Professional Documents

Culture Documents

Al-O With Slag - SUITO 1994

Al-O With Slag - SUITO 1994

Uploaded by

manish pandeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Al-O With Slag - SUITO 1994

Al-O With Slag - SUITO 1994

Uploaded by

manish pandeCopyright:

Available Formats

ISIJ International, Vol. 34 (1 994), No. 2, pp.

177-185

Assessmentof Aluminum-OxygenFquilibrium in Liquid lron and

Activities In CaO-Al203-Si02 Slags

Sung-WookCHO

and Hideaki SUITO

Institute for AdvancedMaterials Processing. Tohoku University. Katahira. Aoba-ku. Sendai. Miyagi-ken, 980 Japan.

(Received on September9. l993, accepted in final form on October 2~ l993)

The equilibrium constant KAI for the reaction: 2~l + 3~=AI203(s) and the first-order interaction parameter

e~1

were estimated at 1873 Kby using the values for the contents of oxygen, aluminumand other components

obtained in slag-metal equilibrium experiments and those for activity of alumina, along with the respective

interaction parameters. The values for log KAI and e~l were found to be 13.3~0.59 and -6.83~0.07.

respectively.

Activities of slag components in the CaO-Al.03-Si02 system were also evaluated at 1873 Kfrom the

values for nitride and sulfide capacities coupled with nitrogen and sulfur distribution ratios. These results

were discussed by comparing with previous values.

KEYWORDS:

slag-metal equilibrium; activityj deoxidation; distribution ratio; Ca0~].03-Si02 slag;

nitrogen, Sulfur

1. Introduction 2Al+3Q=Al203(s) ........ ..........

(1)

of great importance in order

Slag refining in the ladle is

Fromthe equilibrium constant Kl of Eq. (1), the apparent

to produce high-quality, clean steels. Knowledge of

thermodynamic properties, such as the activities in

equilibrium constant, Ki

{

= [masso/o Al]2 [masso/o

O]3},

and the first-order interaction parameters, the following

.

CaO-Al203-Si02 slags whose values by Rein and relation is derived,

Chipmanl) are commonlyused, is required for the better

understanding of the deoxidation and reoxidation

10g Ki + 2~eAXl[masso/oX] + 3~e~[masso/oY] - Iog aAl,0=

phenomena. Although there have been a number of =

-eAOl{2[masso/o O] 1.78[masso/oAl]} -10g Kl "(2)

+

available data on activities, deoxidation equilibrium

constants and interaction parameters in relation to ladle

where Xand Y

represent componentsother than and O

A1, respectively.

refining, these values are still not unambiguously de-

termined due to experimental difficulties.

Thevalues of e~6,8,9) used in this study are summarized

in Table 1. In the derivation of Eq. (2), the terms with

This paper deals with the assessment of the activity

respect to the second-order interaction parameters, the

values in CaO-Si02, CaO-Al203and CaO-Al203-Si02

slags, the equilibrium constant KAI for the reaction: oxygen self interaction parameter, the effect of calcium

2Al + 3Q=Al203(s) and the first-order interaction on oxygen and aluminum and that of magnesiumon

parameter e~1' based on the results obtained in oxygen are neglected. A

Iinear relationship with a slope

previous2 ~ 7) and present sla~~metal equilibrium experi-

of -eAol and an intercept of -log Ki is expected in a

plot of the left hand side of Eq. (2) vs. {2[masso/o O] +

1

ments at 873K. In the estimation of activity, the

1.78[masso/o Al]} term, if the assumption madein the

following three procedures were used; 1) the relation

derivation of Eq. (2) is valid. The relation between

betweennitride capacity, C(N)

{=

(masso/o N) P~/4/P~/2}, •

~)/ the left hand side of Eq. (2) and {2[masso/o O] +

and nitrogen distribution ratio, LN = (masso/o

[masso/o N]}, 2) the intercept of the line in a plot of

{ l.78[masso/o Al]} term is plotted in Fig. 1, using the

the relation between the activities contents of oxygen, aluminumand the other components

of metal components

obtained in previous equilibrium experiments3~7) and

in liquid iron and 3) the relation between sulfide capaci-

the present experiment whoseresults are given in Table

ty, Cs'-{=(masso/o S) P~/2/Psl/2}, • and sulfur distribu-

~)/[~asso/o 2. Experimental details are described elsewhere.4'7) For

tion ratio, Ls

{=

(masso/o S]}.

the values of aAl,0= given in Table 3, the Rein and

Chipman's valuesl) were used except for those in

2. Equilibrium Constant of AluminumDeoxidation and

Interaction Parameter CaO-MgO-Al203slags.7) The slag compositions in

CaO-Al203-Si02 and CaO-Mg(l~Al203 systems are

Deoxidation equilibrium for aluminumis given by denoted by AC, CA, ACS, CAS(see Fig. 9) and ACM,

177 C 1994 iSIJ

ISIJ International, Vol. 34 (1 994), No. 2

MAC.CAM(see Table 2), respectively. The ranges I, CAM).This indicates that the effect ofcalcium on oxygen

II, and 111 shownin be explained next.

Fig. I will is

so strong in the slags with high calcium content, since

The data points in the range I represented by a the terms with respect to the second-order and the self

half-filled mark were neglected in drawing the line. The interaction parameters are negligibly small.

reason for this will be described later. As can be seen The calcium-oxygen equilibrium in liquid iron was

from Fig. 1, the positive deviation from the line was ob- studied by Kimura and Suit06) using a slag-metal

served for the data in CaO-saturated slags (CA. CAS8, equilibration technique. They estimated the values for

the equilibrium constant Kc* for the reaction: CaO(s)

=

Table 1. Interaction

present work.

parameters at 1873K9) used in the

Q

~~+ and the first-order interaction parameter eg• (eco.)

by using the values for the intercepts and the slopes

obtained in three different ranges I, 11 and 111. These

j results are shownin Fig. in which the present data are 2

Al S 0.030

Si 0.056 o~

,N

Al 0.045 ~

co

_6

O Al -3.9 eJO Acs2

Si -0.131 ~ Acs4

[S]

S -0.133 I -8

Q CAs5

Ca (Table 4) ~ X cAs8

N

~~s)

+ cAs9

Al

- 0.028

-o

~o

_10

X

Si

Si

S

O.047

0.056

F~l

cr) _12

AVAA

~{~~~;]~/A~,1itJ~1

.40~r~[]

o v

Al 0.058

+ .,

Si O.

11 -~~>.:~~]

_

>

~: RangeI u,

m

-14

Ca S 140*

--0.072

~ ~!~~.~~

Ac o o

Al >

CA A ~

Si -0.097 ACM[] r]

~16

O (Table 4) ~l

c~]

MAC ~>

S S -0.028 + CAMv v

Al 0.035 ~~ -18

Ca -I lO* eJO

o

O O.1 O.2 0.3 0.4 0.5 0.6

Si 0.063

2[%O]+1.78[%Al]

* Ref. 8) Fig. l.

