Professional Documents

Culture Documents

15no03 Ds 020 008 Portable Loading Diesel Pump (3322 P 003)

15no03 Ds 020 008 Portable Loading Diesel Pump (3322 P 003)

Uploaded by

bagus handokoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

15no03 Ds 020 008 Portable Loading Diesel Pump (3322 P 003)

15no03 Ds 020 008 Portable Loading Diesel Pump (3322 P 003)

Uploaded by

bagus handokoCopyright:

Available Formats

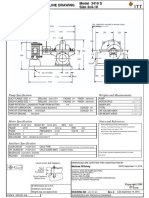

DATA SHEET FOR PORTABLE LOADING DIESEL CONTRACT NO :

PUMP -

DOCUMENT NUMBER

Pages 1 OF 7

15NO 03-DS-020-008

PENGADAAN SEMARANG GAS DISTRIBUTION PIPE LINE (CP-16)

PORTABLE LOADING DIESEL PUMP

CLIENT : PT. PERUSAHAAN GAS NEGARA (Persero) Tbk.

CONTRACTOR : KONSORSIUM WIKA - MGP - SGI

PROJECT NAME : PENGADAAN SEMARANG GAS

DISTRIBUTION PIPELINE (CP-16)

LOCATION : SEMARANG

DOCUMENT NO. : 15NO 03-DS-020-008

A 5/3/2015 Issued for Bid AS AN

Revision By Checked Approved Checked Approved

DATE Status Code

Code ENG. DIP PT. WIKA BUS. DEV

DATA SHEET FOR PORTABLE LOADING DIESEL PUMP

Date :

PENGADAAN SEMARANG GAS DISTRIBUTION PIPE 5/3/2015

15NO 03-DS-020-008 Rev. A

LINE (CP-16)

Page : 2 of 7

REVISION SHEET

REVISION CODE REVISION CODE REVISION CODE

Page Page Attachment

A B C D 0 1 2 A B C D 0 1 2 A B C D 0 1 2

1

2

3

4

5

DATA SHEET FOR PORTABLE LOADING DIESEL PUMP

Date :

PENGADAAN SEMARANG GAS DISTRIBUTION PIPE 5/3/2015

15NO 03-DS-020-008 Rev. A

LINE (CP-16)

Page : 3 of 7

COMMENT SHEET

Revision Comment Implementation

Chapter Page Revision Note Remark

Code (Yes/No)

DATA SHEET FOR PORTABLE LOADING DIESEL PUMP

Rev. No : A

15NO 03-DS-020-008 PENGADAAN SEMARANG GAS DISTRIBUTION PIPE LINE (CP-16)

