Professional Documents

Culture Documents

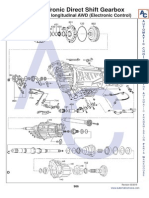

Info For 0B5 Gearboxes

Info For 0B5 Gearboxes

Uploaded by

Catalin BeleaCopyright:

Available Formats

You might also like

- 7-Speed Dual Clutch Gearbox 0B5 (S Tronic)Document237 pages7-Speed Dual Clutch Gearbox 0B5 (S Tronic)ergdeg50% (2)

- 0B5 7-Speed Dual ClutchDocument24 pages0B5 7-Speed Dual ClutchKeldo Gliana93% (94)

- ZF 9 HP 48 ValvebodyDocument26 pagesZF 9 HP 48 Valvebodyสนั่น วิริยะเจริญกุล88% (8)

- Transmision 0CK AudiA62011 UpDocument126 pagesTransmision 0CK AudiA62011 UpCarlos Garcia Godoy87% (30)

- 02E (DQ250) 0BH OBT (DQ500) OB5 (DL501) Inf Tec PDFDocument7 pages02E (DQ250) 0BH OBT (DQ500) OB5 (DL501) Inf Tec PDFFrankkelly Bonilla Frankkelly Bonilla85% (20)

- ZF6HP28 TG PDFDocument94 pagesZF6HP28 TG PDFИгорь Наумов100% (9)

- Holden Commodore VZ Fault CodesDocument5 pagesHolden Commodore VZ Fault Codesashleyshaw0% (1)

- Audi 0B5 TPI 2039534 - Repair Instructions (By Keldo)Document9 pagesAudi 0B5 TPI 2039534 - Repair Instructions (By Keldo)Keldo Gliana100% (3)

- 0B5 7 Speed Dual Clutch PDFDocument24 pages0B5 7 Speed Dual Clutch PDFBalica Lucian80% (5)

- OB5 Transmission InfoDocument98 pagesOB5 Transmission InfoRobert Moreau95% (21)

- 8L90 IntroductionDocument66 pages8L90 IntroductionBrandon100% (6)

- Technical Service Information: The 01J Multitronic®Document75 pagesTechnical Service Information: The 01J Multitronic®Fernando Bas100% (2)

- Audi Ob5 Twin Clutch 7 Speed GearboxDocument4 pagesAudi Ob5 Twin Clutch 7 Speed Gearboxrharaksi80% (5)

- 0aw Manual VWDocument4 pages0aw Manual VWJoaquim Lemos75% (4)

- 0B5 MECHATRONIC - Removing - and - InstallingDocument12 pages0B5 MECHATRONIC - Removing - and - InstallingpecirepiNo ratings yet

- Mercedes 9g-Tronic InfoDocument17 pagesMercedes 9g-Tronic InfoRob LeaneyNo ratings yet

- Seven-Speed Dual-Clutch Gearbox 0B5/S TronicDocument11 pagesSeven-Speed Dual-Clutch Gearbox 0B5/S TronicChristian Pach100% (1)

- Manual Transmision 0BH PDFDocument138 pagesManual Transmision 0BH PDFCarlos Garcia Godoy75% (4)

- Manual Transmision 0GC PDFDocument246 pagesManual Transmision 0GC PDFCarlos Garcia Godoy80% (5)

- Clocky Case Study - Group 1Document7 pagesClocky Case Study - Group 1Souhardya BanerjeeNo ratings yet

- 0CK Gear BoxDocument4 pages0CK Gear BoxCosmin66gmcNo ratings yet

- Running Problems - Restricted Functions - Audi 0B5 GearboxDocument4 pagesRunning Problems - Restricted Functions - Audi 0B5 GearboxKeldo Gliana100% (3)

- PDF 0BH ObtDocument3 pagesPDF 0BH ObtHanschristian Rodriguez Flores100% (3)

- 09K K1 DrumDocument3 pages09K K1 Drumnavifreak0100% (3)

- Manual 0am PDFDocument72 pagesManual 0am PDFCarlos Garcia Godoy100% (9)

- Manual 0AWDocument139 pagesManual 0AWJose garcua vargas 2006401321100% (3)

- Dl501 0b5 Repair ServiceDocument13 pagesDl501 0b5 Repair ServiceAlex Maceira Graterol100% (1)

