Professional Documents

Culture Documents

Guia

Guia

Uploaded by

Armando CasallasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guia

Guia

Uploaded by

Armando CasallasCopyright:

Available Formats

Product

Support

Guide

D255 MP 501SPF

D256 MP 601SPF

M281 SP 5300DN

M282 SP 5310DN

v1.0

Introduction Date July 7 2016 SPF

Introduction Date September 15 2016 DN

Replaces SP 5200 series

Product Concept

Reliable, Productive, and Small Leader for your Future Business Success

Smooth Eco & Human

Usability Friendly

Enhanced Usability & BAM, Energy Star

Solutions with Cheetah Ver. 2.0, EPEAT

Operation Panel (MF) Silver

Mutual Controller to Top Level TEC

collaborate with A3 Values compared to

Devices others

Supporting 2 NIC Port

(Option)

1,200 x 1,200 dpi Virtually maintenance

Support Free until 500K.

Paper Handling Its Robust Durability

Capability for different can rely on stable

variety of vertical regular batch printing

MP 501/601SPF SP 5300/5310DN in the office

businesses

(52/62ppm)

(Healthcare etc…) (52/62ppm)

High Quality Stable & Reliable

Output

•Version 1.0 Subject to Change 2

Table of Contents

Product Concept………………………..………..…… • 2

Smart Operation Panel ……..…………………..…...… •5

New Features ………………………………..……..… • 6

Feature Comparison to Previous Model…..………..... • 8

Standard Configuration ….………...………….….… • 9

Options………………………..………….………..….…. • 12

Supplies & Yields ……………….…………..…..…... • 16

Target Reliability …....………….………….………..… • 17

Yield Parts – Mainframe……..…...………….…...….… • 18

Yield Parts – Peripheral………….……….……….…. • 19

Special Tools…………………………………………... • 20

Coverage Ratio ..……………………………………..… • 21

Version 1.0 Subject to Change 3

Table of Contents – cont’d

Installation Requirements ……........…………….…. • 22

Dimensions………………….……….……………..…… • 23

Installation Times..………….....……………….…….… • 24

Storage / Transportation ……………………………… • 26

Training Information…………………….………….…… • 27

Documention…………………………………………… • 28

Contact Information…………………………………….. • 29

Escalation Procedure…………………..………...…….. • 30

Revisions…………….………………………………… • 32

Version 1.0 Subject to Change 4

New Smart Operation Panel

*A customization is required to take advantage of the items written in red.

Speaker Power LED

For USB

memory For USB

camera

SD card

Access LED

HDMI*

SD card

Reset button

*Extended

Function

Keys

Incoming USB NFC*

fax LED

Data-in LED

Check status button Status LED Microphone

•Version 1.0 Subject to Change 5

New Features

Hardware

Features:

– Smart Operation Panel (MF ONLY)

– Support new UI “Smart Apps”

– Specific Use Apps such as ID card copy

– Smart SDK support

– Selectable operation/error sound

– Support New RFU (Remote Firmware Update) to update firmware

automatically by machine

Version 1.0 Subject to Change 6

New Features – cont’d

Connectivity/Software Support

GW controller (15S model)

– GW wireless LAN supports Wi-Fi Direct

– Indicator for log storing is displayed

– Managing of device preferences via a web server is supported

– Ability to obtain logs from Web Image monitor is supported

Smart Operation Panel

– SMC includes Smart Operation Panel information

– Wi-Fi direct support Wi-Fi Protected Setup

– Customization is available per user

– Smart Operation Panel settings are integrated into “User Tools”

– Bluetooth is implemented to Smart Operation Panel

– Support for RICOH Smart Device Connector

– Applications can be installed and uninstalled via the Application Site

– Firmware can be updated and downgraded via the Application Site

– Inclusion of Smart Apps

Version 1.0 Subject to Change 7

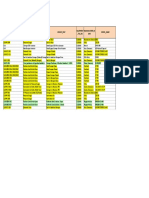

Feature Comparison to Previous Model

D255/D256 M052/M053/M054

Description

M281/M282 M020/M021

Print Speed 52, 62 47,52

1,200 x 1,200 dpi N/A

Gigabit Ethernet Standard Option

1GB (MF)

