Professional Documents

Culture Documents

United States Patent (19) : Jennings, Jr. 11 Patent Number: 4,982,786 45) Date of Patent: Jan. 8, 1991

United States Patent (19) : Jennings, Jr. 11 Patent Number: 4,982,786 45) Date of Patent: Jan. 8, 1991

Uploaded by

ozmdz0 ratings0% found this document useful (0 votes)

17 views4 pagesThis patent describes a method for enhanced oil recovery using carbon dioxide and steam injection into a formation containing two horizontal wellbores. Liquid carbon dioxide is first injected into the lower wellbore to contact hydrocarbon fluids. Steam is then injected, causing the carbon dioxide to expand and drive deeper into the formation, mixing with hydrocarbon fluids. The mixture is produced from the upper wellbore. Repeating carbon dioxide and steam injections improves sweep efficiency over the formation.

Original Description:

Oil recovery

Original Title

GAGD

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis patent describes a method for enhanced oil recovery using carbon dioxide and steam injection into a formation containing two horizontal wellbores. Liquid carbon dioxide is first injected into the lower wellbore to contact hydrocarbon fluids. Steam is then injected, causing the carbon dioxide to expand and drive deeper into the formation, mixing with hydrocarbon fluids. The mixture is produced from the upper wellbore. Repeating carbon dioxide and steam injections improves sweep efficiency over the formation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

17 views4 pagesUnited States Patent (19) : Jennings, Jr. 11 Patent Number: 4,982,786 45) Date of Patent: Jan. 8, 1991

United States Patent (19) : Jennings, Jr. 11 Patent Number: 4,982,786 45) Date of Patent: Jan. 8, 1991

Uploaded by

ozmdzThis patent describes a method for enhanced oil recovery using carbon dioxide and steam injection into a formation containing two horizontal wellbores. Liquid carbon dioxide is first injected into the lower wellbore to contact hydrocarbon fluids. Steam is then injected, causing the carbon dioxide to expand and drive deeper into the formation, mixing with hydrocarbon fluids. The mixture is produced from the upper wellbore. Repeating carbon dioxide and steam injections improves sweep efficiency over the formation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

United States Patent (19) 11 Patent Number: 4,982,786

Jennings, Jr. 45) Date of Patent: Jan. 8, 1991

54 USE OF CO2/STEAM TO ENHANCE Attorney, Agent, or Firm-Alexander J. McKillop;

FLOODS N HORIZONTAL WELLBORES Charles J. Speciale; Charles A. Malone

75 Inventor: Alfred R. Jennings, Jr., Plano, Tex. 57 ABSTRACT

(73) Assignee: Mobil Oil Corporation, Fairfax, Va. A method to enhance steam flooding where at least two

horizontal wellbores are utilized. Carbon dioxide is

21 Appl. No.: 379,759 injected into a lower perforated horizontal wellbore.

Once sufficient carbon dioxide has been injected into

22 Filed: Jul. 14, 1989 the formation, steam is injected through the lower hori

51)Int. Cl’................................................ E03B 3/11 zontal wellbore. The steam displaces the carbon dioxide

52 U.S.C. ...................................... 166/50; 166/272; into the formation where it contacts and mixes with

166/303; 166/309 hydrocarbonaceous fluids. Steam causes the carbon

58 Field of Search ................................... 166/50, 272 dioxide to expand, thereby providing for a better sweep

of the formation. Steam injection is ceased and liquid

56 References Cited carbon dioxide injection again is commenced. After

U.S. PATENT DOCUMENTS wards, steam is injected again into the formation. This

sequence is continued until it becomes uneconomical to

4,257,650 3/1981 Allen ..................................... 166/50 produce hydrocarbonaceous fluids from an upper hori

4,410,216 10/1983 Allen ...... ... 166/50 zontal wellbore. Hydrocarbon displacement efficiencies

4,607,699 8/1986 Stephens ... ... 166/303 are enhanced when hydrocarbons are produced into the

4,736,792 4/988 Brown et al. ....................... 166/252 upper horizontal wellbore due to viscosity and density

4,756,369 7/1988 Jennings et al. .................... 166/272 differences.

