Professional Documents

Culture Documents

BVJFGFSFGFHJKJKL, LKLHKG

BVJFGFSFGFHJKJKL, LKLHKG

Uploaded by

MomenNaeemCopyright:

Available Formats

You might also like

- Power Building PuhelimeenDocument37 pagesPower Building PuhelimeenAleksanteri Kivioja100% (8)

- Epimastic 4100Document2 pagesEpimastic 4100Moin AltafNo ratings yet

- TransactionReceipt 1768222433825 PDFDocument3 pagesTransactionReceipt 1768222433825 PDFNalika SilvaNo ratings yet

- Topsperse GX NDocument2 pagesTopsperse GX NRashid SaleemNo ratings yet

- Rust-Oleum TDSDocument2 pagesRust-Oleum TDSAlen ValiyaveettilNo ratings yet

- Floor Coating Urethane Component Dur A Flex Accelera Application InstructionsDocument2 pagesFloor Coating Urethane Component Dur A Flex Accelera Application InstructionsHectorNo ratings yet

- SPC-15 Specialty Tub Tile Refinishing Kit TDS 1Document2 pagesSPC-15 Specialty Tub Tile Refinishing Kit TDS 1Tom CatNo ratings yet

- Spc-38 Glow in The Dark Max TdsDocument2 pagesSpc-38 Glow in The Dark Max TdsnophiaNo ratings yet

- Tds 55Document3 pagesTds 55ShripadNo ratings yet

- Epilux 8: Product DescriptionDocument2 pagesEpilux 8: Product DescriptionMoin AltafNo ratings yet

- Green Couch QLD, WA and Warmer ClimatesDocument8 pagesGreen Couch QLD, WA and Warmer ClimatesashNo ratings yet

- Denso SeaShield SplashZone UW Epoxy PDFDocument2 pagesDenso SeaShield SplashZone UW Epoxy PDFIker MelladoNo ratings yet

- Epilux 82: Product DescriptionDocument2 pagesEpilux 82: Product DescriptionMoin AltafNo ratings yet

- Epilux 155Document2 pagesEpilux 155Allana100% (1)

- EC TDS IN2 Infusion ResinDocument2 pagesEC TDS IN2 Infusion ResinDiego JimenezNo ratings yet

- Epilux 155Document2 pagesEpilux 155Tejinder KumarNo ratings yet

- Ful-Base Basecoat (IF Quality) : GeneralDocument3 pagesFul-Base Basecoat (IF Quality) : GeneralsikgmcNo ratings yet

- EC TDS EL160 High Temperature Laminating ResinDocument2 pagesEC TDS EL160 High Temperature Laminating ResinDILIGENT AM11No ratings yet

- FRP Joining and Repair Guide PDFDocument12 pagesFRP Joining and Repair Guide PDFArjed Ali ShaikhNo ratings yet

- Shalimar SPL Antifouling Paint RedDocument2 pagesShalimar SPL Antifouling Paint Redinderveer solankiNo ratings yet

- Pds Epilux 218 VocDocument2 pagesPds Epilux 218 VocmuthukumarNo ratings yet

- Product DataDocument2 pagesProduct DatapoerwntiNo ratings yet

- Adesan Rinzaffo Calce: Technical FeaturesDocument4 pagesAdesan Rinzaffo Calce: Technical FeaturesM. BeskriNo ratings yet

- Apcoline 4100Document2 pagesApcoline 4100Moin AltafNo ratings yet

- EPIMASTIC 5100-March 2019 Version 2Document2 pagesEPIMASTIC 5100-March 2019 Version 2PraveenNo ratings yet

- Pds Luxaprime 1400 VocDocument2 pagesPds Luxaprime 1400 VocmuthukumarNo ratings yet

- Plasite 7122 PDSDocument4 pagesPlasite 7122 PDSAdityo AgungNo ratings yet

- Making Port Wine (Northern Brewer) PDFDocument1 pageMaking Port Wine (Northern Brewer) PDFplurimusNo ratings yet

- Epilux 218: Product DescriptionDocument2 pagesEpilux 218: Product DescriptionMoin AltafNo ratings yet

- TR Tds Imron Elite Ex Quality 3.5voc Ups EngDocument4 pagesTR Tds Imron Elite Ex Quality 3.5voc Ups Engforex500No ratings yet

- Hempadur 15130Document2 pagesHempadur 15130MuthuKumarNo ratings yet

- Epilux 800Document2 pagesEpilux 800anandNo ratings yet

- Latapoxy SP 100 TDSDocument3 pagesLatapoxy SP 100 TDSBithika DattaNo ratings yet

- Apcotherm Epn 200Document2 pagesApcotherm Epn 200Moin AltafNo ratings yet

- V2100 System Leak Seal - Technical Data SheetDocument2 pagesV2100 System Leak Seal - Technical Data SheetSameer HyderNo ratings yet

- PRO-08 Galvanizing Sprays TDS 2019Document2 pagesPRO-08 Galvanizing Sprays TDS 2019Gulzar AliNo ratings yet

