Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

129 viewsCapstan and Turret Lathes

Capstan and Turret Lathes

Uploaded by

rsdeshmukhThe document compares centre lathes, turret lathes, and capstan lathes. Turret and capstan lathes can hold multiple tools on a turret head rather than a single toolpost. The turret head on a turret lathe mounts directly to the saddle, while a capstan lathe's head mounts on a slide on the saddle. This makes turret lathes more rigid but capstan lathes can handle smaller jobs. Turret lathes are best for mass production due to their automatic tool changing and higher speeds and capacities.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Steam BasicsDocument7 pagesSteam BasicsNirmal CoolNo ratings yet

- Accu-Finish II ManualDocument8 pagesAccu-Finish II ManualOliver CollectorNo ratings yet

- How To Mount and Operate Buck Adjust-Tru ChuckDocument4 pagesHow To Mount and Operate Buck Adjust-Tru ChuckStronghold ArmoryNo ratings yet

- Atlas Mill AccessoriesDocument1 pageAtlas Mill AccessoriesGary RepeshNo ratings yet

- 3 PhaseDocument9 pages3 PhaseArnulfo LavaresNo ratings yet

- Manual TornoDocument60 pagesManual Tornojulie2420140% (1)

- Main Parts of Capstan Lathe and Turret LatheDocument8 pagesMain Parts of Capstan Lathe and Turret LatheShuvoVatt0% (1)

- Atlas 4350 Hacksaw ManualDocument6 pagesAtlas 4350 Hacksaw Manualf4d711No ratings yet

- Screwthread and Gear MeasurementDocument19 pagesScrewthread and Gear MeasurementseenuNo ratings yet

- 2 Snatch Block AssemblyDocument17 pages2 Snatch Block AssemblysoniNo ratings yet

- Tool Makers MicroscopeDocument13 pagesTool Makers MicroscopeLokesh LokiNo ratings yet

- Lecture#09 (A) Shaper, Planer, Slotter and Boring MachineDocument12 pagesLecture#09 (A) Shaper, Planer, Slotter and Boring MachineQazi Muhammed FayyazNo ratings yet

- Steam TurbineDocument17 pagesSteam TurbineDicky Nicky November100% (1)

- Wire Rope Excavator/cranesDocument20 pagesWire Rope Excavator/cranesBhanu ChanderNo ratings yet

- Apron: Apron To Saddle ConnectionDocument10 pagesApron: Apron To Saddle ConnectionFernando EricesNo ratings yet

- Rotary TableDocument2 pagesRotary TableDong Dien KhaNo ratings yet

- Capstan & Turret LatheDocument27 pagesCapstan & Turret LatheMuraliNo ratings yet

- Lathes and Lathe Machining OperationsDocument11 pagesLathes and Lathe Machining OperationsJunayed HasanNo ratings yet

- Surface PlateDocument5 pagesSurface Platetevqwe1No ratings yet

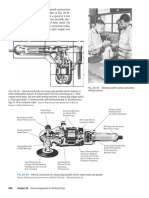

- Fig. 26-54 Fig. 26-55: 26 General Equipment For Welding ShopsDocument7 pagesFig. 26-54 Fig. 26-55: 26 General Equipment For Welding ShopsWilly UioNo ratings yet

- WB the+Awesome+MF+WorkbenchDocument72 pagesWB the+Awesome+MF+WorkbenchZé MarcoNo ratings yet

- Sheet Metal Working PressesDocument48 pagesSheet Metal Working PressesAshish RawatNo ratings yet

- Sheet Metal ToolsDocument20 pagesSheet Metal ToolsRolando DaclanNo ratings yet

- PDFDocument44 pagesPDFBaSzarNo ratings yet

- NASA SP290 Turbine DesignDocument392 pagesNASA SP290 Turbine Designcramerps2084100% (1)

- Steam ValveDocument6 pagesSteam ValveuaisouauNo ratings yet

- 3 Jaw Chuck RepairDocument2 pages3 Jaw Chuck RepairbrianatburleighNo ratings yet