Ram Memory Std. 2GB

768 MB (P)

Operation Panel (MF) 10.1 inch Cheetah Panel 8.5 inch

Controller GW+ GW

Maintenance Kit 500K (Service Required) 120K

Processor 1.46GHz 533 MHz

MF:475×504×645 / MF: 520×510×686 /

Footprint (W×D×H) in MM

P: 420×410×345 P: 411×435×400

HDD MF: Standard / P: Option Option

Envelope Switch/Lever No need to switch or lever

2 NIC Port Option N/A

AirPrint Supported N/A

SDK Smart SDK Java SDK

Version 1.0 Subject to Change 8

Standard Configuration

Product Serial Number

Model Launch Date EDP Code Speed

Code Prefix

MP 501SPF 6/29/2016 D255 407809 G98yfmxxxxx 52ppm

MP 601SPF 6/29/2016 D256 407812 G99yfmxxxxx 62ppm

SP 5300DN 9/15/2016 M281 407815 Y02yfmxxxxx 52ppm

SP 5310DN 9/15/2016 M282 407819 Y12yfmxxxxx 62ppm

Version 1.0 Subject to Change 9

Configuration

N0. Item Machine MP 501/601 SP 5300/5310

Code

1 Paper Feed Unit D3C2-01 Yes Yes

PB1100 *1

2 Caster Table D3C7-01 Yes Yes

Type M24

*1 You can add up to 4 paper feed units.

Version 1.0 Subject to Change 10

Controller Configuration

Slot Option

USB Device Server Option Type M19

IEEE 1284 Interface Board Type M19

[A] I/F slot IEEE 802.11 Interface Unit Type M24

Extended USB Board Type M19

File Format Converter Type M19*2

*1 There is no difference between the left and right USB ports.

*2 MP 501/601 only

Version 1.0 Subject to Change 11

Options

Common /

Item Description Product Code EDP Code Notes

Unique

Paper Feed Unit for Brazil-MF1/P1 Paper Feed Unit PB 1100 D3C201 407850 Unique

Caster Table for Brazil-MF1/P1 Caster Table Type M24 D3C701 407851 Unique

IEEE 802.11 Interface Unit for Brazil-

IEEE 802.11 Interface Unit Type M24 M50008 407863 Unique

MF1/P1

XPS Direct Print Option for Brazil-

XPS Direct Print Option Type M24 D3CP12 408048 Unique

MF1/P1

Not available until

IPDS Unit for Brazil-MF1/P1 IPDS Unit Type P8 M50002 407870 Unique

7/2017

Fax Connection Unit for Brazil-MF1 Fax Connection Unit Type M24 D3CP05 407854 Unique

NFC Card Reader for Brazil-MF1 NFC Card Reader Type M24 D3CP08 407853 Unique

Tall Cabinet Tall Cabinet 52651 Unique

Medium Cabinet Medium Cabinet 52641 Unique

Version 1.0 Subject to Change 12

Options – Cont’d

Common /

Item Description Product Code EDP Code Notes

Unique

Extended USB Board for MF/P Extended USB Board Type M19 D3BS01 417566 Common

IEEE 1284 Interface Board for MF/P IEEE 1284 Interface Board Type M19 D3C017 417596 Common

USB Device Server Option for MF/P USB Device Server Option Type M19 D3BC28 417567 Common

DataOverwriteSecurity Unit for MF DataOverwriteSecurity Unit Type M19 D3BS03 417499 Common

File Format Converter for MF File Format Converter Type M19 D3BR04 417508 Common

OCR Unit for MF OCR Unit Type M13 D3AC23 417428 Common

Optional Counter Interface Unit for MF Optional Counter Interface Unit Type M12 B87021 417111 Common

