Professional Documents

Culture Documents

5G-3 Jointing Urban Intersections

5G-3 Jointing Urban Intersections

Uploaded by

Giovanni ArangoCopyright:

Available Formats

You might also like

- A Practical Guide to Concrete Pavement Technology for Developing CountriesFrom EverandA Practical Guide to Concrete Pavement Technology for Developing CountriesNo ratings yet

- Technical Guide - Typical Pavement ProfilesDocument10 pagesTechnical Guide - Typical Pavement Profilesmodest_dhuNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Dumbbell InterchangeDocument3 pagesDumbbell InterchangeNeil John Solomon Ledda100% (1)

- 5G-2 PCC Joints TypesDocument22 pages5G-2 PCC Joints TypesGiovanni Arango100% (1)

- Pavement Design: SEPTEMBER, 2006 Road Design Manual 7-0Document18 pagesPavement Design: SEPTEMBER, 2006 Road Design Manual 7-0amofaevansNo ratings yet

- Section 7 - Median, Left Turn, and Right Turn Design RequirementsDocument7 pagesSection 7 - Median, Left Turn, and Right Turn Design RequirementsJoenard LaglivaNo ratings yet

- TM503Document11 pagesTM503czdcxdtr2rNo ratings yet

- ROADDocument33 pagesROADAizaz ShaikhNo ratings yet

- Road Markings - Appendix 2Document15 pagesRoad Markings - Appendix 2Grace MunaNo ratings yet

- Road Over Bridge - Presen ScenarioDocument8 pagesRoad Over Bridge - Presen ScenariosombansNo ratings yet

- Ds07 BridgesDocument16 pagesDs07 BridgesthanguctNo ratings yet

- Al Nakheel Avenue Mall - CommentsDocument4 pagesAl Nakheel Avenue Mall - Commentsdilip kumarNo ratings yet

- Guidance Notes ON Panelling Design & Joint Construction of Concrete SlabsDocument12 pagesGuidance Notes ON Panelling Design & Joint Construction of Concrete SlabsMohammed AlkhateebNo ratings yet

- BDM 05 Superstructure DesignDocument78 pagesBDM 05 Superstructure DesignCristopher Alberto GutierrezNo ratings yet

- Overtaking LaneDocument1 pageOvertaking LaneTevita ToloiNo ratings yet

- 09 Chapter 6 - At-Grade Intersections PDFDocument16 pages09 Chapter 6 - At-Grade Intersections PDFdkavitiNo ratings yet

- Be 23Document52 pagesBe 23Zayyan Romjon100% (1)

- 2015 Pavement Design Manual - Final - Part 3 PDFDocument201 pages2015 Pavement Design Manual - Final - Part 3 PDFosama hourani100% (1)

- 02 - Diseño y Localizacion LRFDDocument120 pages02 - Diseño y Localizacion LRFDcesar_castro_1No ratings yet

- Car Parks in Steel: Long Carbon Europe Sections and Merchant BarsDocument32 pagesCar Parks in Steel: Long Carbon Europe Sections and Merchant BarsfoladeNo ratings yet

- Flat Slab (Efficient Construction)Document4 pagesFlat Slab (Efficient Construction)tanhh5678No ratings yet

- December 2017 LRFD Bridge Design 2-1: 2. General Design and Location FeaturesDocument110 pagesDecember 2017 LRFD Bridge Design 2-1: 2. General Design and Location FeaturesMohamed AyoubNo ratings yet

- Comments: Maharashtra Road Improvement Project (MRIP) With Financial Assistance From Asian Development Bank (ADB)Document4 pagesComments: Maharashtra Road Improvement Project (MRIP) With Financial Assistance From Asian Development Bank (ADB)Dushyant JadaunNo ratings yet

- Traffic Engineering Manual Volume 2 Chapter 10 Direction Signs and Route Numbering NonFreewaySep 2013 Ed 3Document126 pagesTraffic Engineering Manual Volume 2 Chapter 10 Direction Signs and Route Numbering NonFreewaySep 2013 Ed 3EL-MUJAHIDNo ratings yet

- Chapter 2 - Design Elements and Design ControlsDocument50 pagesChapter 2 - Design Elements and Design ControlsMaria MarqueNo ratings yet

- Road AlignmentDocument17 pagesRoad Alignmentrowaters100% (1)

- Approach SlabsDocument3 pagesApproach SlabstrabajosicNo ratings yet

- Federal Highway Administration Post-Tensioning Tendon Installation and Grouting ManualDocument95 pagesFederal Highway Administration Post-Tensioning Tendon Installation and Grouting ManualThập NguyễnNo ratings yet

- Chapter02 Rev Dec.09Document14 pagesChapter02 Rev Dec.09pravin bharatiNo ratings yet

- SDM Ch3 ConcreteandReinforcementDetailingDocument17 pagesSDM Ch3 ConcreteandReinforcementDetailingSeifeldin Ali MarzoukNo ratings yet

- Road ReservesDocument9 pagesRoad ReservesChandra SekharNo ratings yet

- Highway Pavement Structural Design: (JRCP)Document37 pagesHighway Pavement Structural Design: (JRCP)sebastian123456No ratings yet