- SW FEA Tutorial ShaftDocument10 pagesSW FEA Tutorial ShaftJoséMiguelSánchezGNo ratings yet

- ACIERA Milling Machine 1Document11 pagesACIERA Milling Machine 1adhencandraNo ratings yet

- Roller Screw BasicsDocument3 pagesRoller Screw BasicskiranNo ratings yet

- Wastewater Treatment Mechanic: Passbooks Study GuideFrom EverandWastewater Treatment Mechanic: Passbooks Study GuideNo ratings yet

- E1102m PDFDocument283 pagesE1102m PDFBhawani Singh RajawatNo ratings yet

- Shaper and PlannerDocument33 pagesShaper and PlannerCody Lee100% (1)

- 2design of Hydraulic Power Pack For Vertical Turret Lathe GM21Feb14 PDFDocument10 pages2design of Hydraulic Power Pack For Vertical Turret Lathe GM21Feb14 PDFSamik MukherjeeNo ratings yet

- Handbook of Me Chan 00 NordDocument296 pagesHandbook of Me Chan 00 NordSingh GurpreetNo ratings yet

- South Bend LatheDocument84 pagesSouth Bend LatheHoltelino TlocaletlasNo ratings yet

- Lightweight Tripod Easel PlanDocument11 pagesLightweight Tripod Easel Planviktor mickovskiNo ratings yet

- Drill DataDocument5 pagesDrill DataDOBJANNo ratings yet

- Metal Working Tools and MachinesDocument35 pagesMetal Working Tools and MachinessolarbobkyNo ratings yet

- South Bend 9" Compound Slide Screw Fabrication For A Large Dial/Thrust Bearing Conversion by Ed Godwin 8 December, 2007Document16 pagesSouth Bend 9" Compound Slide Screw Fabrication For A Large Dial/Thrust Bearing Conversion by Ed Godwin 8 December, 2007asdfNo ratings yet

- Belt Sander - p1Document4 pagesBelt Sander - p1Renato PrevidelliNo ratings yet

- Maintenance For Model Master Rotary TableDocument7 pagesMaintenance For Model Master Rotary Tablejdk3dNo ratings yet

- 1220 LTD Manual 2010 Smitty LatheDocument104 pages1220 LTD Manual 2010 Smitty LatheMark Corona100% (1)

- Pipe FlangesDocument7 pagesPipe FlangesAli SafdarNo ratings yet

- WErbsen CourseworkDocument562 pagesWErbsen CourseworkRoberto Alexis Rodríguez TorresNo ratings yet

- Fordson Major ManualDocument47 pagesFordson Major ManualHassan GDOURANo ratings yet

- Eng Metrology Topic 4 (Noncontact Inspection)Document28 pagesEng Metrology Topic 4 (Noncontact Inspection)asmawi_78No ratings yet

- Tread Hammer RahulDocument36 pagesTread Hammer RahulHemant MaheshwariNo ratings yet

- 03 - Screwcutting in The LatheDocument172 pages03 - Screwcutting in The Lathej43951048No ratings yet

- Design of Sheet Metal Working ToolsDocument38 pagesDesign of Sheet Metal Working ToolsAsef ShahriarNo ratings yet

- Rotating Disc ValvesDocument4 pagesRotating Disc ValvesSergey100% (1)

- TM 9 3416 235 14 and PDocument67 pagesTM 9 3416 235 14 and PMikeNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Capstan and Turret Lathe WorkingDocument8 pagesCapstan and Turret Lathe WorkingRohan SahaNo ratings yet

- MT 4th SemDocument154 pagesMT 4th SemDushyant HarneNo ratings yet

- Capstan Lathe NotesDocument4 pagesCapstan Lathe NoteshashimtkmceNo ratings yet

- Lathe PT-1Document30 pagesLathe PT-1Nikhil PrasannaNo ratings yet

- Diff BWN Turret and Capstan LatheDocument2 pagesDiff BWN Turret and Capstan LatheManojKumarVempatiNo ratings yet

- ED Classwork Problems TcetDocument1 pageED Classwork Problems TcetrsdeshmukhNo ratings yet