Primary Examiner-Ramon S. Britts

Assistant Examiner-Roger J. Schoeppel 5 Claims, 1 Drawing Sheet

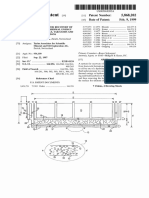

U.S. Patent Jan. 8, 1991 4,982,786

4,982,786

2

naceous fluids therein. While the liquid carbon dioxide

USE OF CO2/STEAM TO ENHANCE FLOODS IN is in the formation, steam is injected into the lower

HORIZONTAL WELLBORES horizontal wellbore so as to cause the liquid carbon

dioxide to be heated and expand. Heating also causes

FIELD OF THE INVENTION the carbon dioxide to go into its gaseous state and make

This invention is directed to a method for carbon additional contact with hydrocarbonaceous fluids in the

dixoide/steam stimulation of hydrocarbonaceous fluids formation. Any carbon dioxide that remains undis

via at least two horizontal wellbores. More particularly, solved in the formation is driven deeper into the forma

it is directed to the use of liquid carbon dioxide and a tion by the steam where it makes additional contact

subsequent steam flood which causes the expansion of 9 with the hydrocarbonaceous fluid-containing forma

carbon dioxide so as to obtain a substantially better tion. Pressure exerted by the steam and the carbon diox

Sweep of a formation containing said horizontal well ide causes a hydrocarbonaceous/carbon dioxide fluid

bores. mixture to form which proceeds upwardly through the

BACKGROUND OF THE INVENTION 15

formation into an upper horizontal wellbore. The mix

ture of hydrocarbonaceous fluids, gaseous carbon diox

With advances in drilling technology, it is currently ide, steam, and water exits the formation through the

possible to drill horizontal wellbores deep into hydro upper horizontal wellbore where it is produced to the

carbon producing reservoirs. Utilization of horizontal surface. Upon reaching the surface, the hydrocarbona

wellbores allows extended contact with a producing ceous fluids are separated from the carbon dioxide,

formation, thereby facilitating drainage and production 20

steam and water.

of the reservoir. It is therefore an object of this invention to increase

Although horizontal wellbores allow more contact the vertical relative permeability of a formation in

with the producing formation, some difficulties are which at least two horizontal wellbores have been

encountered when horizontal wellbores are utilized placed for the removal of hydrocarbonaceous fluids.

which are not commonly experienced when vertical 25

wells are used. Methods used in producing hydrocar It is another object of this invention to use liquid

carbon dioxide and a steam flood in a formation contain

bons from a formation or reservoir via vertical wells

often prove to be inefficient when attempting to remove ing at least two horizontal wellbores so as to maximize

hydrocarbons from a reservoir where horizontal well drainage of the formation.

bores are being used. This inefficiency results in utiliza 30 It is yet another object of this invention to provide for

tion of increased amounts of fluids used during en liquid carbon dioxide stimulation of the formation in

combination with steam so that the formation can be

hanced oil recovery operation. This results in a dimuni stimulated with any length of a horizontal wellbore.

tion in the amount of hydrocarbons removed from the It is a still further object of this invention to provide

formation or reservoir.

This inefficiency is demonstrated when a carbon 35 for a liquid carbon dioxide/steam flood method which

dixoide flood is utilized with a vertical wellbore where can enhance oil recovery from a formation via at least

the formation contains zones of varying permeability. two horizontal wellbores.

Often the carbon dioxide overrides a zone of lower BRIEF DESCRIPTION OF THE DRAWING

permeability leaving hydrocarbonaceous fluids behind.

U.S. Pat. No. 4,736,792, issued to Brown et al. on The drawing is a schematic representation showing

Apr. 12, 1988, discloses a method for treating a well displacement of formation oil by expanded carbon diox

completed in a subterranean formation containing pe ide where two horizontal wellbores are utilized.

troleum where a preconditioning process was em DESCRIPTION OF THE PREFERRED

ployed. The preconditioning process was used to im EMBODIMENTS

prove the receptivity of the formation to steam. The 45

method involved injecting a heated non-condensible In the practice of this invention as is shown in the

and oil soluble gas, in the gaseous phase, into the forma drawing, wellbore 12 penetrates a hydrocarbonaceous

tion so as to avoid permanently fracturing the formation fluid-bearing formation 10. Hydrocarbonaceous fluids

and also avoid the immediate formation of an oil bank. in said formation can have a gravity of from about 10 to

Stephens in U.S. Pat. No. 4,607,699, issued Aug. 26, 50 about 60 API degrees. At its lower end wellbore 10 is