- 08 PDFDocument37 pages08 PDFSara BenavidesNo ratings yet

- ACPA PROJETOS - Design of Concrete Pavement For StreetsDocument16 pagesACPA PROJETOS - Design of Concrete Pavement For StreetsTamara Aparecida de PaulaNo ratings yet

- Joint Design Requirements For Advanced TBM-tunnelling: D2 Consult, Linz D2 Consult, LinzDocument8 pagesJoint Design Requirements For Advanced TBM-tunnelling: D2 Consult, Linz D2 Consult, LinzHarold TaylorNo ratings yet

- NRA TD9 Nov 2011Document77 pagesNRA TD9 Nov 2011Mark CotterNo ratings yet

- Re-Bar Staggered Lap SplicesDocument4 pagesRe-Bar Staggered Lap Splicestyger089100% (2)

- Chapter 18: Expansion Joints and Miscellaneous DetailsDocument17 pagesChapter 18: Expansion Joints and Miscellaneous DetailsNaresh ANo ratings yet

- Bridge Design Manual - Chapter 22Document27 pagesBridge Design Manual - Chapter 22Yoshua YangNo ratings yet

- Bridge Approach SlabsDocument5 pagesBridge Approach SlabsGioChrNo ratings yet

- ACPA - Concrete Joint LayoutDocument8 pagesACPA - Concrete Joint LayoutMaurelNo ratings yet

- 3.5 Alignment Considerations For Switchbeams 3.5.1 GeneralDocument4 pages3.5 Alignment Considerations For Switchbeams 3.5.1 GeneralRaymond CiaoNo ratings yet

- Layout of Compact Grade Separated JuncitonDocument31 pagesLayout of Compact Grade Separated JuncitonWahyu TamadiNo ratings yet

- Design of Rigid Road Pavement For Ainachiwadi Village in Patan TahsilDocument5 pagesDesign of Rigid Road Pavement For Ainachiwadi Village in Patan TahsilsathishNo ratings yet

- Chapter 3 - Intersections PublicationDocument16 pagesChapter 3 - Intersections PublicationHisham Abou HalimaNo ratings yet

- Road Design ManualDocument19 pagesRoad Design ManualAbhijit Haval100% (1)

- Basic Physical Design AN: Unit 3Document17 pagesBasic Physical Design AN: Unit 3Shrey MalikNo ratings yet

- 23.4roadway Pavement DesignDocument13 pages23.4roadway Pavement DesignAnonymous MklNL77No ratings yet

- RecamberingDocument4 pagesRecamberingSuneth ThusharaNo ratings yet

- Civil 3DDocument4 pagesCivil 3DLuwukya IsmaNo ratings yet

- Bs5400 DesignDocument10 pagesBs5400 DesignMahesh Pokhrel67% (3)

- Car Parks in SteelDocument32 pagesCar Parks in SteelGualter MartinsNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Guide for Planning, Construction and Maintenance of Forest RoadsFrom EverandGuide for Planning, Construction and Maintenance of Forest RoadsNo ratings yet

- 5G System Design: Architectural and Functional Considerations and Long Term ResearchFrom Everand5G System Design: Architectural and Functional Considerations and Long Term ResearchNo ratings yet

- Planar Linkage Synthesis: A modern CAD based approachFrom EverandPlanar Linkage Synthesis: A modern CAD based approachNo ratings yet

- Fundamentals of Network Planning and Optimisation 2G/3G/4G: Evolution to 5GFrom EverandFundamentals of Network Planning and Optimisation 2G/3G/4G: Evolution to 5GNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Series NG 1600 Piling and Embedded Retaining WallsDocument30 pagesSeries NG 1600 Piling and Embedded Retaining WallsGiovanni ArangoNo ratings yet

- ch.9 Slurry Displacement PilesDocument47 pagesch.9 Slurry Displacement PilesGiovanni ArangoNo ratings yet

- Florida Method of Test For Viscosity of Slurry: September 1, 2000Document1 pageFlorida Method of Test For Viscosity of Slurry: September 1, 2000Giovanni ArangoNo ratings yet

- Precision Estimates of AASHTO T267 Determination of Organic Content in Soils by Loss On IgnitionDocument43 pagesPrecision Estimates of AASHTO T267 Determination of Organic Content in Soils by Loss On IgnitionGiovanni ArangoNo ratings yet

- 5G-2 PCC Joints TypesDocument22 pages5G-2 PCC Joints TypesGiovanni Arango100% (1)

- Comprehensive Pavement Design ManualDocument17 pagesComprehensive Pavement Design ManualGiovanni ArangoNo ratings yet

- General Information For Joints: Design Manual Chapter 5 - Roadway Design 5G - PCC Pavement JointsDocument6 pagesGeneral Information For Joints: Design Manual Chapter 5 - Roadway Design 5G - PCC Pavement JointsGiovanni ArangoNo ratings yet

- Form 2 (See Rules 10, 14, 17 and 18)Document4 pagesForm 2 (See Rules 10, 14, 17 and 18)AkashSinghNo ratings yet

