE

LOCATIONS OF THE CONCRETE ANCHORS BY HILTI PS 1000 OR OTHER GPR, X-RAY,

CHIPPING OR OTHER APPROVED MEANS.

You might also like

- Hilti HAS-E Anchor RodDocument3 pagesHilti HAS-E Anchor RodBIPIN BALANNo ratings yet

- Retaining Wall DetailDocument9 pagesRetaining Wall DetailRonald KahoraNo ratings yet

- HY 200 - ESR-3187 Hilti HIT-ZDocument38 pagesHY 200 - ESR-3187 Hilti HIT-Zdrac_dracNo ratings yet

- Submittal Re500 EpoxyDocument13 pagesSubmittal Re500 EpoxyErnest NavarroNo ratings yet

- Icc-Es Esr-1917Document15 pagesIcc-Es Esr-1917kmccrapmailNo ratings yet

- Post Installed Anchors General Notes CAN-032013Document2 pagesPost Installed Anchors General Notes CAN-032013Zuhair AliNo ratings yet

- General Notes For Post-Installed Reinforcing Bars SpecificationDocument1 pageGeneral Notes For Post-Installed Reinforcing Bars Specification_jessecaNo ratings yet

- Adhesivos Epoxicos y OtrosDocument33 pagesAdhesivos Epoxicos y OtrossergiosilvahNo ratings yet

- Data Techlib Docs Approvals-Listings-Reports Icbo ESR2678Document5 pagesData Techlib Docs Approvals-Listings-Reports Icbo ESR2678superpiojooNo ratings yet

- Esr 3187Document38 pagesEsr 3187Marcelo ElguetaNo ratings yet

- Hit Hy-150 PDFDocument16 pagesHit Hy-150 PDFEduardo Antonio Duran SepulvedaNo ratings yet

- Elc 3187Document26 pagesElc 3187John SmithNo ratings yet

- Disc Fitting 70 KN (B&S) TypeDocument4 pagesDisc Fitting 70 KN (B&S) TypePasupuleti007No ratings yet

- 1665 03-Vol-Iib Ts HoistDocument15 pages1665 03-Vol-Iib Ts Hoistrvkumar3619690No ratings yet

- Icc Esr-1967 Hit-Hy 150 MasonryDocument8 pagesIcc Esr-1967 Hit-Hy 150 MasonryxpertsteelNo ratings yet

- TI - SPC - OHE - Fittings - 0130 - With A - C - Slip - No - 1Document63 pagesTI - SPC - OHE - Fittings - 0130 - With A - C - Slip - No - 1Nawal RathoreNo ratings yet

- TM 32Document4 pagesTM 32Rakesh SrivastavaNo ratings yet

- Disc Fitting 45 KN (T&C) TypeDocument4 pagesDisc Fitting 45 KN (T&C) TypePasupuleti007No ratings yet

- Government of India Ministry of RailwaysDocument50 pagesGovernment of India Ministry of Railwayskhan11kNo ratings yet

- Hilti Re 500Document16 pagesHilti Re 500Chewfy1No ratings yet

- Hy200v3 Icc-Es Esr-4868Document46 pagesHy200v3 Icc-Es Esr-4868Nazmul HassanNo ratings yet

- Ohe Fitting GuidelineDocument56 pagesOhe Fitting Guidelinepretha56No ratings yet

- Approval Document ASSET DOC LOC 5506285Document48 pagesApproval Document ASSET DOC LOC 5506285Pamela Joyce MaddumaNo ratings yet

- CSA Spec HILTI HIT 100 Technical SupplementDocument32 pagesCSA Spec HILTI HIT 100 Technical SupplementIsidro P. BuquironNo ratings yet

- Technical Specification: Volume - 2BDocument26 pagesTechnical Specification: Volume - 2BVinit JoryNo ratings yet

- Government of India Ministry of RailwaysDocument56 pagesGovernment of India Ministry of RailwaysSalim KhanNo ratings yet

- Icc Esr 4143 (Hilt Hy 270)Document20 pagesIcc Esr 4143 (Hilt Hy 270)SACHINNo ratings yet

- Icc Esr-2322Document45 pagesIcc Esr-2322Omer Atacan KadiogluNo ratings yet

- Hilti Expansion Bolts - CapacityDocument9 pagesHilti Expansion Bolts - CapacitykevinisonlineNo ratings yet

- Product Technical Guide For Kwik Bolt-TZ Expansion Anchor Technical Information ASSET DOC LOC 1543424Document21 pagesProduct Technical Guide For Kwik Bolt-TZ Expansion Anchor Technical Information ASSET DOC LOC 1543424corrokokoNo ratings yet

- Hilti Re 100Document35 pagesHilti Re 100nahuel curleNo ratings yet

- 3.2.2 General Application Fasteners (31-36) r21Document9 pages3.2.2 General Application Fasteners (31-36) r21Jonathan DouglasNo ratings yet

- Elc 1917Document10 pagesElc 1917John SmithNo ratings yet

- Technical Information ASSET DOC LOC 1543385Document21 pagesTechnical Information ASSET DOC LOC 1543385Alfonso ChNo ratings yet