- Epilux 5: Product DescriptionDocument2 pagesEpilux 5: Product DescriptionShyam ShrishNo ratings yet

- Pds - Epigard TL 543 Hs Finish (f15)Document2 pagesPds - Epigard TL 543 Hs Finish (f15)Sachin SinghalNo ratings yet

- Oasis 8922 Glass Flake EpoxyDocument2 pagesOasis 8922 Glass Flake EpoxyNgpdhdvv KlpmmnnNo ratings yet

- BVV - PD 10 10Document2 pagesBVV - PD 10 10angelsfweNo ratings yet

- Nerolac20Sheen20PDS Min MergedDocument6 pagesNerolac20Sheen20PDS Min MergedRishiNo ratings yet

- ZINC Etching ProcedureDocument3 pagesZINC Etching ProcedureAnderson100% (1)

- Hempel's Fast Dry Primer 120SGDocument2 pagesHempel's Fast Dry Primer 120SGJaydenNo ratings yet

- VAR-05 Varathane Water Based Floor Polyurethane TDSDocument2 pagesVAR-05 Varathane Water Based Floor Polyurethane TDSAdam BeilgardNo ratings yet

- FRP Repair Procedure: NotesDocument1 pageFRP Repair Procedure: NotesIan FletcherNo ratings yet

- PDS HEMPADUR EASY 47700 en GBDocument3 pagesPDS HEMPADUR EASY 47700 en GBharshana divankaNo ratings yet

- 5100 SYSTEM Acrylic Dry Fall Coating: Acrylic Technical Data RO-59Document2 pages5100 SYSTEM Acrylic Dry Fall Coating: Acrylic Technical Data RO-59Chereddy RambabuNo ratings yet

- Electrotemp Cement No. 8Document2 pagesElectrotemp Cement No. 8Manuel Alejandro Pontio RamirezNo ratings yet

- Esco - Protektif Coating KansaiDocument2 pagesEsco - Protektif Coating KansaiSugi. masco.proteksiNo ratings yet

- TDS - Jen Eplx 89 HB PDFDocument1 pageTDS - Jen Eplx 89 HB PDFআফজাল -উল ইসলাম নূরNo ratings yet

- Shellac Flake: Restoration, Repair, & Finishing SuppliesDocument1 pageShellac Flake: Restoration, Repair, & Finishing SuppliesvajdazitaNo ratings yet

- TDC SpecDocument1 pageTDC Specgr8mechanicalNo ratings yet

- Luxathane 5160Document2 pagesLuxathane 5160shameelNo ratings yet

- EPILUX 850 SF VOC Jan-2017Document2 pagesEPILUX 850 SF VOC Jan-2017PraveenNo ratings yet

- Steel Shield 1200Document2 pagesSteel Shield 1200Moin AltafNo ratings yet

- Epimastic 7200 SRDocument2 pagesEpimastic 7200 SRqc_531040655No ratings yet

- LavaCellPower 01Document2 pagesLavaCellPower 01UtpalNo ratings yet

- PDS HEMPELS PHENOLIC EPOXY 163US en-USDocument2 pagesPDS HEMPELS PHENOLIC EPOXY 163US en-USRyan DuhonNo ratings yet

- RoClean L811Document1 pageRoClean L811eduardoNo ratings yet

- Creative Resin: Easy techniques for contemporary resin artFrom EverandCreative Resin: Easy techniques for contemporary resin artNo ratings yet

- Assignment 3Document3 pagesAssignment 3MomenNaeemNo ratings yet

- Fem 15-Me-165Document6 pagesFem 15-Me-165MomenNaeemNo ratings yet

- Overseas HBL Account BiomatricDocument1 pageOverseas HBL Account BiomatricShaza Faizan100% (1)

- MMT 20 QuestionDocument3 pagesMMT 20 QuestionMomenNaeemNo ratings yet

- GuaranteeVerification PDFDocument1 pageGuaranteeVerification PDFMomenNaeemNo ratings yet

- Assignment 1: Moman Naeem 15-ME-167 October 17, 2017Document1 pageAssignment 1: Moman Naeem 15-ME-167 October 17, 2017MomenNaeemNo ratings yet

- XHXFTHFTHTFHFHDocument40 pagesXHXFTHFTHTFHFHMomenNaeemNo ratings yet

- Precision Engineering & Metrology - Lecture 2Document12 pagesPrecision Engineering & Metrology - Lecture 2MomenNaeemNo ratings yet

- Degrees My Tutoring ServiceDocument1 pageDegrees My Tutoring ServiceMomenNaeemNo ratings yet

- 15 ME 171 (Project Report)Document11 pages15 ME 171 (Project Report)MomenNaeemNo ratings yet

- Project Report: Subject: Precision Engineering & MetereologyDocument6 pagesProject Report: Subject: Precision Engineering & MetereologyMomenNaeemNo ratings yet