- Fair Fares For Wellington - Bus Fares To Fund Increased Rail CostsDocument15 pagesFair Fares For Wellington - Bus Fares To Fund Increased Rail CostsDavid FarrarNo ratings yet

- Roundabout GuideDocument8 pagesRoundabout GuideWatertown Daily TimesNo ratings yet

- 10/10a Hexham Newcastle Upon Tyne Blaydon Bus TimetableDocument2 pages10/10a Hexham Newcastle Upon Tyne Blaydon Bus TimetableChris HumphreysNo ratings yet

- Introduction To Railway Engineering Track and Alignment DesignDocument34 pagesIntroduction To Railway Engineering Track and Alignment DesignToNy ThiangthongNo ratings yet

- ChauffeurDocument2 pagesChauffeur13harrryNo ratings yet

- PTV+Authorisation+Document - 2023-08-18T121118.028Document1 pagePTV+Authorisation+Document - 2023-08-18T121118.028ragprasathNo ratings yet

- Bus Number FROM (Source) TO (Destination)Document9 pagesBus Number FROM (Source) TO (Destination)Kundan KadamNo ratings yet

- Evolution of Passenger Vehicle SafetyDocument56 pagesEvolution of Passenger Vehicle SafetyHarpreet Singh100% (1)

- Clarence Stein: Town PlanningDocument11 pagesClarence Stein: Town PlanningloveenaNo ratings yet

- New Summary Earth WorkDocument30 pagesNew Summary Earth WorkRajaImranNo ratings yet

- CSS443 TrafficRoad Safety and Equipment 2018 - 2Document4 pagesCSS443 TrafficRoad Safety and Equipment 2018 - 2Shaguolo O. JosephNo ratings yet

- BKV Express Way Brief NotesDocument3 pagesBKV Express Way Brief NotesNeelagiri MallikarjunaNo ratings yet

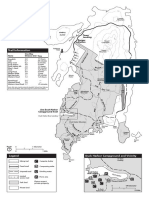

- Acadia Isle Au Haut Trail MapDocument1 pageAcadia Isle Au Haut Trail MapftsmallNo ratings yet

- Rail Walks in Greater ManchesterDocument28 pagesRail Walks in Greater ManchesterHello RainbowNo ratings yet

- Urban Roads Road Sections PDFDocument26 pagesUrban Roads Road Sections PDFtejaswiniNo ratings yet

- 15th MC LettersDocument10 pages15th MC LettersSuresh N GowdaNo ratings yet

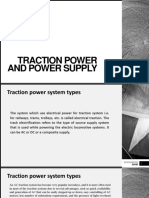

- Traction Power and Power SupplyDocument13 pagesTraction Power and Power SupplyFreddie MendezNo ratings yet

- Parking Principles 1Document37 pagesParking Principles 1Nina ImperialNo ratings yet

- Old Zigzag Road FinalDocument3 pagesOld Zigzag Road FinalAlex PinlacNo ratings yet

- 007 TrafficDocument17 pages007 TrafficLuckyjames FernandezNo ratings yet

- Istanbul: Custom Travel GuideDocument91 pagesIstanbul: Custom Travel GuideNina AzizNo ratings yet

- South African Rules of The Road & Cycling LegislationDocument3 pagesSouth African Rules of The Road & Cycling Legislationwarick mNo ratings yet

- Traffic Jam Research Report BangladeshDocument2 pagesTraffic Jam Research Report BangladeshFarisha OsmanNo ratings yet

- 2330-00-289-7515, 2330002897515, 8358925, M270A1 Data. Get Quote & BuyDocument4 pages2330-00-289-7515, 2330002897515, 8358925, M270A1 Data. Get Quote & BuyBee AscenzoNo ratings yet

- Tetra Tech Pavement Mangement Plan Written ReportDocument92 pagesTetra Tech Pavement Mangement Plan Written ReportAlexCooperRTRNo ratings yet

- Angol Nyelvvizsga Tétel KözlekedésDocument3 pagesAngol Nyelvvizsga Tétel Közlekedésonodiivett100% (1)

- Directions On Web PagesDocument2,303 pagesDirections On Web PagesPcnhs SalNo ratings yet

- Proposal EVRDocument2 pagesProposal EVRpahmi.ltfxNo ratings yet

5G-3 Jointing Urban Intersections

5G-3 Jointing Urban Intersections

Uploaded by

Giovanni ArangoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5G-3 Jointing Urban Intersections

5G-3 Jointing Urban Intersections

Uploaded by

Giovanni ArangoCopyright:

Available Formats

5G-3

Design Manual

Chapter 5 - Roadway Design

5G - PCC Pavement Joints

Jointing Urban Intersections

This section describes examples on how to joint urban intersections. The process will be illustrated

through examples of different types of streets, pavement thickness, and intakes. Even though not all

urban intersections will be exactly like the one used in these examples, the process described is applicable

to other layouts.