Page : 4 of 7

1 APPLICABLE TO: PROPOSALS PURCHASE AS BUILT

2 FOR PENGADAAN SEMARANG DISTRIBUTION PIPELINE PROJECT (CP-16) UNIT 1 (One)

3 SITE SEMARANG, JAWA TENGAH SERVICE Diesel Pump

4 NOTES: INFORMATION BELOW TO BE COMPLETED: BY PURCHASER BY MANUFACTURER BY MANUFACTURER OR PURCHASER

5 DATA SHEETS REVISIONS

6 ITEM NO. ATTACHED ITEM NO. ATTACHED ITEM NO. ATTACHED NO. DATE BY

7 PUMP 1

8 MOTOR 2

9 GEAR 3

10 TURBINE 4

11 APPLICABLE OVERLAY STANDARD (S) : 5

12 OPERATING CONDITIONS (5.1.3) LIQUID (5.1.3)

13 FLOW, NORMAL 11 (USGPM) RATED 12 (USGPM) LIQUID TYPE OR NAME DIESEL FUEL

14 OTHER HAZARDOUS FLAMMABLE (5.1.5)

15 SUCTION PRESSURE MAX./RATED 22.76 / 14.223 (psia) MIN. NORMAL MAX.

16 DISCHARGE PRESSURE 25.602012 (psia) PUMPING TEMP (oC) 86-122 o

F

17 DIFFERENTIAL PRESSURE 12.5165392 (psia) VAPOUR PRESS. (MPa) 0 (kg/cm2)

18 DIFF. HEAD 10.8 (m) NPSHA 19.83 (m) RELATIVE DENSITY (SG) 815 (lbs/ft3)

19 PROCESS VARIATIONS (5.1.4) VISCOSITY (mPa's) 5.26 Cp

20 STARTING CONDITION (5.1.4) SPECIFIC HEAT, Cp (kJ/kg.K)

21 SERVICES: CONT. INTERMITTENT (START / DAY) CHLORIDE CONSENTRATION (6.5.2.4) (mg/kg)

22 PARALEL OPERATION REQ'D (5.1.13) H2S CONCENTRATION (mol fraction) WET (5.12.1.12c)

23 SITE DATA (5.1.3) CORROSIVE / EROSIVE AGENT (5.12.1.9)

24 LOCATION: (2.1.29) MATERIAL (5.12.1.1)

25 INDOOR HEATED OUTDOOR UNHEATED ANNEX H CLASS (5.12.1.1) S-1

26 ELECTRICAL AREA CLASSIFICATION (5.1.24 / 6.1.4) MIN DESIGN METAL TEMP (5.12.4.1) (oC)

27 CL GR DIV REDUCED HARDNESS MATERIALS REQ'D. (5.12.1.12)

28 WINTERIZATION REQ'D TROPICALIZATION REQ'D BARREL / CASE IMPELLER

29 SITE DATA (5.1.30) CASE / IMPELLER WEAR RINGS

30 ALTITUDE (m) BAROMETER (MPa) SHAFT

31 RANGE OF AMBIENT TEMPS: MIN./MAX. / (oC) DIFFUSER

32 RELATIVE HUMIDITY: MIN./MAX> / (%) PERFORMANCE

33 UNUSUAL CONDITIONS: (5.1.30) DUST FUMES PROPOSAL CURVE NO. r/min

34 OTHER IMPELLER DIA. RATED MAX. MIN. (mm)

35 IMPELLER TYPE Fully Enclosed Type

36 RATED POWER 0.08 (HP) EFFICIENCY (%)

37 DRIVER TYPE MINIMUM CONTINUOUS FLOW:

38 INDUCTION MOTOR STEAM TURBINE GEAR THERMAL (m3/h) STABLE (m3/h)

39 OTHER PREFERRED OPERATING REGION TO (m3/h)

40 ALLOWABLE OPERATING REGION TO (m3/h)

41 MOTOR DRIVER (6.1.1 / 6.1.4) MAX HEAD @ RATED IMPELLER (m)

42 MANUFACTURER MAX POWER @ RATED IMPELLER (kW)

43 1.3 (kW) (r/min) NPSHR AT RATED FLOW (m) (5.1.10)

44 FRAME ENCLOSURE TEFC; IP 55 MAX SUCTION SPECIFIC SPEED (5.1.11)

45 HORIZONTAL VERTICAL SERVICE FACTOR MAX. SOUND PRESS. LEVEL REQ'D (dBA) (5.1.16)

46 VOLT/PHASE/HERTZ EST MAX SOUND PRESS. LEVEL (dBA) (5.1.16)

47 TYPE EST MAX SOUND PRESS. LEVEL (dBA) (5.1.16)

48 MINIMUM STARTING VOLTAGE (6.1.5) UTILITY CONDITIONS (5.1.3)

49 INSULATION F TEMP. RISE ELECTRICITY VOLTAGE PHASE HERZT

50 FULL LOAD AMPS DRIVERS 380 3 50

51 LOCKED ROTOR AMPS HEATING 220 1 50

52 STARTING METHOD SYSTEM VOLTAGE DIP 80% OTHER (6.1.5)

53 LUBE STEAM MAX. PRESS. MAX. TEMP. MIN. PRESS. MIN. TEMP.

54 BEARING (TYPE / NUMBER): DRIVERS

55 RADIAL / HEATING

56 THRUST / COOLING WATER : (5.1.19) SOURCE

57 VERTICAL THRUST CAPACITY SUPPLY TEMP. (oC) MAX. RETURN TEMP. (oC)

58 UP (N) DOWN (N) NORM. PRESS. (MPa) DESIGN PRESS. (MPa)

59 MIN. RET. PRESS. (MPa) MAX. ALLOW. D. P. (MPa)

60 CHLORIDE CONCENTRATION : (mg/kg)

431366450.xls (Process Data - pg 1,2)

DATA SHEET FOR PORTABLE LOADING DIESEL PUMP

Rev. No : A

15NO 03-DS-020-008 PENGADAAN SEMARANG GAS DISTRIBUTION PIPE LINE (CP-16)

Page : 5 of 7

1 REMARKS

2 1. Shut off pressure : HOLD (kg/cm2)

3 2. Rated Flow Shall be 80% - 110% of best Eff

4 3. Complete with Space Heater

5 4. Powe Motor 4 kW

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

431366450.xls (Process Data - pg 1,2)

