Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

93 viewsSchmitz Cargobull Case Study DHL Resilience360

Schmitz Cargobull Case Study DHL Resilience360

Uploaded by

Bona HarahapSchmitz Cargobull needed better supply chain visibility to fulfill delivery promises given short lead times. They used DHL Resilience360 to map suppliers, monitor incidents, and identify risks. This provided end-to-end visibility and alerts them to potential disruptions. It helped Schmitz Cargobull enhance delivery capabilities, improve supplier efficiency, and reduce logistics costs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Antarctic Marine Protist PDFDocument582 pagesAntarctic Marine Protist PDFJesús J Hoyos-Acuña100% (2)

- 1 DUW10022-COURSE OUTLINE 1 2022 2023 (PPL-04 (2b) (21-09-21)Document5 pages1 DUW10022-COURSE OUTLINE 1 2022 2023 (PPL-04 (2b) (21-09-21)Hanie MunirahNo ratings yet

- Cross Docking BMWDocument9 pagesCross Docking BMWAsutosh MishraNo ratings yet

- KYC SchlumbergerDocument7 pagesKYC SchlumbergerneeltambeNo ratings yet

- Supply Chain - Kraft CheeseDocument8 pagesSupply Chain - Kraft CheeseBahar RoyNo ratings yet

- Shell Chemicals Case StudyDocument4 pagesShell Chemicals Case StudyNHI NGUYEN THI NGOCNo ratings yet

- SLC ManagementDocument4 pagesSLC ManagementrexjonathanNo ratings yet

- Cognizant Automotive Outbound Logistics Suite PovDocument6 pagesCognizant Automotive Outbound Logistics Suite PovArkar HeinNo ratings yet

- Project Supply Chain Management at Wal MDocument21 pagesProject Supply Chain Management at Wal MRochit LimjeNo ratings yet

- Groove 2 2006 General enDocument28 pagesGroove 2 2006 General enSHANENo ratings yet

- TALPAC-3D BrochureDocument4 pagesTALPAC-3D BrochuredsukocoNo ratings yet

- Cargo Brochure - 210x280 - 20191031 - 150 - PDF - A-1bDocument16 pagesCargo Brochure - 210x280 - 20191031 - 150 - PDF - A-1bShishirNo ratings yet

- Understanding Cross DockingDocument5 pagesUnderstanding Cross DockingHarsh AsthanaNo ratings yet

- Logistic Final XM AsssignmentDocument8 pagesLogistic Final XM AsssignmentBakir RanaNo ratings yet

- Snowy Lilac LmitedDocument8 pagesSnowy Lilac LmitedAnto PuthusseryNo ratings yet

- Procter & Gamble - Gillette, United Kingdom: Warehousemanager Loadbuilder ModuleDocument4 pagesProcter & Gamble - Gillette, United Kingdom: Warehousemanager Loadbuilder ModulesomarritadNo ratings yet

- 04 20 3 Crossdocking PDFDocument8 pages04 20 3 Crossdocking PDFRavi GuptaNo ratings yet

- Siemens Logistics PTE enDocument2 pagesSiemens Logistics PTE enJason (이재승 20238230)No ratings yet

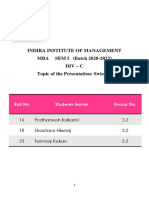

- Indira Institute of Management MBA SEM I (Batch 2020-2022) Div - C Topic of The Presentation: SwisslogDocument5 pagesIndira Institute of Management MBA SEM I (Batch 2020-2022) Div - C Topic of The Presentation: SwisslogBhushan PawarNo ratings yet

- Logisctics and Supply Chain Management - Individual Assignment (Aissam Ouaza)Document8 pagesLogisctics and Supply Chain Management - Individual Assignment (Aissam Ouaza)Aissam OuazaNo ratings yet

- Inbound Logistics 11 2023Document68 pagesInbound Logistics 11 2023Mayckon RuanNo ratings yet

- Case 2 Volvo-SunwindDocument2 pagesCase 2 Volvo-SunwindGunj Kotecha100% (1)

- Supply Chain Groups: Caterpillar LogisticsDocument2 pagesSupply Chain Groups: Caterpillar LogisticsMANOHAR LAKSHMIPATHYNo ratings yet

- 01.introduction To SCMDocument61 pages01.introduction To SCM笨小孩No ratings yet

- 10a51e0045 L& SCM - PTDocument11 pages10a51e0045 L& SCM - PTramalaxmibalivadaNo ratings yet

- Introduction To Hindustan Unilever Limited: Supply Chain Management Solution For Hindustan Unilever: Case StudyDocument5 pagesIntroduction To Hindustan Unilever Limited: Supply Chain Management Solution For Hindustan Unilever: Case StudyDHIRAJMALIVAL7221No ratings yet