During construction, it is likely that location changes will be necessary for some joints within an

intersection. The primary reason is to ensure that joints pass through fixtures like manholes or drainage

inlets that are embedded in the pavement. As a result, it will be desirable for the construction crew to

adjust the location of some joints so they coincide with the actual location of a nearby manhole. The

designer should consider placing a note on the plans to give the field engineer and contractor the latitude

to make appropriate adjustments.

It is common practice for some designers to leave intersection joint layout to the field engineer and

contractor. These designers often justify this practice by citing the many field adjustments that occur

during construction, which they contend negates the usefulness of a jointing plan. However, it is not

desirable to eliminate the jointing plan except for very simple intersections. A jointing plan and

appropriate field adjustments are both necessary for more complex intersections because islands, medians,

and turning lanes complicate joint layout and require some forethought before construction. The jointing

plan will also enable contractors to more accurately bid the project.

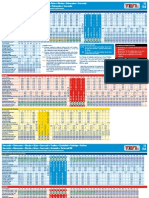

Example: This example is an intersection of a multi-lane street and a two-lane side street. The

intersection is curbed, includes several intakes, and the pavement thickness is 10 inches.

Step 1: Set Joints with Predetermined Locations

Because the location of longitudinal joints for both streets is normally predetermined, these joints should

be set first.

Within the intersection, the street that is paved first determines which joints are longitudinal and which

are transverse. Generally, the mainline street will be paved prior to the side street. Therefore, the

longitudinal joints running down the side street define the locations of the first transverse joints for the

mainline (see Figure 5G-3.01).

To determine an appropriate longitudinal joint to use, refer to SUDAS Specifications Figure 7010.901.

The type of joint used may depend on the pavement thickness. Since the pavement thickness is greater

than 8 inches in this case, either a KT-2 or an L-2 joint is appropriate.

Step 2: Locate Difficult Joints

Intake locations and the boxouts at the corner radii of the intersection are addressed next. After joints

have been placed at these locations, the rest of the joints can be worked in around them.

1. Joints at Intakes: The location of intakes is determined before the joints are laid out, so joints

have to be worked in around them. To start out with, straddle the intake with two transverse

joints spaced according to the standard joint length. These joints can be repositioned later if it

1 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

helps with the placement of other joints. In the final layout, the intake should be centered

between the joints, and adjacent joints should be adjusted accordingly. See the appropriate intake

boxout figure in SUDAS Specifications Section 6010 for boxout length requirements.

CD joints should be used on the mainline since the pavement thickness is greater than 8 inches.

However, the CD joints straddling the intake do not extend all the way through the curb and

gutter. The joints immediately surrounding the intake are specified on the detail plates and are

shown in the example.

2. Joints at Boxouts: Before the mainline is paved, small areas near the corners are boxed-out.

These boxed-out areas (shaded in Figure 5G-3.01) are poured later, after the mainline has been

paved. If the paver were to proceed straight through this area, instead of using boxouts, the

returns of the city street would narrow to a point where they meet the mainline. Pavement less

than 2 feet in width is weak and cracks readily. By using boxouts, this situation can be avoided

without the expense of stopping the paver at the intersection.

Although the width of boxouts is normally the same as the roadway’s gutter width, the size and

shape of boxouts varies depending on where they are used. If placing joints around the boxout,

remember to maintain intersecting angles greater than 70 degrees and joints at least 2 feet long.

KT-2 or L-2 joints are used around the boxout. Figure 5G-3.01 illustrates joints properly placed,

both around the boxouts and extending outward from them.

Step 3: Locate Remaining Joints

After the joints at intakes and boxouts are located, the remaining joints (generally transverse joints) are

located in appropriate locations. The maximum spacing for CD joints is 20 feet (greater than 9 inch

pavement) and the minimum spacing is typically 12 feet. Therefore, the remaining areas on the mainline

that need transverse joints should have CD joints spaced within this range. Since the design year truck

volume on the adjoining street is less than 200 vpd, C transverse joints are used there.

In Figure 5G-3.02, the C joints on the city street nearest the corners are skewed perpendicular to the free

edge of the pavement. If this joint were carried straight through, instead of skewed, the acute angle

between the joint and the free edge of the pavement would be less than 70 degrees, which is not

acceptable.

After all joints are located, the layout should be checked to ensure that all joint spacings and angles are

acceptable. Figure 5G-3.02 shows all of the transverse joints appropriately located.

Step 4: Label Joints

The completed jointing layout of the intersection is shown in Figure 5G-3.02. For pavements 8 inches or

greater, the L-2 and KT-2 joints may be used interchangeably, at the contractor’s discretion, depending on

the paving sequence. Therefore, the designer may identify the longitudinal joints as either L-2 or KT-2

on the jointing layout.

It is not necessary to identify every joint on the jointing layout. A few key joints on the diagram should

be identified and whenever a series of joints changes to a different type of joint, the joint at the location of

the change should be identified. Also, any joint that may be a source of confusion should be identified.

Joint lengths are also shown on the jointing layout, normally rounded to the nearest foot. Similar to

labeling joint types, not every length needs to be identified. However, any length that cannot be inferred

from the diagram should be labeled.