DATA SHEET FOR PORTABLE LOADING DIESEL

PUMP

PENGADAAN SEMARANG GAS DISTRIBUTION Rev. No : A

15NO 03-DS-020-008

PIPE LINE (CP-16) Page : 6 of 7

1 CONSTRUCTION SURFACE PREPARATION AND PAINT

2 ROTATION : (VIEWED FROM COUPLING END) CW CCW MANUFACTURER STANDARD OTHER (SEE BELOW)

3 PUMP TYPE : (4.1) SPECIFICATION NO.

4 OH2 OH3 OH6 OTHER PUMP :

5 CASING MOUNTING PUMP SURFACE PREPARATION

6 CENTERLINE INLINE OTHER PRIMER

7 FINISH COAT

8 CASING TYPE : BASEPLATE : (6.3.17)

9 SINGLE VOLUTE MULTIPLE VOLUTE DIFFUSER BASEPLATE SURFACE PREPARATION

10 PRIMER

11 FINISH COAT

12 DETAILS OF LIFTIN DEVICES (6.3.20)

13 CASE PRESSURE RATING : SHIPMENT : (7.4.1)

14 MAX ALLOWABLE WORKING PRESSURE (MPa) DOMESTIC EXPORT EXPORT BOXING REQUIRED

15 @ (oC) OUTDOOR STORAGE MORE THAN 6 MONTHS

16 HYDROTEST PRESSURE (MPa) SPARE ROTOR ASSEMBLY PACKAGE FOR :

17 SUCTION PRESS. REGIONS MUST BE DESIGNED SHIPPING CONTAINER (8.2.8.3) VERTICAL STORAGE

18 FOR MAWP (5.3.6) TYPE OF SHIPPING PREPARATION N2 PURGE (8.2.8.4)

19 NOZZLE CONNECTIONS : (5.4.2) HEATING AND COOLING

20 SIZE FLANGE FAC'G POSITION HEATING JACKET REQ'D (5.9.8) COOLING REQ'D

21 RATING COOLING WATER (C.W.) PIPING PLAN (6.5.3.1)

22 SUCTION 4" 150# RF SIDE CW. PIPING :

23 DISCHARGE 2" 150# RF SIDE PIPE TUBING; FITTINGS

24 BALANCE DRUM CW. MATERIAL

25 PRESSURE CASING AUX. CONNECTIONS : (5.4.3) S. STEEL C. STEEL GALVANIZED

26 NO. SIZE (DN) TYPE COOLING WATER REQUIREMENT

27 DRAIN BEARING HOUSING (m3/h) @ (MPa)

28 VENT HEAT EXCHANGER (m3/h) @ (MPa)

29 PRESS. GAUGE STEAM PIPING : TUBING PIPE

30 TEMP GAUGE BEARING AND LUBRICATION

31 WARM UP BEARING (TYPE / NUMBER) (5.10.1)

32 BALANCE / LEAK-OFF RADIAL /

33 MACHINED AND STUDDED CONNECTIONS (5.4.3.8) THRUST /

34 CYLINDRICAL THREADS REQUIRED (5.4.3.3) LUBRICATION (5.11.3, 5.11.4)

35 ROTOR : RING OIL HYDRODYNAMIC PURGE OIL MIST PURE OIL MIST

36 COMPONENT BALANCE TO ISO 1940 G1.0 (5.9.4.4) CONSTANT LEVEL OILER PREFERENCE (5.10.2.2) :

37 SHRINK FIT-LIMITED MOVEMENT IMPELLERS (6.2.2.3) PRESSURE LUBE SYS. ISO 10438-3 ISO 10438-2 (8.2.6.1 / 8.2.6.5)

38 COUPLING : (6.2.2) OIL VISC. ISO GRADE

39 MANUFACTURER MODEL OIL PRESSURE TO GREATER THAN COOLANT PRESSURE

40 RATING (kW per 100 r/min) REVIEW AND APPROVE THRUST BEARING SIZE (8.2.5.2.4)

41 SPACER LENGTH (mm) SERVICE FACTOR OIL HEATER REQUIRED : STEAM ELECTRIC

42 DRIVE HALF COUPLING MOUNTED BY : INSTRUMENTATION

43 PUMP MFR. DRIVER MFR. PURCHASER SEE ATTACHED API - 670 DATA SHEET

44 COUPLING WITH HYDRAULIC FIT (6.2.10) ACCELEROMETER (6.4.2.1)

45 COUPLING BALANCE TO ISO 1940-1 G6.3 (6.2.3) PROVISION FOR VIBRATION PROBE (6.4.2.2)

46 COUPLING PER ISO 14691 (6.2.4) RADIAL PER BRG. AXIAL PER BRG.

47 COUPLING PER ISO 10441 (6.2.4) PROVISION FOR MOUNTING ONLY (5.10.2.11)

48 COUPLING PER API 671 (6.2.4) FLAT SURFACE REQ'D (5.10.2.12)

49 NON SPARK COUPLING GUARD (6.2.14c) RADIAL BEARING METAL TEMP. THRUST BEARING METAL TEMP.

50 COUPLING GUARD STANDARD PER (6.2.14a) TEMP. GAUGES (WITH THERMOWELLS)

51 BASEPLATES : MONITOR AND CABLES SUPPLIED BY (6.4.2.4)

52 API BASEPLATE NUMBER (ANNEX D) REMARKS :

53 NON GROUT CONSTRUCTION (6.3.13) 1. If other than ANSI, Vendor Shall supply the Companion flange

54 OTHER

55 MECHANICAL SEAL : (5.8.1)

56 SEE ATTACHED ISO 21049 / API 682 DATASHEET

57 MASSES (kg)

58 PUMP BASEPLATE

59 DRIVER TOTAL

60 GEAR

431366450.xls (OH type - pg 3,4)

