Professional Documents

Culture Documents

4.7. Standard Pressures Obtained From This Process

4.7. Standard Pressures Obtained From This Process

Uploaded by

Ahmed Mohamed Abd ElhakamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.7. Standard Pressures Obtained From This Process

4.7. Standard Pressures Obtained From This Process

Uploaded by

Ahmed Mohamed Abd ElhakamCopyright:

Available Formats

4.7.

Standard pressures obtained from this process

The standards for each product establish the working pressures for each piping series and application (domestic hot water or heating)

according to the previous calculations. The table below summarises the working pressures for each class of application and material,

according to the aforementioned standards, for the piping series S5:

Working pressures

APPLICATION CLASS PB PEX PP-R PE-RT I PP-RTC PVC-C

Domestic hot water at 60º Class 1 10 6 6 6 6 8

Domestic hot water at 70º Class 2 10 6 4 4 6 8

Heating at low temperature Class 4 10 8 6 6 6 -

Heating at high temperature Class 5 8 6 - 4 4 -

* Pressures in bar.

* Categories 4 and 5 are not applicable for PVC-C.

4.8. Dimensional equivalences

In accordance with the above, and in view of the availability of standardised dimensions for each material, the correspondence of

commercial piping between materials is set out below.

The equivalence shall be made according to the internal diameter, which is what provides the flow and defines the nominal diameter

(ND) in Central European countries, as opposed to the Spanish criterion of defining the ND by the external diameter, as indicated in

the product standards. Remember that, beyond the following equivalence, the final selection is determined by the designer, but that

in any event plastic piping, and especially PB, permits higher fluid velocities, so the interior diameters of the pipes are always smaller.

Galvanised steel CLASS 2 / 10 bar CLASS 2 / 8 bar PP-R CLASS 2 / 6 bar CU (DIN1786)

PEX CLASS 2 / 10 bar STAINLESS

DIN2440/2448 PB PP-R Series 2.5 (SDR 6) Series 3.2 (SDR 7.4) STEEL

ND Inches De Di De Di SDR De Di De Di De Di

10 3/8” 17.2 12.5 15* 11.6 9 --- --- --- --- 15 13.0

10 3/8” 17.2 12.5 16* 12.4 9 --- --- 16 11.6 15 13.0

15 ½” 21.3 16.0 20 15.4 9 25 16.6 20 14.4 18 16.0

20 ¾” 26.9 21.6 22 18 11 --- --- 25 18.0 22 19.6

20 ¾” 26.9 21.6 25 20.4 11 32 21.2 --- --- --- ---

25 1” 33.7 27.2 28** 23.0 11 --- --- --- --- 28 25.6

25 1” 33.7 27.2 32 26.2 11 40 26.6 32 23.2 28 25.6

32 1 ¼” 42.4 35.9 40 32.6 11 50 33.4 40 29.0 35 32.0

40 1 ½” 48.3 41.8 50 40.8 11 63 42.0 50 36.2 42 39.0

50 2 60.3 53.0 63 51.4 11 75 50.0 63 45.8 54 51.0

65 2 ½” 76.1 68.8 75 61.4 11 90 60.0 75 54.4 76.1 72.0

80 3” 88.9 80.8 90 73.6 11 110 73.4 90 65.4 88.9 85.0

100 4” 114.3 105.3 110 ** 90.0 11 125 83.4 110 79.8 108.0 103.0

(125) (102.2) 11

125 5” 139.7 131.7 125 ** 102.2 11 160 106.8 133.0 127.0

(160) (130.8) 11

150 6” 168.3 159.3 160 130.8 11 159.0 153.0

* Considered ½” due to the greater flow rate permitted in PB

* * Official conversion by the manufacturer

Note: Due to its low roughness, PB piping can transport fluid at higher velocities, therefore small-

er diameters can be used to transport the same flow.

32

You might also like

- The Stregth, Fracture Toughnees and Low Cycle 17-4PH PDFDocument11 pagesThe Stregth, Fracture Toughnees and Low Cycle 17-4PH PDFLarissaNo ratings yet

- Evaluattive Study If Autophoretic Coating Performance PDFDocument1 pageEvaluattive Study If Autophoretic Coating Performance PDFjchemNo ratings yet

- 2004 Timbre To DissonanceDocument4 pages2004 Timbre To DissonancetgraubaenaNo ratings yet

- HDPE Pipe Catalogue PDFDocument12 pagesHDPE Pipe Catalogue PDFRadicalNo ratings yet