2 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

Figure 5G-3.01: Locating Predetermined and Difficult Joints

3 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

Figure 5G-3.02: Final Jointing Layout

Note: All longitudinal joints will be either KT-2 or L-2 unless otherwise indicated.

4 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

Figure 5G-3.03: Typical Municipal Jointing at Multiple Intersection Locations

(SUDAS Specifications Figure 7010.904)

5 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

A. Jointing Urban Transition Areas

This section provides examples of how to joint transition areas, such as approaches, to intersections.

Many times, approaches to intersections are wider than the street and thus require a transition section.

The importance of considering constructability when developing jointing layouts for transition areas

cannot be overstated. As previously noted, lane delineation with jointing should not be the

predominate factor in joint layouts, particularly in urban areas. Critical lane delineation can be

handled with other methods, such as pavement markings and a raised island.

Therefore, adequate jointing should be governed by the function of the joint, proper load transfer, and

constructability.

Two basic widening types (with and without medians) are shown in the following figures. There are:

1. Two-lane to Three-lane: (i.e. 31 foot to 41 foot)

Quarter-point jointing

o Concentric widening (Figure 5G-3.04)

o One side widening (Figure 5G-3.05)

Third-point jointing

o Concentric widening (Figure 5G-3.06)

o One side widening (Figure 5G-3.07)

Gutterline jointing

o Concentric widening (Figure 5G-3.08)

o One side widening (Figure 5G-3.09)

2. Four-lane to Five-lane:

Concentric widening (Figure 5G-3.10)

Widening one side (Figure 5G-3.11)

6 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

Figure 5G-3.04: Quarter-Point Jointing - Concentric Widening (31 Foot to 41 Foot)

7 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

Figure 5G-3.05: Quarter-Point Jointing - Widening One Side (31 Foot to 41 Foot)

8 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

Figure 5G-3.06: Third-Point Jointing - Concentric Widening (31 Foot to 41 Foot)

9 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

Figure 5G-3.07: Third-Point Jointing - Widening One Side (31 Foot to 41 Foot)

10 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

Figure 5G-3.08: Gutterline Jointing - Concentric Widening (31 Foot to 41 Foot)

11 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

Figure 5G-3.09: Gutterline Jointing - Widening One Side (31 Foot to 41 Foot)

12 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

Figure 5G-3.10: Concentric Widening - Four Lane to Five Lane

13 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

Figure 5G-3.11: Widening One Side - Four Lane to Five Lane

14 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

B. Jointing Cul-de-sacs

This section describes how to joint a cul-de-sac. The process is illustrated through an example of a

street that is terminated with a cul-de-sac. Assume the pavement thickness is 7 inches.

Step 1: Locate Longitudinal Joints

The longitudinal joints running down the street should be extended into the cul-de-sac. The

remaining longitudinal joints in the cul-de-sac should be placed roughly a lane width apart -

somewhere in the range of 8 to 12 feet is acceptable.

A BT-1 or L-1 is an appropriate longitudinal joint, since the pavement thickness is less than 8 inches.

Step 2: Locate Transverse Joints

The next step is to place the transverse joints. The maximum spacing for transverse joints is 15 feet

and the minimum spacing is 12 feet. Therefore, the joints within the cul-de-sac should be spaced

within this range (see Figure 5G-3.12).

A C joint is the appropriate joint to use since the pavement thickness is less than 8 inches.

Step 3: Extend Joints Through the Free Edge of the Pavement

When extending the previously placed joints through the free edge of the pavement, the acute angle

between the joint and the pavement edge (and between the joint and other joints) must be greater than

or equal to 70 degrees. Also, all joints should be at least two feet long. Details A, B, and C in Figure

5G-3.13 illustrate how this can be accomplished.

Detail A shows a transverse joint that is extended through the free edge of the pavement

unaltered. These are acceptable because all angles between the transverse joint and the

longitudinal joints and between the transverse joint and the free edge of the pavement are greater

than 70 degrees.

Detail B uses a dashed line to show the original position of a transverse joint whose angle, with

the free edge of the pavement, is less than 70 degrees. This joint should be skewed to make it

perpendicular to the free edge of the pavement, as shown by the solid line.

Detail C illustrates a situation where skewing the joint to make it perpendicular to the free edge of

the pavement would cause the angle between the joint and a longitudinal joint to be less than 70

degrees (shown by the dashed line). When this situation occurs, the joint is extended a minimum

of two feet beyond the longitudinal joint, and then it is skewed to make it perpendicular to the

free edge of the pavement. Both segments of the joint should be at least two feet long.

Step 4: Label Joints

The completed jointing layout for the cul-de-sac is shown in the figures that follow. The L-1 and BT-

1 joints may be used interchangeably, at the contractor’s discretion, depending on the paving

sequence. Therefore, the designer may identify the longitudinal joints as either L-1 or BT-1 on the

jointing layout.

Because the majority of the joints are either the C or the BT-1 or L-1, it is not necessary to identify

every joint on the jointing layout. A note on the plan describing the transverse joints as C and

longitudinal joints as L-1 or BT-1 except as noted otherwise is sufficient, provided that a few key

joints on the diagram are identified. Whenever a series of joints changes to a different type of joint,

the joint at the location of change is identified. Any joint that may be a source of confusion should

also be labeled.