DATA SHEET FOR PORTABLE LOADING DIESEL

PUMP

PENGADAAN SEMARANG GAS DISTRIBUTION Rev. No : A

15NO 03-DS-020-008

PIPE LINE (CP-16) Page : 7 of 7

1 SPARE PARTS (TABLE 18) QA INSPECTION AND TESTING (CONT.)

2 START-UP NORMAL MAINTENANCE TEST NON-WIT WIT OBSERVE

3 SPECIFY HYDROSTATIC (7.3.2)

4 PERFORMANCE (7.3.3)

5 OTHER PURCHASER REQUIREMENTS NPSH (7.3.4.2)

6 COORDINATION MEETING REQUIRED (9.1.3) RETEST ON SEAL LEAKAGE (7.3.3.2d)

7 MAXIMUM DISCHARGE PRESSURE TO INCLUDE (5.3.2) RETEST REQUIRED AFTER FINAL

8 MAX RELATIVE DENSITY HEAD ADJUSMENT (7.3.3.5b)

9 MAX DIA. IMPELLERS AND / OR NO. STAGES COMPLETE UNIT TEST (7.3.4.3)

10 OPERATION TO TRIP SPEED SOUND LEVEL TEST (7.3.4.4)

11 CONNECTION DESIGN APPROVAL (5.12.3.4) CLEANLINESS PRIOR TO

12 INERT GAS INHIBITED STORAGE - SPARE CARTRIDGE (8.2.8.4) FINAL ASSEMBLY (7.2.2.2)

13 TORSIONAL ANALYSIS REQUIRED (5.9.2.1) NOZZLE LOAD TEST (6.3.6)

14 TORSIONAL ANALYSIS REPORT (5.9.2.6) CHECK FOR CO-PLANAR

15 PROGRESS REPORTS (9.3.3) MOUNTING PAD SURFACE (6.3.3)

16 OUTLINE OF PROCEDURES FOR OPTIONAL TESTS (9.2.5) MECHANICAL RUN UNTIL OIL

17 ADDITIONAL DATA REQUIRING 20 YEARS RETENTION (7.2.1.11) TEMP. STABLE (7.3.4.7.1)

18 LATERAL ANALYSIS REQUIRED (8.2.4.1 / 8.2.4.1.3) 4 HR. MECHANICAL RUN AFTER

19 DYNAMIC BALANCE ROTOR (8.2.4.2) OIL TEMP. STABLE (7.3.4.7.3)

20 MANIFOLD PIPING TO SINGLE CONNECTION (6.5.1.6) 4 HR. MECH. RUN TEST (7.3.4.7.2)

21 VENT DRAIN COOLING WATER TRUE PEAK VELOCITY

22 MOUNT SEAL RESERVOIR OFF BASEPLATE (6.5.1.4) DATA (7.3.3.4d)

23 FLANGES REQ'D PLACE OF SOCKET WELD UNIONS (6.5.2.8) BRG HSG RESONANCE

24 CONNECTION BOLTING TEST (7.3.4.6)

25 PTFE COATING ASTM A153 GALVANIZED REMOVE / INSPECT

26 PAINTED SS HYDRODYNAMIC BEARINGS

27 INSTALLATION LIST IN PROPOSAL (9.2.3L) AFTER TEST (8.2.7.5)

28 QA INSPECTION AND TESTING AUXILIARY EQUIPMENT

29 SHOP INSPECTION (7.1.4) TEST (7.3.4.5)

30 PERFORMANCE CURVE APPROVAL CHARPY TEST (EN 13445 / ASME VII)

31 TEST WITH SUBSTITUTE SEAL (7.3.3.2b)

32 MATERIAL CERTIFICATION REQUIRED (5.12.1.8)

33 CASING IMPELLER SHAFT

34 OTHER VENDOR KEEP REPAIR AND HT RECORDS (7.2.1.1c)

35 CASTING REPAIR PROCEDURE APPROVAL REQ'D (5.12.2.5) VENDOR SUBMIT TEST PROCEDURES (7.3.1.2 / 9.2.5)

36 INSPECTION REQUIRED FOR CONNECTION WELDS (5.12.3.4e) VENDOR SUBMIT TEST DATA WITHIN 24 HOURS (7.3.3.3e)

37 MAG PARTICLE LIQUID PENETRANT INCLUDE PLOTTED VIBRATION SPECTRA (5.9.3.3)

38 RADIOGRAPHIC ULTRASONIC RECORD FINAL ASSEMBLY RUNNING CLEARANCES

39 INSPECTION REQUIRED FOR CASTINGS (7.2.1.3 / 5.12.1.5) COMPLETION OF INSPECTION CHECK LIST (7.1.6)

MAG PARTICLE LIQUID PENETRANT

40 RADIOGRAPHIC ULTRASONIC

41 HARDNESS TEST REQUIRED : (7.2.2.3)

42 ADDITIONAL SUBSURFACE EXAMINATION FOR 7.2.1.3

43 FOR

44 METHOD

45

46 REMARKS

47

48

49

50

51

52

53

54

55

431366450.xls (OH type - pg 3,4)