1986, discusses a huff-puff cyclic steam stimulation deviated in a manner so as to form a lower horizontal

method. Here a formation is fractured by liquid carbon wellbore 28 which contains perforations 14 on its top

dioxide injection. While carbon dioxide is still in place side. At a desired distance from horizontal wellbore 28

within the formation, steam is injected into the forma is placed an upper horizontal wellbore 26 which has

tion. After a suitable soaking period, the well is opened 55 perforations 14 on its bottomside. Horizontal wellbore

to production. 26 is fluidly connected to wellbore 12. The angle of

Therefore, what is needed is a method to improve the deviation from vertical wellbore 12 for both horizontal

sweep efficiency of liquid carbon dioxide in a formation wellbore 26 and horizontal wellbore 28 is about 10' to

where only horizontal wellbores are utilized and the about 90°. Tubing 16 is centered in the vertical portion

formation is not fractured. of wellbore 12 by packer 18 so as to cause fluid commu

SUMMARY OF THE INVENTION

nication by tubing 16 with only lower horizontal well

bore 28. Tubing 16 being centered in wellbore 12 and

This invention is directed to a method for the re held in place by packer 18 forms annulus 24 in wellbore

moval of hydrocarbonaceous fluids from a formation 12 which annulus fluidly communicates with upper

which is penetrated by at least two horizontal well 65 horizontal wellbore 26 only.

bores. In the practice of this invention, liquid carbon In order to remove hydrocarbonaceous fluids from

dioxide is injected into a lower horizontal wellbore formation 10, liquid carbon dioxide is injected into tub

where it enters the formation and contacts hydrocarbo ing 16 where it flows into formation 10 via perforations

4,982,786

3 4.

14 contained in lower horizontal wellbore 28. Once in zontal wellbore can be used as a producer well. Multi

formation 10, the temperature of formation 10 causes ple lower and upper horizontal wellbores can be uti

some of the liquid carbon dioxide to form a gas which lized.

penetrates the formation and mixes with hydrocarbona Obviously, many other variations and modifications

ceous fluids contained therein. A portion of the liquid of this invention as previously set forth may be made

carbon dioxide dissolves in the oil lowering the oil's without departing from the spirit and scope of this in

viscosity and causing the formation contacted to be vention, as those skilled in the art readily understand.

more receptive to steam penetration. Any undissolved Such variations and modifications are considered part

liquid carbon dioxide that remains in the formation is of this invention and within the purview and scope of

driven deeper into formation 10 by a subsequent steam 10 the appended claims.

flood. Liquid carbon dioxide is injected into the forma What is claimed is:

tion at a rate and volume which will not fracture the 1. A method for recovering hydrocarbonaceous flu

formation. Once sufficient liquid carbon dioxide has ids from a formation penetrated by at least two horizon

been injected into formation 10, injection of liquid car tal wells comprising:

bon dioxide into formation 10 is ceased. A method for 15 (a) injecting liquid carbon dioxide through at least

injecting liquid carbon dioxide into formation 10 is dis one lower horizontal well into said formation at a

closed in U.S. Pat. No. 4,607,699, issued to Stephens on pressure insufficient to fracture said formation;

Aug. 26, 1986. This patent is hereby incorporated by (b) thereafter injecting steam into said lower horizon

reference. The teachings of this patent can be utilized so tal well, thereby causing said liquid carbon dioxide

long as the fracturing pressure of formation 10 is not 20

to convert to its gaseous state and expand thereby

exceeded by liquid carbon dioxide injection. making a substantially better sweep of the forma

After all the liquid carbon dioxide has been injected, tion;

steam injection is commenced. A method for injecting (c) recovering hydrocarbonaceous fluids, gaseous

steam into the formation is discussed in U.S. Pat. No.

4,607,699, as mentioned above. Steam is injected via 25 carbon dioxide, steam and water from said forma

tubing 16 into lower horizontal wellbore 28 by perfora tion via at least one upper horizontal well; and

tions 14 where it enters formation 10. Steam injection is (d) repeating steps (a), (b) and (c).

continued until a sufficient amount of steam has been 2. The method as recited in claim 1 where fluids

directed into the formation. When the steam contacts recovered from step (c) are separated.