Power Filter ESP AC1 Power Filter ESPAC1 Common

ESP XG-PCS-15D Power Filter ESP XG-PCS-15D Power Filter 006428MIU Common

Version 1.0 Subject to Change 13

Option Compatibility

Category Product Name You Must Install You Cannot Install Comments

Paper Feed Unit for Brazil-

- Up to 4 PFU’s

MF1/P1

Caster Table for Brazil- Medium Cabinet

3 or 4 PFU’s 3 or 4 PFU’s

MF1/P1 Tall Cabinet

Paper Feeding Caster Table

Medium Cabinet 1 or 2 PFU’s 1 or 2 PFU’s

Tall Cabinet

Caster Table

MF with Main Tray

Tall Cabinet - Medium Cabinet

Only

PFU’s

USB Device Server Option

- -

Type M19

IEEE 1284 Interface Board

- -

Type M19

IEEE 802.11 Interface Unit Only 1 can be

I/F slot - -

Type M24 installed at a time

Extended USB Board Type

- -

M19

File Format Converter Type

- -

M19

OCR Unit for MF - -

Fax Connection Unit for

- -

Brazil-MF1

Must merge if using

SD Cards IPDS Unit for Brazil-MF1/P1 - -

more than 2 SD cards

XPS Direct Print Option for

- -

Brazil-MF1/P1

DataOverwriteSecurity Unit

- -

for MF

Version 1.0 Subject to Change 14

Option Compatibility – Cont’d

Category Product Name You Must Install You Cannot Install Comments

Optional Counter Interface

- - -

Unit for MF

NFC Card Reader for Brazil-

- - -

MF1

Other

ESP XG-PCS-15D Power

Power Filter - Recommended for MFP

Filter

ESP XG-PCS-15D Power

- Power Filter Recommended for printer

Filter

Version 1.0 Subject to Change 15

Supplies & Yields

Description EDP Code Yield

Print Cartridge Black 407823 25K*

Feed Roller MP 601 408049 500K

Feed Roller MP 601PB 408050 500K

Starter Toner 10K

*Declared yield value in accordance with ISO/IEC 19752

Version 1.0 Subject to Change 16

Target Reliability

Model PM AMV Max MV

D255 500K 5K 16.6K

D256 500K 6.5K 16.6K

M281 500K 4K 16.6K

M282 500K 5.5K 16.6K

Notes: The figures above are calculated based on the following:

Recommended paper types are used.

The machine is installed under operable environmental conditions

A4 (LT) short-edge feed

Image coverage ratio: 5%

3 P/J

Version 1.0 Subject to Change 17

Yield Parts - Mainframe

Expected Yield Unique Or

Part

The Number

expected yield of all PM partsDescription

is calculated assuming the following conditions:

(Pages) Common

A4 (LT) short-edge feed

Mainframe

Color ratio: 30%

M2813040

Expected ACV: Drum unit 500K U

M2813030

Coverage: 5% Development unit 500K U

M2814070 (NA) Fusing unit 500K U

M2812838 Transfer roller unit 500K U

M2812821 Paper feed roller 500K U

M2812824 Pickup roller 500K U

M2812520 Separation roller 500K U

Note 1: The above listed parts are treated as “Yield Parts”, which means that they are not expected to require replacement during the

entire lifecycle of the machine, assuming the machine is used at the target ACV and coverage ratio. This is why these parts are not

listed as PM parts.

Note 2: The yield figures in the above table are based on the following conditions:

•A4 (LT) short-edge feed

•5% image coverage ratio

•3 P/J

Version 1.0 Subject to Change 18

Yield Parts - Peripheral

Expected Yield Unique Or

Part Number Description

(Pages) Common

ARDF MF1 Only

D2555567 Feed roller assy 200K U

D2555568 Separation Pad 200K U

1-Tray Paper Feed Unit

M2812821 Paper feed roller 500K U

M2812824 Pickup roller 500K U

M2812520 Separation roller 500K U

Note 1: The above listed parts are treated as “Yield Parts”, which means that they are not expected to require replacement during the

entire lifecycle of the machine, assuming the machine is used at the target ACV and coverage ratio. This is why these parts are not

listed as PM parts.