A plot for the relation expressed by Eq. (2) at 1873 K.

Table 2. Chemical compositions of metal and slag phases obtained in the present experiment,

Metal Slag

[Si] [Mg] [Al] [Ca] [O] [N] (N) (Ca) (Si) (Al) (Mg)

(o/o) (p pm) (ppm) (o/')

ACS2

O,

177 30.3 0.41 39.6 171 17.1 16.4 11.7 27.5

0.183 42.8 0.62 38.0 145 21.8 16.3 lI.4 28.0

O, 140 12.3 0.41 59.4 l 27 13.7 16.2 ll.6 28.1

ACS4

0,800 46.0 1.36 13.7 l 28 57.8 21.4 7.0 29 . 1

O. 93

1 20.5 1.17 25.3 427 69 . 6 21.7 7.4 28.7

0,198 17.7 l.33 23.3 396 76.0 22. l 7.2 28.2

CAS5

O,0571 80.0 2.54 3.1 l 69 52.0 38.2 7.8 15.9

0,176 78.6 3.22 3.9 155 156 38.5 8.0 15.8

O, 12

1 56.4 2.40 4.7 252 lll 39.0 7.3 15.6

CAS8

0,743 1750 15.6 l .8 63.6 143 45.1 3.9 14.8

O.

132 89.8 8.82 2.5 119 69.4 44.3 4.

1 15.0

ACM

0.44 1110 1.52 3.1 49.4 136 21.1 36.0 2,

l

0.32 339 3.38 4.6 177 163 20 . 8 36.5 2.3

MAC 0.20 20.2 1.49 8.2 90 . 2 9.5 22.9 29. l 7,8

0.21 9.33 l .34 9.1 68.6 l I .4 23.l 29.0 7.6

ACM

: 30 Imass .

o/o

Ca0-66 3masso/o A12O3-3 2masso/o MgO

. '

MAC:31.7masso/oCa0-52.9masso/oAl203-14.8masso/oMgO

CAM

: 54 8mass .

o/o Ca0-385masso/o Al 2O3-6 8masso/o MgO

. .

C 1994 ISIJ 178

ISIJ International, Vol. 34 (1 994). No. 2

not included and the values for Kc* and eg•6) are

summarizedin Table 4.

containing MgO. The value for eAOI

= _ 6.83~0.07)

obtained from the slope of the line shownin Fig. I agrees

(

Whenthe effect of calcium on oxygen was taken into well with the reported value of eAOI (= 6.69)). The

account to obtain the data points in the range I in Fig.

_

standard deviation of eAOI

was obtained as 0.07 in the ~

l by using Eq. (2), the data points were found to scatter range of {2[masso/o O] + 1.78[masso/o Al]}>0.1. The

considerably. This is thought to be due to the extremely equilibrium constant for the Reaction (1) in logarithmic

high value for eg•

(

= - 5OOO).Therefore, the data points

in the range I were neglected to estimate the values for

form was estimated as 13.3+0.59 at 1873K from the

intercept of the line, which is in excellent agreementwith

eAOI

and K1 It should be noted that in the equilibrium

'

the reported value of logK1 (= 13.39'10)).

(

given by Eq. 1) the interaction parameters given in Ta-

ble 4 cannot be used for the data in the ranges 11 and 3. Activities in CaO-Al203-Si02 Slags

III. This is because these interaction parameters are

linked up with the values for log Kc* which have no

3.1. Estimation from Nitride Capacity and Nitrogen

Distribution Ratio

thermodynamic meaning. Furthermore, the effect of

magnesiumon oxygen should be considered in the slags A gasslag reaction for nitrogen can be written in an

ionic form for free nitride,

Table 3. vatues for a^*,., *) c(N)**) and c~,-'6) at 1873K. 1/2N2 + 3/2(02-) = (N3 ~) + 31402 """""""(3)

Slag aAl203 log C(N) 10g Cs2- and for incorporated nitrogen

ACS2 0.81

- 11.09 l/2N2+2(O~)=(N~)+ l/2(02~)+31402 """'(4)

ACS4 0.60

- 11.64

CAS5 0.063 12.05 Without respect to the form of nitrogen in slag, however,

-

CAS8 0.0048

- 12.94 nitride capacity C(N) rs defined as,

CAS9 O.066

- II ,84 P~/4/ P~/2

CS - I 1.50 (- 3.45) C(N)

~ (masso/o N) '

, . . . . . . . . .

(5)

AC 0.33

- 12.20 3.48

- The ~i/Si02(s) equilibrium can be expressed by

CA 0.0048

- 12.91

-

2. 05

ACM 0.51*

MAC O.09*

CAM 0.0003* AG~=-816200+216OT (J/mol)9 Io)

* Ref. 7), and the nitrogen dissolution reaction in liquid iron is

() See text. written by

tt

o~

I

~

II III

-4

bJ) l l

o

l

-5 l

l +~~~l~~7F~E~i+O'~o o

~i~~s0>~o tlOOD-lO-~~~

,t:~

~~:~)

-6

l

- l

~i~~;( []

o(J 'A[]D~ ~> Acs2

P~I -7 ~l ACs4

+

~)~;'*~*+~

~~~:1~~

o Q CAs5

~~~c) -8 X CAs8

~ + cAs9

~(Do

vv o cs

~9

-9 O Ac

+ [% Al] O.3 ACA

~,~ -10

[] ACM Fig. 2.

[9if~'

Si] 1.0

~ MAC

eJ)

o v CAM A plot for the deoxidation equilibrium for calcium at

-11 tt 1873 K.6)

o o002 o004 o006 o008 o,cn o.015 0.020

[%Ca] +2.5 1[%O]

Table 4. Values for Kc* and eg• at 1873 K.6)

Range* [olo Ca] +2.51 [~/o O] log Kc* ca

eo o

eca log K12* *

I o.o008

-7.6

10.3

- 5ooo + 400 - 13OOO l 6.0

- 1500

II o.o008 o,003

- - + 0.3 - 600+ 80 l0.6

III

> o.003 -

5.8 + 0.3 -60+4 - 150

7.0

* See Fig. 2.

** FromKc" K6 and K09) (for ll202=Q)'

179 C 1994 ISIJ

ISIJ international. Vol. 34 (1994), No. 2

from a gas-slag equilibration technique,ll) nitrogen

l/2N2=~ ••••••••••••,••••••••••••••••••••••••••••••••••••••..•(7)

distribution ratio, the Si and Al contents obtained from

AG~= 3600+23.9T (J/g'atom)9) the supersaturation experiments4) as well as present

By substituting Po, and PN, obtained from Eqs. (6) and (Table 2) and previous equilibrium experiments4) and the

(7), respectively, into Eq. (5), the following relation is respective interaction parameters listed in Table I .

derived fN4/3 asi/K~/3)

log asio,

= 4/3 Iog(C(N)/LN) + Iog(K6 ' .

C(N)=LN'(K7 as3,/04,)/(K3/4 fN a~,/4) ..........(8)

.