- TranmisiiDocument15 pagesTranmisiiCătălin-Ionuţ Cioabă100% (2)

- 01J No Drive or Delayed D or R P1743-18151 PDFDocument4 pages01J No Drive or Delayed D or R P1743-18151 PDFsender78100% (1)

- 5r55 OverheatingDocument46 pages5r55 OverheatingAhmed Ali100% (3)

- Subaru 4EATDocument2 pagesSubaru 4EATGuilherme Zoboli100% (1)

- Delphi 7 - Developers GuideDocument1,113 pagesDelphi 7 - Developers GuideJurandi100% (2)

- GX120 160 200 UT2 English PDFDocument61 pagesGX120 160 200 UT2 English PDFRazielboy Kain100% (1)

- Tcu Dsg7 Dq200: Complaints and Error CodesDocument5 pagesTcu Dsg7 Dq200: Complaints and Error CodesEmre YAPICI0% (1)

- Tcu Dsg7 Dq200 - Actronics LTDDocument7 pagesTcu Dsg7 Dq200 - Actronics LTDjawad nassar100% (1)

- SM 22 UnlockedDocument126 pagesSM 22 UnlockedSebastian Gomez Gomez100% (2)

- 0B5 Etails About The SevenDocument19 pages0B5 Etails About The SevenLili100% (3)

- Ob 5Document4 pagesOb 5AdamCzulewicz100% (1)

- 0b5 TransmisionDocument6 pages0b5 TransmisionAnonymous NzJUyHq4100% (3)

- DSG Clutch Removal Tool Set Eng Printer PDFDocument16 pagesDSG Clutch Removal Tool Set Eng Printer PDFMohammed Mochrif100% (1)

- 7 Speed Dual Clutch Gearbox 0bh EngDocument138 pages7 Speed Dual Clutch Gearbox 0bh EngAlex Maceira Graterol100% (7)

- Audi 0AW TSB 37H5 UPDATEDocument21 pagesAudi 0AW TSB 37H5 UPDATEossoski100% (1)

- Reading Hardware Number and Software Version DSGDocument4 pagesReading Hardware Number and Software Version DSGgreemaxNo ratings yet

- DSG 02e SSP - 308 PDFDocument64 pagesDSG 02e SSP - 308 PDFcataroxi100% (2)

- Valve Body and Mechatronic Service PDFDocument44 pagesValve Body and Mechatronic Service PDFSamuel Zuniga100% (4)

- 18b-105-115 Toyota k313 CVT Transmission DCT p2757 TCC Pcs Performance FaultDocument11 pages18b-105-115 Toyota k313 CVT Transmission DCT p2757 TCC Pcs Performance FaultMahsnNo ratings yet

- 1995 Ford Escort 1Document11 pages1995 Ford Escort 1Francisco SanchezNo ratings yet

- 6r140w IntroDocument58 pages6r140w IntroFrank Araya Diaz100% (3)

- Aw60 41sn Zip BookDocument8 pagesAw60 41sn Zip BookRiki Nurzaman100% (3)

- WK Measurement PointDocument8 pagesWK Measurement PointSanda NeumanNo ratings yet

- Attachment PDFDocument2 pagesAttachment PDFJORFRENo ratings yet

- Mercedes Automatic Transmission Conductor PlateDocument4 pagesMercedes Automatic Transmission Conductor PlateAnonymous WzR5h9g8VNo ratings yet

- Document Number: Document TitleDocument8 pagesDocument Number: Document TitletalangocdayNo ratings yet

- Workshop Manual (2006MY) : Service Procedures: SECTION 3 - PowertrainDocument86 pagesWorkshop Manual (2006MY) : Service Procedures: SECTION 3 - PowertrainCarlos Luis Santos Somcar100% (1)

- C-100 Service Training Manual: Automatic Transmission: Participant's HandoutDocument76 pagesC-100 Service Training Manual: Automatic Transmission: Participant's HandoutJarden VegaNo ratings yet

- Automatic ValvesDocument33 pagesAutomatic ValvesManjeet kumarNo ratings yet

- Operation Manual Wj-3 LHDDocument64 pagesOperation Manual Wj-3 LHDJopeth YoussefNo ratings yet