- About Resource Book Chain Management (SCM) " This Resource Book Has Been Designed AccordingDocument2 pagesAbout Resource Book Chain Management (SCM) " This Resource Book Has Been Designed AccordingrsdeshmukhNo ratings yet

- Classwork Problems TcetDocument1 pageClasswork Problems TcetrsdeshmukhNo ratings yet

- Computer Aided Machine Drawing Q BankDocument1 pageComputer Aided Machine Drawing Q BankrsdeshmukhNo ratings yet

- MEE7014 Supply Chain Management 3+1: Modul e Detailed Contents Hours 01Document3 pagesMEE7014 Supply Chain Management 3+1: Modul e Detailed Contents Hours 01rsdeshmukhNo ratings yet

- CAD CAM Question BankDocument2 pagesCAD CAM Question BankrsdeshmukhNo ratings yet

- Types of Manufacturing SystemsDocument7 pagesTypes of Manufacturing SystemsrsdeshmukhNo ratings yet

- Inbound Supply Chain Modeling in Sugar IndustryDocument10 pagesInbound Supply Chain Modeling in Sugar Industryrsdeshmukh0% (1)

- Basics of Supply Chain Management Business ConceptsDocument7 pagesBasics of Supply Chain Management Business ConceptsrsdeshmukhNo ratings yet

- MalappuramDocument20 pagesMalappuramFayizNo ratings yet

- 3M CorporationDocument3 pages3M CorporationIndoxfeeds GramNo ratings yet

- Capitalisation AssignmentDocument5 pagesCapitalisation AssignmentFayis FYSNo ratings yet

- Measurement of Thermal Conductivity: Engineering Properties of Biological Materials and Food Quality 3 (2+1)Document17 pagesMeasurement of Thermal Conductivity: Engineering Properties of Biological Materials and Food Quality 3 (2+1)Mel CapalunganNo ratings yet

- DorkDocument5 pagesDorkJeremy Sisto ManurungNo ratings yet

- Company Profile For ICB TechnimontDocument4 pagesCompany Profile For ICB TechnimontShankarMukherjeeNo ratings yet

- Thou Hast Made MeDocument3 pagesThou Hast Made Meyour dady0% (1)

- Applications Guide 2021 Covering LettersDocument8 pagesApplications Guide 2021 Covering LettersLALUKISNo ratings yet

- Drama Bahasa InggrisDocument24 pagesDrama Bahasa InggrisCahyo Yang bahagiaNo ratings yet

- Elrc 4507 Unit PlanDocument4 pagesElrc 4507 Unit Planapi-284973023No ratings yet

- Development of TOSRA (Test of Science Related Attitudes) Instrument For Science Related Attitude Studies in Sindh ProvinceDocument16 pagesDevelopment of TOSRA (Test of Science Related Attitudes) Instrument For Science Related Attitude Studies in Sindh ProvinceYhann Buyan GeverolaNo ratings yet

- Software Engineering. Specification, Implementation, VerificationDocument186 pagesSoftware Engineering. Specification, Implementation, Verificationazariel.rodrigo100% (1)

- Scholastic Instant Practice Packets Numbers - CountingDocument128 pagesScholastic Instant Practice Packets Numbers - CountingcaliscaNo ratings yet

- Crossing The Bar Critique PaperDocument2 pagesCrossing The Bar Critique PapermaieuniceNo ratings yet

- Loads Table LV Power Panel Tag: 100-Dp-001Document1 pageLoads Table LV Power Panel Tag: 100-Dp-001Erwin CarrascoNo ratings yet

- Telegram DocumeDocument21 pagesTelegram Documemilli birhanuNo ratings yet

- ResearchDocument38 pagesResearchHelen McClintockNo ratings yet

- Tle 7-1st Periodic TestDocument2 pagesTle 7-1st Periodic TestReymart TumanguilNo ratings yet

- The Holy Spirit: A New LifeDocument2 pagesThe Holy Spirit: A New LifeKatu2010No ratings yet

