Professional Documents

Culture Documents

Cover - Jrc12 & Jrc14

Cover - Jrc12 & Jrc14

Uploaded by

raghebomOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cover - Jrc12 & Jrc14

Cover - Jrc12 & Jrc14

Uploaded by

raghebomCopyright:

Available Formats

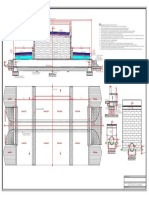

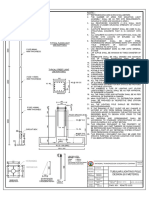

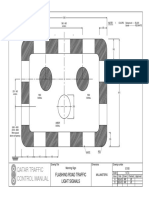

NOTES :

1. MATERIAL - DUCTILE IRON.

2. MARKING - COVER SHALL BE MARKED WITH

INSCRIPTION AS PER DRAWING

OF EACH COVER. MANUFACTURER'S

CODE LETTERS AND LAST TWO FIGURES OF

GREGORIAN YEAR OF MANUFACTURE SHALL BE

MARKED ON THE UNDER SIDE OF EACH COVER.

3. FINISH - SOLID TOP DESIGN WITH NON-SKID RAISED

PATTERN ON THE UPPER FACE.

4. CLEARANCE - 2MM TO 5MM SHALL EXIST ALL

AROUND COVERS WHEN INSTALLED IN FRAME.

5. DIMENSION - ALL DIMENSIONS ARE IN MM.

6. REF. SEC. X-X THE DESIGN OF THE BOTTOM

RE-INFORCING WEB CASTING SHOULD BE ADEQUATE

TO MEET THE LOADING SPECIFICATION AND TO

ENSURE THE BALANCE OF THE COVER CENTERED

APPROXIMATELY ON THE KEY HOLES.

7. THE UNDER SIDE OF KEY HOLE SHALL HAVE A RECESS

CAST IN TO PREVENT KEY BEING TURNED WHEN

BEARING WEIGHT OF COVER. DIMENSIONS WILL BE

TO MATCH KEY HOLE.

8. THE DIA OF HOLE WILL BE 25MM AND PLACED WITH

CENTER AT 25MM FROM THE SURFACE OF THE COVER.

9. THE COVER ELEVATION DIAGRAM FLANGE BEARING

MEASUREMENTS SHOWN SHOULD CONFORM

WITH FRAME SEAT MEASUREMENT TO ENSURE

A NON ROCKING AND NON JAMMING FITTING.

812

12

10. TOLERANCE - FOR THICKNESS ± 2MM AND

300 OVERALL ± 3MM.

11. WEIGHT - TOTAL WEIGHT SHOULD BE NOT LESS THAN

90

60 KG. FOR EACH TRIANGULAR.

172

12. PAINTING - TWO COATS OF BLACK BITUMINOUS

PAINT APPLIED ON TOP OF GREY COLOUR PRIMER

AS PER BS 4164:2002.

13. CERTIFICATION - THE PRODUCT NEEDS KITEMARK

CERTIFICATION FROM BSI (UK).

14. KEY HOLE - TO BE APPLIED FOR ALL DUCTILE TYPE

COVERS.

12

12

56 690 56

59

93

120

97

75

175

8

13

8

8

13

COVER TO FIT FRAMES OF JRC12 & JRC14

CVL14001

SAEED AHMED

You might also like

- QNBN Tech Spec For UPVC Ducts D54 D56 BendsDocument26 pagesQNBN Tech Spec For UPVC Ducts D54 D56 Bendsraghebom50% (2)

- Isometric View: Dymac GlobalDocument2 pagesIsometric View: Dymac GlobalMaarij AnjumNo ratings yet

- Material SubmittalDocument154 pagesMaterial Submittalraghebom100% (1)

- QTCM Vol1 Part03 SignsSpecificRoads-UsersDocument11 pagesQTCM Vol1 Part03 SignsSpecificRoads-UsersraghebomNo ratings yet

- PWA CAD Standards Manual Ver. 3.0 September 2013Document73 pagesPWA CAD Standards Manual Ver. 3.0 September 2013raghebomNo ratings yet