You might also like

- TEM-En-001-00 - Spring Support Data SheetDocument2 pagesTEM-En-001-00 - Spring Support Data SheetPhilippe AlexandreNo ratings yet

- Method Statement For RetubingDocument4 pagesMethod Statement For RetubingJeffrey78% (9)

- Notes Information Below To Be Completed: by Manufacturer or PurchaserDocument5 pagesNotes Information Below To Be Completed: by Manufacturer or Purchaserrajindo1No ratings yet

- Hoja de Datos de BombaDocument5 pagesHoja de Datos de Bombaluis zambranoNo ratings yet

- Microsoft Word - 8100a Flame ArresterDocument4 pagesMicrosoft Word - 8100a Flame Arresterhasan_676489616100% (1)

- Carbon Steel Strainer Fig 34 HP-Technical InformationDocument3 pagesCarbon Steel Strainer Fig 34 HP-Technical InformationSouljah KhifferNo ratings yet

- CEN-ING-18011-MEE-PL-001-2 Trampa de Despacho JF PDFDocument1 pageCEN-ING-18011-MEE-PL-001-2 Trampa de Despacho JF PDFAlexanderNo ratings yet

- Air Eliminator DatasheetDocument2 pagesAir Eliminator DatasheetbecpavanNo ratings yet

- Mechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraDocument5 pagesMechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraAhmad RifaiNo ratings yet

- SBC (Safety Break-Away Couplings) v140630Document16 pagesSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- Data Sheet Centrifugal Pump ASME B73.1 B73.2: CUS TOM LOG ODocument4 pagesData Sheet Centrifugal Pump ASME B73.1 B73.2: CUS TOM LOG Ogabriel riveroNo ratings yet

- Engrasadora NEUMATICAFLOWSERVERDocument16 pagesEngrasadora NEUMATICAFLOWSERVERLuis E. Barcelo TovarNo ratings yet

- Catalogo Valvulas Forged Velan PDFDocument36 pagesCatalogo Valvulas Forged Velan PDFCarlosEduardoMorenoManceraNo ratings yet

- Datasheet BombaDocument4 pagesDatasheet BombasaculNo ratings yet

- Guides For Storage Tanks Nozzles Orientation - LinkedInDocument5 pagesGuides For Storage Tanks Nozzles Orientation - LinkedInragulNo ratings yet

- Anderson-Greenwood-general Valvulas de Alivio PDFDocument24 pagesAnderson-Greenwood-general Valvulas de Alivio PDFPedro Luis Choque MamaniNo ratings yet

- TVA Flowmeter-Technical InformationDocument2 pagesTVA Flowmeter-Technical InformationRandy PalmaNo ratings yet

- Project: Title:: Equipment ListDocument3 pagesProject: Title:: Equipment ListMartin DanzeNo ratings yet

- C18H0 UFAA78 ProposalDocument9 pagesC18H0 UFAA78 Proposaledward baskaraNo ratings yet

- Agip-15801 Pip Mec SDSDocument64 pagesAgip-15801 Pip Mec SDSFAUSTO SAMPIETRONo ratings yet

- Pga1000998050010 01Document1 pagePga1000998050010 01Amit SaxenaNo ratings yet

- R-P-AP-0001 Rev00 Georg Fischer CATA SPEC Parametrization of Catalogue Elements PDFDocument5 pagesR-P-AP-0001 Rev00 Georg Fischer CATA SPEC Parametrization of Catalogue Elements PDFdesai_tejasNo ratings yet

- Duplex Strainer.Document1 pageDuplex Strainer.Roshan ShanmughanNo ratings yet

- VALVULA VAPOR Joseestrada PDFDocument5 pagesVALVULA VAPOR Joseestrada PDFRaulRodriguezNo ratings yet

- ARO 666300 XXX C 3 Inch Metallic Diaphragm Pump ManualDocument8 pagesARO 666300 XXX C 3 Inch Metallic Diaphragm Pump Manualroyert80No ratings yet

- Anexo I - Típicos de Soportes Metálicos PDFDocument174 pagesAnexo I - Típicos de Soportes Metálicos PDFAngely Canales100% (1)

- Bomba Goulds 3X4 - E213h513 PDFDocument18 pagesBomba Goulds 3X4 - E213h513 PDFRoger ChavezNo ratings yet