- Schlumberger BackgroundDocument2 pagesSchlumberger BackgroundMohanned TayebNo ratings yet

- Risk Sharing Partnership - Supply Chain Reilience - 2015Document7 pagesRisk Sharing Partnership - Supply Chain Reilience - 2015valdivijNo ratings yet

- FogHorn Case StudyDocument2 pagesFogHorn Case StudyCarlosIgnacioNo ratings yet

- Om Cia 3Document11 pagesOm Cia 3RNo ratings yet

- Materials HandDocument1 pageMaterials HandchandytoshNo ratings yet

- Ntenna: The TheDocument68 pagesNtenna: The TheAquiles BaezaNo ratings yet

- Agent-Based Factory Modelling: Eurobios and SCA Packaging A Case StudyDocument11 pagesAgent-Based Factory Modelling: Eurobios and SCA Packaging A Case StudyDeo SinghNo ratings yet

- A KPI-driven Approach To Tactical and Operational ControlDocument12 pagesA KPI-driven Approach To Tactical and Operational ControlGaluizu001No ratings yet

- Achieving Competitive Edge Through Supply Chain ManagementDocument4 pagesAchieving Competitive Edge Through Supply Chain Managementmanishkakran1626No ratings yet

- WarehousingDocument16 pagesWarehousingSanil MambullyNo ratings yet

- Jaguar Land RoverDocument24 pagesJaguar Land RoverRavi Shankar Prasad100% (1)

- Case13 ContinentalTiresDocument11 pagesCase13 ContinentalTiresbramwill.bbNo ratings yet

- Assignment Of: Lovely School of BusinessDocument7 pagesAssignment Of: Lovely School of BusinessDhirendra YadavNo ratings yet

- Synchronised Automotive Logistics An Optimal Mix oDocument6 pagesSynchronised Automotive Logistics An Optimal Mix oMohamed IbrahimovicNo ratings yet

- Study of IT Reinforced Supply Chain Management ModelDocument23 pagesStudy of IT Reinforced Supply Chain Management ModelPuneetGuptaNo ratings yet

- COM643A SCM CRM UNIT 1BDocument50 pagesCOM643A SCM CRM UNIT 1Bpisah94899No ratings yet

- Drone Technology: Vastly Improves Performance ForDocument8 pagesDrone Technology: Vastly Improves Performance ForSurya Teja SarmaNo ratings yet

- Yard Management Getting Beyond ROI White Paper2Document8 pagesYard Management Getting Beyond ROI White Paper2Maria MirandaNo ratings yet

- EBS GPE Presentation DF VW 2023-SharedOutDocument18 pagesEBS GPE Presentation DF VW 2023-SharedOutDeepa HegdeNo ratings yet

- Navigating The COVID-19 Impact To U.S. Transportation and Logistics EcosystemsDocument3 pagesNavigating The COVID-19 Impact To U.S. Transportation and Logistics Ecosystemsshivshankar HondeNo ratings yet

- Kalmar General BrochureDocument9 pagesKalmar General BrochureOscar Acevedo MirandaNo ratings yet

- Ndustrial Rganization - : Value Stream MappingDocument34 pagesNdustrial Rganization - : Value Stream Mappingchegg KhmerNo ratings yet

- Lecture 1-Introduction DR Matloub HussainDocument30 pagesLecture 1-Introduction DR Matloub Hussainmatloub1No ratings yet

- Milkrun Vehicle Routing Approach For Shop-Floor Logistics 2013Document6 pagesMilkrun Vehicle Routing Approach For Shop-Floor Logistics 2013Mohit A.No ratings yet

- Understanding Organistaion, Understanding Job Market, Getting Ready For JobDocument8 pagesUnderstanding Organistaion, Understanding Job Market, Getting Ready For JobDeepanshu WadhwaNo ratings yet

- Supply Chains A Managers GuideDocument193 pagesSupply Chains A Managers GuideLoredana Mihaela BobeicaNo ratings yet

- Global1 2002Document37 pagesGlobal1 2002hamunaptra egyptNo ratings yet

- VBG Group Publ Ab - 2020Document124 pagesVBG Group Publ Ab - 2020AlexNo ratings yet

- KGR MarketRiskDocument8 pagesKGR MarketRiskAlejandro Julio Alvarez McCrindleNo ratings yet

- Maf651 S1 Supply Chain ManagementDocument19 pagesMaf651 S1 Supply Chain ManagementMOHAMMAD ASYRAF NAZRI SAKRINo ratings yet