Note 2: The yield figures in the above table are based on the following conditions:

•A4 (LT) short-edge feed

•6% image coverage ratio

•3 P/J

Version 1.0 Subject to Change 19

Special Tools

The following special tools should be prepared for maintenance of the new model in the field:

Unique or Common:

U: Unique for this model

C: Common with listed model

Item Part Number Description Q’ty Unique or Common

1 B6455030 SD Card 2GB 1 C (General)

2 B6455040 SD Card 8GB 1 C (General)

3 B6455060 SD Card 16GB 1 C (General)

NOTE: A PC (Personal Computer) is required for creating the Encryption key file to an SD card when replacing the

controller board for a model in which HDD encryption has been enabled.

Version 1.0 Subject to Change 20

Coverage Ratio

1P/J 2P/J 3P/J ISO

Toner Cartridge N/A 17.5k*1 17.5k*1 25k*2

*1: The yield figures in the above table are based on the following conditions:

• A4 (LT) short-edge feed

• 6% image coverage ratio

*2 *Declared yield value in accordance with ISO/IEC 19752

Version 1.0 Subject to Change 21

Installation Requirements

Power requirements

– Input voltage level: 120 to 127 V, 15A, 60 Hz ± 2%

– Do not use an extension plug or cord

Footprint

1. Rear: Over 300 mm (11.9")

2. Right: Over 200 mm (7.9")

3. Front: Over 500 mm (19.7")

4. Left: Over 300 mm (11.9")

Weight

D255 / D256 Less than 62lbs

M281 /M282 less than 40lbs

Version 1.0 Subject to Change 22

Dimensions

MP 501SPF/601SPF SP 5300DN/5310DN

WxDxH (including ARDF and operation panel): WxDxH:

475 x 504 x 645 mm (18.8" x 19.9" x 25.4“) 420 x 410 x 345 mm (16.6" x 16.2" x 13.6")

• [A]: 475 mm (18.8") • [A]: 420 mm (16.6")

• [B]: 645 mm (25.4") • [B]: 345 mm (13.6")

Version 1.0 Subject to Change 23

Installation Times

Model Installation

Peripheral User Installation

MF P Times (minutes)

Paper Feed Unit PB1100 ✔ ✔ 5 (✔)*

Caster Table Type M24 ✔ ✔ 10 (✔)*

Extended USB Board Type M19 ✔ ✔ 5 ✔

IEEE1284 Interface Board Type

✔ ✔ 5 ✔

M19

IEEE802.11 Interface Unit Type

✔ ✔ 5 ✔

M24

USB Device Server Option

✔ ✔ 5 ✔

Type M19

IPDS Unit Type M24 ✔ ✔ 5 ✔

Fax Connection Unit Type M24 ✔ 10 ✔

NFC Card Reader Type M24 ✔ 15

Data Overwrite Security Unit

✔ 10 ✔

Type M19

Version 1.0 Subject to Change 24

Installation Times

Model Installation

Peripheral User Installation

MF P Times (minutes)

File Format Converter Type M19 ✔ 10 ✔

OCR Unit Type M13 ✔ 5

Optional Counter Interface Unit

✔ 10

Type M12

Hard Disk Drive Option Type P8 ✔ 15

VM CARD Type P8 ✔ 5 ✔

* Installation by service technician may be required depending on the machine configuration. Please refer to the table written in

the mainframe for the details.

Version 1.0 Subject to Change 25

Storage / Transportation

Storage Transportation

Temperature -20 ~ 40℃ Temperature -20 ~ 40℃

Mainframe

Humidity 10 ~ 90% Humidity 10 ~ 90%

*1) *3)

Storage Period 12 Months Storage Period 1 Month

Temperature -20 ~ 40℃ Temperature -20 ~ 40℃

Toner (Bk) Humidity 10 ~ 90% Humidity 10 ~ 90%

*1) *2) Storage Period 12 Months Storage Period 1 Month

Max Stack 10 Cartons Max Stack 5 Cartons

*1) Temperature gradient should be under 20℃/hour. Please prevent from dewfall.

*2) Possible to store within 1 month in a temperature of 55℃and a humidity of 90%.

*3) Possible to store within 1 month in a temperature of 36 to 40℃.

Possible to store within 12 hours in a temperature of 41 to 43℃.