(9)

where LN is the nitrogen distribution ratio defined as The values for log C(N) used in this study are listed in

(masso/o N)/[masso/o N] and the values for K6 and K7 are Table 3. The log asio, values were calculated from Eq. (9)

the equilibrium constants for Eqs. (6) and (7), re- as a function of log[masso/o Si]. The results are shown

spectively. The values for ai and fi are the activity and in Fig. 3, in which the values of Rein and Chipmanl) are

the activity coefficient of i component, respectively, in also indicated by an arrow mark. The asio, values for CS

liquid iron with*respect to a dilute one masso/o standard slags will be explained in Chap. 4. As is clear from Fig.

state .

3, the asio, values agree fairly Rein well with those of

The values

for asio, relative to the solid standard state and Chipman.

can be calculated from the following relation given by The values for aAl,0= and ac*o can also be calculated

Eq. (9), using the values for nitride capacity obtained in a similar mannermentioned above by using the values

for C(N) and LN, the A1 and Cacontents and the respective

1)o CS ACS2 1873K

interaction parameters listed in Tables I and 4. The

> CAS8 ACS4

E~l

+ CAS9 Q CAS5 O

~1)-O-oTF(:~~>0 *HF Rein & Chipman

O ~!' t~l

~l

~]_r~[E~~l-

-2

L~~]~l

1873K 2

O -2

o

o + o

O_

CO

X X -4 ~i-=

-2

X O

eJ)

O

o -6

~ *'---'~~f

-4

l~~;~~~~)~

~~

eJO

O X X

~]E~E!ir~],_.

2

~7[E~~1[E~l

-2 -~I

~~I r~]

o ~~~,-~-/??~'~~\~~_

~>~ ~ Acs2

_Q,Q_~!_S!_~)j~ Q Q

E;1

Acs4

Q G))~ Q

-4 -2 ~tQ~QQ(~)-Q- X

cAs5

cAs8

-~ Rein &Chipman Q C~)

+ cAs9

-3 -2 -1

O 1 -4

-4 -3 -2 -1 O

log [%Si]

log [%Al]

Fig. 3. Activity of Si02(s) calculated from Eq. (9) vs. silicon

content in logarithmic form. Half-filled marks re- Fig. 4. Activityof Al203(s) calculated by using the values for

present the data calculated by using the values for Cs' - C(N)11)and LN vs, aluminium content obtained from

and Ls'2) present and previous4) works.

Table 5. Estimated activities relative to the solid standard state in CaO-Si02, CaO-Al203 and CaC~Si02~1203slags at

1873 K.

from C(N) and LN (from Cs2- and Ls) from intercepts in Figs. 5and 6

Slag

log asi02 log aAl203 log acao log aA~203 log acao

ACS2 + 16 - I ,43 + O. 13 + O. 11 +0.14

+ O. 10 1.69

- O.63 0.63

.68

- 0.97

O. O,

- -

ACS4 - I .99 + 0.23 O.95 + 0.40

- .87 +0.41 - I + 13 - 0.99 + O. Il - l.44 +0. 14

CAS5 -3.39+0.15 I -0,1 1+0,33 I,92 +0, 12 -0.067 + 0.35

- 3.35 -

CAS8 -4.5 1+ 0.22 -0.93 + 0.83 -3.18+0,17 0.82 + 0.76

- 0.62 + 0.66 -

CAS9 - 2.34 + 0.07 - + O. 13 - I .60 + 0.40

,OO 0,49

- 0.76 + 0,30 -

1.37 +0.02

CS - I .20 + O. 17* I

- .08 + O.

AC - 0.57 + 0.23 - I + 13

(- 0.90 ~0.23)

CA - 2.82 + 0.4 1

- 15+

O. O.44

(- 2.62 ~0.40)

* Values obtained from Cs' - and Ls are included.

C 1994 ISIJ 180

ISIJ International, Vol. 34 (1994), No. 2

results for aAl,o, are shown in Fig. as a function of 4 Activities of A1203in CaO-A1203-Si02Slags relative

log[masso/o Al]. It can be seen that the results obtained to the solid standard state can be calculated from the

are significantly different from those reported by Rein intercepts in Fig. 5, by using the equilibrium constant

and Chipman,1) despite the fact that those for asio, are Klo and the asio, values obtained from C(N) and LN. These

in satisfactory agreement with their values. This dis- values are summarized in Table 5. The aAl,o, values

crepancy is not certain at present. The values for asio,, obtained from intercepts are in good agreement with

aAl,o, and ac*o are summarizedin Table 5. those obtained in Sec. 3.1.

3.2. Estimation from the

Re]ation between Metal

The siliconcalcium equilibrium is expressed as,

Componentsin Liquid lron 2~~~+Si02(s)=2CaO(s) +~i •••••••••••••••(12)

The silicon-aluminum equilibrium can be expressed Using the equilibrium constant K12 of Eq. (12), the

by Eqs. (1) and (6) as,

following equation is derived.

3Si+ 2Al203(s)= 4~l + 3Si02(s) .................(10) log ac* + I/2 Iog K12

AGl0=65.8300-107.2T (J/mol)9'10)

= I/2 Iog aSi + I/2 (2 Iog ac.o ~ Iog as,o ) (1 3)

Using the equilibrium constant Klo of Eq.(lO), the fol-

lowing relation is deduced. In the equilibrium given by Eq. (12), the interaction

parameters given in Table 4can be used, if the equilibrium

log aAl

= 3/4 Iog asi constant K12 is modified by the respective values for Kc*'

+ l/4(2 Iog aAl,o, ~3

Iog asio, + Iog Klo) -"-'(1 l) The values for ecO. and log K12 given in Table 4were used

for the calculation of the left hand side of Eq, (1 3) using

The values for aAl and asi Werecalculated by using the

A1 and Si contents obtained in the present equilibrium the previous4) and present equilibrium results, along

experiments and the previous equilibrium and super- with the values for the A1 and Si contents below O.3 and

saturation experiments4) together with the respective 1.O masso/o, respectively. Thesevalues are plotted against

interaction those for log asi in Fig. 6, where a linear relationship with

parameters. The relations betweenaAl and asi

in logarithmic form for different slag compositions ar'~~"e a slope of l/2 as predicted from Eq. (1 3) is approximate-

ly observed except for CAS8slags. Activities of CaOin

shown in Fig. 5, indicating the linear relationship with

a slope of 3/4 as predicted from Eq. (1 l). It should be

CaO-A1203-Si02slags relative to the solid standard

pointed out that the values in equilibrium experiments state can be obtained from the intercepts in Fig. 6, by

using the equilibrium constant K12 and the asiO, values

agree well with those in supersaturation experiments

represented by a half-filled obtained from the values for C(N) and LN. These values

mark. This suggests that the

reaction expressed by Eq. (lO) is not affected by the are given in Table 5. The ac*o values obtained from the

intercepts agree closely with those obtained in Sec. 3.1.

content of oxygen.