- 3d-Printed Spare Parts Revolutionize Maritime Supply Chain - Bulker Insights - MARITIME IMPACT - DNV GLDocument8 pages3d-Printed Spare Parts Revolutionize Maritime Supply Chain - Bulker Insights - MARITIME IMPACT - DNV GLManuel RibeiroNo ratings yet

- Overcoming Barriers To Multitier Supplier CollaborationDocument6 pagesOvercoming Barriers To Multitier Supplier CollaborationAbdulrahman AlnasharNo ratings yet

- Press Release: Demag Cranes Supplies Its First Mobile Harbour Cranes To Papua New GuineaDocument3 pagesPress Release: Demag Cranes Supplies Its First Mobile Harbour Cranes To Papua New GuineaMohamed AdelNo ratings yet

- Potential Business and Staff Impact AnalysisDocument5 pagesPotential Business and Staff Impact AnalysisMichelle EsternonNo ratings yet

- Automated Guided Vehicle Systems: A Primer with Practical ApplicationsFrom EverandAutomated Guided Vehicle Systems: A Primer with Practical ApplicationsNo ratings yet

- Agile Procurement: Volume II: Designing and Implementing a Digital TransformationFrom EverandAgile Procurement: Volume II: Designing and Implementing a Digital TransformationNo ratings yet

- GP 09 04 01Document34 pagesGP 09 04 01Henry SaenzNo ratings yet

- Human Behavior and Victimology (Finals)Document22 pagesHuman Behavior and Victimology (Finals)Jaydine DavisNo ratings yet

- Information Kit Summer School 2023 - V3Document13 pagesInformation Kit Summer School 2023 - V3Ufairanisa IslamatasyaNo ratings yet

- System Testing ApproachDocument12 pagesSystem Testing ApproachRohit KhuranaNo ratings yet

- Understanding Unconscious BiasDocument7 pagesUnderstanding Unconscious BiasHermay BanarioNo ratings yet

- Cobas 4000 Analyzer Series: Test Installation Guide - Elecsys Anti-Sars-Cov-2Document10 pagesCobas 4000 Analyzer Series: Test Installation Guide - Elecsys Anti-Sars-Cov-2HadiNo ratings yet

- Mips TutorialDocument44 pagesMips TutorialIoana MarussiNo ratings yet

- THE EFFECTS OF LONG-TERM AUDITOR CLIENT RELATIONSHIP ON AUDIT QUALITY IN SMEsDocument18 pagesTHE EFFECTS OF LONG-TERM AUDITOR CLIENT RELATIONSHIP ON AUDIT QUALITY IN SMEsDonaDeguzmanPilapilNo ratings yet

- School Motivation and Learning Strategies and College Readiness of Senior High School Graduates in The PhilippinesDocument8 pagesSchool Motivation and Learning Strategies and College Readiness of Senior High School Graduates in The PhilippinesElla TablizoNo ratings yet

- Medium-Voltage, Solid-State, Reduced-Voltage ControllersDocument2 pagesMedium-Voltage, Solid-State, Reduced-Voltage ControllersDiomar LopezNo ratings yet

- Discrete Math Chapter 2Document12 pagesDiscrete Math Chapter 2kumar_anup11No ratings yet

- Local Studies in The Philippines Local Studies in The Philippines Play A Significant Role in The Study and Understanding of The FilipinoDocument2 pagesLocal Studies in The Philippines Local Studies in The Philippines Play A Significant Role in The Study and Understanding of The FilipinoEduard CarvajalNo ratings yet

- Assignment 2Document3 pagesAssignment 2tinsaeNo ratings yet

- Eurobay 2003Document2 pagesEurobay 2003api-3725711No ratings yet

- Pietro Maria Bardi, Quadrante, and The Architecture of Fascist ItalyDocument11 pagesPietro Maria Bardi, Quadrante, and The Architecture of Fascist ItalypatNo ratings yet

- Index - Theosophia - Boris de ZirkoffDocument22 pagesIndex - Theosophia - Boris de ZirkoffMark R. JaquaNo ratings yet

- Open Letter To The Electoral Commission of GhanaDocument8 pagesOpen Letter To The Electoral Commission of GhanaKweku ZurekNo ratings yet

- Adobe Scan Dec 17, 2023Document6 pagesAdobe Scan Dec 17, 2023Anuj PathakNo ratings yet

- Celstran PP-GF40-04 Natural: Celanese Corporation - PolypropyleneDocument2 pagesCelstran PP-GF40-04 Natural: Celanese Corporation - PolypropyleneZubair AamirNo ratings yet

- GAD Checklists 2: For The Project Identification and Design StagesDocument3 pagesGAD Checklists 2: For The Project Identification and Design StagesTago DinNo ratings yet