3. The method as recited in claim 1 where the API

the liquid carbon dioxide 20, it converts the liquid car 30

gravity of hydrocarbonaceous fluids in said formation

bon dioxide into its gaseous state whereupon it mixes

with hydrocarbonaceous fluids in formation 10 and is prior to carbon dioxide injection is from about 10 to

pushed outwards toward upper wellbore 26. When the about 60 API degrees.

mixture comes into contact with wellbore 26, it enters 4. A method for recovering hydrocarbonaceous flu

perforations 14 and exits wellbore 26 via annulus 24 and 35 ids from a formation penetrated by at least two horizon

is removed from the formation by wellbore 12 to the tal wells comprising:

surface. After removing the carbon dioxide/hydrocar (a) injecting liquid carbon dioxide through at least

bonaceous fluid mixture from the formation, it is sepa one lower horizontal well into said formation at a

rated from the carbon dioxide, steam and water. pressure insufficient to fracture said formation;

Displacement efficiencies in directing hydrocarbona (b) thereafter injecting steam into said lower horizon

ceous fluids to the upper horizontal wellbore 26 are tal well, thereby causing said liquid carbon dioxide

enhanced by injecting liquid carbon dioxide again into to convert to its gaseous state and expand thereby

the formation. Once sufficient liquid carbon dioxide has making a substantially better sweep of the forma

been injected into the formation, injection of carbon tion;

dioxide is ceased and steam injection once again con 45 (c) repeating steps (a) and (b);

menced. This sequence is repeated until the desired (d) recovering hydrocarbonaceous fluids, gaseous

amount of hydrocarbonaceous fluids has been removed carbon dioxide, steam and water from said forma

from the formation. tion via at least one upper horizontal well; and

As will be understood by those skilled in the art, (e) separating the fluids recovered from step d.

although an upper and lower wellbore are shown in the 50 5. The method as recited in claim 4 where the API

drawing communicating fluidly with the vertical sec gravity of hydrocarbonaceous fluids in said formation

tion of wellbore 12, individual horizontal wellbores can prior to carbon dioxide injection is from about 10 to

be utilized. A separate lower horizontal wellbore can be about 60 API degrees.

used as an injector well, while an upper separated hori

55

You might also like

- SPE 124409 Formation and Removal of Hydrates Inside Wellhead ConnectorsDocument15 pagesSPE 124409 Formation and Removal of Hydrates Inside Wellhead ConnectorsEnriCruzNo ratings yet

- FCCU Reactor and Transfer Line CokingDocument4 pagesFCCU Reactor and Transfer Line Cokingsaleh4060No ratings yet

- A Comparative Study of Enhanced Oil Recovery For The Depleted Oil Field in Iraq A Simulation Modes Using Eclipse Software PDFDocument85 pagesA Comparative Study of Enhanced Oil Recovery For The Depleted Oil Field in Iraq A Simulation Modes Using Eclipse Software PDFMuezzElerebyNo ratings yet

- United States PatentDocument6 pagesUnited States PatentJayaraj VNo ratings yet

- Method For Enhanced Recovery of Viscous Oil DepositsDocument5 pagesMethod For Enhanced Recovery of Viscous Oil DepositsRishel Mae VeraNo ratings yet

- Deaerator - WikipediaDocument8 pagesDeaerator - Wikipediaameen alhakimiNo ratings yet

- CokeDocument6 pagesCokeDendy Wahyu RadityaNo ratings yet

- Sulpur ProductionDocument10 pagesSulpur ProductionhukNo ratings yet

- ABSORBERDocument7 pagesABSORBERDendy Wahyu RadityaNo ratings yet

- Oct. 5, 1965 J. D. Alexander Etal 3,209,825: Filed Feb. 14, 1962Document5 pagesOct. 5, 1965 J. D. Alexander Etal 3,209,825: Filed Feb. 14, 1962EzequielNo ratings yet

- Patente Cryoplus Linde Us4617039Document13 pagesPatente Cryoplus Linde Us4617039rubenpeNo ratings yet

- Us2503724 - Ca2941105a1Document8 pagesUs2503724 - Ca2941105a1Facundo MendezNo ratings yet

- Filed March 9, 1953 2 Sheets-Sheet 1: March 4, 1958 K. M. Watson 2,825,408Document6 pagesFiled March 9, 1953 2 Sheets-Sheet 1: March 4, 1958 K. M. Watson 2,825,408KrozeNo ratings yet