Possible to store within 14 days in a temperature of 40℃ and 70% Humidity.

Version 1.0 Subject to Change 26

Training Information

HARDWARE SUPPORT

Service Training

Service training should be completed before the first machine is delivered to

distributors, dealers, or users.

Training Method:

Trainees who completed service training for predecessor model SP5200DN /

SP5200SF

Self-paced Training through RLI

Trainees who did not complete service training for predecessor model SP5200DN /

SP5200SF

Self-paced Training through RLI

Version 1.0 Subject to Change 27

Documentation

Description RFG E-Source Number

Operating Instruction rfg072513

Point-to-Point rfg072514

Parts Catalog MF1 rfg072515

Parts Catalog P1 rfg072516

Service Manual rfg072512

Please refer to the https://ricohusa.csod.com/client/ricohusa/default.aspxweb site for the most

up to date training information.

Please be aware that once a model or series is out of production, the Field Service Manual,

Technical Service Bulletins and Ricoh University should be referenced for the most current

information. Check the TSRC website and e-source.

Version 1.0 Subject to Change 28

Contact Information

Name Contact

Parts (800) 333-3147

Ricoh: (800) 537-4264

Savin: (800) 291-6044

Lanier: (800) 346-6057

Canada (800) 922-4072

Technical Services Call Center Latin America (877) 742-6407

(Hotline) Solutions (888) 424-1573

Customer Support (800) 577-4264

Automated Services (866) 239-8494 myricoh@ricoh-usa.com

Printer/Scanner/Projector Support (800) 742- 6438

Realer Printer Customers (800) 972-8796

Warranty Processing (800) 557-4264

Hytec Parts and Logistics Control (800) 883-1001 www.hytecrepair.com

Technology Solutions Resource

http://www.tscweb.net

Center

Ricoh Corporation: http://www.ricoh-usa.com

Headquarter Web Sites Savin Corporation: http://www.savin.com

Lanier Corporation: http://www.lanier.com

Material Safety Data Sheets (800) 336-MSDS (6737) http://msds.ricoh-usa.com/msds/

Ricoh Learning Institute (973) 882-2200 email address: www.ricohlearninginstitute.com

Version 1.0 Subject to Change 29

Escalation Procedure

Solutions Support and Escalation Intake Guide

http://rfg-esource/nj03ntas02/groups/public/documents/communication/rfg057276.pdf

Required Information for Hardware Issues

Symptom

Possible cause

Description and result of the action taken

Parts replaced

Model type and serial number

Printer configuration sheet and maintenance report sheet

Occurrence frequency

Whether or not the symptom could be duplicated on a lab machine (YES/NO)

Occurrence conditions

When the symptom start to appear

Optional equipment information

Results after installing the units/options on another machine

Whether or not have any customized parts been applied

Log-storing data (controller, engine, and operation logs) with SP5-857

SMC Report (SP5992-001)

Version 1.0 Subject to Change 30

Escalation Procedure – cont’d

Required Information for Computer connectivity problems:

Printer configuration page

Any actions already taken (step-by-step)

Computer specifications (manufacturer, model, type, CPU, memory, etc.)

OS and applications installed (versions and service packs)

Driver and utilities used (versions and service packs)

Network environment (protocol, topology, address, and configuration)

Network packet capture/print capture file

Document originals (files)

PIF (Problem Information Form)

– PIFs can be downloaded from the Global Knowledge:

– http://tscweb.custhelp.com/app/answers/detail/a_id/119457

Version 1.0 Subject to Change 31

Revisions

1.0 Original

1.1 Added rfg numbers for the manuals

Version 1.0 Subject to Change 32

You might also like

- Michaels Hardware CaseDocument5 pagesMichaels Hardware Casesadyia carmel67% (3)

- Electrical Failure Analysis For Fire and Incident InvestigationDocument155 pagesElectrical Failure Analysis For Fire and Incident InvestigationIngeniería Eléctrica Forense100% (2)

- Roduct Upport Uide: D262 MPC W2201Document59 pagesRoduct Upport Uide: D262 MPC W2201OSCARNo ratings yet

