Professional Documents

Culture Documents

Ultra-High Temperature (UHT) Sterilisation by Steam Infusion Objectives

Ultra-High Temperature (UHT) Sterilisation by Steam Infusion Objectives

Uploaded by

Aziemah AulanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultra-High Temperature (UHT) Sterilisation by Steam Infusion Objectives

Ultra-High Temperature (UHT) Sterilisation by Steam Infusion Objectives

Uploaded by

Aziemah AulanCopyright:

Available Formats

MICET

CFB20504 Food Process Engineering

Laboratory 2: Thermal Processing of Food

Ultra-High Temperature (UHT) Sterilisation by Steam Infusion

Objectives

1. Familiarise the boiler operation as energy supply for UHT equipment

2. Quantify the UHT process parameters

3. Analysing the effect of UHT on physical properties of food

Introduction

Thermal treatment is an approach to preserve food products. Pasteurisation is one technique of thermal treatment

which is widely being used to prolong the shelf life of food product. The aim of pasteurisation is to reduce the

microbial numbers to a safe level and not to kill it. Pasteurisation inactivate enzymes and kill relatively

heat-sensitive microorganisms that cause spoilage with minimal changes in food physicochemical properties. The

purpose of thermal treatment mostly relies on the pH of the food. For low-acid foods (i.e pH>4.5) pasteurisation is

for destruction of pathogenic bacteria. Other purposes of pasteurisation in relation to pH of food are given in

Table 1.

Table 1: Purpose for pasteurisation for different foods (Handbook of Food Preservation, 2 nd Edition)

SFI CFB20504 JAN18’ P a g e 1|7

MICET

Generally, to achieve desired pasteurisation conditions involves a combination of time and temperature such as

heating foods to relatively lower temperature at a longer time. Alternately, pasteurisation can be done through

higher temperature and shorter time. Test to evaluate effectiveness of pasteurisation process include colorimetric

tests, rapid enzymatic assay (Alkaline phosphatase, ALP) and determination of redox potential (in citrus juices).

Common type of pasteurisation are:

1. In-package pasteurisation- heating to sterility level is not required. Gradual change in temperature is

preferred in some containers.

2. Pasteurisation prior to packaging- preheating. Suitable for heat-sensitive foods.

3. Batch pasteurisation- low temperature short time process

4. Continuous pasteurisation- high-temperature-short-time (HTST) process

Ultra-High-Temperature Pasteurisers (UHT)

UHT pasteurisation takes place at ultra-high temperature as high as 131oC compared to the normal pasteurisation

that is achieved at 72oC for 15 seconds. In order to arrive at such a high temperature in short time, high temperature

and pressure steam is either injected or infused into the food mass. The food is then flashed in a vacuum vessel

such that the same amount of water as the amount of steam infused is removed. UHT treatment is desirable

because of its efficiency to reduce greater amount of microbial growth even its effects on ice-cream texture.

Although pasteurisation is a mild heat treatment, deterioration of pasteurised food is inevitable. Quality of

pasteurised foods may reduce in flavour, aroma and vitamins. Colour changes in juices and milk are not because

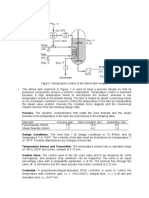

of pasteurisation but because of enzymatic browning or homogenisation. Figure 1 to Figure 3 are the schematics

for the UHT unit.

Materials and Equipment

1. Milk powder 5. UHT Pasteurisation unit

2. Water 6. Boiler

3. Tintometer

4. Viscometer

SFI CFB20504 JAN18’ P a g e 2|7

MICET

Procedures

A (Boiler operation)

1. Open the steam valve and all valves in the water feed line (ensure the feed water pump is primed).

2. Switch the door isolator to the ‘ON’ position.

3. Ensure the boiler selector and all tank elements are ‘ON’. Turn the feed water pump to the off position.

4. Open the boiler blowdown valve and lower the water level in the boiler until the low water alarm reset button

illuminated and triggered (sound).

5. Close the blowdown valve. Turn the feed water switch to ‘ON’. The feed water pump should start and restore

the water level to the normal position and stop.

6. Press the low water level reset button. The illuminating light should disappear and the audible alarm should

cease. Elements should re-energise. The elements selector switches should illuminate.

7. Boiler is now ready for use. The on/off steam pressure controller will control the on/off cycle of the elements

once the boiler is operating.

8. The low water relays, automatically maintain level of water in the boiler (and tank if fitted) and will immediately

shut off the power to the elements should the water level fall to an unsafe level.