- Submetal (2) HdpeDocument5 pagesSubmetal (2) HdpeEmilAbdoNo ratings yet

- U PVCDocument12 pagesU PVCGeorge SobhyNo ratings yet

- Pressure Nominal - PN: Cto60 C Considering The Change ofDocument5 pagesPressure Nominal - PN: Cto60 C Considering The Change ofCarlos KraljevicNo ratings yet

- Pipe Quality Manual 1Document1 pagePipe Quality Manual 1Nasir AhmadNo ratings yet

- Upvc Pressure CatalogueDocument7 pagesUpvc Pressure CatalogueAmir ShahzadNo ratings yet

- Installation and Maintenance Guidelines For Nibco Butterfly Valves With Rubber SeatsDocument16 pagesInstallation and Maintenance Guidelines For Nibco Butterfly Valves With Rubber SeatsJosé marinNo ratings yet

- NP Pressure Pipe SystemDocument11 pagesNP Pressure Pipe SystemMustafa AlluhaibiNo ratings yet

- Pipe Wall ThicknessDocument2 pagesPipe Wall ThicknessTomi Kazuo0% (1)

- NEISCO HDPE PIPES CatalougeDocument16 pagesNEISCO HDPE PIPES CatalougeAhmed HussienNo ratings yet

- Parvatiudyog HDPE CatalogueDocument11 pagesParvatiudyog HDPE CataloguesathishNo ratings yet

- Brochure Valen TechnologiesDocument12 pagesBrochure Valen TechnologiesLakshay UniplarNo ratings yet

- HDPE Pipe SizesDocument6 pagesHDPE Pipe SizesAshar HassanNo ratings yet

- Part A: Piping and Instrumentation DiagramDocument33 pagesPart A: Piping and Instrumentation Diagramwavhal maheshNo ratings yet

- Upvc Pipe PDFDocument1 pageUpvc Pipe PDFSuman MaityNo ratings yet

- Aqua Terra Product Catalouge Open by Illustrator 20-01-2020 UpdatedDocument24 pagesAqua Terra Product Catalouge Open by Illustrator 20-01-2020 UpdatedOsama sayedNo ratings yet

- Technical Guidelines For HydroPlast U-PVC FittingsDocument20 pagesTechnical Guidelines For HydroPlast U-PVC FittingsOsama AhmedNo ratings yet

- PE Pipe Wallthickness Mass Table DIN8074 PDFDocument3 pagesPE Pipe Wallthickness Mass Table DIN8074 PDFzoveisiNo ratings yet

- Basics of Piping EngineeringDocument43 pagesBasics of Piping EngineeringAyushNo ratings yet

- Hdpe Pipe Specifications PDFDocument5 pagesHdpe Pipe Specifications PDFawanarifNo ratings yet

- Liebherr LTM1050 4 Ratings ChartDocument4 pagesLiebherr LTM1050 4 Ratings Chartساحرة العيونNo ratings yet

- Liebherr 50TDocument18 pagesLiebherr 50TAbdelali WafiNo ratings yet

- CI2400 BS2400 Product DataDocument6 pagesCI2400 BS2400 Product DataDaniel BrownNo ratings yet

- U-Pvc Sewage & Drainage Piping System: Plastic Pipes & Fittings Factory Yousif Khalid Al-Adasani EstDocument12 pagesU-Pvc Sewage & Drainage Piping System: Plastic Pipes & Fittings Factory Yousif Khalid Al-Adasani EstCarlos Benjamin BC100% (1)

- Nexum Technical DataDocument8 pagesNexum Technical DatadesignsNo ratings yet

- HDPE Pipe Dimensions and Pressure Ratings1 - P.E.S CoDocument2 pagesHDPE Pipe Dimensions and Pressure Ratings1 - P.E.S CoJGon100% (1)

- Air CondenserDocument40 pagesAir CondenserAlvaro DiazNo ratings yet

- Iso 4162Document2 pagesIso 4162Guillermo TorresNo ratings yet

- 2006 National Standard Plumbing Code ILLUSTRATED 397&398Document2 pages2006 National Standard Plumbing Code ILLUSTRATED 397&398Hussain Al SanonaNo ratings yet

- PIPE - Pipe Wall ThicknessDocument1 pagePIPE - Pipe Wall ThicknessVishal MistryNo ratings yet

- Bondstrand 2400 Series Product Data: Uses and ApplicationsDocument4 pagesBondstrand 2400 Series Product Data: Uses and ApplicationsChristopher Kenneth ChoaNo ratings yet

- Wall Thickness Chart For HDPE Pipes As Per IS:4984:1995Document3 pagesWall Thickness Chart For HDPE Pipes As Per IS:4984:1995Manish03011983No ratings yet