15 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

Joint lengths are also shown on the jointing layout, normally rounded to the nearest foot. Similar to

labeling joint types, not every length needs to be indicated. However, any length that cannot be

inferred from the diagram should be labeled.

Figure 5G-3.12: Placement of Longitudinal and Transverse Joints

Figure 5G-3.13: Final Jointing Layout - Gutterline Jointing Examples

16 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

Figure 5G-3.14: Cul-de-sac Joint Locations - Quarter-point Jointing Examples

(SUDAS Specifications Figure 7010.905, sheet 1)

17 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

Figure 5G-3.15: Cul-de-sac Joint Locations - Third-point Jointing Examples

(SUDAS Specifications Figure 7010.905, sheet 2)

18 Revised: 2013 Edition

Chapter 5 - Roadway Design Section 5G-3 - Jointing Urban Intersections

Figure 5G-3.16: Cul-de-sac Joint Locations - Gutterline Jointing Examples

(SUDAS Specifications Figure 7010.905, sheet 3)

19 Revised: 2013 Edition

You might also like

- A Practical Guide to Concrete Pavement Technology for Developing CountriesFrom EverandA Practical Guide to Concrete Pavement Technology for Developing CountriesNo ratings yet

- Technical Guide - Typical Pavement ProfilesDocument10 pagesTechnical Guide - Typical Pavement Profilesmodest_dhuNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Dumbbell InterchangeDocument3 pagesDumbbell InterchangeNeil John Solomon Ledda100% (1)

- 5G-2 PCC Joints TypesDocument22 pages5G-2 PCC Joints TypesGiovanni Arango100% (1)

- Pavement Design: SEPTEMBER, 2006 Road Design Manual 7-0Document18 pagesPavement Design: SEPTEMBER, 2006 Road Design Manual 7-0amofaevansNo ratings yet

- Section 7 - Median, Left Turn, and Right Turn Design RequirementsDocument7 pagesSection 7 - Median, Left Turn, and Right Turn Design RequirementsJoenard LaglivaNo ratings yet

- TM503Document11 pagesTM503czdcxdtr2rNo ratings yet

- ROADDocument33 pagesROADAizaz ShaikhNo ratings yet

- Road Markings - Appendix 2Document15 pagesRoad Markings - Appendix 2Grace MunaNo ratings yet

- Road Over Bridge - Presen ScenarioDocument8 pagesRoad Over Bridge - Presen ScenariosombansNo ratings yet

- Ds07 BridgesDocument16 pagesDs07 BridgesthanguctNo ratings yet

- Al Nakheel Avenue Mall - CommentsDocument4 pagesAl Nakheel Avenue Mall - Commentsdilip kumarNo ratings yet

- Guidance Notes ON Panelling Design & Joint Construction of Concrete SlabsDocument12 pagesGuidance Notes ON Panelling Design & Joint Construction of Concrete SlabsMohammed AlkhateebNo ratings yet

- BDM 05 Superstructure DesignDocument78 pagesBDM 05 Superstructure DesignCristopher Alberto GutierrezNo ratings yet

- Overtaking LaneDocument1 pageOvertaking LaneTevita ToloiNo ratings yet

- 09 Chapter 6 - At-Grade Intersections PDFDocument16 pages09 Chapter 6 - At-Grade Intersections PDFdkavitiNo ratings yet

- Be 23Document52 pagesBe 23Zayyan Romjon100% (1)

- 2015 Pavement Design Manual - Final - Part 3 PDFDocument201 pages2015 Pavement Design Manual - Final - Part 3 PDFosama hourani100% (1)

- 02 - Diseño y Localizacion LRFDDocument120 pages02 - Diseño y Localizacion LRFDcesar_castro_1No ratings yet

- Car Parks in Steel: Long Carbon Europe Sections and Merchant BarsDocument32 pagesCar Parks in Steel: Long Carbon Europe Sections and Merchant BarsfoladeNo ratings yet

- Flat Slab (Efficient Construction)Document4 pagesFlat Slab (Efficient Construction)tanhh5678No ratings yet

- December 2017 LRFD Bridge Design 2-1: 2. General Design and Location FeaturesDocument110 pagesDecember 2017 LRFD Bridge Design 2-1: 2. General Design and Location FeaturesMohamed AyoubNo ratings yet

- Comments: Maharashtra Road Improvement Project (MRIP) With Financial Assistance From Asian Development Bank (ADB)Document4 pagesComments: Maharashtra Road Improvement Project (MRIP) With Financial Assistance From Asian Development Bank (ADB)Dushyant JadaunNo ratings yet

- Traffic Engineering Manual Volume 2 Chapter 10 Direction Signs and Route Numbering NonFreewaySep 2013 Ed 3Document126 pagesTraffic Engineering Manual Volume 2 Chapter 10 Direction Signs and Route Numbering NonFreewaySep 2013 Ed 3EL-MUJAHIDNo ratings yet