- 5 Steps To Writing A Position Paper: ASSH2005Document2 pages5 Steps To Writing A Position Paper: ASSH2005KrishaNo ratings yet

- Flexi Scope GuideDocument15 pagesFlexi Scope Guide69nino69No ratings yet

- Mopo SimopsDocument1 pageMopo SimopsKamal DeshapriyaNo ratings yet

- Webinar Reflection PaperDocument4 pagesWebinar Reflection PaperMitz Lorraine ZambranoNo ratings yet

- CAC F1 F2 Communication Check With A Multi-TesterDocument9 pagesCAC F1 F2 Communication Check With A Multi-Testersonic8659No ratings yet

- B Box Datasheet BYD BatteriesDocument6 pagesB Box Datasheet BYD BatteriesC WaiteNo ratings yet

- Answers (Chapter 4)Document3 pagesAnswers (Chapter 4)Abhijit Singh100% (1)

Schmitz Cargobull Case Study DHL Resilience360

Schmitz Cargobull Case Study DHL Resilience360

Uploaded by

Bona Harahap0 ratings0% found this document useful (0 votes)

93 views2 pagesSchmitz Cargobull needed better supply chain visibility to fulfill delivery promises given short lead times. They used DHL Resilience360 to map suppliers, monitor incidents, and identify risks. This provided end-to-end visibility and alerts them to potential disruptions. It helped Schmitz Cargobull enhance delivery capabilities, improve supplier efficiency, and reduce logistics costs.

Original Description:

Case study logistics

Original Title

Schmitz Cargobull Case Study Dhl Resilience360

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSchmitz Cargobull needed better supply chain visibility to fulfill delivery promises given short lead times. They used DHL Resilience360 to map suppliers, monitor incidents, and identify risks. This provided end-to-end visibility and alerts them to potential disruptions. It helped Schmitz Cargobull enhance delivery capabilities, improve supplier efficiency, and reduce logistics costs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

93 views2 pagesSchmitz Cargobull Case Study DHL Resilience360

Schmitz Cargobull Case Study DHL Resilience360

Uploaded by

Bona HarahapSchmitz Cargobull needed better supply chain visibility to fulfill delivery promises given short lead times. They used DHL Resilience360 to map suppliers, monitor incidents, and identify risks. This provided end-to-end visibility and alerts them to potential disruptions. It helped Schmitz Cargobull enhance delivery capabilities, improve supplier efficiency, and reduce logistics costs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

RESILIENCE360

SCHMITZ CARGOBULL EXPANDS SUPPLY CHAIN

VISIBILITY TO FULFILL DELIVERY PROMISES

WITH DHL RESILIENCE360

CUSTOMER OBJECTIVES:

nn Improve visibility of inbound-to-manufac-

turing supply chains and logistics flows

nn Obtain a global yet detailed view of

Schmitz Cargobull AG is Europe’s leading manufacturer of

daily events impacting suppliers and

semi-trailers and trailers, with annual production in excess

production

of 45,000 vehicles and turnover of €1.6 billion. As a pioneer

in the industry, this family-run German company attributes nn Build awareness and knowledge of Tier 1

success to its comprehensive brand strategy, consistent quality suppliers and the outbound distribution

standards, and fulfilment of delivery promises despite short lead network to improve efficiency and reduce

times and high demand volatility. The company operates today logistics costs

on a global scale, with plants across Europe and Asia (China),

and requires optimal network transparency to handle longer, DHL SOLUTION:

more complex supply chains featuring greater interdependen- DHL’s innovative supply chain risk

cies. With DHL Resilience360, Schmitz Cargobull not only management solution, Resilience360,

improved their supply chain visibility, but is now able to more supported Schmitz Cargobull with:

proactively protect on-time delivery of their customer orders.

nn Supply Chain Visualization: Mapping the

material flow and supplier clustering

CUSTOMER OBJECTIVES nn Incident Monitoring: Providing simple,

efficient 24 / 7 alerting on potential supply

Following rapid business growth and expansion into new geographies,

chain disruption in near-real time and

Schmitz Cargobull needed better supply chain visibility and transparency

globally

on logistics flows, right down to component level (e.g., axles, tires, etc.) –

a considerable challenge in this automotive sub-sector which is character-

ized by extremely short lead times. Trailer customers can typically change CUSTOMER BENEFITS:

their order right up to the point of production. Some custom-built items nn At-a-glance end-to-end supply chain

must be urgently produced within 18 hours and the frozen zone begins visibility at production component level

only 10 hours before production starts. The trailer subsector also features

nn Enhanced capability to fulfill delivery

high demand volatility, requiring just-in-time and 100% make-to-order

promises

inbound supply chain processes.