- GDPR ReportDocument84 pagesGDPR ReportKingPlaysNo ratings yet

- Questionnaire For Technical AssistantDocument4 pagesQuestionnaire For Technical AssistantHabtamu Ye Asnaku LijNo ratings yet

- Semantically Partitioned Object Sap BW 7.3Document23 pagesSemantically Partitioned Object Sap BW 7.3smiks50% (2)

- Module - 1 IntroductionDocument33 pagesModule - 1 IntroductionIffat SiddiqueNo ratings yet

- EmpiricalBasis GottmanDocument10 pagesEmpiricalBasis GottmanMundoSinViolenciaNo ratings yet

- Optimizing The Lasing Quality of Diode Lasers by Anti-Reflective CoatingDocument21 pagesOptimizing The Lasing Quality of Diode Lasers by Anti-Reflective CoatingDannyNo ratings yet

- UNIT HistoryDocument2 pagesUNIT HistorySanders StephenNo ratings yet

- 15p3 Fourier IntegralDocument7 pages15p3 Fourier IntegralBhargav BhalaraNo ratings yet

- Comfort ZoneDocument4 pagesComfort Zonesigal ardanNo ratings yet

- September 23, Infer The Purpose of The Poem Listened ToDocument4 pagesSeptember 23, Infer The Purpose of The Poem Listened ToLouelle GonzalesNo ratings yet

- CEA Farms Logistics USA Slide Deck (2023!10!31 10-38-56 UTC)Document18 pagesCEA Farms Logistics USA Slide Deck (2023!10!31 10-38-56 UTC)SiyabongaNo ratings yet

Capstan and Turret Lathes

Capstan and Turret Lathes

Uploaded by

rsdeshmukh0 ratings0% found this document useful (0 votes)

129 views2 pagesThe document compares centre lathes, turret lathes, and capstan lathes. Turret and capstan lathes can hold multiple tools on a turret head rather than a single toolpost. The turret head on a turret lathe mounts directly to the saddle, while a capstan lathe's head mounts on a slide on the saddle. This makes turret lathes more rigid but capstan lathes can handle smaller jobs. Turret lathes are best for mass production due to their automatic tool changing and higher speeds and capacities.

Original Description:

Comparison between Capstan and Turret Lathes with centre lathe

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document compares centre lathes, turret lathes, and capstan lathes. Turret and capstan lathes can hold multiple tools on a turret head rather than a single toolpost. The turret head on a turret lathe mounts directly to the saddle, while a capstan lathe's head mounts on a slide on the saddle. This makes turret lathes more rigid but capstan lathes can handle smaller jobs. Turret lathes are best for mass production due to their automatic tool changing and higher speeds and capacities.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

129 views2 pagesCapstan and Turret Lathes

Capstan and Turret Lathes

Uploaded by

rsdeshmukhThe document compares centre lathes, turret lathes, and capstan lathes. Turret and capstan lathes can hold multiple tools on a turret head rather than a single toolpost. The turret head on a turret lathe mounts directly to the saddle, while a capstan lathe's head mounts on a slide on the saddle. This makes turret lathes more rigid but capstan lathes can handle smaller jobs. Turret lathes are best for mass production due to their automatic tool changing and higher speeds and capacities.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

CAPSTAN AND TURRET LATHES

Comparison among Centre lathe, Capstan Lathe and Turret Lathe:

Feature Centre Lathe Turret Lathe Capstan Lathe

Headstock Cons pulley or all gear Heavy construction, Same as Turret Lathe

driven. Can Provide wider range of spindle

lesser speed than the speeds from more

other two powerful motor than

centre lathes

Toolpost Usually a single Toolpost Its cross slide carries a Same as Turret Lathe

(with a single tool). square turret type

Sometimes, a square Toolpost carrying 4 tools.

turret type Toolpost is Additionally, it has a

provided which can hold Toolpost at its rear to

4 tools. hold 1 or 2 tools.