- 1366 - Volume-2B - Vibrating Feeder PDFDocument16 pages1366 - Volume-2B - Vibrating Feeder PDFkumarNo ratings yet

- ICC-ES Evaluation Report ESR-3814Document48 pagesICC-ES Evaluation Report ESR-3814kcNo ratings yet

- RFP - 2023 02 16 17 14 06Document53 pagesRFP - 2023 02 16 17 14 06Barun kumar paridaNo ratings yet

- Hilti HVU PDFDocument15 pagesHilti HVU PDFAlan Gabriel Montesinos CahuanaNo ratings yet

- Hit-Re-500-V3 - Eta 2019Document100 pagesHit-Re-500-V3 - Eta 2019pate84No ratings yet

- 1574 - 03 Vol 2B - DS Package PDFDocument69 pages1574 - 03 Vol 2B - DS Package PDFanjnaNo ratings yet

- Hilti Epoxy Technical InfoDocument69 pagesHilti Epoxy Technical InfoAnonymous xcFcOgMiNo ratings yet

- Draft SpecDocument61 pagesDraft SpecRakesh RoshanNo ratings yet

- Icc Esr-1385 Kb3 MasonryDocument4 pagesIcc Esr-1385 Kb3 MasonryxpertsteelNo ratings yet

- Asset Doc Loc 34 Apc RawDocument41 pagesAsset Doc Loc 34 Apc RawlaurenjiaNo ratings yet

- ETA 07 0260 HIT-RE 500-SD Injection Mortar For Anchoring Application ETAG 001-05 Option 1 Approval Document ASSET DOC APPROVAL 0152Document52 pagesETA 07 0260 HIT-RE 500-SD Injection Mortar For Anchoring Application ETAG 001-05 Option 1 Approval Document ASSET DOC APPROVAL 0152Marcelo San MartinNo ratings yet

- Hit Hy 70Document12 pagesHit Hy 70Rahim GhorbaniNo ratings yet

- Hilt I Technical Bulletin For Hy 200Document1 pageHilt I Technical Bulletin For Hy 200Koresh KhalpariNo ratings yet

- Ti SPC Ohe Atd 0060Document16 pagesTi SPC Ohe Atd 0060pradeeepgarg100% (1)

- Mechanical Section Comments: SubjectDocument5 pagesMechanical Section Comments: SubjectUmmair ChNo ratings yet

- Adani Parsa Coal Washery - WriteupDocument7 pagesAdani Parsa Coal Washery - Writeupanon_211762843No ratings yet

- Legacy Report: ICC Evaluation Service, IncDocument2 pagesLegacy Report: ICC Evaluation Service, Incjmcc2No ratings yet

- 1 Input Data: Profis Anchor 2.6.6Document6 pages1 Input Data: Profis Anchor 2.6.6Collin NguNo ratings yet

- Hilti AnchoringDocument15 pagesHilti Anchoringwdavid81No ratings yet

- 1443 - Volume 2B PDFDocument128 pages1443 - Volume 2B PDFzsmithNo ratings yet

- 75190139Document148 pages75190139Munya BengezaNo ratings yet

- TS - LGSS MARRIED OFFICER Living Shelter 17 CORPS SINGLE STOREYDocument20 pagesTS - LGSS MARRIED OFFICER Living Shelter 17 CORPS SINGLE STOREYdesignNo ratings yet

- Hilti HIT HY 70 Injection Mortar For MasonryDocument26 pagesHilti HIT HY 70 Injection Mortar For MasonryVenkatesh PadmanabhanNo ratings yet

- Hilti-Hy 200-RDocument74 pagesHilti-Hy 200-RHumberto EstevezNo ratings yet

- Indian RDSO-Guidelines For HSFG Bolts On India RailDocument16 pagesIndian RDSO-Guidelines For HSFG Bolts On India RailUpaliFernando100% (1)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- VLSI Design for Video Coding: H.264/AVC Encoding from Standard Specification to ChipFrom EverandVLSI Design for Video Coding: H.264/AVC Encoding from Standard Specification to ChipNo ratings yet

- E 1688 84.2Document1 pageE 1688 84.2ZABIHULLAH SAFINo ratings yet

- Etag 001 Annex B 07 11 13Document28 pagesEtag 001 Annex B 07 11 13ZABIHULLAH SAFINo ratings yet

- Pediatric IllnessDocument82 pagesPediatric IllnessZABIHULLAH SAFINo ratings yet

- New South Wales Specification 274: Masonry WallsDocument16 pagesNew South Wales Specification 274: Masonry WallsZABIHULLAH SAFINo ratings yet

- Letter of Invitation: Country Office For AfghanistanDocument10 pagesLetter of Invitation: Country Office For AfghanistanZABIHULLAH SAFINo ratings yet

- E Megagrout 100 PDFDocument2 pagesE Megagrout 100 PDFZABIHULLAH SAFINo ratings yet