- United States Patent (19) : Teyssier Et Al. 11) 4,299,809Document5 pagesUnited States Patent (19) : Teyssier Et Al. 11) 4,299,809apriyansyahNo ratings yet

- Boiler Feedwater: A. DeaerationDocument11 pagesBoiler Feedwater: A. DeaerationRaja TNo ratings yet

- US3039853 (Channel Patent)Document2 pagesUS3039853 (Channel Patent)Dewi Aiiu NabillaNo ratings yet

- Joya Us4569799Document9 pagesJoya Us4569799Agustin CantilloNo ratings yet

- Filed Oct. 15, 1947: R. L. GholsonDocument6 pagesFiled Oct. 15, 1947: R. L. GholsonGustavo RamosNo ratings yet

- US3983032Document4 pagesUS3983032Diego RossoNo ratings yet

- Removal of Hydrogen Sulfide From A Carbon Dioxide Containing Gas MixtureDocument4 pagesRemoval of Hydrogen Sulfide From A Carbon Dioxide Containing Gas MixtureIveth RomeroNo ratings yet

- United States Patent (19) (11) Patent Number: 5,868,202: Hsu (45) Date of Patent: Feb. 9, 1999Document13 pagesUnited States Patent (19) (11) Patent Number: 5,868,202: Hsu (45) Date of Patent: Feb. 9, 1999KrozeNo ratings yet

- Q 3. Yaziliavis U: Sept. 20, 1966 J. F. Hutto Etal 3,274,275Document6 pagesQ 3. Yaziliavis U: Sept. 20, 1966 J. F. Hutto Etal 3,274,275BüşraNo ratings yet

- Q 3. Yaziliavis U: Sept. 20, 1966 J. F. Hutto Etal 3,274,275Document6 pagesQ 3. Yaziliavis U: Sept. 20, 1966 J. F. Hutto Etal 3,274,275BüşraNo ratings yet

- Q 3. Yaziliavis U: Sept. 20, 1966 J. F. Hutto Etal 3,274,275Document6 pagesQ 3. Yaziliavis U: Sept. 20, 1966 J. F. Hutto Etal 3,274,275BüşraNo ratings yet

- CARBONDocument11 pagesCARBONnayanNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2009/0206007 A1Document13 pagesPatent Application Publication (10) Pub. No.: US 2009/0206007 A1Tree SilviaNo ratings yet

- Dispositibo BHMDocument5 pagesDispositibo BHMB1No ratings yet

- United States PatentDocument4 pagesUnited States Patentwiam wiamNo ratings yet

- Paten Produksi Syn GasDocument12 pagesPaten Produksi Syn GasFarras HaidaryNo ratings yet

- Patent AnalysisDocument4 pagesPatent AnalysisShabnamNo ratings yet

- US4931098Document5 pagesUS4931098ALEXANDER FRANCO CASTRILLONNo ratings yet

- Coker Meyers QInd IIDocument57 pagesCoker Meyers QInd IIAusten83790% (1)

- IntroductionDocument10 pagesIntroductionMurtibaahshe HDNo ratings yet

- United States Patent (19) : Filed: Apr. 20, 1977 57Document5 pagesUnited States Patent (19) : Filed: Apr. 20, 1977 57Iqbal KhanNo ratings yet

- ANEXO 8 US2436432 A Método para La Fabricación de Ácido Clorhídrico (18 de Mayo 1937)Document7 pagesANEXO 8 US2436432 A Método para La Fabricación de Ácido Clorhídrico (18 de Mayo 1937)CésarSánchezRosasNo ratings yet

- J. Biol. Chem.-1923-Hall-751-5Document6 pagesJ. Biol. Chem.-1923-Hall-751-5AnjacNo ratings yet

- Calcining CopperasDocument3 pagesCalcining Copperasanaaziz100% (1)

- SPE 144961-PP Large Scale CO Flood Begins Along Texas Gulf CoastDocument11 pagesSPE 144961-PP Large Scale CO Flood Begins Along Texas Gulf CoastDarrell DavisNo ratings yet

- Aeasy44: March 6, 1956 E. S. Roberts Et Al 2,737,440Document4 pagesAeasy44: March 6, 1956 E. S. Roberts Et Al 2,737,440cryovikas1975No ratings yet