Tailstock Usually used for Carries a hexagonal turret Carries a square, round

supporting the WP. head instead of tailstock, or hexagonal turret

Sometimes, some cutting which may hold a tool or called Capstan head in

tools (drills, reamers etc) tool head on each of its place of tailstock. This

installed to perform face. They are provides the same

operations at the end face automatically indexed in facility of mounting and

of WP. sequence to bring each indexing 4-6 tools as in

tool in proper position for case of turret lathe.

performing operations

sequentially.

Leadscrew Always provided on Thread cutting generally Same as Turret Lathe

centre lathe to enable performed by taps and die

thread cutting by a single heads fitted to the turret

point tool. head.

Method of Not applicable Turret head directlyCapstan head is

mounting the mounted on a saddle and mounted on a ram or

Turret or for feeding the tool on theslide, which travels on

Capstan Head WP the entire saddle has the fixed saddle. The

to be moved. tools are fed on the WP

by moving the slide.

No. of tools Usually 1 for single tool 4 tools on the front tool Same as Turret Lathe

mounted post. If a square turret post, 1 or 2 on the rear

type Toolpost is provided tool post and 4-6 tools on

then 4 tools can be the square or hexagonal

mounted. turret head. No. of tools

can be increased by using

multiple tool holders on

the turret.

Skill required Very high Very nominal after setting Same as Turret Lathe

for operator of tools

Tool setting High. Tool has to be Initial tool setting time Same as Turret Lathe

time changed every time a required. During

new operation is to be operation all the tool are

done. available in the turret.

Degree of Very nominal (manual) Semi automatic Semi automatic

automation

Application More versatile. Made in Used in mass production Used for relatively

various sizes and of identical components. lighter and smaller jobs

capabilities to handle Can handle heavier jobs than turret lathes, but

jobs of various sizes and than capstan lathes. with more precision.

level of machining.

Rate of Lower Higher Higher

production

Overhead Less than the other two Higher than centre lathes Same as Turret Lathe

charges because of higher initial

investments, more power

consumption and higher

maintenance.

Labour cost Higher (require skill Lower, because after Same as Turret Lathe

labour) initial tool setting

unskilled/semi-skilled

labour is required.

Difference between a Turret and Capstan Lathe:

S. No Turret Lathe Capstan Lathe

1. Its turret head is directly mounted on the Its turret head is mounted on an auxiliary

saddle slide which moves on the guideways of the

saddle.

2. For feeding the tool on the WP, the entire For feeding the tool on the WP, the slide

saddle is moved moves over the guideways of fixed saddle

3. The above arrangement enables better As the ram or slide is overhung, hence less

rigidity as all the cutting forces are rigidity due to vibration, bending and

transferred to the lathe bed deflection.

4. Due to the above, this lathe can Due to the above, its use is confined to

accommodate heavier WP, involve heavier relatively lighter and smaller jobs.

cutting forces and severe cutting

conditions.

5. Operations my be performed on bars size Up to 60 mm diameter only.

up to 200 mm in diameter

6. Since the turret saddle (along with all the Tool feeding done by movement of slide

tools) moves over the guideways of the over the saddle. Hence, movement is limited

lathe bed, hence it can move almost the

entire length of the bed.

7. Heavier designs of turret lathes are No such arrangements provided

provided with pneumatic or hydraulic

chucks to hold the heavier jobs firmly.

8. Some versions of this lathe may provide for No such arrangements provided

cross feeding of the hexagonal turret.

You might also like

- Steam BasicsDocument7 pagesSteam BasicsNirmal CoolNo ratings yet

- Accu-Finish II ManualDocument8 pagesAccu-Finish II ManualOliver CollectorNo ratings yet

- How To Mount and Operate Buck Adjust-Tru ChuckDocument4 pagesHow To Mount and Operate Buck Adjust-Tru ChuckStronghold ArmoryNo ratings yet

- Atlas Mill AccessoriesDocument1 pageAtlas Mill AccessoriesGary RepeshNo ratings yet

- 3 PhaseDocument9 pages3 PhaseArnulfo LavaresNo ratings yet

- Manual TornoDocument60 pagesManual Tornojulie2420140% (1)

- Main Parts of Capstan Lathe and Turret LatheDocument8 pagesMain Parts of Capstan Lathe and Turret LatheShuvoVatt0% (1)