- Erw Steel Tubes (Black & Galvanized) Conforming To Is:1239 (Pt-1) / Bs:1387 & Structural Tubes Conforming To Is:1161Document1 pageErw Steel Tubes (Black & Galvanized) Conforming To Is:1239 (Pt-1) / Bs:1387 & Structural Tubes Conforming To Is:1161dyke_enggNo ratings yet

- HDPEThickness ChartDocument3 pagesHDPEThickness ChartM Jamal SUltanNo ratings yet

- 2wt Arita Ci Bfly VLV Uni Flanged MalaysiaDocument2 pages2wt Arita Ci Bfly VLV Uni Flanged MalaysiaannaomarNo ratings yet

- Pipe Series: Wall Thickness and MassDocument24 pagesPipe Series: Wall Thickness and MassTammam HassanNo ratings yet

- TD01077E - Design Specs Heavy Duty PDFDocument4 pagesTD01077E - Design Specs Heavy Duty PDFPacifier NothingfaceNo ratings yet

- NPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'Document1 pageNPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'SUJIT PATELNo ratings yet

- Engineering Manual: Contents PageDocument32 pagesEngineering Manual: Contents PageLambas TinambunanNo ratings yet

- Sprinkler Temperature RefferenceDocument1 pageSprinkler Temperature RefferenceFardin ShawonNo ratings yet

- 管径计算表Document11 pages管径计算表Ascend032No ratings yet

- Ficha SSV InglésDocument8 pagesFicha SSV InglésFelipe AlonsoNo ratings yet

- Hdpe Pipe Chart1Document3 pagesHdpe Pipe Chart1BENJAMIN UNALANNo ratings yet

- Pipe Sizes Chart PDFDocument1 pagePipe Sizes Chart PDFMukesh Kumar Jha100% (1)

- ERA PPR Pipes Fittings Master Catalogue 4Document30 pagesERA PPR Pipes Fittings Master Catalogue 4Milinda HerathNo ratings yet

- Pipe Outside Diameter GuideDocument1 pagePipe Outside Diameter GuideRonaldo Daniel Martín Pasapera MontalbánNo ratings yet

- Metering Pumps: Models A and BDocument5 pagesMetering Pumps: Models A and Bbmanojkumar16No ratings yet

- Din 126-2Document1 pageDin 126-2Safi Zabihullah SafiNo ratings yet

- Spektek Pipa PVC-OrientedDocument16 pagesSpektek Pipa PVC-OrientedRusdy NugrahaNo ratings yet

- Style 257Document5 pagesStyle 257Ummes AhmedNo ratings yet

- ASME Pressure Vessel Shell and Head Thickness (Sharing)Document18 pagesASME Pressure Vessel Shell and Head Thickness (Sharing)vanchai sapaNo ratings yet

- SAE Size ChartDocument1 pageSAE Size ChartjcNo ratings yet

- Upvc Pressure Pipe Standard PDFDocument4 pagesUpvc Pressure Pipe Standard PDFchairul anwarNo ratings yet

- Bolt and Screw Torque SpecsDocument3 pagesBolt and Screw Torque SpecsBilal TayyabNo ratings yet

- Butterfly Valve DatasheetDocument2 pagesButterfly Valve DatasheetKanthan DevanNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Indoor Wireless Communications: From Theory to ImplementationFrom EverandIndoor Wireless Communications: From Theory to ImplementationNo ratings yet

- Power Electronic Converters: Dynamics and Control in Conventional and Renewable Energy ApplicationsFrom EverandPower Electronic Converters: Dynamics and Control in Conventional and Renewable Energy ApplicationsNo ratings yet

- GROHE Specification Sheet 22940001 PDFDocument1 pageGROHE Specification Sheet 22940001 PDFAhmed Mohamed Abd ElhakamNo ratings yet

- GROHE Specification Sheet 22940000Document1 pageGROHE Specification Sheet 22940000Ahmed Mohamed Abd ElhakamNo ratings yet

- Instructions For Installation, Operation, Care and MaintenanceDocument10 pagesInstructions For Installation, Operation, Care and MaintenanceAhmed Mohamed Abd ElhakamNo ratings yet

- Drainage Pumps: Multi-PurposeDocument2 pagesDrainage Pumps: Multi-PurposeAhmed Mohamed Abd ElhakamNo ratings yet

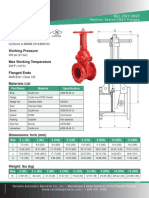

- OS&Y Gate Valve PDFDocument1 pageOS&Y Gate Valve PDFAhmed Mohamed Abd Elhakam100% (1)