- Piping Specification: Piping Class: A2ADocument30 pagesPiping Specification: Piping Class: A2AAbhijeet WayaseNo ratings yet

- R-P-AP-0004 Rev01 Georg Fischer CATA SPEC Transfer Protocol PDFDocument488 pagesR-P-AP-0004 Rev01 Georg Fischer CATA SPEC Transfer Protocol PDFdesai_tejasNo ratings yet

- C890 Ceramic Fiber PDFDocument6 pagesC890 Ceramic Fiber PDFKf LiauNo ratings yet

- Catálogo Válvulas de Control Red Valve PDFDocument30 pagesCatálogo Válvulas de Control Red Valve PDFFranciscoNo ratings yet

- Ucd 345Document2 pagesUcd 345psgkanakarajNo ratings yet

- Anvil Fig B-268 Type F Size 13Document1 pageAnvil Fig B-268 Type F Size 13zguy360No ratings yet

- 3 Stack 00001Document1 page3 Stack 00001karioke mohaNo ratings yet

- IPS MBD20031 in 523 Data Sheet of Thermal Relief Valve ADocument9 pagesIPS MBD20031 in 523 Data Sheet of Thermal Relief Valve ANikhil KarkeraNo ratings yet

- Zmitoiii: Nnovation Efficiency QualityDocument12 pagesZmitoiii: Nnovation Efficiency QualityCristian Muñoz AlarcónNo ratings yet

- ASME B16 48 Dimensions of Spades and Ring Spacers PDFDocument11 pagesASME B16 48 Dimensions of Spades and Ring Spacers PDFpippalla aswiniNo ratings yet

- Malmedi 50HZ 14-09-04Document538 pagesMalmedi 50HZ 14-09-04rhusseinpos4765No ratings yet

- Amreya Petroleum Refinery Company (Aprc) : Atlas Copco CrepelleDocument9 pagesAmreya Petroleum Refinery Company (Aprc) : Atlas Copco Crepelleالبريمه المصريهNo ratings yet

- Data Sheet 26 - Fig Tc704 Conical (Witches Hat) StrainerDocument1 pageData Sheet 26 - Fig Tc704 Conical (Witches Hat) StrainerSteve NewmanNo ratings yet

- A.3.7 JP152-300-DQP-05.81-90005-02 Pneumatic Pressure TestingDocument12 pagesA.3.7 JP152-300-DQP-05.81-90005-02 Pneumatic Pressure TestingJabel Oil Services Technical DPTNo ratings yet

- MIS-M-DS-04052 50m3 Treated Water Tank Data Sheet (T-04320) - CDocument2 pagesMIS-M-DS-04052 50m3 Treated Water Tank Data Sheet (T-04320) - Chappale2002No ratings yet

- Piping Class - AC11Document2 pagesPiping Class - AC11Дмитрий РыбаковNo ratings yet

- Steel Castings, Creep-Strength Enhanced Ferritic Alloy, For Pressure-Containing Parts, Suitable For High Temperature ServiceDocument5 pagesSteel Castings, Creep-Strength Enhanced Ferritic Alloy, For Pressure-Containing Parts, Suitable For High Temperature Servicemohammed karasnehNo ratings yet

- Foundation Loading Data of Skid For Pipe Supports of Amine Circulation Pumps (Skid 1)Document6 pagesFoundation Loading Data of Skid For Pipe Supports of Amine Circulation Pumps (Skid 1)Aisha SajidNo ratings yet

- HD 201 Rsteam PipingDocument24 pagesHD 201 Rsteam PipingalexissalazarNo ratings yet

- Series FB: Floating Ball ValveDocument12 pagesSeries FB: Floating Ball ValveCarlos Alberto Aguilera MendezNo ratings yet

- 1824 000 PI SPC 0003 - 7 - IFP - CleanedDocument22 pages1824 000 PI SPC 0003 - 7 - IFP - CleanedJudith HidalgoNo ratings yet

- Flare Scrubber DSDocument8 pagesFlare Scrubber DSsudjonoNo ratings yet

- Checklist - Duct Detailing - Non Pressure Parts Drgs - 01Document2 pagesChecklist - Duct Detailing - Non Pressure Parts Drgs - 01Ramalingam PrabhakaranNo ratings yet

- XMZ 210Document3 pagesXMZ 210Carlos GutierrezNo ratings yet

- Polyken 2036Document2 pagesPolyken 2036nrd9771No ratings yet

- Hoja de Datos Bomba Sumergible Amarex KRTDocument8 pagesHoja de Datos Bomba Sumergible Amarex KRTRicardo BarrosNo ratings yet

- 150# Cs Ball Valve Datasheet: GeneralDocument3 pages150# Cs Ball Valve Datasheet: GeneralVijay GaikwadNo ratings yet

- 4C-01-02 Rev 2Document5 pages4C-01-02 Rev 2Christian Martínez G.No ratings yet

- 8-1280-13 Pipe Class HF-1Document4 pages8-1280-13 Pipe Class HF-1Jesus MendezNo ratings yet