- eVP-500 ManualDocument13 pageseVP-500 ManualGeorgi ShukovNo ratings yet

- Group 10 Engine Control System: 1. CPU CONTROLLER AND ECM (Electronic Control Module)Document7 pagesGroup 10 Engine Control System: 1. CPU CONTROLLER AND ECM (Electronic Control Module)douahchia rachedNo ratings yet

- Electrical Output ComponentsDocument11 pagesElectrical Output ComponentsBroCactusNo ratings yet

- Valve Lash Adjustment Sullair Engine C4Document3 pagesValve Lash Adjustment Sullair Engine C4Rommy SudarnoNo ratings yet

- Toyotaa750 A761 IntroductionDocument81 pagesToyotaa750 A761 IntroductionJohn Eduard Sierra Velandia60% (5)

- 722.6 TruthTable 2Document2 pages722.6 TruthTable 2Jack CarlNo ratings yet

- Iim Indore'S: Integrated Program in Business Analytics (IPBA)Document7 pagesIim Indore'S: Integrated Program in Business Analytics (IPBA)rickykheraNo ratings yet

- Train Gate UPPALDocument38 pagesTrain Gate UPPALIsmail DinarNo ratings yet

- H1 Educationist ProfileDocument13 pagesH1 Educationist ProfileAmit KumarNo ratings yet

- IEEE PES Aug 18 - Corrosion - TDGDocument66 pagesIEEE PES Aug 18 - Corrosion - TDGtekno foniNo ratings yet

- TD-SCDMA Handover Method and Time-Delay Performance AnalysisDocument8 pagesTD-SCDMA Handover Method and Time-Delay Performance Analysisİsmail AkkaşNo ratings yet

- Shift Report: Shift: DAY Team: CDocument3 pagesShift Report: Shift: DAY Team: CdhavalNo ratings yet

- John Ngaya Mukabi, PHD Full CV 23NOV09Document104 pagesJohn Ngaya Mukabi, PHD Full CV 23NOV09John Ngaya MukabiNo ratings yet

- PTS Thermal InsulationDocument44 pagesPTS Thermal InsulationJustin LowNo ratings yet

- SIMATIC S7 S7-1200 Programmable Controller - CPU 1214C Wiring DiagramsDocument4 pagesSIMATIC S7 S7-1200 Programmable Controller - CPU 1214C Wiring DiagramsazzszoNo ratings yet

- GPS Users GuideDocument9 pagesGPS Users GuideSimple SimonNo ratings yet

- PPTC 142Document8 pagesPPTC 142testNo ratings yet

- Saving Reading UploadingDownloading Mechanism of CSV File and Text File Using Csharp AspnetDocument4 pagesSaving Reading UploadingDownloading Mechanism of CSV File and Text File Using Csharp AspnetLajapathy ArunNo ratings yet

- Vehicle Maintenance PDFDocument58 pagesVehicle Maintenance PDFPethuraj100% (1)

- Courses ListDocument2 pagesCourses Listapi-281148847No ratings yet

- Shogun HTDocument5 pagesShogun HTprasadgayuNo ratings yet

- SIMCA 13 Multivariate Batch Process ModelingDocument2 pagesSIMCA 13 Multivariate Batch Process ModelingJbel PiNo ratings yet

- Khubaib Akhtar: Career ObjectiveDocument3 pagesKhubaib Akhtar: Career Objectivekhubaib akhtarNo ratings yet

- DD Security Configuration GuideDocument50 pagesDD Security Configuration GuideRatataNo ratings yet

- Project Report: Project Topic: Role of Prime Bank LTD On Encouraging EntrepreneursDocument2 pagesProject Report: Project Topic: Role of Prime Bank LTD On Encouraging EntrepreneursZahid Bin Islam100% (1)

- Manual Casa de Marcat Sapel Seria HTDocument77 pagesManual Casa de Marcat Sapel Seria HTHendea TeodoraNo ratings yet

- Practical Exercise A51Document5 pagesPractical Exercise A51semuaNo ratings yet

- DTC P0135 Oxyge (A/F) Sensor Heater Circuit (Bank 1 Sensor 1)Document3 pagesDTC P0135 Oxyge (A/F) Sensor Heater Circuit (Bank 1 Sensor 1)Erln Lima100% (1)