- KUYKJUYFJKDocument14 pagesKUYKJUYFJKMomenNaeemNo ratings yet

- Degrees My Tutoring ServiceDocument1 pageDegrees My Tutoring ServiceMomenNaeemNo ratings yet

- Gas DynamicDocument10 pagesGas DynamicMomenNaeemNo ratings yet

- Internship CertificateDocument1 pageInternship CertificateMomenNaeemNo ratings yet

- Gas Dynamic 1Document12 pagesGas Dynamic 1MomenNaeemNo ratings yet

- Fabrication of Lamborghini Aventador On An Aluminum Chassis Using Advance Composite TechniquesDocument1 pageFabrication of Lamborghini Aventador On An Aluminum Chassis Using Advance Composite TechniquesMomenNaeemNo ratings yet

- Project Title: Students: Supervisor: Email:: Aneela - Wakeel@uettaxila - Edu.pkDocument1 pageProject Title: Students: Supervisor: Email:: Aneela - Wakeel@uettaxila - Edu.pkMomenNaeemNo ratings yet

- Cosgrove Payment Plan... JulyDocument10 pagesCosgrove Payment Plan... JulyAminu QaluNo ratings yet

- Connectors and LinkersDocument8 pagesConnectors and Linkersuam22No ratings yet

- GEM2xxxManualEN RevD1Document73 pagesGEM2xxxManualEN RevD1Aldo Germán Pavez MoraNo ratings yet

- Laq 1Document2 pagesLaq 1aipoint2007No ratings yet

- Types of Educational Research Design: QuantitativeDocument20 pagesTypes of Educational Research Design: QuantitativeJessica NivashiniNo ratings yet

- Solar Tree-Mutai Write UpDocument22 pagesSolar Tree-Mutai Write UpMutai DanielNo ratings yet

- Defining Engagement Success - Architecture AlignedDocument28 pagesDefining Engagement Success - Architecture AlignedAshish TiwariNo ratings yet

- TEAM ASSIGNMENT BUS 420 Fraser Valley INDIA 2022 WinterDocument4 pagesTEAM ASSIGNMENT BUS 420 Fraser Valley INDIA 2022 WinterRithik KhannaNo ratings yet

- Argumentative Essay Conclusion ExampleDocument6 pagesArgumentative Essay Conclusion Exampleglzhcoaeg100% (2)

- 1-6 Concrete Sleepers PDFDocument16 pages1-6 Concrete Sleepers PDFAndita Tri BudiantoNo ratings yet

- SoapDocument4 pagesSoapSi OneilNo ratings yet

- Electrical Power Supply and DistributionDocument122 pagesElectrical Power Supply and Distributionmmalamuti9325100% (4)

- Final Analysis On Monno PDFDocument6 pagesFinal Analysis On Monno PDFbrsumonNo ratings yet

- Ccie Lab k8Document2 pagesCcie Lab k8sosapabec0% (1)

- Earth and Life Science: (Quarter 2-Module 4/lesson 4/ Week 4) Genetic EngineeringDocument20 pagesEarth and Life Science: (Quarter 2-Module 4/lesson 4/ Week 4) Genetic EngineeringRomel Christian Zamoranos Miano100% (6)

- Bahasa Inggeris Peralihan Penilaian SatuDocument8 pagesBahasa Inggeris Peralihan Penilaian SatuNazurah ErynaNo ratings yet

- CP 864Document5 pagesCP 864ALGAROBA GAMERNo ratings yet

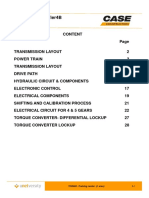

- 06 - Transmission-7-8-921F-14 Sept.15Document29 pages06 - Transmission-7-8-921F-14 Sept.15Franky Fernandez100% (1)

- French Polish - TutorialDocument24 pagesFrench Polish - TutorialAdriano AngelicoNo ratings yet

- Veterinary MicrobiologyDocument53 pagesVeterinary MicrobiologyLicinio Rocha100% (1)

- Fyba Foundtion Course PDFDocument252 pagesFyba Foundtion Course PDFrusa websiteNo ratings yet

- Environmental Hazards Assessment at Pre Saharan Local Scale - Case Study From The Draa Valley MoroccoDocument19 pagesEnvironmental Hazards Assessment at Pre Saharan Local Scale - Case Study From The Draa Valley MoroccoChaymae SahraouiNo ratings yet

- UntitledDocument9 pagesUntitled박준수No ratings yet

- Eee-III-Analog Electronic Circuits m1Document52 pagesEee-III-Analog Electronic Circuits m1My WritingsNo ratings yet

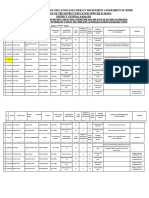

- School Education and Literacy Department Government of Sindh Office of The District Education Officer (E, S&H.S) District Central KarachiDocument15 pagesSchool Education and Literacy Department Government of Sindh Office of The District Education Officer (E, S&H.S) District Central KarachiNaya PakistanNo ratings yet

- Procedure For Return DemonstrationDocument30 pagesProcedure For Return DemonstrationMaria Angelika BughaoNo ratings yet