- ElevationDocument1 pageElevationZABIHULLAH SAFINo ratings yet

- LRFD Bridge Design GuideDocument2 pagesLRFD Bridge Design GuideZABIHULLAH SAFINo ratings yet

- Direct Shear Test PDFDocument6 pagesDirect Shear Test PDFZABIHULLAH SAFINo ratings yet

- Baghouse Filter Modular Pulse Jet Type: Operation and ApplicationDocument5 pagesBaghouse Filter Modular Pulse Jet Type: Operation and ApplicationBudy AndikaNo ratings yet

- Curriculum Vitae: Tubagus G.PDocument3 pagesCurriculum Vitae: Tubagus G.PTB Gita PriadiNo ratings yet

- Mir Waw PDFDocument56 pagesMir Waw PDFAwiatorzy WielcyNo ratings yet

- OxnardPD ThousandOaks Borderline DispatchDocument8 pagesOxnardPD ThousandOaks Borderline DispatchThomas BusseNo ratings yet

- AmulDocument63 pagesAmuljassi7nishadNo ratings yet

- LLP NewsWeekly 6 Months Backlog Detailed NotesDocument430 pagesLLP NewsWeekly 6 Months Backlog Detailed NotesManik GoyalNo ratings yet

- Usc Thesis CenterDocument6 pagesUsc Thesis Centergja8e2sv100% (2)

- Emission Control (2uz-Fe)Document15 pagesEmission Control (2uz-Fe)Abbode HoraniNo ratings yet

- CU210ASPLUSDocument2 pagesCU210ASPLUSEnrique MoralesNo ratings yet

- IJARCCE5J A Rashmi Varma Automatic Battery Charger PDFDocument4 pagesIJARCCE5J A Rashmi Varma Automatic Battery Charger PDFParu LechuNo ratings yet

- Grade 11 Microeconomics & Contemporary Economic Issues Essays 2023Document48 pagesGrade 11 Microeconomics & Contemporary Economic Issues Essays 2023kamogelongwato56No ratings yet

- 800-Organic Fertilizer For Greenhouse TomatoesDocument10 pages800-Organic Fertilizer For Greenhouse Tomatoesgonzalo_hbNo ratings yet

- Chapter Five: Memory InterfacingDocument15 pagesChapter Five: Memory Interfacingoumer beshirNo ratings yet

- WASTEWATER STABILIZATION LAGOON PROCESS PowerPoint Presentation, Free Download - ID - 6206424Document2 pagesWASTEWATER STABILIZATION LAGOON PROCESS PowerPoint Presentation, Free Download - ID - 6206424shoyebNo ratings yet

- Gr10 - IT Theory LB Print 16jan2020 PDFDocument174 pagesGr10 - IT Theory LB Print 16jan2020 PDFConfused PickleNo ratings yet

- Planning 3Document105 pagesPlanning 3Kevin RimandimanNo ratings yet

- JD01 Hoppin Vacancy Jeffco PR FINAL-1Document4 pagesJD01 Hoppin Vacancy Jeffco PR FINAL-1Circuit MediaNo ratings yet

- Company BackgroundDocument4 pagesCompany BackgroundaabrunhosaNo ratings yet

- Balan Dragos Alexandru: Curriculum VitaeDocument3 pagesBalan Dragos Alexandru: Curriculum VitaeMa TaNo ratings yet

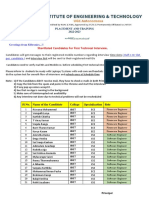

- Efftronics Shortlisted FirstroundDocument1 pageEfftronics Shortlisted FirstroundVinukonda snehaNo ratings yet

- Dxmic User Manual: Warning: This Manual Contains Important Safety and Operating InformationDocument23 pagesDxmic User Manual: Warning: This Manual Contains Important Safety and Operating InformationKishan ChandrasekaraNo ratings yet

- By Dawit Tesfay: Adigrat University Collage of Enginering and Thechnology Department of Architecture Urban PlaningDocument5 pagesBy Dawit Tesfay: Adigrat University Collage of Enginering and Thechnology Department of Architecture Urban PlaningDawit TesfayNo ratings yet

- ASS 7free PDF Reader WebsiteDocument20 pagesASS 7free PDF Reader WebsiteOluyiNo ratings yet

- Inner Product SpaceDocument3 pagesInner Product SpaceDharmendra KumarNo ratings yet

- Philips Lx600 Manual Do UtilizadorDocument21 pagesPhilips Lx600 Manual Do UtilizadorPaulo MasselliNo ratings yet

- Stream Processing: Instant Insight Into Data As It FlowsDocument14 pagesStream Processing: Instant Insight Into Data As It FlowsVlad VikernesNo ratings yet

- Cyberpower Ds Sm20kapmx Sm120-200kamfx en v1Document2 pagesCyberpower Ds Sm20kapmx Sm120-200kamfx en v1Kibsain LunaNo ratings yet

- Dianna Abdala: Case IncidentDocument1 pageDianna Abdala: Case IncidentKilian FontaineNo ratings yet

- Research Paper On Logic GatesDocument5 pagesResearch Paper On Logic Gatesafedoeike100% (1)