- Atlas 4350 Hacksaw ManualDocument6 pagesAtlas 4350 Hacksaw Manualf4d711No ratings yet

- Screwthread and Gear MeasurementDocument19 pagesScrewthread and Gear MeasurementseenuNo ratings yet

- 2 Snatch Block AssemblyDocument17 pages2 Snatch Block AssemblysoniNo ratings yet

- Tool Makers MicroscopeDocument13 pagesTool Makers MicroscopeLokesh LokiNo ratings yet

- Lecture#09 (A) Shaper, Planer, Slotter and Boring MachineDocument12 pagesLecture#09 (A) Shaper, Planer, Slotter and Boring MachineQazi Muhammed FayyazNo ratings yet

- Steam TurbineDocument17 pagesSteam TurbineDicky Nicky November100% (1)

- Wire Rope Excavator/cranesDocument20 pagesWire Rope Excavator/cranesBhanu ChanderNo ratings yet

- Apron: Apron To Saddle ConnectionDocument10 pagesApron: Apron To Saddle ConnectionFernando EricesNo ratings yet

- Rotary TableDocument2 pagesRotary TableDong Dien KhaNo ratings yet

- Capstan & Turret LatheDocument27 pagesCapstan & Turret LatheMuraliNo ratings yet

- Lathes and Lathe Machining OperationsDocument11 pagesLathes and Lathe Machining OperationsJunayed HasanNo ratings yet

- Surface PlateDocument5 pagesSurface Platetevqwe1No ratings yet

- Fig. 26-54 Fig. 26-55: 26 General Equipment For Welding ShopsDocument7 pagesFig. 26-54 Fig. 26-55: 26 General Equipment For Welding ShopsWilly UioNo ratings yet

- WB the+Awesome+MF+WorkbenchDocument72 pagesWB the+Awesome+MF+WorkbenchZé MarcoNo ratings yet

- Sheet Metal Working PressesDocument48 pagesSheet Metal Working PressesAshish RawatNo ratings yet

- Sheet Metal ToolsDocument20 pagesSheet Metal ToolsRolando DaclanNo ratings yet

- PDFDocument44 pagesPDFBaSzarNo ratings yet

- NASA SP290 Turbine DesignDocument392 pagesNASA SP290 Turbine Designcramerps2084100% (1)

- Steam ValveDocument6 pagesSteam ValveuaisouauNo ratings yet

- 3 Jaw Chuck RepairDocument2 pages3 Jaw Chuck RepairbrianatburleighNo ratings yet

- SW FEA Tutorial ShaftDocument10 pagesSW FEA Tutorial ShaftJoséMiguelSánchezGNo ratings yet

- ACIERA Milling Machine 1Document11 pagesACIERA Milling Machine 1adhencandraNo ratings yet

- Roller Screw BasicsDocument3 pagesRoller Screw BasicskiranNo ratings yet

- Wastewater Treatment Mechanic: Passbooks Study GuideFrom EverandWastewater Treatment Mechanic: Passbooks Study GuideNo ratings yet

- E1102m PDFDocument283 pagesE1102m PDFBhawani Singh RajawatNo ratings yet

- Shaper and PlannerDocument33 pagesShaper and PlannerCody Lee100% (1)

- 2design of Hydraulic Power Pack For Vertical Turret Lathe GM21Feb14 PDFDocument10 pages2design of Hydraulic Power Pack For Vertical Turret Lathe GM21Feb14 PDFSamik MukherjeeNo ratings yet

- Handbook of Me Chan 00 NordDocument296 pagesHandbook of Me Chan 00 NordSingh GurpreetNo ratings yet

- South Bend LatheDocument84 pagesSouth Bend LatheHoltelino TlocaletlasNo ratings yet

- Lightweight Tripod Easel PlanDocument11 pagesLightweight Tripod Easel Planviktor mickovskiNo ratings yet

- Drill DataDocument5 pagesDrill DataDOBJANNo ratings yet

- Metal Working Tools and MachinesDocument35 pagesMetal Working Tools and MachinessolarbobkyNo ratings yet