The values for asio, are plotted in CaO-Si02-AIO1.5

-1 phase diagrarn in Fig. 7, indicating the reasonable

ACs2

agreement with those of Rein and Chipman.1) However,

the values for aAlo*:= and ac.o Plotted

L9 ~] Acs4 in Figs.

8 and 9,

_2 o~ cAS5

o

A~ CAs8

+ cAs9

~ Acs2 1873K

*3 -1 ~! Acs4 3

~) cAS5

X

'~~\'_

/A\ X cAS8

X 2

l)~1:/A/ + cAs9

~1 l! Ir> -2

1

cu /2~ ~E~i

~l!J1 x+

ll'~/ItA

X

~ l!~i]

'*F_r~l

/ c~

~~

X

O

-1

~

IL

/ e~~)/Q'~l~/

*3 eJ)

O

c~

3 -1

~Ll!

-2 -4

+ 2 ~)-Q;/_/11

Q ~l

~

nj]

oi)'~ ~1 ~~e)

('1 ~O Q 2

O

*3

~1 ~i~~)j>~>

O

E~1~1*~l~/Eg

~g~/

If~

~~

17r ~ 1873K

-1

lr:~~~ _/~~;~:~ep!~

-4 *2

*3 -2 - 1 O 1 v

-3

log aS!:

*2 -1 O 1

Fig. 5. Relation between aAl and asi logarithmic form

expressed by Eq. (1 l). Half-filied

m log asj

marks represent the

data for the supersaturation experiments.4) Fig. 6.

A plot for the relation expressed by Eq. (13).

181 C 1994 ISIJ

ISIJ lnternational, Vol. 34 (1 994). No. 2

asi02 SiO 2

cs S2A6

(0,063

40

0.20

C3S O. 10

C2S .

05 Al O1.5

CAS9 0.025

80

ACS2

(O,0046) 0.010 (0.11) 20

'\_ACS4

CAS5 0.005 Fig. 7.

(0,00041) 10-3 (0.010) CAI2

CaO CAS8

(0,000031) .\ 10 -4 CA4

Activities of Si02(s) along with the values of Rein

and Chipmanin CaO-Si02-AIO1.5 phase diagram

at 1873 K.

CaO 20 40 60 80 AIO1.5

(mol %)

aAlol'5 SiO 2

S2A6

60 40

/ ,,/,

O. 25

C3s

C2S AIO1.5

CAS9 O.75 ACS2

80 (0.46) ,,

20

(O.48)

CAS5 ACS4 CAI2

(0.11) (0.33) Fig. 8.

CaO cAS8 Activities of AIO1.5(s) along with the values of Rein

(0.024) CA4

and Chipmanin CaO-Si02-AIOi Phase diagram

5

CA at 1873 K.

20 AC

CaO (0.042)

60 (0.44)

80 AIO1.5

(mol 9{:.)

a(~o SiO 2

0.003

S2A6

cs 0.005 40

(0,025~

0.01

C3S 0.02 \\

80

C2S

CAS9

(0.072)

0.05 \\ \ ACS2

\(0.021)

Al O1.5

20

CAS5 O.

I

0.82 ACS4 CA12 Fig. 9.

(O.037) Activities

0.2 of CaO(s) along with the values of Rein

CaO CAS8 0.5

CA4

(0.13) O and Chipmanin Ca(:~Si02~101.s Phase diagram

at 1873K.

CA AC

CaO 20 (0.71)

60 (0.083)

80 AIO1.5

(mol %)

which are the average values obtained in above Figs. IO 1

to 2. The experimental uncertainty obtained in

mentioned two methods, are significantly different from the values of ac,o, aAl,o, and asio, Ieads to the marked

those of Rein and Chipman.1) deviation from the previous values of AG;-

The free energy of formation (AG;) of CaO6Al203, '

The activities of Si02 in logarithmic form at the slag

CaO2Al203 and 2CaOSi02 are shownin Figs. 10, 11

' ' compositions saturated with lime and alumina crucibles

and 12, respectively. The free energy of formation of are plotted against the mole fraction of Si02 in Fig. 13,

CaO6Al203 Wascalculated by using the present values

'

along with the results by other investigators.1'20,23,24)

for ac.o and aAl'o, obtained in ACS2slags. The AGf The values by other investigators except for those of

values for CaO2Al203 (ACS4, AC) and for 2CaOSi02

' '

Rein and Chipman1) were recalculated using the same

(CAS5, CAS9)were also calculated by using the present value of AG~as that of Rein and Chipman.1) As can

values for the respective activities. As a result, the values be seen from Fig. 13, the asiO, values estimated in the

of 197.5 kJ/mol for ACS2(CaO 6Al203), 120. I kJ/ present study agree well with those of Rein and Chip-

-

mol for ACS4(CaO 2Al203),

-

90.5kJ/mol for AC

'

- '

manl) and Kay and Taylor.24) The reason for the dis-

(CaO 2Al203), 127.7kJ/mol for CAS5(2CaO Si02) agreement of the present estimated values for aAl,o, and

'

-

and 165.8 kJ/mol for CAS9(2CaO Si02) are markedly

'

- '

ac*o With those by Rein and Chipmanis not clear at

different from those of previous worksl'l2 ~ 22) shownin

present, although the relation between the activities of

C 1994 ISIJ 182

ISIJ International, Vol. 34 (1994), No. 2

o o

CaOeruc. Al203 cruc.

-1

v.~('~/

A~I

//

Allibcrt ct al.

~!

o

~

-50

~~\

Hailstedt Nagata et ai. Fujisawa

O

ct al. 6~~

-2

/

/

/

~

Kumar& Kay COc'o

/ /

.~ _3

/

,* eJ)

O O

-100

-4

/

CaO•6A 12O3 -5

~ 1873K

/

Rein& Chipman -- -- •

Langenbergct

Ozturk

al.

& Fruchan

-150 Kay &Taylor O This work

80O 1200 1600 2000 -6

O 0,2 0.4 O O.2 0.4

Temp./ K

XSi02

Fig. lO. The free energy of formation of Ca0•6Al203 from

solid CaOand Al203.12- 15,18] Fig. 13. Logarithm of activity of Si02(s) vs, mole fraction of

Si02 at 1873 K.

o 2

1873K c:~o

o

Allibcrt Fujisawa ct al.