- Vocational TrainingDocument34 pagesVocational TrainingTushar SahuNo ratings yet

- Industrial Comm Solutions GuideDocument16 pagesIndustrial Comm Solutions GuideEngSampaio ManoelNo ratings yet

- PC-PRO+ Advanced 9 00 Release NotesDocument8 pagesPC-PRO+ Advanced 9 00 Release NotesBruno De BridaNo ratings yet

- Cloudera Administration Handbook Sample ChapterDocument22 pagesCloudera Administration Handbook Sample ChapterPackt PublishingNo ratings yet

Info For 0B5 Gearboxes

Info For 0B5 Gearboxes

Uploaded by

Catalin BeleaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Info For 0B5 Gearboxes

Info For 0B5 Gearboxes

Uploaded by

Catalin BeleaCopyright:

Available Formats

Tech News

W-BWAWD.OIL01

W-BWAWD.OIL02

VAG 0B5

Torque specification:

Valve body bolts 12Nm

Oil Pan 10Nm

Clutch Clearance:

K1 Clutch (1 / 3 / 5 / 7) 1.5-2.0mm (.059”-.079”)

K2 Clutch (2 / 4 / 6 / R) 1.5-2.0mm (.059”-.079”)

Correct direction of both plates:

Software:

Before even start the repair always see if there is a software update available, this prevents problems

afterwards when repairs are already done.

Attention! Due to the apparent difficulties with programming of certain mechatronic units, Automatic

Choice cannot accept any responsibility for programming of this mechatronic unit.

Oil specifications:

Dry fill 7.5 Ltr

Solenoids:

1-3 Shift Fork Solenoid N433 5 Ohms

7-5 Shift Fork Solenoid N434 5 Ohms

K1 Clutch Control Solenoid N435 15 Ohms

Odd Gear Pressure Regulator N436 5 Ohms *

2-R Shift Fork Solenoid N437 5 Ohms

www.automaticchoice.com

4-6 Shift Fork Solenoid

K2 Clutch Control Solenoid

N438

N439

5 Ohms

15 Ohms

Tech News

Software:

Before even start the repair always see if there is a software update available, this prevents problems

afterwards when repairs are already done.

Attention! Due to the apparent difficulties with programming of certain mechatronic units, Automatic

Choice cannot accept any responsibility for programming of this mechatronic unit.

Oil specifications:

Dry fill 7.5 Ltr

Solenoids:

1-3 Shift Fork Solenoid N433 5 Ohms

7-5 Shift Fork Solenoid N434 5 Ohms

K1 Clutch Control Solenoid N435 15 Ohms

Odd Gear Pressure Regulator N436 5 Ohms *

2-R Shift Fork Solenoid N437 5 Ohms

4-6 Shift Fork Solenoid N438 5 Ohms

K2 Clutch Control Solenoid N439 15 Ohms

Even Gear Pressure Regulator N440 5 Ohms *

Clutch Cooling Oil Solenoid N471 4.5 Ohms *

Main Pressure Control Solenoid N472 4.5 Ohms

( * = part of 0B5.SOL20)

Gear Actuator Adjustment:

Mechatronic up to L31B1137 28mm

Mechatronic from L31B1138 on 32mm

Common failures:

1. Because the PWM solenoids work very hard in these units they are prone to premature wear,

this in turn causes a number of issues with engagement and shift quality, it is also highly

recommended that the valve body loom is replaced with the modified version.

We stock a repair kit for this 0B5.SOL20.

2. Due to a coolant leakage at the Coolant control valve there can go coolant thru the wiring

harness into the mechatronic connector ( see AC News January 2018 )

3. P17E1 can be set if Synchronizer ring from 2nd gear is damaged due to bad alignment while

shifting, fork will not engage properly and get stuck. This recognised by the travel sensor, as

the second gear isn’t fully set.

www.automaticchoice.com

You might also like

- 7-Speed Dual Clutch Gearbox 0B5 (S Tronic)Document237 pages7-Speed Dual Clutch Gearbox 0B5 (S Tronic)ergdeg50% (2)

- 0B5 7-Speed Dual ClutchDocument24 pages0B5 7-Speed Dual ClutchKeldo Gliana93% (94)