- 15no03-Ds-020-006 Diesel Engine Fire Water Pump (3322-P-004)Document6 pages15no03-Ds-020-006 Diesel Engine Fire Water Pump (3322-P-004)bagus handoko100% (1)

- 13NO03 GN 60 001 Deliverable ListDocument4 pages13NO03 GN 60 001 Deliverable Listbagus handokoNo ratings yet

- 15no03-Ds-60-004. Datasheet BDV & SDVDocument6 pages15no03-Ds-60-004. Datasheet BDV & SDVbagus handokoNo ratings yet

- 15NO03 DS 60 008. Datasheet Temperature GaugeDocument4 pages15NO03 DS 60 008. Datasheet Temperature Gaugebagus handokoNo ratings yet

- #Timeline Sequence Pekerjaan 08 Agustus 2022Document1 page#Timeline Sequence Pekerjaan 08 Agustus 2022bagus handokoNo ratings yet

- Prpoerties VitonDocument4 pagesPrpoerties Vitonbagus handokoNo ratings yet

- Auger Boring Presentation-1Document14 pagesAuger Boring Presentation-1bagus handokoNo ratings yet

- Bukti Transaksi MCU AndriyantoDocument1 pageBukti Transaksi MCU Andriyantobagus handokoNo ratings yet

- #Timeline Sequence Pekerjaan 22 Juli 2022Document1 page#Timeline Sequence Pekerjaan 22 Juli 2022bagus handokoNo ratings yet

- Justifikasi MTO Pipe, Valve & Fitting 14 July 2021 (Update Status) - REKON KOMDAN 17072021Document24 pagesJustifikasi MTO Pipe, Valve & Fitting 14 July 2021 (Update Status) - REKON KOMDAN 17072021bagus handokoNo ratings yet

- #Planning Sequence Pekerjaan 08 Agustus 2022Document1 page#Planning Sequence Pekerjaan 08 Agustus 2022bagus handokoNo ratings yet

- Catalogue - HDD ServicesDocument16 pagesCatalogue - HDD Servicesbagus handokoNo ratings yet

- Drawing Split TeeDocument8 pagesDrawing Split Teebagus handokoNo ratings yet

- Planning Timeline HDD PROJECT - YIA JOGJADocument15 pagesPlanning Timeline HDD PROJECT - YIA JOGJAbagus handoko100% (1)

- Hal 6 - BiDi PigDocument1 pageHal 6 - BiDi Pigbagus handokoNo ratings yet

- c.1. Tool Datasheet HDD-OS-50Document1 pagec.1. Tool Datasheet HDD-OS-50bagus handokoNo ratings yet

- d.1. Tool Datasheet HDD RX-77Document1 paged.1. Tool Datasheet HDD RX-77bagus handokoNo ratings yet

- Baching Solar (1 Tie in Point) - Paralel: ProyekDocument2 pagesBaching Solar (1 Tie in Point) - Paralel: Proyekbagus handokoNo ratings yet

- Calculation Precommisioning CBIIIDocument8 pagesCalculation Precommisioning CBIIIbagus handokoNo ratings yet

- HAL 16 - Bare Foam PigDocument1 pageHAL 16 - Bare Foam Pigbagus handokoNo ratings yet

- A.1. Tool Datasheet HDD-D220X300Document1 pageA.1. Tool Datasheet HDD-D220X300bagus handokoNo ratings yet

- HDD Lesson and LearnDocument10 pagesHDD Lesson and Learnbagus handokoNo ratings yet

- Transmittal Letter: 1 Approved 1 Set BA5-BB-MA-E-ZEL-001 0 Material Approval of Selemite PanelDocument1 pageTransmittal Letter: 1 Approved 1 Set BA5-BB-MA-E-ZEL-001 0 Material Approval of Selemite Panelbagus handokoNo ratings yet

- Daftar Fittings and AccessoriesDocument3 pagesDaftar Fittings and Accessoriesbagus handokoNo ratings yet

- Pig Speed Calculation MBLDocument1 pagePig Speed Calculation MBLbagus handoko50% (2)

- General Piping Plan TLS-5: ProsysDocument19 pagesGeneral Piping Plan TLS-5: Prosysbagus handokoNo ratings yet

- Daftar Material CLCP - TSKDocument2 pagesDaftar Material CLCP - TSKbagus handokoNo ratings yet

- Equipment Name Sheet No. 1 of 3 Tag No.: Hydraulic Power CalcDocument2 pagesEquipment Name Sheet No. 1 of 3 Tag No.: Hydraulic Power Calcbagus handoko0% (1)

- Katalog Twinflex JMO RevDocument1 pageKatalog Twinflex JMO Revbagus handokoNo ratings yet