- Sem 1 12 - 13 AnswerDocument14 pagesSem 1 12 - 13 AnswerBryan LeeNo ratings yet

- Prosec Ii+ ManualDocument1 pageProsec Ii+ ManualBachtiar WidyantoroNo ratings yet

- The Nature of Philosophical AnthropologyDocument8 pagesThe Nature of Philosophical AnthropologyPaul HorriganNo ratings yet

BVJFGFSFGFHJKJKL, LKLHKG

BVJFGFSFGFHJKJKL, LKLHKG

Uploaded by

MomenNaeemOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BVJFGFSFGFHJKJKL, LKLHKG

BVJFGFSFGFHJKJKL, LKLHKG

Uploaded by

MomenNaeemCopyright:

Available Formats

DIRECTIONS FOR POLYESTER HARDENER

5101 Georgia Avenue • West Palm Beach, FL 33405

Ph. 561-588-1001 POLYESTER RESIN/GELCOAT IS CATALYZED WITH MEKP (METHYL ETHYL KETONE PEROXIDE). THE RATIO IS APPROXIMATELY ONE

Fax 561-585-8583 OUNCE OF HARDENER PER GALLON OF RESIN. USE THE FOLLOWING RATIOS FOR SMALLER AMOUNTS.

AMOUNT OF RESIN OR GELCOAT HARDENER AMOUNT

(Colored GELCOATS can

1 OUNCE 10 DROPS

require upto DOUBLE the

1 PINT (16OZ) 1/8 OUNCE amount of hardener shown.

1 QUART (32OZ) 1/4 OUNCE When temperatures are above 85,

regular ratios should be used.)

1/2 GALLON (64OZ) 1/2 OUNCE

1 GALLON 1 OUNCE

THESE AMOUNTS ARE EASILY MEASURED IN THE OUNCE CUP WHICH IS SUPPLIED WITH THE RESIN. THE ABOVE RATIOS SHOULD GIVE YOU A

POT LIFE OF ABOUT 15 TO 20 MINUTES AT 80 DEGREES F. IF YOU ARE SATURATING FIBERGLASS REINFORCEMENT IT SHOULD BE READY TO

RECOAT IN ABOUT 1-1/2 HOURS. TIME WILL VARY FROM WINTER TO SUMMER SINCE HIGHER TEMPERATURES PRODUCE FASTER CURING. THE

RATIO OF HARDENER TO RESIN CAN BE INCREASED OR DECREASED BY 50% TO ADJUST FOR WEATHER, THICKNESS OR YOUR WORKING

PREFERENCE. TEMPERATURES ABOVE 90 DEGREES WILL DEFINITELY REQUIRE A 50% REDUCTION IN HARDENER AMOUNT.

TIPS: ALWAYS MIX THE MEKP INTO THE RESIN FOR AT LEAST 2 MINUTES, UNDERMIXING WILL RESULT IN UNCURED RESIN.

NEVER MIX QUANTITIES LESS THAN ONE OUNCE, EVEN IF YOU ONLY NEED ONE TEASPOON, MIX UP AT LEAST ONE OUNCE

LEAVING MIXED MATERIAL INSIDE YOUR CUP FOR EXTENDED TIME CAN RESULT IN A MUCH FASTER CURE. USE CAUTION

WHEN WORKING BELOW 60 DEGREES, ALWAYS TEST YOUR RESIN TO MAKE SURE YOU ARE GETTING A PROPER CURE.

PLEASE NOTE CAUTIONS ON BOTH THE HARDENER AND THE POLYESTER RESIN. MEKP IS A NASTY CHEMICAL AND YOU SHOULD AVOID GETTING

IT ON YOU. POLYESTER RESIN, GELCOAT AND SURFACING WAX ARE FLAMMABLE. SMOKING OR WORKING CLOSE TO A RUNNING ELECTRICAL

DEVICE OR AN OPEN FLAME SHOULD BE AVOIDED. GLOVES, FACE AND RESIPIRATORY PROTECTION SHOULD ALWAYS BE WORN.

DIRECTIONS FOR SURFACING WAX

SURFACING WAX IS A LIQUID MIXTURE OF STYRENE AND PARAFFIN. WHEN ADDED TO POLYESTER RESIN/GELCOAT ON THE FINAL

LAYERS TO PRODUCE A SLICK, TACK-FREE, MORE EASILY SANDED SURFACE BEFORE PAINTING OR ADDING MORE POLYESTER RESIN/

GELCOAT. THIS WAX IS NOT NEEDED WHEN AN ADDITIONAL LAYER OR POLYESTER RESIN/GELCOAT IS TO BE APPLIED ON TOP. THIS

THIN WAXY LAYER MUST BE REMOVED BY LIGHTLY SANDING AND CLEANING WITH ACETONE BEFORE RE-COATING OR PAINTING.

AMOUNT OF RESIN OR GELCOAT SURFACING WAX REQUIRED Please note:

When using Surfacing Wax with your resin/gelcoat, you

1 OUNCE 20 DROPS

must also add the MEKP(Hardener).