- Chapter 2 - Design Elements and Design ControlsDocument50 pagesChapter 2 - Design Elements and Design ControlsMaria MarqueNo ratings yet

- Road AlignmentDocument17 pagesRoad Alignmentrowaters100% (1)

- Approach SlabsDocument3 pagesApproach SlabstrabajosicNo ratings yet

- Federal Highway Administration Post-Tensioning Tendon Installation and Grouting ManualDocument95 pagesFederal Highway Administration Post-Tensioning Tendon Installation and Grouting ManualThập NguyễnNo ratings yet

- Chapter02 Rev Dec.09Document14 pagesChapter02 Rev Dec.09pravin bharatiNo ratings yet

- SDM Ch3 ConcreteandReinforcementDetailingDocument17 pagesSDM Ch3 ConcreteandReinforcementDetailingSeifeldin Ali MarzoukNo ratings yet

- Road ReservesDocument9 pagesRoad ReservesChandra SekharNo ratings yet

- Highway Pavement Structural Design: (JRCP)Document37 pagesHighway Pavement Structural Design: (JRCP)sebastian123456No ratings yet

- 08 PDFDocument37 pages08 PDFSara BenavidesNo ratings yet

- ACPA PROJETOS - Design of Concrete Pavement For StreetsDocument16 pagesACPA PROJETOS - Design of Concrete Pavement For StreetsTamara Aparecida de PaulaNo ratings yet

- Joint Design Requirements For Advanced TBM-tunnelling: D2 Consult, Linz D2 Consult, LinzDocument8 pagesJoint Design Requirements For Advanced TBM-tunnelling: D2 Consult, Linz D2 Consult, LinzHarold TaylorNo ratings yet

- NRA TD9 Nov 2011Document77 pagesNRA TD9 Nov 2011Mark CotterNo ratings yet

- Re-Bar Staggered Lap SplicesDocument4 pagesRe-Bar Staggered Lap Splicestyger089100% (2)

- Chapter 18: Expansion Joints and Miscellaneous DetailsDocument17 pagesChapter 18: Expansion Joints and Miscellaneous DetailsNaresh ANo ratings yet

- Bridge Design Manual - Chapter 22Document27 pagesBridge Design Manual - Chapter 22Yoshua YangNo ratings yet

- Bridge Approach SlabsDocument5 pagesBridge Approach SlabsGioChrNo ratings yet

- ACPA - Concrete Joint LayoutDocument8 pagesACPA - Concrete Joint LayoutMaurelNo ratings yet

- 3.5 Alignment Considerations For Switchbeams 3.5.1 GeneralDocument4 pages3.5 Alignment Considerations For Switchbeams 3.5.1 GeneralRaymond CiaoNo ratings yet

- Layout of Compact Grade Separated JuncitonDocument31 pagesLayout of Compact Grade Separated JuncitonWahyu TamadiNo ratings yet

- Design of Rigid Road Pavement For Ainachiwadi Village in Patan TahsilDocument5 pagesDesign of Rigid Road Pavement For Ainachiwadi Village in Patan TahsilsathishNo ratings yet

- Chapter 3 - Intersections PublicationDocument16 pagesChapter 3 - Intersections PublicationHisham Abou HalimaNo ratings yet

- Road Design ManualDocument19 pagesRoad Design ManualAbhijit Haval100% (1)

- Basic Physical Design AN: Unit 3Document17 pagesBasic Physical Design AN: Unit 3Shrey MalikNo ratings yet

- 23.4roadway Pavement DesignDocument13 pages23.4roadway Pavement DesignAnonymous MklNL77No ratings yet

- RecamberingDocument4 pagesRecamberingSuneth ThusharaNo ratings yet

- Civil 3DDocument4 pagesCivil 3DLuwukya IsmaNo ratings yet

- Bs5400 DesignDocument10 pagesBs5400 DesignMahesh Pokhrel67% (3)

- Car Parks in SteelDocument32 pagesCar Parks in SteelGualter MartinsNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Guide for Planning, Construction and Maintenance of Forest RoadsFrom EverandGuide for Planning, Construction and Maintenance of Forest RoadsNo ratings yet

- 5G System Design: Architectural and Functional Considerations and Long Term ResearchFrom Everand5G System Design: Architectural and Functional Considerations and Long Term ResearchNo ratings yet

- Planar Linkage Synthesis: A modern CAD based approachFrom EverandPlanar Linkage Synthesis: A modern CAD based approachNo ratings yet

- Fundamentals of Network Planning and Optimisation 2G/3G/4G: Evolution to 5GFrom EverandFundamentals of Network Planning and Optimisation 2G/3G/4G: Evolution to 5GNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Series NG 1600 Piling and Embedded Retaining WallsDocument30 pagesSeries NG 1600 Piling and Embedded Retaining WallsGiovanni ArangoNo ratings yet

- ch.9 Slurry Displacement PilesDocument47 pagesch.9 Slurry Displacement PilesGiovanni ArangoNo ratings yet

- Florida Method of Test For Viscosity of Slurry: September 1, 2000Document1 pageFlorida Method of Test For Viscosity of Slurry: September 1, 2000Giovanni ArangoNo ratings yet