- GOT2000 Technical Presentation 2015Document41 pagesGOT2000 Technical Presentation 2015Tarek KhafagaNo ratings yet

- PL6KDocument36 pagesPL6KRoberto Sanchez ZapataNo ratings yet

- VW Audi Master ID ListDocument55 pagesVW Audi Master ID ListSrđan PavićNo ratings yet

- PSG MPC 307Document32 pagesPSG MPC 307Jose Abraham Grovas VelezNo ratings yet

- Roduct Upport Uide: D0CP-Pro C5300S D0CQ - Pro C5310SDocument46 pagesRoduct Upport Uide: D0CP-Pro C5300S D0CQ - Pro C5310SBrunoNo ratings yet

- D259 Product Support GuideDocument30 pagesD259 Product Support GuideRICHARD ALBERTO NARVA ORTIZNo ratings yet

- Guia Soporte de Producto PDFDocument56 pagesGuia Soporte de Producto PDFcaratulinNo ratings yet

- PSG MP c306Document33 pagesPSG MP c306rodrigo pevidorNo ratings yet

- MP 7503 Guia de SoporteDocument47 pagesMP 7503 Guia de SoporteSamuelDelgadoR.No ratings yet

- DF-G1 Expert Dual Display Fiber Amplifier: Instruction ManualDocument34 pagesDF-G1 Expert Dual Display Fiber Amplifier: Instruction ManualJorge Abraham Rodriguez MontielNo ratings yet

- PSG SP C352DNDocument23 pagesPSG SP C352DNJose Abraham Grovas VelezNo ratings yet

- Guia de ProductoDocument45 pagesGuia de Productoalejandro lopez100% (1)

- Product Service Manual - Level 2Document144 pagesProduct Service Manual - Level 2Kukla LossNo ratings yet

- ACS150 EN Reva 050831 LR. PDFDocument16 pagesACS150 EN Reva 050831 LR. PDFArif ImronNo ratings yet

- Labelview8 Installation GuideDocument32 pagesLabelview8 Installation GuideSergio Eu CaNo ratings yet

- Ideapad 1 14igl05 Platform Specifications: Mobilemark 2014: 8 HRDocument1 pageIdeapad 1 14igl05 Platform Specifications: Mobilemark 2014: 8 HRabacus89No ratings yet

- LifeBook® T4215 Tablet PCDocument2 pagesLifeBook® T4215 Tablet PCervin_bhrNo ratings yet

- Omniview: Pro2 Series KVM SwitchDocument37 pagesOmniview: Pro2 Series KVM SwitchRita Leilah DunnNo ratings yet

- Dell Monitor SE2417HG User GuideDocument43 pagesDell Monitor SE2417HG User GuideKevin HuangNo ratings yet

- WhatsNew 2020 enDocument49 pagesWhatsNew 2020 enVigneshwaran KandaswamyNo ratings yet

- Migration Solutions: Panelview™ Component Graphic Terminals To Panelview 800 Graphic TerminalsDocument4 pagesMigration Solutions: Panelview™ Component Graphic Terminals To Panelview 800 Graphic TerminalsRidho AnjikoNo ratings yet

- TUSB3210 Universal Serial Bus General-Purpose Device ControllerDocument48 pagesTUSB3210 Universal Serial Bus General-Purpose Device Controllergenije72973No ratings yet

- Genus g1 User ManualDocument53 pagesGenus g1 User ManualMartaNo ratings yet

- SMP Io Distributed Io Platform Catalog Ca912005enDocument16 pagesSMP Io Distributed Io Platform Catalog Ca912005enlnoriega9637No ratings yet

- IMX6SDLIECDocument161 pagesIMX6SDLIECYNSAP DATA-2020No ratings yet

- Operational Manual ODS-D55UDocument32 pagesOperational Manual ODS-D55UGralFalconNo ratings yet

- Lifebook P702 Notebook: Data SheetDocument3 pagesLifebook P702 Notebook: Data SheetIman SulaimanNo ratings yet