1 PINT (16OZ) 1/4 OUNCE

In temperatures below 70 degrees, the paraffin can

1 QUART (32OZ) 1/2 OUNCE solidify in the bottle. Put the bottle in the sun or in front of

1 GALLON 2 OUNCES a lamp to reliquify. Product is flammable, use caution!

DIRECTIONS FOR POLYESTER HARDENER

5101 Georgia Avenue • West Palm Beach, FL 33405

POLYESTER RESIN/GELCOAT IS CATALYZED WITH MEKP (METHYL ETHYL KETONE PEROXIDE). THE RATIO IS APPROXIMATELY ONE

Ph. 561-588-1001

Fax 561-585-8583

OUNCE OF HARDENER PER GALLON OF RESIN. USE THE FOLLOWING RATIOS FOR SMALLER AMOUNTS.

AMOUNT OF RESIN OR GELCOAT HARDENER AMOUNT

(Colored GELCOATS can

1 OUNCE 10 DROPS

require upto DOUBLE the

1 PINT (16OZ) 1/8 OUNCE amount of hardener shown.

1 QUART (32OZ) 1/4 OUNCE When temperatures are above 85,

regular ratios should be used.)

1/2 GALLON (64OZ) 1/2 OUNCE

1 GALLON 1 OUNCE

THESE AMOUNTS ARE EASILY MEASURED IN THE OUNCE CUP WHICH IS SUPPLIED WITH THE RESIN. THE ABOVE RATIOS SHOULD GIVE YOU A

POT LIFE OF ABOUT 15 TO 20 MINUTES AT 80 DEGREES F. IF YOU ARE SATURATING FIBERGLASS REINFORCEMENT IT SHOULD BE READY TO

RECOAT IN ABOUT 1-1/2 HOURS. TIME WILL VARY FROM WINTER TO SUMMER SINCE HIGHER TEMPERATURES PRODUCE FASTER CURING. THE

RATIO OF HARDENER TO RESIN CAN BE INCREASED OR DECREASED BY 50% TO ADJUST FOR WEATHER, THICKNESS OR YOUR WORKING

PREFERENCE. TEMPERATURES ABOVE 90 DEGREES WILL DEFINITELY REQUIRE A 50% REDUCTION IN HARDENER AMOUNT.

TIPS: ALWAYS MIX THE MEKP INTO THE RESIN FOR AT LEAST 2 MINUTES, UNDERMIXING WILL RESULT IN UNCURED RESIN.

NEVER MIX QUANTITIES LESS THAN ONE OUNCE, EVEN IF YOU ONLY NEED ONE TEASPOON, MIX UP AT LEAST ONE OUNCE

LEAVING MIXED MATERIAL INSIDE YOUR CUP FOR EXTENDED TIME CAN RESULT IN A MUCH FASTER CURE. USE CAUTION

WHEN WORKING BELOW 60 DEGREES, ALWAYS TEST YOUR RESIN TO MAKE SURE YOU ARE GETTING A PROPER CURE.

PLEASE NOTE CAUTIONS ON BOTH THE HARDENER AND THE POLYESTER RESIN. MEKP IS A NASTY CHEMICAL AND YOU SHOULD AVOID GETTING

IT ON YOU. POLYESTER RESIN, GELCOAT AND SURFACING WAX ARE FLAMMABLE. SMOKING OR WORKING CLOSE TO A RUNNING ELECTRICAL

DEVICE OR AN OPEN FLAME SHOULD BE AVOIDED. GLOVES, FACE AND RESIPIRATORY PROTECTION SHOULD ALWAYS BE WORN.

DIRECTIONS FOR SURFACING WAX

SURFACING WAX IS A LIQUID MIXTURE OF STYRENE AND PARAFFIN. WHEN ADDED TO POLYESTER RESIN/GELCOAT ON THE FINAL

LAYERS TO PRODUCE A SLICK, TACK-FREE, MORE EASILY SANDED SURFACE BEFORE PAINTING OR ADDING MORE POLYESTER RESIN/

GELCOAT. THIS WAX IS NOT NEEDED WHEN AN ADDITIONAL LAYER OR POLYESTER RESIN/GELCOAT IS TO BE APPLIED ON TOP. THIS

THIN WAXY LAYER MUST BE REMOVED BY LIGHTLY SANDING AND CLEANING WITH ACETONE BEFORE RE-COATING OR PAINTING.

AMOUNT OF RESIN OR GELCOAT SURFACING WAX REQUIRED Please note:

1 OUNCE 20 DROPS When using Surfacing Wax with your resin/gelcoat, you

must also add the MEKP(Hardener).