O

~ti

et

r OO

(~c~~d!~)~r:;_*~i~l~~D~)(?,(?~O~

~\_ ~-Kumar&Kay camcronet al. AC

'!~)

-

'

~~5'~C~'i~)

~-~

1)O'-•,t~~ 'f~L~~_.J"'O.:iJ_

l'\. Nagata ct al,

j-C] O (D) *1

o~ -50 H~tllstedt

Ot

'D ti)

--

1)O -2

:!~

o

Kor &Richardson o

O -3

*~

.*

~

Rcin & Chipman

~

eJ)

A

J:~

A J~JI~:~

-100 -2 ~

O J~..~

IL AA ~L_Is~c~~~;~L~A~efd:i~~~~,~~L_

-3 CA ~r~J~~: Al)~'A"~2~~~Ae~'~

~A

-4

~ ~

CaO•2Al 2O3 ~

-5

-15O

1200 1600 2000 -6

-~ Rein & Chipman

800

-5 -4 -3 -2 -1

O 1

Temp. /K log [%Al]

Fig. Il. The free energy of formation of Ca0•2Al203 from Fig. 14. Activity of Al203(s) vs, aluminum content in

solid CaOand Al203.1'12- 18)

logarithmic form. Open and half-filled marks re-

present the data calculated by using the values for

-50

C(N)11) and

L 3 6) and those for -26) and Ls'3,5,25)

C

respectively; Ieft half-filled marks by Inoue et a!.3)

and Tanabe and Suit05] and right half-filled marks

2CaO•SiO 2 by Ozturk and Turkdogan.25)

metal componentsshowsa good linearity and the values

os

-100 for aAl203 and ac.o obtained from the intercepts of the

lines are consistent with those obtained from the values

Langcnberg ct al.

~~ of C(N) and LN. Moredetailed study is necessary to clarify

.~ Barin et al. & Macfarlanc

Cartcr this discrepancy.

,*

~ -150 Rcin & Chipma~~~~l

Sharrna &Richardson 4. Activities in CaO-Si02and CaO-Al203Slags

4. 1. Estimation from Nitride Capacity and Nitrogen

Distribution Ratio

-200

The values for asi02 and acao in CaO-Si02 slags

800 1200 1600 2000 saturated with CaOcrucible (CS) and those for aAl203

and ac.o in CaO-Al203slags saturated with Al203(AC)

Temp./ K and CaO(CA)crucibles can be obtained from the results

for C(N)11) and LN2,3,6) in the

Fig. 12. The free energy of formation of 2CaO'Si02 from manner similar to that

solid CaOand Si02'1'19-22) mentioned in Sec. 3.1. The data in equilibrium experi-

183 C 1994 ISIJ

ISIJ International, Vol. 34 (1 994), No. 2

ments where the Al and Si contents are below 0.3 and and Cs'- and Ls are -0.72~0.28 and -2.74~0.41 for

1.Omasso/o, respectively, were used to estimate the ac*o ACand CAslags, respectively, and these are in reasona-

values in CS, andAC CA

slags. The results are sum- ble agreement with the values of Rein and Chipman.1)

marized in Table The asiO, values in CSslags and the

5. The asio, values in CSslags can also be estimated in a

aAl,0= values in and AC CA

slags are plotted in Figs. similar mannerusing the values for Cs'- and Ls' Since

3 and 14 by an open mark, respectively, indicating a the Cs'- value for CSslags is not available at 1873 K,

reasonable agreement with the values by Rein and this value

was estimated to be - 3.45 from the results

Chi pman.i ) obtained at 1773K by Carter and Macfarlane21) and

4.2. Estimation from Sulfide Capacity and Sulfur Dis- Sharmaand Richardson22) and those obtained at 1923 K

tribution Ratio by extrapolating the Cs'- values of Fincham and

Richardson27) and Abrahamand Richardson28) to the

Agas-slag reaction with respect to sulfur can be written

2CaOSi02 • saturated composition, whereas the values

in an ionic form as,

by Carter and Macfarlane21) and Fincham and

Richardson2 7) were corrected by the newersulfur-oxygen

ll2S2 + (02~) = (S2 ~) + 11202 """"""""(14)

gas equilibrium data.28) The Ls values by Inoue and

Using the equilibrium constant K14 of Reaction (14), Suit02)

sulfide capacity Cs'- is defined as, were used in this study. The results are shown

by a half-filled mark in Fig. 3, along with those from

Cs'- ~: (mass Vo S) P~/2/Pi/2 ...........(1 5) C(N) and LN by an open mark. Both results are in good

agreement with each other. It can be seen from Figs. 3

The ~!/A1203(s) equilibrium can be written by and 13 that the asio, value in CSslag agrees well with

Al+ 31402= l/2A1203(s) ...............................(16) those obtained by other investigators.1'20,24)

AG16=-776800+188.8T (J/mol)9'10) 5. Conclusions

and the reaction for sulfur dissolution in liquid iron is

represented by The following conclusions were derived from the

assessment of previous and present results obtained in

1/2S2 =~ ••••••••••••••••••••••••••••••••••••,,••,,•••,••••••••••(17)

sla~~metal experiments.

AG17= 135 100+23.4T (J/g'atom)9) (1) The equilibrium constant for the reaction: 2A1+

- 30=Al203(s) in logarithmic form and the first-order

By substituting Po, and Ps, obtained from Eqs. (16) and interaction parameter e~1 were estimated to be 13.3 0.59

(17) into Eq. (15), the following relation is derived ~

and -6.83 0.07 at 1873 K, respectively.

~activities

Cs'-

= Ls ' (K17 alA{~0,)1(K~~3 fs

' • '

a2A(3)

..........

(18) (2) The for Si02 in CaOAl203-Si02slags

obtained from the values of C(N) and LNagreed well with

where Ls is the sulfur distribution ratio defined as those reported by Rein and Chipmanand by Kay and

(masso/o S)/[masso/o S] and the values for K16 and Ki7 Taylor. However, the values for aAl,0= and ac.o Were

are the equilibrium constants for Eqs. (16) and (17), significantly different from their values.

respectively. The values for ai and fi are the activity and (3) The values for asio, in CaO-Si02slags and those

the activity coefficient i

of component, respectively, in for aAl=0, in CaO-Al203slags estimated from Cs'- and

liquid iron with respect to a dilute one masso/o standard Ls agreed with those obtained from C(N) and LN. These

state . values as well as the ac*o Values in CaO-Si02 and

The aA1,0, values in CaO-Al203slags can be estimat- CaO-A1203slags were in reasonable agreement with

ed from the following relation given by Eq. (19), using those by Rein and Chipman.

the Cs'- values obtained in slag-metal experiments2s)

or gas-slag equilibrium experiments26) at 867 K, and 1 REFERENCES

Ls Values obtained in slag-metal equilibrium experi- R. H. Rein and

l) J. chipman: Trans. Metatt, soc. AIME, 233

ments.3'5,25)

(1965), 415.

2) R. Inoue and H. Suito: Metall. Trans. B, 23B (1992), 613.

= 3Iog(Cs' a~l/KI

fs3

log aAl,o,

-

/Ls) +Iog(KI 6

' . 7)

3) R. Inoue, H. Inoue and H. Suito: ISIJ Int., 31 (1991), 1389.

.(19) 4) F. Tamuraand H. Suito: Metall. Trans. B, 24B (1993), 121.

5) J. Tanabeand H. Suito: CAMP-ISIJ, 6(1993), 1058.

In the present work, the Cs'- values by Hino et al.26) 6) T. Kimura and H. Suito: Metall. Trans. B, 25B (1994). Feb.