- HP Prodesk 400 G4 Desktop Mini: Support and Service ConsiderationsDocument20 pagesHP Prodesk 400 G4 Desktop Mini: Support and Service ConsiderationsfdelizNo ratings yet

- c06137581 PDFDocument38 pagesc06137581 PDFcallNo ratings yet

- POS J2 520ex Technical ManualDocument30 pagesPOS J2 520ex Technical ManualMatthew GattNo ratings yet

- Devman NX Ent ConfDocument42 pagesDevman NX Ent Confwilliam lozadaNo ratings yet

- Duo Datasheet v1.2Document22 pagesDuo Datasheet v1.2ninioperdidoNo ratings yet

- D2907 PCI Express Gigabit Ethernet Adapter With DASH FunctionalityDocument23 pagesD2907 PCI Express Gigabit Ethernet Adapter With DASH FunctionalityNguyễn Trần Đăng KhoaNo ratings yet

- Benq mp515 Ver.00b Level2 PDFDocument108 pagesBenq mp515 Ver.00b Level2 PDFOsvaldo Jose Antonio DeloguNo ratings yet

- Product Selection GuideDocument79 pagesProduct Selection GuideDuc NguyenNo ratings yet

- Intel Extreme Graphics 2: Developer's Guide: WhitepaperDocument28 pagesIntel Extreme Graphics 2: Developer's Guide: WhitepapercopslockNo ratings yet

- IC-705 Advanced UserDocument218 pagesIC-705 Advanced UserJack FrazerNo ratings yet

- Lenovo Desktop Manual 3 - 7l - 05 - Ug - v1.0 - en - 20200422Document102 pagesLenovo Desktop Manual 3 - 7l - 05 - Ug - v1.0 - en - 20200422RamananthanNo ratings yet

- NovoDS User Manual ENG V2.1 V1.1Document48 pagesNovoDS User Manual ENG V2.1 V1.1Steven Van DriesscheNo ratings yet

- Gis Datapro: User Manual / Getting Started With The Gis Datapro SoftwareDocument84 pagesGis Datapro: User Manual / Getting Started With The Gis Datapro Softwarejose antonio carazoNo ratings yet

- Data Sheet: Diskonchip 2000 DipDocument21 pagesData Sheet: Diskonchip 2000 DipRevazi AbuladzeNo ratings yet

- ThinkCentre M92 M92p DatasheetDocument4 pagesThinkCentre M92 M92p Datasheetkuaker81No ratings yet

- RFG 080439Document30 pagesRFG 080439RafaelNo ratings yet

- Guia de Producto Im5000Document35 pagesGuia de Producto Im5000Jacob Campos VillanuevaNo ratings yet

- GUI IMAS User Guide Public - Rev007USDocument25 pagesGUI IMAS User Guide Public - Rev007USeedsNo ratings yet

- The Essential Guide MagelisDocument24 pagesThe Essential Guide Magelislin2m3No ratings yet

- NVCNC DDCSV2 enDocument91 pagesNVCNC DDCSV2 enDuy MotorNo ratings yet

- ZBook 15 G2Document27 pagesZBook 15 G2Vlad George PopescuNo ratings yet

- Gsmart MiniDocument1 pageGsmart MinisasfiokNo ratings yet

- ThinkPad T490s Single Model 202004200434Document3 pagesThinkPad T490s Single Model 202004200434Yudi DjohanNo ratings yet

- Quickspecs: HP Zbook 15 G3 Mobile WorkstationDocument39 pagesQuickspecs: HP Zbook 15 G3 Mobile Workstationbulli babuNo ratings yet

- 998 20312057 Product Selection Guide EcoStruxureBuildingDocument80 pages998 20312057 Product Selection Guide EcoStruxureBuildingmariookkNo ratings yet

- Psref: Thinkpad TabletsDocument15 pagesPsref: Thinkpad TabletsEmanuelNo ratings yet

- Guia de Producto MP402Document29 pagesGuia de Producto MP402Jacob Campos VillanuevaNo ratings yet

- Dell U2415 User's Guide: Model: U2415 Regulatory Model: U2415bDocument65 pagesDell U2415 User's Guide: Model: U2415 Regulatory Model: U2415bEvina KarathanasiNo ratings yet