1 PINT (16OZ) 1/4 OUNCE

In temperatures below 70 degrees, the paraffin can

1 QUART (32OZ) 1/2 OUNCE

solidify in the bottle. Put the bottle in the sun or in front

1 GALLON 2 OUNCES of a lamp to reliquify. Product is flammable, use caution!

You might also like

- Power Building PuhelimeenDocument37 pagesPower Building PuhelimeenAleksanteri Kivioja100% (8)

- Epimastic 4100Document2 pagesEpimastic 4100Moin AltafNo ratings yet

- TransactionReceipt 1768222433825 PDFDocument3 pagesTransactionReceipt 1768222433825 PDFNalika SilvaNo ratings yet

- Topsperse GX NDocument2 pagesTopsperse GX NRashid SaleemNo ratings yet

- Rust-Oleum TDSDocument2 pagesRust-Oleum TDSAlen ValiyaveettilNo ratings yet

- Floor Coating Urethane Component Dur A Flex Accelera Application InstructionsDocument2 pagesFloor Coating Urethane Component Dur A Flex Accelera Application InstructionsHectorNo ratings yet

- SPC-15 Specialty Tub Tile Refinishing Kit TDS 1Document2 pagesSPC-15 Specialty Tub Tile Refinishing Kit TDS 1Tom CatNo ratings yet

- Spc-38 Glow in The Dark Max TdsDocument2 pagesSpc-38 Glow in The Dark Max TdsnophiaNo ratings yet

- Tds 55Document3 pagesTds 55ShripadNo ratings yet

- Epilux 8: Product DescriptionDocument2 pagesEpilux 8: Product DescriptionMoin AltafNo ratings yet

- Green Couch QLD, WA and Warmer ClimatesDocument8 pagesGreen Couch QLD, WA and Warmer ClimatesashNo ratings yet

- Denso SeaShield SplashZone UW Epoxy PDFDocument2 pagesDenso SeaShield SplashZone UW Epoxy PDFIker MelladoNo ratings yet

- Epilux 82: Product DescriptionDocument2 pagesEpilux 82: Product DescriptionMoin AltafNo ratings yet

- Epilux 155Document2 pagesEpilux 155Allana100% (1)

- EC TDS IN2 Infusion ResinDocument2 pagesEC TDS IN2 Infusion ResinDiego JimenezNo ratings yet

- Epilux 155Document2 pagesEpilux 155Tejinder KumarNo ratings yet

- Ful-Base Basecoat (IF Quality) : GeneralDocument3 pagesFul-Base Basecoat (IF Quality) : GeneralsikgmcNo ratings yet

- EC TDS EL160 High Temperature Laminating ResinDocument2 pagesEC TDS EL160 High Temperature Laminating ResinDILIGENT AM11No ratings yet

- FRP Joining and Repair Guide PDFDocument12 pagesFRP Joining and Repair Guide PDFArjed Ali ShaikhNo ratings yet

- Shalimar SPL Antifouling Paint RedDocument2 pagesShalimar SPL Antifouling Paint Redinderveer solankiNo ratings yet

- Pds Epilux 218 VocDocument2 pagesPds Epilux 218 VocmuthukumarNo ratings yet

- Product DataDocument2 pagesProduct DatapoerwntiNo ratings yet

- Adesan Rinzaffo Calce: Technical FeaturesDocument4 pagesAdesan Rinzaffo Calce: Technical FeaturesM. BeskriNo ratings yet

- Apcoline 4100Document2 pagesApcoline 4100Moin AltafNo ratings yet

- EPIMASTIC 5100-March 2019 Version 2Document2 pagesEPIMASTIC 5100-March 2019 Version 2PraveenNo ratings yet

- Pds Luxaprime 1400 VocDocument2 pagesPds Luxaprime 1400 VocmuthukumarNo ratings yet

- Plasite 7122 PDSDocument4 pagesPlasite 7122 PDSAdityo AgungNo ratings yet

- Making Port Wine (Northern Brewer) PDFDocument1 pageMaking Port Wine (Northern Brewer) PDFplurimusNo ratings yet

- Epilux 218: Product DescriptionDocument2 pagesEpilux 218: Product DescriptionMoin AltafNo ratings yet

- TR Tds Imron Elite Ex Quality 3.5voc Ups EngDocument4 pagesTR Tds Imron Elite Ex Quality 3.5voc Ups Engforex500No ratings yet

- Hempadur 15130Document2 pagesHempadur 15130MuthuKumarNo ratings yet

- Epilux 800Document2 pagesEpilux 800anandNo ratings yet

- Latapoxy SP 100 TDSDocument3 pagesLatapoxy SP 100 TDSBithika DattaNo ratings yet

- Apcotherm Epn 200Document2 pagesApcotherm Epn 200Moin AltafNo ratings yet

- V2100 System Leak Seal - Technical Data SheetDocument2 pagesV2100 System Leak Seal - Technical Data SheetSameer HyderNo ratings yet

- PRO-08 Galvanizing Sprays TDS 2019Document2 pagesPRO-08 Galvanizing Sprays TDS 2019Gulzar AliNo ratings yet

- Epilux 5: Product DescriptionDocument2 pagesEpilux 5: Product DescriptionShyam ShrishNo ratings yet