- ZF 9 HP 48 ValvebodyDocument26 pagesZF 9 HP 48 Valvebodyสนั่น วิริยะเจริญกุล88% (8)

- Transmision 0CK AudiA62011 UpDocument126 pagesTransmision 0CK AudiA62011 UpCarlos Garcia Godoy87% (30)

- 02E (DQ250) 0BH OBT (DQ500) OB5 (DL501) Inf Tec PDFDocument7 pages02E (DQ250) 0BH OBT (DQ500) OB5 (DL501) Inf Tec PDFFrankkelly Bonilla Frankkelly Bonilla85% (20)

- ZF6HP28 TG PDFDocument94 pagesZF6HP28 TG PDFИгорь Наумов100% (9)

- Holden Commodore VZ Fault CodesDocument5 pagesHolden Commodore VZ Fault Codesashleyshaw0% (1)

- Audi 0B5 TPI 2039534 - Repair Instructions (By Keldo)Document9 pagesAudi 0B5 TPI 2039534 - Repair Instructions (By Keldo)Keldo Gliana100% (3)

- 0B5 7 Speed Dual Clutch PDFDocument24 pages0B5 7 Speed Dual Clutch PDFBalica Lucian80% (5)

- OB5 Transmission InfoDocument98 pagesOB5 Transmission InfoRobert Moreau95% (21)

- 8L90 IntroductionDocument66 pages8L90 IntroductionBrandon100% (6)

- Technical Service Information: The 01J Multitronic®Document75 pagesTechnical Service Information: The 01J Multitronic®Fernando Bas100% (2)

- Audi Ob5 Twin Clutch 7 Speed GearboxDocument4 pagesAudi Ob5 Twin Clutch 7 Speed Gearboxrharaksi80% (5)

- 0aw Manual VWDocument4 pages0aw Manual VWJoaquim Lemos75% (4)

- 0B5 MECHATRONIC - Removing - and - InstallingDocument12 pages0B5 MECHATRONIC - Removing - and - InstallingpecirepiNo ratings yet

- Mercedes 9g-Tronic InfoDocument17 pagesMercedes 9g-Tronic InfoRob LeaneyNo ratings yet

- Seven-Speed Dual-Clutch Gearbox 0B5/S TronicDocument11 pagesSeven-Speed Dual-Clutch Gearbox 0B5/S TronicChristian Pach100% (1)

- Manual Transmision 0BH PDFDocument138 pagesManual Transmision 0BH PDFCarlos Garcia Godoy75% (4)

- Manual Transmision 0GC PDFDocument246 pagesManual Transmision 0GC PDFCarlos Garcia Godoy80% (5)

- Clocky Case Study - Group 1Document7 pagesClocky Case Study - Group 1Souhardya BanerjeeNo ratings yet

- 0CK Gear BoxDocument4 pages0CK Gear BoxCosmin66gmcNo ratings yet

- Running Problems - Restricted Functions - Audi 0B5 GearboxDocument4 pagesRunning Problems - Restricted Functions - Audi 0B5 GearboxKeldo Gliana100% (3)

- PDF 0BH ObtDocument3 pagesPDF 0BH ObtHanschristian Rodriguez Flores100% (3)

- 09K K1 DrumDocument3 pages09K K1 Drumnavifreak0100% (3)

- Manual 0am PDFDocument72 pagesManual 0am PDFCarlos Garcia Godoy100% (9)

- Manual 0AWDocument139 pagesManual 0AWJose garcua vargas 2006401321100% (3)

- Dl501 0b5 Repair ServiceDocument13 pagesDl501 0b5 Repair ServiceAlex Maceira Graterol100% (1)

- TranmisiiDocument15 pagesTranmisiiCătălin-Ionuţ Cioabă100% (2)

- 01J No Drive or Delayed D or R P1743-18151 PDFDocument4 pages01J No Drive or Delayed D or R P1743-18151 PDFsender78100% (1)

- 5r55 OverheatingDocument46 pages5r55 OverheatingAhmed Ali100% (3)

- Subaru 4EATDocument2 pagesSubaru 4EATGuilherme Zoboli100% (1)

- Delphi 7 - Developers GuideDocument1,113 pagesDelphi 7 - Developers GuideJurandi100% (2)