3

given in Table were chosen for and CAslags in AC 7) T. Kimura: Master of Engineering Thesis, Tohoku University,

order to estimate the aA~,0= values. The results are (1993).

5

summarized in Table and are plotted in Fig. 14 by 8) Recommended Values of Equilibrium Constant for Steelmaking

Reaction, The 19th Committee (Steelmaking), The Japan Soc.

a mark; a

half-filled mark by Inoue et

left half-filled

Promotion of Sci., Rep. No. 10588 (Nov. 1984).

al.3)and Tanabeand Suitos) and a right half-filled mark G. K. Sigworth and J. F.

by Ozturk and Turkdogan.25) The values of Rein and

9) EIliott: Met. Sci.,

8 (1974), 298.

l O) J. F. Elliott, M. Gleiser and V. Ramakrishna: Thermochemistry

Chipmanl) are also indicated by an arrow mark. It can 1

for Steelmaking, Vol. 2, Addison-Wesley, Massachusetts, 963)

( .

be seen from Fig. 14 that the results obtained from Cs'- 11) K. Tomiokaand H. Suito: ISIJ Inl., 31 (1991), 1316; Steel Res.,

63 (1992), 1.

and Ls agree with those obtained from C(N) and LN, al-

though the data points scatter considerably. The av- l 2) M. Allibert, C. Chatillon, K. T. Jacob and R. Lourtau: J. Am.

Ceram. Soc., 64 (1981), 307.

erage values of logaAl,o, obtained from C(N) and LN 13) R. V. Kumarand D. A. R. Kay: Metall. Trans. B, 16B (1985),

C 1994 ISIJ 184

ISIJ International, Vol. 34 (1994), No. 2

l 07 .

York, (1958), 65.

14) K. Nagata, J. TanabeandK. S. Goto: Tetsu-to-Hagan~,75(1989), 21) P. T. Carterand T. G. Macfarlane: J. Iron Steel Inst., 185 (1957),

2023 .

62.

15) T. Fujisawa, C. Yamauchiand H. Sakao: Tetsu-to-Hagan~, 76 22) R. A. Sharmaand F. D. Richardson: J. Iron Steel Inst., 200

(1990), 368. (1962), 373.

16) J. Cameron.T. B. Gibbons and J. Taylor: J. Iron Steel Inst., 204 23) B. Ozturk and R. J. Fruehan: Meta!l. T,'ans. B, 18B (1987), 746.

(1966), 1223. 24) D. A. R. Kay and J. Taylor: Trans. Faraday Soc., 56 (1960), 1372.

17) G. J.W.Kor and F.D.Richardson: J. Iron Steellnst.,206 (1968), 25) B. Ozturk and E. T. Turkdogan: M:et. Sci., 18 (1984) 299.

700. 26) M. Hino, S Kitagawa and S. Ban-ya: Tetsu-to-Hagan~, 79 (1993),

18) B. Hallstedt: Am. Ce,'am. Soc., 73 (1990), 15.

J. 34.

19) I. Barin, O. Knacke and O. Kubaschewski: Thermochemical 27) F. D. Richardson and C. J. B. Fincham: J. Iron Stee[ Inst., 178

Properties of Inorganic Substances, Supplement. Springer-Verlag, (1954), 4.

Berlin and NewYork, (1977). 28) K. P. Abrahamand F. D. Richardson: J. Iron Steel Inst. 196

20) F. C.Langenberg. H.Kaplan and J. Chipman:Physicai Chemistry (1960), 313.

of Steelmaking, ed. by J, F, Elliott, John Wiley and Sons, New

185 C 1994 ISIJ

You might also like

- Is: 8887:2018Document13 pagesIs: 8887:2018Indira Banerjee100% (7)

- Methodology For FabricationDocument35 pagesMethodology For FabricationBhushan KumarNo ratings yet

- Colloid Chemistry in Mineral ProcessingDocument429 pagesColloid Chemistry in Mineral ProcessingNataniel Linares100% (1)

- Chemistry Investigatory ProjectDocument5 pagesChemistry Investigatory ProjectHarsh Gupta0% (2)

- Estimating Viscosities in Iron and Steelmaking Slags in The Cao-Al O - Mgo-Sio - (Tio) System With Basis On A Thermodynamic ModelDocument7 pagesEstimating Viscosities in Iron and Steelmaking Slags in The Cao-Al O - Mgo-Sio - (Tio) System With Basis On A Thermodynamic ModelMaiman LatoNo ratings yet

- Temperature Dependence of The Electrical Conductivity of Salicylaldazinate Metal ChelatesDocument4 pagesTemperature Dependence of The Electrical Conductivity of Salicylaldazinate Metal ChelatesBereket YohanisNo ratings yet

- Structuer Ag, Au, PT Lee2003 (VDE - Exper)Document12 pagesStructuer Ag, Au, PT Lee2003 (VDE - Exper)ht117No ratings yet

- Mathematical Slag-Metal Steelmaking Model: Expression Process by OuadraticDocument10 pagesMathematical Slag-Metal Steelmaking Model: Expression Process by OuadraticMaiman LatoNo ratings yet

- 8.self Diffusion in AluminumDocument6 pages8.self Diffusion in Aluminum이상벽No ratings yet

- Results in Physics: SciencedirectDocument12 pagesResults in Physics: SciencedirectMelis YararNo ratings yet

- Processing Microstructure and Mechanical Strength of Reaction Bonded Al2O3 Ceramics 2003 Ceramics InternationalDocument10 pagesProcessing Microstructure and Mechanical Strength of Reaction Bonded Al2O3 Ceramics 2003 Ceramics InternationalaryamesaNo ratings yet

- Roasting Reduction Kinetics of An Indonesian Nickeliferous Laterite OreDocument7 pagesRoasting Reduction Kinetics of An Indonesian Nickeliferous Laterite OreIoannis KapageridisNo ratings yet

- SL - PAP - G.Zhang K.Chou - 2009 - Simple Method For Estimating The Electrical Conductivity of Oxide Melts WitDocument6 pagesSL - PAP - G.Zhang K.Chou - 2009 - Simple Method For Estimating The Electrical Conductivity of Oxide Melts WitEduardo CandelaNo ratings yet

- WT% Oxides ReportedDocument2 pagesWT% Oxides ReportedSAMIR ENRIQUE MENDEZ PINEDANo ratings yet

- Revie% 14, (Camg (Co3) 2) T J. F.: Physical 10 Raman SpectraDocument3 pagesRevie% 14, (Camg (Co3) 2) T J. F.: Physical 10 Raman SpectraSaulNo ratings yet

- Physical Properties of Al-R MeltsDocument4 pagesPhysical Properties of Al-R MeltsJohn YjabNo ratings yet

- Adv. Funct. Mater. 2016, 26, 7955-7964 Supp (MOH)Document21 pagesAdv. Funct. Mater. 2016, 26, 7955-7964 Supp (MOH)Chuah Chong YangNo ratings yet