- Emirates Online Check inDocument1 pageEmirates Online Check inraghebomNo ratings yet

- Piping Fabrication and ConstructionDocument56 pagesPiping Fabrication and Constructionkaruna100% (4)

- HANSEN P4 Service ManualDocument44 pagesHANSEN P4 Service ManualNinad Monpara67% (3)

- Cover - Jrc12 & Jrc14Document1 pageCover - Jrc12 & Jrc14hatem hamaidiNo ratings yet

- إنشاء غرف أمن جدة (2) -ModelDocument1 pageإنشاء غرف أمن جدة (2) -ModelTariq KhanNo ratings yet

- PDW-TB-487 Paved Area Detail For A-Type Store at Kotri-Pdw-Tv-487 Iso A3Document1 pagePDW-TB-487 Paved Area Detail For A-Type Store at Kotri-Pdw-Tv-487 Iso A3ihsan ul haqNo ratings yet

- General: 5. Construction Notes: WarehouseDocument1 pageGeneral: 5. Construction Notes: WarehouseJayson EscobarNo ratings yet

- E. Formworks: (Structural)Document1 pageE. Formworks: (Structural)Nonoy Justiniane-Giray JrNo ratings yet

- Structural IfpDocument4 pagesStructural IfpDanny NguyenNo ratings yet

- Section A-A: NotesDocument1 pageSection A-A: NotesYazan MohammadNo ratings yet

- Typical Truss Detail Construction Notes S-5: Not To Scale Not To Scale Sheet Content: M G Tambalque Design & ConstructionDocument1 pageTypical Truss Detail Construction Notes S-5: Not To Scale Not To Scale Sheet Content: M G Tambalque Design & ConstructionCedrixe MadridNo ratings yet

- Distribution - SS Rev.7A AP-2023.07.06Document12 pagesDistribution - SS Rev.7A AP-2023.07.06sundareee96No ratings yet

- CHB Connection Details: 1.0 General NotesDocument1 pageCHB Connection Details: 1.0 General NotesSabling DritzcNo ratings yet

- CarparkingDocument1 pageCarparkingAK DESIGN DESTINYNo ratings yet

- HPC VupDocument1 pageHPC VupShivam SharmaNo ratings yet

- DSS - Layout.Without - TX AP-2023.07.06Document1 pageDSS - Layout.Without - TX AP-2023.07.06sundareee96No ratings yet

- 4a405 Bathroom Detail-2Document1 page4a405 Bathroom Detail-2Bismo AnggoroNo ratings yet

- General Construction Notes:: Two Story Residential Building Jerg Sunogan S-1Document6 pagesGeneral Construction Notes:: Two Story Residential Building Jerg Sunogan S-1clemennikki29No ratings yet

- QAHD Office Building 30 M Structural Plans-S100.0Document1 pageQAHD Office Building 30 M Structural Plans-S100.0Adrian PachecoNo ratings yet

- Jurucita ConsultantDocument1 pageJurucita ConsultantHong Jin YaoNo ratings yet

- Cross Drain DrawingDocument1 pageCross Drain DrawingManoj BatraNo ratings yet

- STR 05Document1 pageSTR 05Karrena ArabiaNo ratings yet

- 1) General Notes: 9) Design Consideration: AS Civil Engg ServicesDocument4 pages1) General Notes: 9) Design Consideration: AS Civil Engg ServicesCivil Engineering projectNo ratings yet

- 2024 - Powerhouse-Roadway Detailed DesignDocument1 page2024 - Powerhouse-Roadway Detailed Designadonis bibatNo ratings yet

- 1002016-0100-DRG-CC-0003 Typical Details Pipe Marker DetailDocument1 page1002016-0100-DRG-CC-0003 Typical Details Pipe Marker Detailhexiaogang167No ratings yet

- Wall Details For Engr Tyabo PrintDocument5 pagesWall Details For Engr Tyabo PrintMarshallNo ratings yet

- 100 Bed Hospital Okpala StructuralDocument83 pages100 Bed Hospital Okpala StructuralEngr Josh ChisimdiNo ratings yet