- CV Bagus Handoko-2021 For MedcoDocument4 pagesCV Bagus Handoko-2021 For Medcobagus handokoNo ratings yet

- Calculation Note - Cathodic Protection For 12in Pipeline - Section A & Section B - Sept 2019Document12 pagesCalculation Note - Cathodic Protection For 12in Pipeline - Section A & Section B - Sept 2019bagus handoko100% (4)

- Company Profle - FBIDocument4 pagesCompany Profle - FBIbagus handokoNo ratings yet

- Mto Pipa HdpeDocument5 pagesMto Pipa Hdpebagus handokoNo ratings yet

- Engineering Deliverables List - 10 Sept 2020Document190 pagesEngineering Deliverables List - 10 Sept 2020bagus handoko100% (1)

- Widos MaxiplastDocument1 pageWidos Maxiplastsealion72No ratings yet

- Unit Rates & Cost Establishment For SSIP AGPDocument65 pagesUnit Rates & Cost Establishment For SSIP AGPketemaNo ratings yet

- Flanges - Hydrostatic Test Pressure PDFDocument8 pagesFlanges - Hydrostatic Test Pressure PDFnoha azamaliNo ratings yet

- Ralston PumpDocument20 pagesRalston Pumpابزار دقیقNo ratings yet

- 3 s2.0 B9780123868886000146 Main PDFDocument27 pages3 s2.0 B9780123868886000146 Main PDFYRNo ratings yet

- First Filling & Emptying of Pressure TunnelsDocument10 pagesFirst Filling & Emptying of Pressure TunnelssdasbdknNo ratings yet

- Perma Pipe - 13-01-19Document13 pagesPerma Pipe - 13-01-19redaNo ratings yet

- The Concrete Required For Arzak Project1Document4 pagesThe Concrete Required For Arzak Project1Yamen Eldehleb.officialNo ratings yet

- SOR 2012-13 - Part-I& Part-IVDocument148 pagesSOR 2012-13 - Part-I& Part-IVkarri1963No ratings yet

- METHOD STATEMENT FOR INSTALLATION OF FCUs: AHU: FAHU - ZARADocument20 pagesMETHOD STATEMENT FOR INSTALLATION OF FCUs: AHU: FAHU - ZARARAJANo ratings yet

- Asme A112.4.1Document12 pagesAsme A112.4.1Ahmed Abd El RahmanNo ratings yet

- Nickel Alloys Monel 400 N04400Document4 pagesNickel Alloys Monel 400 N04400David Balboa VillenasNo ratings yet

- Gantry Crane BrochureDocument28 pagesGantry Crane BrochureThein MaungNo ratings yet

- Adapters - Part Numbering SystemDocument1 pageAdapters - Part Numbering Systemphankhoa83-1No ratings yet

- Bike Repair Stand: A Cycle Support From The Plumbing AisleDocument2 pagesBike Repair Stand: A Cycle Support From The Plumbing AisleMykel VelasquezNo ratings yet

- Yanbu: Export Refinery ProjectDocument6 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- MD 101 Smem Eg Me SPC 0003Document18 pagesMD 101 Smem Eg Me SPC 0003Mike HernandezNo ratings yet

- Water Softener ManualDocument24 pagesWater Softener ManualQuietRideNo ratings yet

- KURD-SPC-PRJ-002 Flange Joint Integrity SpecificationDocument13 pagesKURD-SPC-PRJ-002 Flange Joint Integrity Specificationbmanojkumar16No ratings yet

- Agricultural Mechanics Fundamentals and Applications 7th Edition Herren Solutions Manual DownloadDocument5 pagesAgricultural Mechanics Fundamentals and Applications 7th Edition Herren Solutions Manual DownloadRoberta Fleming100% (24)

- QCS 2014 - Section 21.17-Eelctrical GeneratorDocument19 pagesQCS 2014 - Section 21.17-Eelctrical GeneratorEng. JamalNo ratings yet

- MSS - SP 61 2009 - Pressure Test of Valve PDFDocument9 pagesMSS - SP 61 2009 - Pressure Test of Valve PDFLaylaNo ratings yet

- Lapeta Pipe BrochureDocument5 pagesLapeta Pipe BrochureAnilNo ratings yet

- MFE Introduction PDFDocument22 pagesMFE Introduction PDFMuhamed MahmoudNo ratings yet

- Asco TodasDocument36 pagesAsco TodasEduardo Landa GonzalezNo ratings yet

- PDFDocument63 pagesPDFIsidro MendozaNo ratings yet

- Pec Report KP2488 PDFDocument11 pagesPec Report KP2488 PDFMarcus AntoniusNo ratings yet

- O MC 12 04 012 # 3 - Specification & DrawingDocument5 pagesO MC 12 04 012 # 3 - Specification & DrawingiuliiulianNo ratings yet

- Norma AASHTO M 304Document9 pagesNorma AASHTO M 304Vianey MartinezNo ratings yet