nn Opportunities to improve Tier 1 supplier

Schmitz Cargobull also aimed to obtain a global yet detailed view of daily efficiency and outbound distribution

events (strikes, weather alerts, public holidays, etc.), especially any events

nn Identified new potentials to drive down

impacting their own production sites or their supplier base all over the world.

logistics costs

Furthermore Schmitz Cargobull wanted to build awareness and knowledge

of Tier 1 suppliers and the outbound distribution network to improve ef-

ficiency and reduce logistics costs. Schmitz Cargobull has a broad supplier

base located in 19 countries; these suppliers input to a total

of 8 production facilities, and there are drop-off points for

CUSTOMER BENEFITS

finished trailers in 25 countries. Supply chain visualization

Schmitz Cargobull has achieved end-to-end supply chain

was therefore an essential step to creating a comprehensive

visibility at production component level with a significantly

disruption management system for Schmitz Cargobull.

lower investment of manpower than in the past. The orga-

nization enhanced its capabilities to fulfill delivery prom-

DHL SOLUTION ises, thanks to proactive alerting on potential supply chain

disruptions in the inbound and outbound logistics flows.

The DHL Resilience360 team provided Schmitz Cargobull Resilience360 also provides Schmitz Cargobull with the abil-

with an interactive global map of its end-to-end supply ity to improve efficiency by monitoring Tier 1 suppliers and

chain. This captures the logic of network interdependen- protecting Tier 2 suppliers. Schmitz Cargobull and DHL are

cies, both upstream and downstream, and provides a expanding the alerting scope to critical parts of the Tier 2

multi-tiered view of all key component suppliers and logis- supplier base.

tical locations. Easy-to-use search and filter capabilities

enable Schmitz Cargobull supply chain executives – each Schmitz Cargobull also benefits from improved demand fore-

responsible for specific production components – to moni- casting at supplier materials level. For example, Schmitz

tor products, parts, materials, and other sub-network attri- Cargobull was not impacted by strikes in Germany and

butes. This interactive solution enables Schmitz-Cargobull Turkey because with the help of “Incident Monitoring” the

to achieve valuable route visualization and derive views on SC-organization was able to proactively increase buffer

material logistic movements. stock before this disruption could affect its operations.

In addition, visualization also helps Schmitz Cargobull to

For Schmitz Cargobull, supply chain visualization helped reduce logistics costs by identifying potential supplier ex-

to identify two significant risks – the potential for bottle- work transformation and supplier consolidation projects. A

necks in the road network located in the south eastern useful spin-off of this new visibility is that Schmitz

region of Europe, and the relative unfamiliarity of operat- Cargobull is saving on travel costs by rationalizing its

ing in China. worldwide supplier audit activity.

The DHL team customized a supply chain incident monitor-

ing platform which provides 24 / 7 near real-time alerting and

feedback loops on disruption occurring anywhere in the

world. DHL and Schmitz Cargobull cooperated closely to con-

figure dedicated incident alerting profiles that would ensure

each member of the supply chain team would receive only

relevant e-mail alerts. This platform also provides a feature

to manually add incident, enabling Schmitz Cargobull to

quickly disseminate information about its network incidents

across the organization (and not in the public domain).

CUSTOMER’S VIEW

This user-friendly, integrated web based platform enables

“With Resilience360, we gain better visibility of our end-

Schmitz Cargobull to easily track and prepare for incidents

to-end supply chain, and we’re aiming to expand this view

well before they become threats and can be accessed any

to our first tier suppliers and our outbound supply chains.

time and anywhere in the world. The organization can now

By integrating Incident Monitoring functionality into our

plan and arrange emergency shipments to stay ahead of the

supply and delivery processes, we are able to anticipate

competition and save production, so business never slows

events and avoid disruptions, and reserve alternative re-

down and customer orders can be delivered on time.

sources before the competition can, effectively safeguard-

ing the delivery of each customer order.”

As a testament to the flexibility of Resilience360, DHL has

also created more than 10 new solution features to meet

Peter Schonefeld, Head of Supply Chain Management,

Schmitz Cargobull’s specific needs, including a customized

Schmitz Cargobull AG

product view which connects sites and products according

to the customer´s organizational structure. Further long-

term development is planned to more closely tailor Resil-

For further information

ience360 to Schmitz Cargobull´s make-to-order supply chain

Resilience360@dhl.com

processes.

www.dhl.com/Resilience360

You might also like

- Antarctic Marine Protist PDFDocument582 pagesAntarctic Marine Protist PDFJesús J Hoyos-Acuña100% (2)