- MSS SP-69Document20 pagesMSS SP-69Ahmed Mohamed Abd ElhakamNo ratings yet

- Retain: Spare PartsDocument1 pageRetain: Spare PartsAhmed Mohamed Abd ElhakamNo ratings yet

- Solar Thermal Storage Using Phase Change MaterialsDocument51 pagesSolar Thermal Storage Using Phase Change MaterialsAhmed Mohamed Abd ElhakamNo ratings yet

- CompositesDocument17 pagesCompositesMathew JohnNo ratings yet

- 13 GrangerDocument19 pages13 GrangerDinesh Kumar MishraNo ratings yet

- Gao-Cfd RefrigeratorDocument13 pagesGao-Cfd RefrigeratorMonowarul IslamNo ratings yet

- Project SynopsisDocument8 pagesProject Synopsistaran jot100% (1)

- Axial Flow Valves AMDocument28 pagesAxial Flow Valves AMDavid SaldarriagaNo ratings yet

- Near Bit GammaDocument2 pagesNear Bit GammaQiang ZhangNo ratings yet

- A. Soal Pilihan GandaDocument10 pagesA. Soal Pilihan GandaMAS Al HIdayah WarungkondangNo ratings yet

- Secado Por Atomización PDFDocument40 pagesSecado Por Atomización PDFAndrés DuqueNo ratings yet

- Electronic Measurements and Instrumentation QBDocument38 pagesElectronic Measurements and Instrumentation QBSrilekha031No ratings yet

- Cramers Rule 3 by 3 PracticeDocument5 pagesCramers Rule 3 by 3 PracticeSaherNo ratings yet

- Lesson 8 - Curvature and Refraction, Measuring Vertical DistancesDocument10 pagesLesson 8 - Curvature and Refraction, Measuring Vertical DistancesDumalag Banaay JoshuaNo ratings yet

- Bins Am Suri 2010Document32 pagesBins Am Suri 2010FarahNo ratings yet

- Linear Induction Motor: A Report OnDocument17 pagesLinear Induction Motor: A Report OnUtsav GoyalNo ratings yet

- Free PHPDocument10 pagesFree PHPPaulNo ratings yet

- Abutment DesignDocument28 pagesAbutment DesignPreeti goswamiNo ratings yet

- The Effect of Saba Banana (Musa Acuminata X Balbisiana) Peel Ash and Lime On The Stability of Expansive SoilDocument21 pagesThe Effect of Saba Banana (Musa Acuminata X Balbisiana) Peel Ash and Lime On The Stability of Expansive SoilKimberly Joy TulinNo ratings yet

- Arc Welding: CarbonDocument3 pagesArc Welding: CarbonmanandpatelNo ratings yet

- Eigenvalues, Eigenvectors and Vector Space - SUMMER 2019-20Document14 pagesEigenvalues, Eigenvectors and Vector Space - SUMMER 2019-20tasnimNo ratings yet

- Newton's Laws of Motion.Document2 pagesNewton's Laws of Motion.Gokul Nath100% (1)

- Experiment No. 15: Zener DiodeDocument2 pagesExperiment No. 15: Zener DiodeSatyam TripãthìNo ratings yet

- ANSYS Case Study - Three Dimensional Elasticity Problem 2: Laporan Metode Elemen HinggaDocument5 pagesANSYS Case Study - Three Dimensional Elasticity Problem 2: Laporan Metode Elemen Hinggairfan najmudinNo ratings yet

- Fundamentals of Rendering - Reflectance Functions: Chapter 9 of "Physically Based Rendering" by Pharr&HumphreysDocument13 pagesFundamentals of Rendering - Reflectance Functions: Chapter 9 of "Physically Based Rendering" by Pharr&HumphreysnhariharaprasadNo ratings yet

- Application of Numerical MethodsDocument7 pagesApplication of Numerical MethodsMd Saidur Rahman Kohinoor100% (1)

- Me2401 MechatronicsDocument3 pagesMe2401 MechatronicsJaya Om100% (1)

- Extraction and Isolation of Caffeine From Ground Coffee BeansDocument5 pagesExtraction and Isolation of Caffeine From Ground Coffee BeansRemjohn Magtaas100% (1)

- 12 - Right Angle Drives: Catalog Series Material Pages RatiosDocument16 pages12 - Right Angle Drives: Catalog Series Material Pages RatiosODG_290473No ratings yet

- (A) MARTIN 2003 - What Is Field TheoryDocument50 pages(A) MARTIN 2003 - What Is Field TheoryDiego Maganhotto CoraiolaNo ratings yet