- GX120 160 200 UT2 English PDFDocument61 pagesGX120 160 200 UT2 English PDFRazielboy Kain100% (1)

- Tcu Dsg7 Dq200: Complaints and Error CodesDocument5 pagesTcu Dsg7 Dq200: Complaints and Error CodesEmre YAPICI0% (1)

- Tcu Dsg7 Dq200 - Actronics LTDDocument7 pagesTcu Dsg7 Dq200 - Actronics LTDjawad nassar100% (1)

- SM 22 UnlockedDocument126 pagesSM 22 UnlockedSebastian Gomez Gomez100% (2)

- 0B5 Etails About The SevenDocument19 pages0B5 Etails About The SevenLili100% (3)

- Ob 5Document4 pagesOb 5AdamCzulewicz100% (1)

- 0b5 TransmisionDocument6 pages0b5 TransmisionAnonymous NzJUyHq4100% (3)

- DSG Clutch Removal Tool Set Eng Printer PDFDocument16 pagesDSG Clutch Removal Tool Set Eng Printer PDFMohammed Mochrif100% (1)

- 7 Speed Dual Clutch Gearbox 0bh EngDocument138 pages7 Speed Dual Clutch Gearbox 0bh EngAlex Maceira Graterol100% (7)

- Audi 0AW TSB 37H5 UPDATEDocument21 pagesAudi 0AW TSB 37H5 UPDATEossoski100% (1)

- Reading Hardware Number and Software Version DSGDocument4 pagesReading Hardware Number and Software Version DSGgreemaxNo ratings yet

- DSG 02e SSP - 308 PDFDocument64 pagesDSG 02e SSP - 308 PDFcataroxi100% (2)

- Valve Body and Mechatronic Service PDFDocument44 pagesValve Body and Mechatronic Service PDFSamuel Zuniga100% (4)

- 18b-105-115 Toyota k313 CVT Transmission DCT p2757 TCC Pcs Performance FaultDocument11 pages18b-105-115 Toyota k313 CVT Transmission DCT p2757 TCC Pcs Performance FaultMahsnNo ratings yet

- 1995 Ford Escort 1Document11 pages1995 Ford Escort 1Francisco SanchezNo ratings yet

- 6r140w IntroDocument58 pages6r140w IntroFrank Araya Diaz100% (3)

- Aw60 41sn Zip BookDocument8 pagesAw60 41sn Zip BookRiki Nurzaman100% (3)

- WK Measurement PointDocument8 pagesWK Measurement PointSanda NeumanNo ratings yet

- Attachment PDFDocument2 pagesAttachment PDFJORFRENo ratings yet

- Mercedes Automatic Transmission Conductor PlateDocument4 pagesMercedes Automatic Transmission Conductor PlateAnonymous WzR5h9g8VNo ratings yet

- Document Number: Document TitleDocument8 pagesDocument Number: Document TitletalangocdayNo ratings yet

- Workshop Manual (2006MY) : Service Procedures: SECTION 3 - PowertrainDocument86 pagesWorkshop Manual (2006MY) : Service Procedures: SECTION 3 - PowertrainCarlos Luis Santos Somcar100% (1)

- C-100 Service Training Manual: Automatic Transmission: Participant's HandoutDocument76 pagesC-100 Service Training Manual: Automatic Transmission: Participant's HandoutJarden VegaNo ratings yet

- Automatic ValvesDocument33 pagesAutomatic ValvesManjeet kumarNo ratings yet

- Operation Manual Wj-3 LHDDocument64 pagesOperation Manual Wj-3 LHDJopeth YoussefNo ratings yet

- eVP-500 ManualDocument13 pageseVP-500 ManualGeorgi ShukovNo ratings yet

- Group 10 Engine Control System: 1. CPU CONTROLLER AND ECM (Electronic Control Module)Document7 pagesGroup 10 Engine Control System: 1. CPU CONTROLLER AND ECM (Electronic Control Module)douahchia rachedNo ratings yet

- Electrical Output ComponentsDocument11 pagesElectrical Output ComponentsBroCactusNo ratings yet

- Valve Lash Adjustment Sullair Engine C4Document3 pagesValve Lash Adjustment Sullair Engine C4Rommy SudarnoNo ratings yet