- 26 - RT609 - U - TYP - 014 - A MH Cover AdjustingDocument1 page26 - RT609 - U - TYP - 014 - A MH Cover AdjustinganooppattazhyNo ratings yet

- Kaf Hotel StructDocument29 pagesKaf Hotel StructMarshallNo ratings yet

- STR - 1Document1 pageSTR - 1shankar9841469226No ratings yet

- Shuttering Arrangement For Box GirderDocument1 pageShuttering Arrangement For Box GirdershakeelNo ratings yet

- Abutment Details River Bharja D2001 R0Document1 pageAbutment Details River Bharja D2001 R0borkarsd007No ratings yet

- FF To Roof: Storey MarkingDocument1 pageFF To Roof: Storey MarkingHong Jin YaoNo ratings yet

- PDW-TZ-1133 Tubular Lighting Pole DesignDocument1 pagePDW-TZ-1133 Tubular Lighting Pole Designihsan ul haqNo ratings yet

- S-1 RevisedDocument1 pageS-1 Revisedbernard1agoncillioNo ratings yet

- E. Reinforcement A. General B. Foundation: NotesDocument12 pagesE. Reinforcement A. General B. Foundation: NotesIsrael AdegboyegaNo ratings yet

- Awetu - Jimma - Shopes and Public Restroom - STDocument13 pagesAwetu - Jimma - Shopes and Public Restroom - STAhmed KedirNo ratings yet

- D-EUGP1-TPT-G-000-GEN-FWG-001-R00 With Comments 18 10 2021Document1 pageD-EUGP1-TPT-G-000-GEN-FWG-001-R00 With Comments 18 10 2021debapriyoNo ratings yet

- General Notes: General Notes: NOTES FOR STORM WATER: (Continuation) Notes For Sewer LinesDocument1 pageGeneral Notes: General Notes: NOTES FOR STORM WATER: (Continuation) Notes For Sewer LinestogireeshNo ratings yet

- North Direction: Makkah: Steel Structural PlatformDocument8 pagesNorth Direction: Makkah: Steel Structural PlatformDer3'am Al m7armehNo ratings yet

- General Notes: D.P.W.HDocument1 pageGeneral Notes: D.P.W.HJemil Rose SamosNo ratings yet

- Column LayoutDocument1 pageColumn Layoutlagnajit dasNo ratings yet

- Column LayoutDocument1 pageColumn Layoutlagnajit dasNo ratings yet

- Ee9al Ee5d Pedro Dalino PDF File 1Document11 pagesEe9al Ee5d Pedro Dalino PDF File 1jenixson tamondongNo ratings yet

- Proposed Three Bedroom-P2Document1 pageProposed Three Bedroom-P2MatthewNo ratings yet

- 1 Footing Plan PDFDocument1 page1 Footing Plan PDF114 Gopal jagtapNo ratings yet

- (S01-S12) CDocument12 pages(S01-S12) CMa'arif Nuzul AddibNo ratings yet

- Preliminary ContractsDocument16 pagesPreliminary ContractsLaura Rivas LópezNo ratings yet

- Fire Protection Bid SetDocument7 pagesFire Protection Bid SetMaxwellNo ratings yet

- Cemex Solid K4 - Raw Meal SiloDocument3 pagesCemex Solid K4 - Raw Meal Silojoselito navarroNo ratings yet

- MR - Rasul - Set - 2 - Structural - Drawing-12.RCC NOTES PDFDocument1 pageMR - Rasul - Set - 2 - Structural - Drawing-12.RCC NOTES PDFMr. SinghNo ratings yet

- 20171003-Beam & Slab Schedule-01Document1 page20171003-Beam & Slab Schedule-01Atul ShrivastavaNo ratings yet

- CDCBP P086 Cp02a Jec SD STR 1119 1Document1 pageCDCBP P086 Cp02a Jec SD STR 1119 1Md ArifNo ratings yet

- 1) General Notes:: Karthikeyan AssociatesDocument12 pages1) General Notes:: Karthikeyan AssociatesSLV GROUPNo ratings yet