9. The element switches situated on the control panel enable elements to be switched on/off independently to

meet steam requirements.

When the low water level alarm sounds, elements that are energised should de-energise and the element

selector switches should disappear.

B (UHT operation)

1. Ensure that all on/off valves are closed initially. Open valve (29) to allow compressed air to the pressure

regulating valve (20). Adjust the pressure on gauge (P4) until it reads 5 bar.

2. Feed tank (A) can accept a batch of 2.0 litres of process fluid. Start by using de-mineralised water so that the

running conditions can be approximated. Pour water into the feed tank after removing the filler plug. This plug

must not be removed if vessel is pressurised as indicated on pressure gauge (P1). Valve (16) is designed to

exhaust any pressure in (A) when moved to allow the plug to be lifted out. Make sure the plug is firmly replaced

before operating valve (16) to re-apply pressure. The air pressure on this vessel determines the throughput

rate and this is varied using hand wheel on regulating valve (22). The initial setting will be 1 bar above the

pressure required in the steam vessel (C).

3. Carefully open valve (28) which will admit steam to the pressure control valve (27). The steam pressure in

the vessel (C) determines the process temperature and valve (27) will be adjusted to suit requirements but this

can be set initially at 3 bar (gauge P2). Steam will enter the vessel (C), some will vent through orifice (K)

making hissing sound and the pressure will gradually rise to the adjusted value.

SFI CFB20504 JAN18’ P a g e 3|7

MICET

4. Open valve (2) using MANUAL SELECT button on the control console. Steam will pass through orifice (E) to

the vacuum chamber (F).

5. Open valve (19). Check the water is flowing into liquid ring vacuum pump and switch on the pump. Valve (19)

should be carefully adjusted to allow a reading of approximately 100mbar on gauge (P3). Carefully open

valve (8).

6. Set the process timers on the control console to:

HOLDING TIME- 0.40

PROCESS TIME- 010 sec

DRAIN TIME- 05.0

Close valve (2) before initiating cycle. Press the PROCESS START button to begin the process.

7. Samples are collected in vessel (F) and this can be disposed of by first closing vacuum valve (8) then open

valves (12) and (9) then open valve (3) and carefully (4)-the sample will pass through the cooling coil and out

through valve (4) to waste.

8. Close all on/off valves again except (19), (28) and (29). Release any pressure in (F) through the discharge

system valves (3) and (4) before opening valve (8) to reintroduce vacuum to vessel (F).

9. Using MANUAL SELECT switch open valve (2). This will push out any condensate that has collected in sight

glass (D) and steam will continue to push any condensate vacuum vessel (F). This is the STANDBY condition

and now it is possible to regulate the air flow rates. Ensure air pressure of valve (20) is reading approximately

2.0 bar above the process vessel pressure (P2). Open valves (13) and (15) then open valve (17), air will

pass through V13 and V15. Temperature will fall and fall steady. If temperature DECREASED during run,

open valve (18) slowly. Closed valve (17) sufficiently to return the temperature to its original value. Do the

opposite it the temperature INCREASED during run.

C (Analysis of sample)

1. Take a volume of sample and test for colour changes and viscosity.

SFI CFB20504 JAN18’ P a g e 4|7

MICET

Fig 1: UHT/ Aseptic unit

A- FEED CHAMBER J- PTFE FILTER

B- ATOMIZING NOZZLE K- ORIFICE PLATE

C- STEAM VESSEL L- STERILE AIR FILTER

D- SIGHT GLASS M- STERILE AIR FILTER

E- ORIFICE PLATE N- ELCB SWITCH

F- VACUUM CHAMBER P- PRESSURE GAUGE

G- COOLING COIL T-TYPE K THERMOCOUPLE

H- STEAM DRIER V- AIR FILTER

W- DRAIN VALVE NO 1-32: VALVES

SFI CFB20504 JAN18’ P a g e 5|7

MICET

Fig 2: UHT/ Aseptic unit

SFI CFB20504 JAN18’ P a g e 6|7

MICET

Fig 3: PID UHT/ Aseptic unit

Data Analysis and Questions

Using recorded data:

1. Determine the steam temperature used, heated temperature of products and holding time.

2. Compute the mass and energy balance for the process.

3. Evaluate and discuss the effects of thermal treatment onto the physical properties of sample.

4. Elaborate on the efficiency of boiler.

SFI CFB20504 JAN18’ P a g e 7|7

You might also like

- TGD 13Document3 pagesTGD 13Latanya JenkinsNo ratings yet

- Temperature Control Lab Report MuzDocument18 pagesTemperature Control Lab Report MuzAhmad Muzammil75% (8)