- RR PDFDocument5 pagesRR PDFBekraoui KeltoumNo ratings yet

- Al-O Deoxidation Part 3 - With MNDocument11 pagesAl-O Deoxidation Part 3 - With MNmanish pandeNo ratings yet

- 60 - Isijint 2020 101Document14 pages60 - Isijint 2020 101Satadal GhoraiNo ratings yet

- Excess of Calcium Oxide Alloy by Raman SpectraDocument2 pagesExcess of Calcium Oxide Alloy by Raman SpectraKalyan VillariNo ratings yet

- Slag Metal ReactionsDocument7 pagesSlag Metal ReactionsEr Dikshant Malhotra100% (1)

- The Physical Chemistry of Inoculation of Cast IronDocument10 pagesThe Physical Chemistry of Inoculation of Cast IronDon_GostavitoNo ratings yet

- Slag/metal Reactions During Ladle Treatment With Focus On DesulphurisationDocument23 pagesSlag/metal Reactions During Ladle Treatment With Focus On DesulphurisationwefewfwefNo ratings yet

- Lattice Energy and Chemical PredicitionDocument7 pagesLattice Energy and Chemical PredicitionGuadalupeNo ratings yet

- Rapid Solidification of Cu-25at.% Ni Alloy: Molecular Dynamics Simulations Using Embedded Atom MethodDocument7 pagesRapid Solidification of Cu-25at.% Ni Alloy: Molecular Dynamics Simulations Using Embedded Atom MethodThanh DinhNo ratings yet

- 1997 CST Creep of Al MMCs With SiC, Al2O3 and TiB2 ParticlesDocument6 pages1997 CST Creep of Al MMCs With SiC, Al2O3 and TiB2 Particlesyaswanth1992No ratings yet

- Effect of Slag Composition On Desulfurization and Inclusion Modification During Ladle Furnace RefiningDocument7 pagesEffect of Slag Composition On Desulfurization and Inclusion Modification During Ladle Furnace RefiningBoujemaa DrifNo ratings yet

- Of In: The Kinetics Carbonyl Formation AsphaltDocument8 pagesOf In: The Kinetics Carbonyl Formation AsphaltArief Fath100% (1)

- Matsumoto 1995Document6 pagesMatsumoto 1995lic.escobar2018No ratings yet

- 10.1515 htmp.2001.20.3-4.185Document10 pages10.1515 htmp.2001.20.3-4.185ajayNo ratings yet

- Prediction of Element Transfer in Submerged Arc WeldingDocument12 pagesPrediction of Element Transfer in Submerged Arc Weldingsn200709No ratings yet

- The Lamb Shift of Hydrogen and Low-Energy Tests of QedDocument30 pagesThe Lamb Shift of Hydrogen and Low-Energy Tests of QedTL NarasimhamNo ratings yet

- Anexo 2. Smith-Acidity Scale For Oxides 1987Document2 pagesAnexo 2. Smith-Acidity Scale For Oxides 1987Ivan ArroyoNo ratings yet

- SL - PAP - M.Tanahashi N.Furut - 2001 - Phase Equilibria of The MnO-SiO2-CrOx System at 1873K Under Controlled OxygDocument7 pagesSL - PAP - M.Tanahashi N.Furut - 2001 - Phase Equilibria of The MnO-SiO2-CrOx System at 1873K Under Controlled OxygEduardo CandelaNo ratings yet

- Mechanism and Kinetics of Oxygen Reduction On Porous La SR Coo ElectrodesDocument10 pagesMechanism and Kinetics of Oxygen Reduction On Porous La SR Coo ElectrodessinytellsNo ratings yet

- Silicon Resistivity BehaviourDocument7 pagesSilicon Resistivity BehaviourarashmasNo ratings yet

- Madelung ConstantDocument8 pagesMadelung Constantsarthak100% (1)

- Use of Phase Diagrams in Studies of Refractories CorrosionDocument19 pagesUse of Phase Diagrams in Studies of Refractories CorrosionVictorNo ratings yet

- Copper Solubility in Matte Smelting Slag: Molten Slags, Fluxes and Salts '97 Conference - 329Document11 pagesCopper Solubility in Matte Smelting Slag: Molten Slags, Fluxes and Salts '97 Conference - 329Álvaro JaraNo ratings yet

- Estudo Sobre Propriedades de Nanocompostos de AlDocument7 pagesEstudo Sobre Propriedades de Nanocompostos de AlAssis RochaNo ratings yet

- Sulfide Capacity of The Cao-Sio2-Mno Slag at 1 873 K: Isij International September 2011Document33 pagesSulfide Capacity of The Cao-Sio2-Mno Slag at 1 873 K: Isij International September 2011joyNo ratings yet

- 1 s2.0 S1387181123000628 MainDocument10 pages1 s2.0 S1387181123000628 Mainsambitachoudhury95No ratings yet

- Thermodynamic Properties of CaCO 3 Calcite and AraDocument9 pagesThermodynamic Properties of CaCO 3 Calcite and AramakramNo ratings yet

- Thermodynamics On The Formation of Spinel Nonmetallic Inclusion in Liquid Steel PDFDocument4 pagesThermodynamics On The Formation of Spinel Nonmetallic Inclusion in Liquid Steel PDFRasul BzNo ratings yet

- Electrical Conductivity and The Surface Characteristics of Kaolinitic Clays and Clay-Humic Acid ComplexesDocument6 pagesElectrical Conductivity and The Surface Characteristics of Kaolinitic Clays and Clay-Humic Acid ComplexesLarisa ChindrișNo ratings yet

- Geometry Optimization and UV.vis Spectra of Organometallic ChalconesDocument8 pagesGeometry Optimization and UV.vis Spectra of Organometallic ChalconesdiamandshutupNo ratings yet

- Fletcher 2005Document7 pagesFletcher 2005Vidyadhara VNo ratings yet

- Overconsolidated Case StudyDocument13 pagesOverconsolidated Case StudyChub BokingoNo ratings yet

- Effect of Chromium On Tensile and Fatigue Behaviour of Copper Nickel Spinodal AlloyDocument8 pagesEffect of Chromium On Tensile and Fatigue Behaviour of Copper Nickel Spinodal AlloyTJPRC PublicationsNo ratings yet

- CRE Assignment-1 GATE-19 (Answer)Document5 pagesCRE Assignment-1 GATE-19 (Answer)AjitNo ratings yet

- On The Planar Periodic Table: Tidjani NégadiDocument6 pagesOn The Planar Periodic Table: Tidjani NégadiRudolf KiraljNo ratings yet

- Modeling The High-Pressure Behavior of Binary Mixtures of Carbon Dioxide+Alkanols Using An Excess Free Energy Mixing RuleDocument8 pagesModeling The High-Pressure Behavior of Binary Mixtures of Carbon Dioxide+Alkanols Using An Excess Free Energy Mixing RulejuanNo ratings yet