- Mo Krys 1993Document16 pagesMo Krys 1993wsanchez_soteloNo ratings yet

- Plug and Abandonment of A Deep High-Pressure and High-Temperature Gulf of Mexico Well Using Coiled Tubing: A Case History KopyaDocument9 pagesPlug and Abandonment of A Deep High-Pressure and High-Temperature Gulf of Mexico Well Using Coiled Tubing: A Case History Kopyaerdal aydinNo ratings yet

- US4767543Document6 pagesUS4767543Baba DookNo ratings yet

- 5 Underground Coal GasificationDocument11 pages5 Underground Coal GasificationAhilesh100% (1)

- Sagd Process in Fractured Heavy Oil Reservoirs: A. Suat Bagci, Heriot-Watt UniversityDocument14 pagesSagd Process in Fractured Heavy Oil Reservoirs: A. Suat Bagci, Heriot-Watt UniversitykuzapNo ratings yet

- Sept. 5, 1972 R. E. Lane Etal 3,689,229: WaterDocument3 pagesSept. 5, 1972 R. E. Lane Etal 3,689,229: WaterMuhammad Iqbal Khan ChandioNo ratings yet

- Nov. 11, 1958 E. K. Jones Et Al: Manufacture of Isopropyl Benzene by Alkylation Filed JanDocument8 pagesNov. 11, 1958 E. K. Jones Et Al: Manufacture of Isopropyl Benzene by Alkylation Filed JanRizal EffendiNo ratings yet

- Evaluation of Co Carrying Capacity of Reactivated Cao by HydrationDocument23 pagesEvaluation of Co Carrying Capacity of Reactivated Cao by HydrationPiyush GodseNo ratings yet

- SPE 15176 Carb (N Dioxide Corrosion in Oilwell Cements: Dowell SchlumbergerDocument9 pagesSPE 15176 Carb (N Dioxide Corrosion in Oilwell Cements: Dowell SchlumbergerJohnSmithNo ratings yet

- United States PatentDocument5 pagesUnited States PatentPraveen SinghNo ratings yet

- Thermal Recovery ProcessesDocument19 pagesThermal Recovery Processesحسين رامي كريم A 12No ratings yet

- US4652381Document8 pagesUS4652381Mahmudul HasanNo ratings yet

- US4780224Document4 pagesUS4780224Mohamad Reza JahanbakhshNo ratings yet

- US1938609Document3 pagesUS1938609分析室信箱No ratings yet

- R. Albion, S. - World&apos S First SAGD Facility Using Evaporators, Drum Boilers, and ZDocument7 pagesR. Albion, S. - World&apos S First SAGD Facility Using Evaporators, Drum Boilers, and ZLuqmanNo ratings yet

- Capturing and Sequestering Flue-Gas CO Using A Wet Limestone ScrubberDocument6 pagesCapturing and Sequestering Flue-Gas CO Using A Wet Limestone ScrubberMaria Jafar KhanNo ratings yet

- March 15,: Distillation Apparatus UsefueforDocument5 pagesMarch 15,: Distillation Apparatus UsefueforsambasivaNo ratings yet

- OMC2007 Acid TunnelingDocument13 pagesOMC2007 Acid TunnelingGuidoNo ratings yet

- Separation of Oil From Water by Dissolved Air FlotationDocument12 pagesSeparation of Oil From Water by Dissolved Air FlotationMarcosChaprãoNo ratings yet

- Us 4776288Document7 pagesUs 4776288nguyenhuutan91No ratings yet

- The Steam Engine Explained and Illustrated (Seventh Edition) With an Account of its Invention and Progressive Improvement, and its Application to Navigation and Railways; Including also a Memoir of WattFrom EverandThe Steam Engine Explained and Illustrated (Seventh Edition) With an Account of its Invention and Progressive Improvement, and its Application to Navigation and Railways; Including also a Memoir of WattNo ratings yet

- Higher Order Time Discretization of Compartmentalized ReservoirsDocument151 pagesHigher Order Time Discretization of Compartmentalized ReservoirsMEJRI AbirNo ratings yet

- 2013 Adipec 687Document22 pages2013 Adipec 687Эльхан ИмановNo ratings yet

- Conclusions Underground Storage of Gas Seminar SibiuDocument21 pagesConclusions Underground Storage of Gas Seminar SibiuMustafa 1741144No ratings yet

- Water Shut Off Review - Slumberger - Technology With Cover Page v2Document23 pagesWater Shut Off Review - Slumberger - Technology With Cover Page v2Aminollah PayvandNo ratings yet