- Precision Estimates of AASHTO T267 Determination of Organic Content in Soils by Loss On IgnitionDocument43 pagesPrecision Estimates of AASHTO T267 Determination of Organic Content in Soils by Loss On IgnitionGiovanni ArangoNo ratings yet

- 5G-2 PCC Joints TypesDocument22 pages5G-2 PCC Joints TypesGiovanni Arango100% (1)

- Comprehensive Pavement Design ManualDocument17 pagesComprehensive Pavement Design ManualGiovanni ArangoNo ratings yet

- General Information For Joints: Design Manual Chapter 5 - Roadway Design 5G - PCC Pavement JointsDocument6 pagesGeneral Information For Joints: Design Manual Chapter 5 - Roadway Design 5G - PCC Pavement JointsGiovanni ArangoNo ratings yet

- Form 2 (See Rules 10, 14, 17 and 18)Document4 pagesForm 2 (See Rules 10, 14, 17 and 18)AkashSinghNo ratings yet

- Fair Fares For Wellington - Bus Fares To Fund Increased Rail CostsDocument15 pagesFair Fares For Wellington - Bus Fares To Fund Increased Rail CostsDavid FarrarNo ratings yet

- Roundabout GuideDocument8 pagesRoundabout GuideWatertown Daily TimesNo ratings yet

- 10/10a Hexham Newcastle Upon Tyne Blaydon Bus TimetableDocument2 pages10/10a Hexham Newcastle Upon Tyne Blaydon Bus TimetableChris HumphreysNo ratings yet

- Introduction To Railway Engineering Track and Alignment DesignDocument34 pagesIntroduction To Railway Engineering Track and Alignment DesignToNy ThiangthongNo ratings yet

- ChauffeurDocument2 pagesChauffeur13harrryNo ratings yet

- PTV+Authorisation+Document - 2023-08-18T121118.028Document1 pagePTV+Authorisation+Document - 2023-08-18T121118.028ragprasathNo ratings yet

- Bus Number FROM (Source) TO (Destination)Document9 pagesBus Number FROM (Source) TO (Destination)Kundan KadamNo ratings yet

- Evolution of Passenger Vehicle SafetyDocument56 pagesEvolution of Passenger Vehicle SafetyHarpreet Singh100% (1)

- Clarence Stein: Town PlanningDocument11 pagesClarence Stein: Town PlanningloveenaNo ratings yet

- New Summary Earth WorkDocument30 pagesNew Summary Earth WorkRajaImranNo ratings yet

- CSS443 TrafficRoad Safety and Equipment 2018 - 2Document4 pagesCSS443 TrafficRoad Safety and Equipment 2018 - 2Shaguolo O. JosephNo ratings yet

- BKV Express Way Brief NotesDocument3 pagesBKV Express Way Brief NotesNeelagiri MallikarjunaNo ratings yet

- Acadia Isle Au Haut Trail MapDocument1 pageAcadia Isle Au Haut Trail MapftsmallNo ratings yet

- Rail Walks in Greater ManchesterDocument28 pagesRail Walks in Greater ManchesterHello RainbowNo ratings yet

- Urban Roads Road Sections PDFDocument26 pagesUrban Roads Road Sections PDFtejaswiniNo ratings yet

- 15th MC LettersDocument10 pages15th MC LettersSuresh N GowdaNo ratings yet

- Traction Power and Power SupplyDocument13 pagesTraction Power and Power SupplyFreddie MendezNo ratings yet

- Parking Principles 1Document37 pagesParking Principles 1Nina ImperialNo ratings yet

- Old Zigzag Road FinalDocument3 pagesOld Zigzag Road FinalAlex PinlacNo ratings yet

- 007 TrafficDocument17 pages007 TrafficLuckyjames FernandezNo ratings yet

- Istanbul: Custom Travel GuideDocument91 pagesIstanbul: Custom Travel GuideNina AzizNo ratings yet

- South African Rules of The Road & Cycling LegislationDocument3 pagesSouth African Rules of The Road & Cycling Legislationwarick mNo ratings yet

- Traffic Jam Research Report BangladeshDocument2 pagesTraffic Jam Research Report BangladeshFarisha OsmanNo ratings yet

- 2330-00-289-7515, 2330002897515, 8358925, M270A1 Data. Get Quote & BuyDocument4 pages2330-00-289-7515, 2330002897515, 8358925, M270A1 Data. Get Quote & BuyBee AscenzoNo ratings yet

- Tetra Tech Pavement Mangement Plan Written ReportDocument92 pagesTetra Tech Pavement Mangement Plan Written ReportAlexCooperRTRNo ratings yet

- Angol Nyelvvizsga Tétel KözlekedésDocument3 pagesAngol Nyelvvizsga Tétel Közlekedésonodiivett100% (1)

- Directions On Web PagesDocument2,303 pagesDirections On Web PagesPcnhs SalNo ratings yet

- Proposal EVRDocument2 pagesProposal EVRpahmi.ltfxNo ratings yet