- Tunis MallDocument16 pagesTunis Mallعبدالمجيد اشرف عادل مجيدNo ratings yet

- General Notes:: Construction Joints 5.0Document1 pageGeneral Notes:: Construction Joints 5.0Jack O SalemNo ratings yet

- Principle Qtrs PlanDocument1 pagePrinciple Qtrs PlanazhustuddyingNo ratings yet

- 1.Rc Details Industrial Building Details-Rev-1Document7 pages1.Rc Details Industrial Building Details-Rev-1Civil StructureNo ratings yet

- Moiré Fringes in Strain Analysis: The Commonwealth and International Library: Applied Mechanics DivisionFrom EverandMoiré Fringes in Strain Analysis: The Commonwealth and International Library: Applied Mechanics DivisionRating: 4 out of 5 stars4/5 (1)

- PNT190251-2 VMS20L-88x480-RGB - A2Document1 pagePNT190251-2 VMS20L-88x480-RGB - A2raghebomNo ratings yet

- PNT190251-4 VMS20L-64x64 20190505Document1 pagePNT190251-4 VMS20L-64x64 20190505raghebomNo ratings yet

- WIS 4-08-02.PDF - Water UKDocument6 pagesWIS 4-08-02.PDF - Water UKraghebom100% (1)

- QNBN Tech Spec For Warning TapeDocument5 pagesQNBN Tech Spec For Warning TaperaghebomNo ratings yet

- Pipe Design 4Document6 pagesPipe Design 4raghebomNo ratings yet

- QTM DrawingsDocument449 pagesQTM DrawingsraghebomNo ratings yet

- List of Accepted Safety Barriers Updated 2016Document16 pagesList of Accepted Safety Barriers Updated 2016raghebom0% (1)

- Manhole Shaft For Use in Carriageway or FootwayDocument1 pageManhole Shaft For Use in Carriageway or FootwayraghebomNo ratings yet

- Professional Engineering Practice: OntarioDocument30 pagesProfessional Engineering Practice: OntarioraghebomNo ratings yet

- QTCM Vol1 Front CoverDocument1 pageQTCM Vol1 Front CoverraghebomNo ratings yet

- QNBN Tech Spec For F& C Rev August 2014Document21 pagesQNBN Tech Spec For F& C Rev August 2014raghebom100% (1)

- QTCM Vol1 FrontPages4 TableOfContents CombinedDocument34 pagesQTCM Vol1 FrontPages4 TableOfContents CombinedraghebomNo ratings yet

- QTCM - Vol1 - FrontPage3 - Sheiikh Hamad Bin Khalifa Al-ThaniDocument1 pageQTCM - Vol1 - FrontPage3 - Sheiikh Hamad Bin Khalifa Al-ThaniraghebomNo ratings yet

- Basrah Gas E+ps Contract InductionDocument4 pagesBasrah Gas E+ps Contract InductionraghebomNo ratings yet

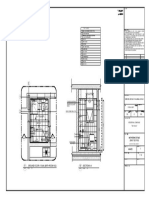

- Notes:: Frames Carriageway No 3 JRC14Document1 pageNotes:: Frames Carriageway No 3 JRC14raghebomNo ratings yet

- Civil and Structural Standards For Intelligent Transportation System (ITS) V3 PDFDocument85 pagesCivil and Structural Standards For Intelligent Transportation System (ITS) V3 PDFraghebomNo ratings yet

- QP TrackingDocument3 pagesQP TrackingraghebomNo ratings yet

- Resource Some Common Professional Practice Issues PDFDocument2 pagesResource Some Common Professional Practice Issues PDFraghebomNo ratings yet

- Re-Evaluating The Duty To Report: by Bernard Ennis, P.EngDocument3 pagesRe-Evaluating The Duty To Report: by Bernard Ennis, P.EngraghebomNo ratings yet

- Section 13 Approach DetailsDocument3 pagesSection 13 Approach DetailsraghebomNo ratings yet