- Estimation of Corrosion Kinetics ParametersDocument16 pagesEstimation of Corrosion Kinetics ParametersFelipe Cepeda SilvaNo ratings yet

- Cesium NumbersDocument31 pagesCesium NumbersNicola BarrettNo ratings yet

- Desulphurization by Slag TreatmentDocument22 pagesDesulphurization by Slag TreatmentanandvinaygeraNo ratings yet

- CPL 252 384Document5 pagesCPL 252 384YashonathSubramanianNo ratings yet

- Effect of Ce On Stainless Steel Performance During Electroslag Remelting (Esr)Document4 pagesEffect of Ce On Stainless Steel Performance During Electroslag Remelting (Esr)X800XLNo ratings yet

- О-Acetylation of 4-Hydroxybenzoic Acid with Acetic AnhydrideDocument6 pagesО-Acetylation of 4-Hydroxybenzoic Acid with Acetic AnhydrideRichaNo ratings yet

- Removal of Hydrogen, Nitrogen and Sulphur From Tool Steel During Vacuum DegassingDocument7 pagesRemoval of Hydrogen, Nitrogen and Sulphur From Tool Steel During Vacuum DegassingRasul BzNo ratings yet

- SL - PAP - G.Zhang B.Yan - 2011 - Relation Between Viscosity and Electrical Conductivity of Silicate MeltsDocument4 pagesSL - PAP - G.Zhang B.Yan - 2011 - Relation Between Viscosity and Electrical Conductivity of Silicate MeltsEduardo CandelaNo ratings yet

- Experimental Thermodynamics and Surface Properties of Ag-Cu-Ge Solder/Braze AlloysDocument11 pagesExperimental Thermodynamics and Surface Properties of Ag-Cu-Ge Solder/Braze AlloysDilmurod JuraevNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: FundamentalsFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: FundamentalsNo ratings yet

- Cubic Formalism - Jacob 2013Document8 pagesCubic Formalism - Jacob 2013manish pandeNo ratings yet

- 05-10-2021 - Primary Steelmaking 1 - SlidesDocument8 pages05-10-2021 - Primary Steelmaking 1 - Slidesmanish pandeNo ratings yet

- MM439: Iron and Steel MakingDocument12 pagesMM439: Iron and Steel Makingmanish pandeNo ratings yet

- MM439: Iron and Steel Making: Course ContentsDocument11 pagesMM439: Iron and Steel Making: Course Contentsmanish pandeNo ratings yet

- Tire Cord Review-ZhangDocument12 pagesTire Cord Review-Zhangmanish pande100% (1)

- Al-O Deoxidation Part 3 - With MNDocument11 pagesAl-O Deoxidation Part 3 - With MNmanish pandeNo ratings yet

- Pelton Bale1986 ModifiedInteractionParameterFDocument5 pagesPelton Bale1986 ModifiedInteractionParameterFmanish pandeNo ratings yet

- Kinetic FundamentalsDocument26 pagesKinetic Fundamentalsmanish pandeNo ratings yet

- IRN Format Rev 0Document1 pageIRN Format Rev 0shaheenkm88No ratings yet

- New Customer ListDocument34 pagesNew Customer ListMTI Materials Technical Sales-VimalNo ratings yet

- Technical College of Engineering Department of Petrochemical CourseDocument6 pagesTechnical College of Engineering Department of Petrochemical CourseBryar HusenNo ratings yet

- Acrylamide Tertiary Butyl Sulfonic AcidDocument2 pagesAcrylamide Tertiary Butyl Sulfonic AcidocalensNo ratings yet

- High-Concentration Synthesis of Sub-10-Nm Copper NanoparticlesDocument8 pagesHigh-Concentration Synthesis of Sub-10-Nm Copper NanoparticlesAshpavi ArunNo ratings yet

- Wa0017.Document7 pagesWa0017.Nischal Reddy SareddyNo ratings yet

- Art and Craft Defined Grade 6 - 084245Document14 pagesArt and Craft Defined Grade 6 - 084245alooben2No ratings yet

- Acknowledment 2 3: Topic Page NumberDocument31 pagesAcknowledment 2 3: Topic Page NumberDeepChacNo ratings yet

- Material Tech SpecsDocument8 pagesMaterial Tech SpecsSachin JawaleNo ratings yet

- Welding Map and Monitoring Field Weld Actifity Bbe Tahap 2Document13 pagesWelding Map and Monitoring Field Weld Actifity Bbe Tahap 2Cak NhassNo ratings yet

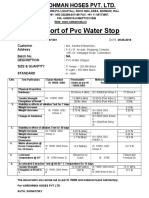

- Test Report of PVC Water Stop: Customer: Address: Batch No.: Na Description: Size & Quantity: StandardDocument1 pageTest Report of PVC Water Stop: Customer: Address: Batch No.: Na Description: Size & Quantity: StandardR.ThangarajNo ratings yet

- Oh Xmas TreeDocument11 pagesOh Xmas TreeCarla HegedűsNo ratings yet

- SIKA Product Information ChartDocument32 pagesSIKA Product Information ChartPrateek ModyNo ratings yet

- 3-StrataTex HSR Brochure - Web - StarWallDocument8 pages3-StrataTex HSR Brochure - Web - StarWallshurl88No ratings yet

- Biogon N Liquid E941: Nitrogen For FoodstuffsDocument2 pagesBiogon N Liquid E941: Nitrogen For FoodstuffsTamar MakhviladzeNo ratings yet

- 2 Concrete (Hand Mixed)Document10 pages2 Concrete (Hand Mixed)Cloud NyeinNo ratings yet

- Acids Bases SaltsDocument10 pagesAcids Bases SaltsGauri ChirwatkarNo ratings yet

- Acoustic Energy Absorption Properties of Fibrous Materials A Review PDFDocument47 pagesAcoustic Energy Absorption Properties of Fibrous Materials A Review PDFFloreaNo ratings yet

- PK-ANQ - Related SB Sundowner C23 - TPU 13Document3 pagesPK-ANQ - Related SB Sundowner C23 - TPU 13Rivaldo Alfaridzki AviadiNo ratings yet

- Maraging Steel Data SheetDocument2 pagesMaraging Steel Data SheetdavideNo ratings yet

- Fibre Reinforced ConcreteDocument16 pagesFibre Reinforced ConcreteSîdDhàñt SätYãmNo ratings yet

- LS Copper Wire Rod: Leading SolutionDocument12 pagesLS Copper Wire Rod: Leading SolutionhuynhvanquynhNo ratings yet

- P BLOCK Class 12Document26 pagesP BLOCK Class 12Parth BajajNo ratings yet

- This Study Resource Was: Properties and Testing MaterialsDocument5 pagesThis Study Resource Was: Properties and Testing MaterialsStephanie Love T. BaringNo ratings yet

- Midterm Es 404Document4 pagesMidterm Es 404Ian GaleonNo ratings yet

- Block Elements Class 12Document15 pagesBlock Elements Class 12Åmìßhã PŕãťãpNo ratings yet