- 1 DUW10022-COURSE OUTLINE 1 2022 2023 (PPL-04 (2b) (21-09-21)Document5 pages1 DUW10022-COURSE OUTLINE 1 2022 2023 (PPL-04 (2b) (21-09-21)Hanie MunirahNo ratings yet

- Cross Docking BMWDocument9 pagesCross Docking BMWAsutosh MishraNo ratings yet

- KYC SchlumbergerDocument7 pagesKYC SchlumbergerneeltambeNo ratings yet

- Supply Chain - Kraft CheeseDocument8 pagesSupply Chain - Kraft CheeseBahar RoyNo ratings yet

- Shell Chemicals Case StudyDocument4 pagesShell Chemicals Case StudyNHI NGUYEN THI NGOCNo ratings yet

- SLC ManagementDocument4 pagesSLC ManagementrexjonathanNo ratings yet

- Cognizant Automotive Outbound Logistics Suite PovDocument6 pagesCognizant Automotive Outbound Logistics Suite PovArkar HeinNo ratings yet

- Project Supply Chain Management at Wal MDocument21 pagesProject Supply Chain Management at Wal MRochit LimjeNo ratings yet

- Groove 2 2006 General enDocument28 pagesGroove 2 2006 General enSHANENo ratings yet

- TALPAC-3D BrochureDocument4 pagesTALPAC-3D BrochuredsukocoNo ratings yet

- Cargo Brochure - 210x280 - 20191031 - 150 - PDF - A-1bDocument16 pagesCargo Brochure - 210x280 - 20191031 - 150 - PDF - A-1bShishirNo ratings yet

- Understanding Cross DockingDocument5 pagesUnderstanding Cross DockingHarsh AsthanaNo ratings yet

- Logistic Final XM AsssignmentDocument8 pagesLogistic Final XM AsssignmentBakir RanaNo ratings yet

- Snowy Lilac LmitedDocument8 pagesSnowy Lilac LmitedAnto PuthusseryNo ratings yet

- Procter & Gamble - Gillette, United Kingdom: Warehousemanager Loadbuilder ModuleDocument4 pagesProcter & Gamble - Gillette, United Kingdom: Warehousemanager Loadbuilder ModulesomarritadNo ratings yet

- 04 20 3 Crossdocking PDFDocument8 pages04 20 3 Crossdocking PDFRavi GuptaNo ratings yet

- Siemens Logistics PTE enDocument2 pagesSiemens Logistics PTE enJason (이재승 20238230)No ratings yet

- Indira Institute of Management MBA SEM I (Batch 2020-2022) Div - C Topic of The Presentation: SwisslogDocument5 pagesIndira Institute of Management MBA SEM I (Batch 2020-2022) Div - C Topic of The Presentation: SwisslogBhushan PawarNo ratings yet

- Logisctics and Supply Chain Management - Individual Assignment (Aissam Ouaza)Document8 pagesLogisctics and Supply Chain Management - Individual Assignment (Aissam Ouaza)Aissam OuazaNo ratings yet

- Inbound Logistics 11 2023Document68 pagesInbound Logistics 11 2023Mayckon RuanNo ratings yet

- Case 2 Volvo-SunwindDocument2 pagesCase 2 Volvo-SunwindGunj Kotecha100% (1)

- Supply Chain Groups: Caterpillar LogisticsDocument2 pagesSupply Chain Groups: Caterpillar LogisticsMANOHAR LAKSHMIPATHYNo ratings yet

- 01.introduction To SCMDocument61 pages01.introduction To SCM笨小孩No ratings yet

- 10a51e0045 L& SCM - PTDocument11 pages10a51e0045 L& SCM - PTramalaxmibalivadaNo ratings yet

- Introduction To Hindustan Unilever Limited: Supply Chain Management Solution For Hindustan Unilever: Case StudyDocument5 pagesIntroduction To Hindustan Unilever Limited: Supply Chain Management Solution For Hindustan Unilever: Case StudyDHIRAJMALIVAL7221No ratings yet

- Schlumberger BackgroundDocument2 pagesSchlumberger BackgroundMohanned TayebNo ratings yet

- Risk Sharing Partnership - Supply Chain Reilience - 2015Document7 pagesRisk Sharing Partnership - Supply Chain Reilience - 2015valdivijNo ratings yet

- FogHorn Case StudyDocument2 pagesFogHorn Case StudyCarlosIgnacioNo ratings yet

- Om Cia 3Document11 pagesOm Cia 3RNo ratings yet

- Materials HandDocument1 pageMaterials HandchandytoshNo ratings yet

- Ntenna: The TheDocument68 pagesNtenna: The TheAquiles BaezaNo ratings yet

- Agent-Based Factory Modelling: Eurobios and SCA Packaging A Case StudyDocument11 pagesAgent-Based Factory Modelling: Eurobios and SCA Packaging A Case StudyDeo SinghNo ratings yet