- QP Protection Structures Gates and Fences Elements and Details Sheet 4 of 5Document1 pageQP Protection Structures Gates and Fences Elements and Details Sheet 4 of 5raghebomNo ratings yet

- Problems of Dyeing Polyester With Disperse DyesDocument1 pageProblems of Dyeing Polyester With Disperse DyesrashidtexNo ratings yet

- POwered Pallet Trucks - Manuals - AtlasCopco - FBW - FBW2440RevADocument16 pagesPOwered Pallet Trucks - Manuals - AtlasCopco - FBW - FBW2440RevAEduardo.s. EurolevaNo ratings yet

- Environmental DeterminismDocument7 pagesEnvironmental DeterminismSafdar HussainNo ratings yet

- Factsheet The Later Stages of DementiaDocument20 pagesFactsheet The Later Stages of DementiaMspamNo ratings yet

- Pro Tip Catalogue 4 07Document28 pagesPro Tip Catalogue 4 07notengofffNo ratings yet

- Cantilever Sheet Pile Wall DesignDocument7 pagesCantilever Sheet Pile Wall Designต้นหญ้าNo ratings yet

- NIRB Screening Decision Report, Nanisivik Naval FacilityDocument20 pagesNIRB Screening Decision Report, Nanisivik Naval FacilityNunatsiaqNewsNo ratings yet

- Girimananda SuttaDocument22 pagesGirimananda SuttaBuddhist Publication SocietyNo ratings yet

- Cooling Load Calculation Through Transmission and ProductDocument4 pagesCooling Load Calculation Through Transmission and ProductKenneth CariñoNo ratings yet

- Pashu Prahari April To June MagzineDocument129 pagesPashu Prahari April To June MagzinesumNo ratings yet

- Roads On Peat R Munro PDFDocument46 pagesRoads On Peat R Munro PDFHabib Musa MohamadNo ratings yet

- EasyPact CVS - LV510804Document3 pagesEasyPact CVS - LV510804Mouath AlraoushNo ratings yet

- Q-Read1 Upload AA155-V1 May2020Document68 pagesQ-Read1 Upload AA155-V1 May2020April Joy Rempillo FiestaNo ratings yet

- Interview For DomRAC TechnicianDocument5 pagesInterview For DomRAC TechnicianAldrine LatorreNo ratings yet

- Workover Well Control Rev 1 PDFDocument197 pagesWorkover Well Control Rev 1 PDFmoussa mrzgNo ratings yet

- Transportation ProblemDocument53 pagesTransportation ProblemJapa SonNo ratings yet

- Profile Radiography Article Estimationof CorrosionDocument10 pagesProfile Radiography Article Estimationof Corrosioncoolguy12345No ratings yet

- CRG Ambhit CapitalDocument25 pagesCRG Ambhit Capitalsidhanti26No ratings yet

- API Vol 2Document220 pagesAPI Vol 2Mosam ShuklaNo ratings yet

- Cells Concept MapDocument1 pageCells Concept MapprameetaNo ratings yet

- Convoy Commander's Checklist PacketDocument29 pagesConvoy Commander's Checklist PacketPenis Chicken TitsNo ratings yet

- Hidden FiguresDocument3 pagesHidden FiguresDrnNo ratings yet

- Complete Block DesignsDocument80 pagesComplete Block DesignsTaddese GashawNo ratings yet

- Demo Teaching Online Class DLLDocument14 pagesDemo Teaching Online Class DLLTcher CharleeneNo ratings yet

- Simatic St80 STPC Complete English 2021Document744 pagesSimatic St80 STPC Complete English 2021Hyeok LeeNo ratings yet

- LS-Fiber Optical Interface Mini Card For Loop-AM3440: FeaturesDocument4 pagesLS-Fiber Optical Interface Mini Card For Loop-AM3440: FeaturesAmrNo ratings yet

- Metallized Polyester Film Capacitors (MKT)Document44 pagesMetallized Polyester Film Capacitors (MKT)m3y54mNo ratings yet

- Design Principles For Thick CylindersDocument18 pagesDesign Principles For Thick CylindersDinesh VaghelaNo ratings yet