- WF DesignDocument49 pagesWF DesignAviiCaph100% (1)

- Chapter 1 & 2 - Introduction & Microscopic Displacement of Fluids in ReservoirDocument43 pagesChapter 1 & 2 - Introduction & Microscopic Displacement of Fluids in ReservoirAfiqah Che MatNo ratings yet

- Transient Flow - An OverviewDocument14 pagesTransient Flow - An OverviewDheeraj Chowdary DhanekulaNo ratings yet

- Lesson 1 - Introduction To Petroleum and Natural Gas EngineeringDocument8 pagesLesson 1 - Introduction To Petroleum and Natural Gas Engineeringmghareeb100% (1)

- Choosing An Optimum Sand Control MethodDocument10 pagesChoosing An Optimum Sand Control MethodShahbaz AhmadNo ratings yet

- Rod Pump Ver3-201205Document199 pagesRod Pump Ver3-201205doner72No ratings yet

- Reservoir and Production Conformance in Dev Wells - QUITO - FINALDocument228 pagesReservoir and Production Conformance in Dev Wells - QUITO - FINALDiego Gerardo FabaraNo ratings yet

- Safety Data Reporting User Guide - Scope and Definitions (2019 Data)Document78 pagesSafety Data Reporting User Guide - Scope and Definitions (2019 Data)Septian Adi WibowoNo ratings yet

- Integrated Reservoir Management: Hesham Mokhtar Ali Senior Reservoir Engineer In/heshammokhtaraliDocument74 pagesIntegrated Reservoir Management: Hesham Mokhtar Ali Senior Reservoir Engineer In/heshammokhtaraliThierry ThomasNo ratings yet

- FPSO BasicsDocument63 pagesFPSO BasicsNagesh Kumar100% (2)

- تقنية الانتاج ثانيDocument240 pagesتقنية الانتاج ثانيsnariaNo ratings yet

- Fine Reservoir Description Techniques Current Status Challenges and Solutions Huanqing Chen Full ChapterDocument57 pagesFine Reservoir Description Techniques Current Status Challenges and Solutions Huanqing Chen Full Chapterthomas.frazier143100% (16)

- Gas Flaring Regulation - World BankDocument108 pagesGas Flaring Regulation - World BankWale Adeleke100% (1)

- HW 1Document5 pagesHW 1Ali MahmoudNo ratings yet

- Flooding Polymer EORDocument14 pagesFlooding Polymer EORximenaesgNo ratings yet

- Short Course ON Reservoir Management: Tutorial QuestionsDocument10 pagesShort Course ON Reservoir Management: Tutorial QuestionsAnyasi UcheNo ratings yet

- Ahmad Alavian NTNU PHD Thesis PDFDocument275 pagesAhmad Alavian NTNU PHD Thesis PDFHamahid pourNo ratings yet

- Study of Enhanced-Oil-Recovery Mechanism of Alkali/Surfactant/Polymer Flooding in Porous Media From ExperimentsDocument8 pagesStudy of Enhanced-Oil-Recovery Mechanism of Alkali/Surfactant/Polymer Flooding in Porous Media From ExperimentsSanjay singhNo ratings yet

- Petroskills Course Schedule 2017Document9 pagesPetroskills Course Schedule 2017Connor SailorNo ratings yet

- Concepts of Ceor Implementation From Laboratory To Field: SurtekDocument67 pagesConcepts of Ceor Implementation From Laboratory To Field: SurtekIndra WijayaNo ratings yet

- Reasearch Paper - OilDocument18 pagesReasearch Paper - OilAmr Abou HusseinNo ratings yet

- SC TecDocument33 pagesSC TecChunyu LiNo ratings yet

- Overview of CO2 Injection and WAG Sensitivity in SACROC: January 2016Document23 pagesOverview of CO2 Injection and WAG Sensitivity in SACROC: January 2016Jorge Andrés TovarNo ratings yet

- Environmental Protection and Enhancement Act - E12 - Activities Designation Regulation - Reg276.2003Document52 pagesEnvironmental Protection and Enhancement Act - E12 - Activities Designation Regulation - Reg276.2003Canten ChrapkoNo ratings yet

- Smart Well CompletionDocument10 pagesSmart Well CompletionLuis David Concha CastilloNo ratings yet