- Data Sheet - Hmi 10 InchDocument5 pagesData Sheet - Hmi 10 InchArmada Bumi Pratiwi LinesNo ratings yet

- ACS350 Technical CatalogueDocument20 pagesACS350 Technical CatalogueJNo ratings yet

- Abit NF-M2S ManualDocument40 pagesAbit NF-M2S ManualnicknuckNo ratings yet

- Joint Photographic Experts Group: Unlocking the Power of Visual Data with the JPEG StandardFrom EverandJoint Photographic Experts Group: Unlocking the Power of Visual Data with the JPEG StandardNo ratings yet

- Overhead Crane Safety and Inspection RequirementsDocument69 pagesOverhead Crane Safety and Inspection RequirementsAhmed ReguiegNo ratings yet

- ZD Company PresentationDocument38 pagesZD Company Presentationcheng xinxianNo ratings yet

- CaseworkDocument4 pagesCaseworkMilacel Mitra BeltranNo ratings yet

- Change ManagementDocument130 pagesChange ManagementAnum Akmal67% (3)

- Zaid Raqeeb AlqadhiDocument5 pagesZaid Raqeeb AlqadhizaidalqadhiNo ratings yet

- Ready Mix ConcreteDocument3 pagesReady Mix ConcreteYoga Raj0% (1)

- Industrial BoilersDocument26 pagesIndustrial BoilersAnkit bohra0% (1)

- MILLING CATALOG 38 - 2021 p001 094Document94 pagesMILLING CATALOG 38 - 2021 p001 094MeuMundoMinecraftNo ratings yet

- Richard Nakka's Experimental Rocketry SiteDocument9 pagesRichard Nakka's Experimental Rocketry SiteMikeVVNo ratings yet

- BDC VEndor MasterDocument39 pagesBDC VEndor MastersudhakpNo ratings yet

- ht26rt oDocument280 pagesht26rt oمحمد مباركNo ratings yet

- 21 - Asset Financials and ValuationDocument210 pages21 - Asset Financials and ValuationHasan AliNo ratings yet

- Samsung 40ES6100 Manual PDFDocument318 pagesSamsung 40ES6100 Manual PDFcarrier2No ratings yet

- Site AnalysisDocument5 pagesSite AnalysisUtkarsh KumarNo ratings yet

- Tag - Number Inst - Type - Desc Service - Desc Equipment - TAG - NO. Manufacturer - N AME Model - NameDocument2 pagesTag - Number Inst - Type - Desc Service - Desc Equipment - TAG - NO. Manufacturer - N AME Model - NameFirdaus NasirNo ratings yet

- 30XA 16PD (Chillers)Document168 pages30XA 16PD (Chillers)Fernando CaffroniNo ratings yet

- Toyota Executive SummaryDocument16 pagesToyota Executive SummaryAmirahNo ratings yet

- AJP Outputs2Document18 pagesAJP Outputs2ᴀʙʜɪsʜᴇᴋ ᴄʜɪɴᴄʜᴏʟᴇNo ratings yet

- PSTNDocument29 pagesPSTNSagar Gudka0% (1)

- Final Training ReportDocument19 pagesFinal Training ReportAkshay JadhavNo ratings yet

- Mca PDFDocument73 pagesMca PDFkirthivasanNo ratings yet

- Sdarticle 30Document165 pagesSdarticle 30Corina EsanuNo ratings yet

- 411 - 66000e MLT Ring Torque Book Fourth Edition Oct 06Document62 pages411 - 66000e MLT Ring Torque Book Fourth Edition Oct 06angelogobin100% (1)

- Sakthivel Rajamani: ToolsDocument5 pagesSakthivel Rajamani: ToolsSanthanu SugumaranNo ratings yet

- Abhishek SampleDocument4 pagesAbhishek SampleABHILASH KUMARNo ratings yet

- The Factors Influencing Procurement Strategy Construction EssayDocument5 pagesThe Factors Influencing Procurement Strategy Construction EssayDivina Teja Rebanal-GlinoNo ratings yet