- Toyotaa750 A761 IntroductionDocument81 pagesToyotaa750 A761 IntroductionJohn Eduard Sierra Velandia60% (5)

- 722.6 TruthTable 2Document2 pages722.6 TruthTable 2Jack CarlNo ratings yet

- Iim Indore'S: Integrated Program in Business Analytics (IPBA)Document7 pagesIim Indore'S: Integrated Program in Business Analytics (IPBA)rickykheraNo ratings yet

- Train Gate UPPALDocument38 pagesTrain Gate UPPALIsmail DinarNo ratings yet

- H1 Educationist ProfileDocument13 pagesH1 Educationist ProfileAmit KumarNo ratings yet

- IEEE PES Aug 18 - Corrosion - TDGDocument66 pagesIEEE PES Aug 18 - Corrosion - TDGtekno foniNo ratings yet

- TD-SCDMA Handover Method and Time-Delay Performance AnalysisDocument8 pagesTD-SCDMA Handover Method and Time-Delay Performance Analysisİsmail AkkaşNo ratings yet

- Shift Report: Shift: DAY Team: CDocument3 pagesShift Report: Shift: DAY Team: CdhavalNo ratings yet

- John Ngaya Mukabi, PHD Full CV 23NOV09Document104 pagesJohn Ngaya Mukabi, PHD Full CV 23NOV09John Ngaya MukabiNo ratings yet

- PTS Thermal InsulationDocument44 pagesPTS Thermal InsulationJustin LowNo ratings yet

- SIMATIC S7 S7-1200 Programmable Controller - CPU 1214C Wiring DiagramsDocument4 pagesSIMATIC S7 S7-1200 Programmable Controller - CPU 1214C Wiring DiagramsazzszoNo ratings yet

- GPS Users GuideDocument9 pagesGPS Users GuideSimple SimonNo ratings yet

- PPTC 142Document8 pagesPPTC 142testNo ratings yet

- Saving Reading UploadingDownloading Mechanism of CSV File and Text File Using Csharp AspnetDocument4 pagesSaving Reading UploadingDownloading Mechanism of CSV File and Text File Using Csharp AspnetLajapathy ArunNo ratings yet

- Vehicle Maintenance PDFDocument58 pagesVehicle Maintenance PDFPethuraj100% (1)

- Courses ListDocument2 pagesCourses Listapi-281148847No ratings yet

- Shogun HTDocument5 pagesShogun HTprasadgayuNo ratings yet

- SIMCA 13 Multivariate Batch Process ModelingDocument2 pagesSIMCA 13 Multivariate Batch Process ModelingJbel PiNo ratings yet

- Khubaib Akhtar: Career ObjectiveDocument3 pagesKhubaib Akhtar: Career Objectivekhubaib akhtarNo ratings yet

- DD Security Configuration GuideDocument50 pagesDD Security Configuration GuideRatataNo ratings yet

- Project Report: Project Topic: Role of Prime Bank LTD On Encouraging EntrepreneursDocument2 pagesProject Report: Project Topic: Role of Prime Bank LTD On Encouraging EntrepreneursZahid Bin Islam100% (1)

- Manual Casa de Marcat Sapel Seria HTDocument77 pagesManual Casa de Marcat Sapel Seria HTHendea TeodoraNo ratings yet

- Practical Exercise A51Document5 pagesPractical Exercise A51semuaNo ratings yet

- DTC P0135 Oxyge (A/F) Sensor Heater Circuit (Bank 1 Sensor 1)Document3 pagesDTC P0135 Oxyge (A/F) Sensor Heater Circuit (Bank 1 Sensor 1)Erln Lima100% (1)

- Vocational TrainingDocument34 pagesVocational TrainingTushar SahuNo ratings yet

- Industrial Comm Solutions GuideDocument16 pagesIndustrial Comm Solutions GuideEngSampaio ManoelNo ratings yet

- PC-PRO+ Advanced 9 00 Release NotesDocument8 pagesPC-PRO+ Advanced 9 00 Release NotesBruno De BridaNo ratings yet

- Cloudera Administration Handbook Sample ChapterDocument22 pagesCloudera Administration Handbook Sample ChapterPackt PublishingNo ratings yet