- A KPI-driven Approach To Tactical and Operational ControlDocument12 pagesA KPI-driven Approach To Tactical and Operational ControlGaluizu001No ratings yet

- Achieving Competitive Edge Through Supply Chain ManagementDocument4 pagesAchieving Competitive Edge Through Supply Chain Managementmanishkakran1626No ratings yet

- WarehousingDocument16 pagesWarehousingSanil MambullyNo ratings yet

- Jaguar Land RoverDocument24 pagesJaguar Land RoverRavi Shankar Prasad100% (1)

- Case13 ContinentalTiresDocument11 pagesCase13 ContinentalTiresbramwill.bbNo ratings yet

- Assignment Of: Lovely School of BusinessDocument7 pagesAssignment Of: Lovely School of BusinessDhirendra YadavNo ratings yet

- Synchronised Automotive Logistics An Optimal Mix oDocument6 pagesSynchronised Automotive Logistics An Optimal Mix oMohamed IbrahimovicNo ratings yet

- Study of IT Reinforced Supply Chain Management ModelDocument23 pagesStudy of IT Reinforced Supply Chain Management ModelPuneetGuptaNo ratings yet

- COM643A SCM CRM UNIT 1BDocument50 pagesCOM643A SCM CRM UNIT 1Bpisah94899No ratings yet

- Drone Technology: Vastly Improves Performance ForDocument8 pagesDrone Technology: Vastly Improves Performance ForSurya Teja SarmaNo ratings yet

- Yard Management Getting Beyond ROI White Paper2Document8 pagesYard Management Getting Beyond ROI White Paper2Maria MirandaNo ratings yet

- EBS GPE Presentation DF VW 2023-SharedOutDocument18 pagesEBS GPE Presentation DF VW 2023-SharedOutDeepa HegdeNo ratings yet

- Navigating The COVID-19 Impact To U.S. Transportation and Logistics EcosystemsDocument3 pagesNavigating The COVID-19 Impact To U.S. Transportation and Logistics Ecosystemsshivshankar HondeNo ratings yet

- Kalmar General BrochureDocument9 pagesKalmar General BrochureOscar Acevedo MirandaNo ratings yet

- Ndustrial Rganization - : Value Stream MappingDocument34 pagesNdustrial Rganization - : Value Stream Mappingchegg KhmerNo ratings yet

- Lecture 1-Introduction DR Matloub HussainDocument30 pagesLecture 1-Introduction DR Matloub Hussainmatloub1No ratings yet

- Milkrun Vehicle Routing Approach For Shop-Floor Logistics 2013Document6 pagesMilkrun Vehicle Routing Approach For Shop-Floor Logistics 2013Mohit A.No ratings yet

- Understanding Organistaion, Understanding Job Market, Getting Ready For JobDocument8 pagesUnderstanding Organistaion, Understanding Job Market, Getting Ready For JobDeepanshu WadhwaNo ratings yet

- Supply Chains A Managers GuideDocument193 pagesSupply Chains A Managers GuideLoredana Mihaela BobeicaNo ratings yet

- Global1 2002Document37 pagesGlobal1 2002hamunaptra egyptNo ratings yet

- VBG Group Publ Ab - 2020Document124 pagesVBG Group Publ Ab - 2020AlexNo ratings yet

- KGR MarketRiskDocument8 pagesKGR MarketRiskAlejandro Julio Alvarez McCrindleNo ratings yet

- Maf651 S1 Supply Chain ManagementDocument19 pagesMaf651 S1 Supply Chain ManagementMOHAMMAD ASYRAF NAZRI SAKRINo ratings yet

- 3d-Printed Spare Parts Revolutionize Maritime Supply Chain - Bulker Insights - MARITIME IMPACT - DNV GLDocument8 pages3d-Printed Spare Parts Revolutionize Maritime Supply Chain - Bulker Insights - MARITIME IMPACT - DNV GLManuel RibeiroNo ratings yet

- Overcoming Barriers To Multitier Supplier CollaborationDocument6 pagesOvercoming Barriers To Multitier Supplier CollaborationAbdulrahman AlnasharNo ratings yet

- Press Release: Demag Cranes Supplies Its First Mobile Harbour Cranes To Papua New GuineaDocument3 pagesPress Release: Demag Cranes Supplies Its First Mobile Harbour Cranes To Papua New GuineaMohamed AdelNo ratings yet

- Potential Business and Staff Impact AnalysisDocument5 pagesPotential Business and Staff Impact AnalysisMichelle EsternonNo ratings yet