- Pds - Epigard TL 543 Hs Finish (f15)Document2 pagesPds - Epigard TL 543 Hs Finish (f15)Sachin SinghalNo ratings yet

- Oasis 8922 Glass Flake EpoxyDocument2 pagesOasis 8922 Glass Flake EpoxyNgpdhdvv KlpmmnnNo ratings yet

- BVV - PD 10 10Document2 pagesBVV - PD 10 10angelsfweNo ratings yet

- Nerolac20Sheen20PDS Min MergedDocument6 pagesNerolac20Sheen20PDS Min MergedRishiNo ratings yet

- ZINC Etching ProcedureDocument3 pagesZINC Etching ProcedureAnderson100% (1)

- Hempel's Fast Dry Primer 120SGDocument2 pagesHempel's Fast Dry Primer 120SGJaydenNo ratings yet

- VAR-05 Varathane Water Based Floor Polyurethane TDSDocument2 pagesVAR-05 Varathane Water Based Floor Polyurethane TDSAdam BeilgardNo ratings yet

- FRP Repair Procedure: NotesDocument1 pageFRP Repair Procedure: NotesIan FletcherNo ratings yet

- PDS HEMPADUR EASY 47700 en GBDocument3 pagesPDS HEMPADUR EASY 47700 en GBharshana divankaNo ratings yet

- 5100 SYSTEM Acrylic Dry Fall Coating: Acrylic Technical Data RO-59Document2 pages5100 SYSTEM Acrylic Dry Fall Coating: Acrylic Technical Data RO-59Chereddy RambabuNo ratings yet

- Electrotemp Cement No. 8Document2 pagesElectrotemp Cement No. 8Manuel Alejandro Pontio RamirezNo ratings yet

- Esco - Protektif Coating KansaiDocument2 pagesEsco - Protektif Coating KansaiSugi. masco.proteksiNo ratings yet

- TDS - Jen Eplx 89 HB PDFDocument1 pageTDS - Jen Eplx 89 HB PDFআফজাল -উল ইসলাম নূরNo ratings yet

- Shellac Flake: Restoration, Repair, & Finishing SuppliesDocument1 pageShellac Flake: Restoration, Repair, & Finishing SuppliesvajdazitaNo ratings yet

- TDC SpecDocument1 pageTDC Specgr8mechanicalNo ratings yet

- Luxathane 5160Document2 pagesLuxathane 5160shameelNo ratings yet

- EPILUX 850 SF VOC Jan-2017Document2 pagesEPILUX 850 SF VOC Jan-2017PraveenNo ratings yet

- Steel Shield 1200Document2 pagesSteel Shield 1200Moin AltafNo ratings yet

- Epimastic 7200 SRDocument2 pagesEpimastic 7200 SRqc_531040655No ratings yet

- LavaCellPower 01Document2 pagesLavaCellPower 01UtpalNo ratings yet

- PDS HEMPELS PHENOLIC EPOXY 163US en-USDocument2 pagesPDS HEMPELS PHENOLIC EPOXY 163US en-USRyan DuhonNo ratings yet

- RoClean L811Document1 pageRoClean L811eduardoNo ratings yet

- Creative Resin: Easy techniques for contemporary resin artFrom EverandCreative Resin: Easy techniques for contemporary resin artNo ratings yet

- Assignment 3Document3 pagesAssignment 3MomenNaeemNo ratings yet

- Fem 15-Me-165Document6 pagesFem 15-Me-165MomenNaeemNo ratings yet

- Overseas HBL Account BiomatricDocument1 pageOverseas HBL Account BiomatricShaza Faizan100% (1)

- MMT 20 QuestionDocument3 pagesMMT 20 QuestionMomenNaeemNo ratings yet

- GuaranteeVerification PDFDocument1 pageGuaranteeVerification PDFMomenNaeemNo ratings yet

- Assignment 1: Moman Naeem 15-ME-167 October 17, 2017Document1 pageAssignment 1: Moman Naeem 15-ME-167 October 17, 2017MomenNaeemNo ratings yet

- XHXFTHFTHTFHFHDocument40 pagesXHXFTHFTHTFHFHMomenNaeemNo ratings yet

- Precision Engineering & Metrology - Lecture 2Document12 pagesPrecision Engineering & Metrology - Lecture 2MomenNaeemNo ratings yet

- Degrees My Tutoring ServiceDocument1 pageDegrees My Tutoring ServiceMomenNaeemNo ratings yet

- 15 ME 171 (Project Report)Document11 pages15 ME 171 (Project Report)MomenNaeemNo ratings yet

- Project Report: Subject: Precision Engineering & MetereologyDocument6 pagesProject Report: Subject: Precision Engineering & MetereologyMomenNaeemNo ratings yet

- KUYKJUYFJKDocument14 pagesKUYKJUYFJKMomenNaeemNo ratings yet

- Degrees My Tutoring ServiceDocument1 pageDegrees My Tutoring ServiceMomenNaeemNo ratings yet