- South Bend 9" Compound Slide Screw Fabrication For A Large Dial/Thrust Bearing Conversion by Ed Godwin 8 December, 2007Document16 pagesSouth Bend 9" Compound Slide Screw Fabrication For A Large Dial/Thrust Bearing Conversion by Ed Godwin 8 December, 2007asdfNo ratings yet

- Belt Sander - p1Document4 pagesBelt Sander - p1Renato PrevidelliNo ratings yet

- Maintenance For Model Master Rotary TableDocument7 pagesMaintenance For Model Master Rotary Tablejdk3dNo ratings yet

- 1220 LTD Manual 2010 Smitty LatheDocument104 pages1220 LTD Manual 2010 Smitty LatheMark Corona100% (1)

- Pipe FlangesDocument7 pagesPipe FlangesAli SafdarNo ratings yet

- WErbsen CourseworkDocument562 pagesWErbsen CourseworkRoberto Alexis Rodríguez TorresNo ratings yet

- Fordson Major ManualDocument47 pagesFordson Major ManualHassan GDOURANo ratings yet

- Eng Metrology Topic 4 (Noncontact Inspection)Document28 pagesEng Metrology Topic 4 (Noncontact Inspection)asmawi_78No ratings yet

- Tread Hammer RahulDocument36 pagesTread Hammer RahulHemant MaheshwariNo ratings yet

- 03 - Screwcutting in The LatheDocument172 pages03 - Screwcutting in The Lathej43951048No ratings yet

- Design of Sheet Metal Working ToolsDocument38 pagesDesign of Sheet Metal Working ToolsAsef ShahriarNo ratings yet

- Rotating Disc ValvesDocument4 pagesRotating Disc ValvesSergey100% (1)

- TM 9 3416 235 14 and PDocument67 pagesTM 9 3416 235 14 and PMikeNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Capstan and Turret Lathe WorkingDocument8 pagesCapstan and Turret Lathe WorkingRohan SahaNo ratings yet

- MT 4th SemDocument154 pagesMT 4th SemDushyant HarneNo ratings yet

- Capstan Lathe NotesDocument4 pagesCapstan Lathe NoteshashimtkmceNo ratings yet

- Lathe PT-1Document30 pagesLathe PT-1Nikhil PrasannaNo ratings yet

- Diff BWN Turret and Capstan LatheDocument2 pagesDiff BWN Turret and Capstan LatheManojKumarVempatiNo ratings yet

- ED Classwork Problems TcetDocument1 pageED Classwork Problems TcetrsdeshmukhNo ratings yet

- About Resource Book Chain Management (SCM) " This Resource Book Has Been Designed AccordingDocument2 pagesAbout Resource Book Chain Management (SCM) " This Resource Book Has Been Designed AccordingrsdeshmukhNo ratings yet

- Classwork Problems TcetDocument1 pageClasswork Problems TcetrsdeshmukhNo ratings yet

- Computer Aided Machine Drawing Q BankDocument1 pageComputer Aided Machine Drawing Q BankrsdeshmukhNo ratings yet

- MEE7014 Supply Chain Management 3+1: Modul e Detailed Contents Hours 01Document3 pagesMEE7014 Supply Chain Management 3+1: Modul e Detailed Contents Hours 01rsdeshmukhNo ratings yet

- CAD CAM Question BankDocument2 pagesCAD CAM Question BankrsdeshmukhNo ratings yet

- Types of Manufacturing SystemsDocument7 pagesTypes of Manufacturing SystemsrsdeshmukhNo ratings yet

- Inbound Supply Chain Modeling in Sugar IndustryDocument10 pagesInbound Supply Chain Modeling in Sugar Industryrsdeshmukh0% (1)

- Basics of Supply Chain Management Business ConceptsDocument7 pagesBasics of Supply Chain Management Business ConceptsrsdeshmukhNo ratings yet

- MalappuramDocument20 pagesMalappuramFayizNo ratings yet

- 3M CorporationDocument3 pages3M CorporationIndoxfeeds GramNo ratings yet

- Capitalisation AssignmentDocument5 pagesCapitalisation AssignmentFayis FYSNo ratings yet