- Automated Guided Vehicle Systems: A Primer with Practical ApplicationsFrom EverandAutomated Guided Vehicle Systems: A Primer with Practical ApplicationsNo ratings yet

- Agile Procurement: Volume II: Designing and Implementing a Digital TransformationFrom EverandAgile Procurement: Volume II: Designing and Implementing a Digital TransformationNo ratings yet

- GP 09 04 01Document34 pagesGP 09 04 01Henry SaenzNo ratings yet

- Human Behavior and Victimology (Finals)Document22 pagesHuman Behavior and Victimology (Finals)Jaydine DavisNo ratings yet

- Information Kit Summer School 2023 - V3Document13 pagesInformation Kit Summer School 2023 - V3Ufairanisa IslamatasyaNo ratings yet

- System Testing ApproachDocument12 pagesSystem Testing ApproachRohit KhuranaNo ratings yet

- Understanding Unconscious BiasDocument7 pagesUnderstanding Unconscious BiasHermay BanarioNo ratings yet

- Cobas 4000 Analyzer Series: Test Installation Guide - Elecsys Anti-Sars-Cov-2Document10 pagesCobas 4000 Analyzer Series: Test Installation Guide - Elecsys Anti-Sars-Cov-2HadiNo ratings yet

- Mips TutorialDocument44 pagesMips TutorialIoana MarussiNo ratings yet

- THE EFFECTS OF LONG-TERM AUDITOR CLIENT RELATIONSHIP ON AUDIT QUALITY IN SMEsDocument18 pagesTHE EFFECTS OF LONG-TERM AUDITOR CLIENT RELATIONSHIP ON AUDIT QUALITY IN SMEsDonaDeguzmanPilapilNo ratings yet

- School Motivation and Learning Strategies and College Readiness of Senior High School Graduates in The PhilippinesDocument8 pagesSchool Motivation and Learning Strategies and College Readiness of Senior High School Graduates in The PhilippinesElla TablizoNo ratings yet

- Medium-Voltage, Solid-State, Reduced-Voltage ControllersDocument2 pagesMedium-Voltage, Solid-State, Reduced-Voltage ControllersDiomar LopezNo ratings yet

- Discrete Math Chapter 2Document12 pagesDiscrete Math Chapter 2kumar_anup11No ratings yet

- Local Studies in The Philippines Local Studies in The Philippines Play A Significant Role in The Study and Understanding of The FilipinoDocument2 pagesLocal Studies in The Philippines Local Studies in The Philippines Play A Significant Role in The Study and Understanding of The FilipinoEduard CarvajalNo ratings yet

- Assignment 2Document3 pagesAssignment 2tinsaeNo ratings yet

- Eurobay 2003Document2 pagesEurobay 2003api-3725711No ratings yet

- Pietro Maria Bardi, Quadrante, and The Architecture of Fascist ItalyDocument11 pagesPietro Maria Bardi, Quadrante, and The Architecture of Fascist ItalypatNo ratings yet

- Index - Theosophia - Boris de ZirkoffDocument22 pagesIndex - Theosophia - Boris de ZirkoffMark R. JaquaNo ratings yet

- Open Letter To The Electoral Commission of GhanaDocument8 pagesOpen Letter To The Electoral Commission of GhanaKweku ZurekNo ratings yet

- Adobe Scan Dec 17, 2023Document6 pagesAdobe Scan Dec 17, 2023Anuj PathakNo ratings yet

- Celstran PP-GF40-04 Natural: Celanese Corporation - PolypropyleneDocument2 pagesCelstran PP-GF40-04 Natural: Celanese Corporation - PolypropyleneZubair AamirNo ratings yet

- GAD Checklists 2: For The Project Identification and Design StagesDocument3 pagesGAD Checklists 2: For The Project Identification and Design StagesTago DinNo ratings yet

- 5 Steps To Writing A Position Paper: ASSH2005Document2 pages5 Steps To Writing A Position Paper: ASSH2005KrishaNo ratings yet

- Flexi Scope GuideDocument15 pagesFlexi Scope Guide69nino69No ratings yet

- Mopo SimopsDocument1 pageMopo SimopsKamal DeshapriyaNo ratings yet

- Webinar Reflection PaperDocument4 pagesWebinar Reflection PaperMitz Lorraine ZambranoNo ratings yet

- CAC F1 F2 Communication Check With A Multi-TesterDocument9 pagesCAC F1 F2 Communication Check With A Multi-Testersonic8659No ratings yet

- B Box Datasheet BYD BatteriesDocument6 pagesB Box Datasheet BYD BatteriesC WaiteNo ratings yet

- Answers (Chapter 4)Document3 pagesAnswers (Chapter 4)Abhijit Singh100% (1)