- Gas DynamicDocument10 pagesGas DynamicMomenNaeemNo ratings yet

- Internship CertificateDocument1 pageInternship CertificateMomenNaeemNo ratings yet

- Gas Dynamic 1Document12 pagesGas Dynamic 1MomenNaeemNo ratings yet

- Fabrication of Lamborghini Aventador On An Aluminum Chassis Using Advance Composite TechniquesDocument1 pageFabrication of Lamborghini Aventador On An Aluminum Chassis Using Advance Composite TechniquesMomenNaeemNo ratings yet

- Project Title: Students: Supervisor: Email:: Aneela - Wakeel@uettaxila - Edu.pkDocument1 pageProject Title: Students: Supervisor: Email:: Aneela - Wakeel@uettaxila - Edu.pkMomenNaeemNo ratings yet

- Cosgrove Payment Plan... JulyDocument10 pagesCosgrove Payment Plan... JulyAminu QaluNo ratings yet

- Connectors and LinkersDocument8 pagesConnectors and Linkersuam22No ratings yet

- GEM2xxxManualEN RevD1Document73 pagesGEM2xxxManualEN RevD1Aldo Germán Pavez MoraNo ratings yet

- Laq 1Document2 pagesLaq 1aipoint2007No ratings yet

- Types of Educational Research Design: QuantitativeDocument20 pagesTypes of Educational Research Design: QuantitativeJessica NivashiniNo ratings yet

- Solar Tree-Mutai Write UpDocument22 pagesSolar Tree-Mutai Write UpMutai DanielNo ratings yet

- Defining Engagement Success - Architecture AlignedDocument28 pagesDefining Engagement Success - Architecture AlignedAshish TiwariNo ratings yet

- TEAM ASSIGNMENT BUS 420 Fraser Valley INDIA 2022 WinterDocument4 pagesTEAM ASSIGNMENT BUS 420 Fraser Valley INDIA 2022 WinterRithik KhannaNo ratings yet

- Argumentative Essay Conclusion ExampleDocument6 pagesArgumentative Essay Conclusion Exampleglzhcoaeg100% (2)

- 1-6 Concrete Sleepers PDFDocument16 pages1-6 Concrete Sleepers PDFAndita Tri BudiantoNo ratings yet

- SoapDocument4 pagesSoapSi OneilNo ratings yet

- Electrical Power Supply and DistributionDocument122 pagesElectrical Power Supply and Distributionmmalamuti9325100% (4)

- Final Analysis On Monno PDFDocument6 pagesFinal Analysis On Monno PDFbrsumonNo ratings yet

- Ccie Lab k8Document2 pagesCcie Lab k8sosapabec0% (1)

- Earth and Life Science: (Quarter 2-Module 4/lesson 4/ Week 4) Genetic EngineeringDocument20 pagesEarth and Life Science: (Quarter 2-Module 4/lesson 4/ Week 4) Genetic EngineeringRomel Christian Zamoranos Miano100% (6)

- Bahasa Inggeris Peralihan Penilaian SatuDocument8 pagesBahasa Inggeris Peralihan Penilaian SatuNazurah ErynaNo ratings yet

- CP 864Document5 pagesCP 864ALGAROBA GAMERNo ratings yet

- 06 - Transmission-7-8-921F-14 Sept.15Document29 pages06 - Transmission-7-8-921F-14 Sept.15Franky Fernandez100% (1)

- French Polish - TutorialDocument24 pagesFrench Polish - TutorialAdriano AngelicoNo ratings yet

- Veterinary MicrobiologyDocument53 pagesVeterinary MicrobiologyLicinio Rocha100% (1)

- Fyba Foundtion Course PDFDocument252 pagesFyba Foundtion Course PDFrusa websiteNo ratings yet

- Environmental Hazards Assessment at Pre Saharan Local Scale - Case Study From The Draa Valley MoroccoDocument19 pagesEnvironmental Hazards Assessment at Pre Saharan Local Scale - Case Study From The Draa Valley MoroccoChaymae SahraouiNo ratings yet

- UntitledDocument9 pagesUntitled박준수No ratings yet

- Eee-III-Analog Electronic Circuits m1Document52 pagesEee-III-Analog Electronic Circuits m1My WritingsNo ratings yet

- School Education and Literacy Department Government of Sindh Office of The District Education Officer (E, S&H.S) District Central KarachiDocument15 pagesSchool Education and Literacy Department Government of Sindh Office of The District Education Officer (E, S&H.S) District Central KarachiNaya PakistanNo ratings yet

- Procedure For Return DemonstrationDocument30 pagesProcedure For Return DemonstrationMaria Angelika BughaoNo ratings yet

- Sem 1 12 - 13 AnswerDocument14 pagesSem 1 12 - 13 AnswerBryan LeeNo ratings yet

- Prosec Ii+ ManualDocument1 pageProsec Ii+ ManualBachtiar WidyantoroNo ratings yet

- The Nature of Philosophical AnthropologyDocument8 pagesThe Nature of Philosophical AnthropologyPaul HorriganNo ratings yet