- Measurement of Thermal Conductivity: Engineering Properties of Biological Materials and Food Quality 3 (2+1)Document17 pagesMeasurement of Thermal Conductivity: Engineering Properties of Biological Materials and Food Quality 3 (2+1)Mel CapalunganNo ratings yet

- DorkDocument5 pagesDorkJeremy Sisto ManurungNo ratings yet

- Company Profile For ICB TechnimontDocument4 pagesCompany Profile For ICB TechnimontShankarMukherjeeNo ratings yet

- Thou Hast Made MeDocument3 pagesThou Hast Made Meyour dady0% (1)

- Applications Guide 2021 Covering LettersDocument8 pagesApplications Guide 2021 Covering LettersLALUKISNo ratings yet

- Drama Bahasa InggrisDocument24 pagesDrama Bahasa InggrisCahyo Yang bahagiaNo ratings yet

- Elrc 4507 Unit PlanDocument4 pagesElrc 4507 Unit Planapi-284973023No ratings yet

- Development of TOSRA (Test of Science Related Attitudes) Instrument For Science Related Attitude Studies in Sindh ProvinceDocument16 pagesDevelopment of TOSRA (Test of Science Related Attitudes) Instrument For Science Related Attitude Studies in Sindh ProvinceYhann Buyan GeverolaNo ratings yet

- Software Engineering. Specification, Implementation, VerificationDocument186 pagesSoftware Engineering. Specification, Implementation, Verificationazariel.rodrigo100% (1)

- Scholastic Instant Practice Packets Numbers - CountingDocument128 pagesScholastic Instant Practice Packets Numbers - CountingcaliscaNo ratings yet

- Crossing The Bar Critique PaperDocument2 pagesCrossing The Bar Critique PapermaieuniceNo ratings yet

- Loads Table LV Power Panel Tag: 100-Dp-001Document1 pageLoads Table LV Power Panel Tag: 100-Dp-001Erwin CarrascoNo ratings yet

- Telegram DocumeDocument21 pagesTelegram Documemilli birhanuNo ratings yet

- ResearchDocument38 pagesResearchHelen McClintockNo ratings yet

- Tle 7-1st Periodic TestDocument2 pagesTle 7-1st Periodic TestReymart TumanguilNo ratings yet

- The Holy Spirit: A New LifeDocument2 pagesThe Holy Spirit: A New LifeKatu2010No ratings yet

- GDPR ReportDocument84 pagesGDPR ReportKingPlaysNo ratings yet

- Questionnaire For Technical AssistantDocument4 pagesQuestionnaire For Technical AssistantHabtamu Ye Asnaku LijNo ratings yet

- Semantically Partitioned Object Sap BW 7.3Document23 pagesSemantically Partitioned Object Sap BW 7.3smiks50% (2)

- Module - 1 IntroductionDocument33 pagesModule - 1 IntroductionIffat SiddiqueNo ratings yet

- EmpiricalBasis GottmanDocument10 pagesEmpiricalBasis GottmanMundoSinViolenciaNo ratings yet

- Optimizing The Lasing Quality of Diode Lasers by Anti-Reflective CoatingDocument21 pagesOptimizing The Lasing Quality of Diode Lasers by Anti-Reflective CoatingDannyNo ratings yet

- UNIT HistoryDocument2 pagesUNIT HistorySanders StephenNo ratings yet

- 15p3 Fourier IntegralDocument7 pages15p3 Fourier IntegralBhargav BhalaraNo ratings yet

- Comfort ZoneDocument4 pagesComfort Zonesigal ardanNo ratings yet

- September 23, Infer The Purpose of The Poem Listened ToDocument4 pagesSeptember 23, Infer The Purpose of The Poem Listened ToLouelle GonzalesNo ratings yet

- CEA Farms Logistics USA Slide Deck (2023!10!31 10-38-56 UTC)Document18 pagesCEA Farms Logistics USA Slide Deck (2023!10!31 10-38-56 UTC)SiyabongaNo ratings yet