- Marcet Boiler Lab ReportDocument12 pagesMarcet Boiler Lab ReportShameerSamsuriNo ratings yet

- Albrecht On SallustDocument18 pagesAlbrecht On SallustliberaliviaNo ratings yet

- Experiment 5 - Heat Exchanger Process ControlDocument11 pagesExperiment 5 - Heat Exchanger Process ControlIzhamGhaziNo ratings yet

- Structural Dynamics & Earthquake EngineeringDocument8 pagesStructural Dynamics & Earthquake EngineeringHema Chandra Reddy KarimireddyNo ratings yet

- Pasteurisation Process Objectives: CFB31103 Food Process Engineering Laboratory 4: Thermal ProcessingDocument3 pagesPasteurisation Process Objectives: CFB31103 Food Process Engineering Laboratory 4: Thermal Processingnurul nabilah bt khairul anuarNo ratings yet

- (548353107) FPG-III-705 Rev 12 - BleacherDocument22 pages(548353107) FPG-III-705 Rev 12 - BleacherVijay RajaindranNo ratings yet

- Biotechnology Letters Vol 7 No I0 743-748 (1985)Document6 pagesBiotechnology Letters Vol 7 No I0 743-748 (1985)mohit16ukNo ratings yet

- BKF3731 Lab Manual Edited 26 Jan 2012Document38 pagesBKF3731 Lab Manual Edited 26 Jan 2012Sharifah Nur FasihahNo ratings yet

- Experiment 4-Heat Pump July 2018Document8 pagesExperiment 4-Heat Pump July 2018Salihah AbdullahNo ratings yet

- RacDocument26 pagesRacgurunakhale123No ratings yet

- Basic Temperature Control Elements: Learning Activity Packet 5Document52 pagesBasic Temperature Control Elements: Learning Activity Packet 5Jan Patrick PlatonNo ratings yet

- Sunway Practical Lab Bicarbonate Decomposition 2012Document11 pagesSunway Practical Lab Bicarbonate Decomposition 2012venkieeNo ratings yet

- Group A5 - EXP 5 Batch Packed DistillationDocument35 pagesGroup A5 - EXP 5 Batch Packed DistillationKabilashini Mana Mohan100% (3)

- Prelab Exp1 Refrigeration CycleDocument7 pagesPrelab Exp1 Refrigeration CycleDean Joyce AlborotoNo ratings yet

- Experiment 2Document18 pagesExperiment 2Pravin NairNo ratings yet

- Exp. 2 Heat Transfer Study On Shell and Tube Heat ExchangerDocument5 pagesExp. 2 Heat Transfer Study On Shell and Tube Heat ExchangerElaine PuiNo ratings yet

- SYD-0165A Vacuum Distillation TesterDocument10 pagesSYD-0165A Vacuum Distillation TesterMizanul HoqueNo ratings yet

- Usermanual SU 14Document8 pagesUsermanual SU 14wesley martinsNo ratings yet

- Experiment 4 Heat Pump: 1 CLB20703 Chemical Engineering ThermodynamicsDocument8 pagesExperiment 4 Heat Pump: 1 CLB20703 Chemical Engineering ThermodynamicsHafizie HashimNo ratings yet

- Control ValveDocument2 pagesControl ValveNadia KamaNo ratings yet

- Experiment 4 Heat Pump: 1 CLB20703 Chemical Engineering ThermodynamicsDocument8 pagesExperiment 4 Heat Pump: 1 CLB20703 Chemical Engineering ThermodynamicsMuhammad Al-baihaqiNo ratings yet

- Fractional Distillation Experiment - ChEDocument6 pagesFractional Distillation Experiment - ChEmutencoNo ratings yet

- RefrigerationDocument6 pagesRefrigerationriniz92No ratings yet

- Chiller ManualDocument21 pagesChiller ManualDániel CLNo ratings yet

- Lab Report Heat ExchangerDocument17 pagesLab Report Heat ExchangerFirdaus Zainal AbidinNo ratings yet

- Experiment 1-Refrigeration CycleDocument15 pagesExperiment 1-Refrigeration CycleFarrah DiyanaNo ratings yet

- AMK H2 Plant TrainingDocument16 pagesAMK H2 Plant TrainingsoxalNo ratings yet

- Didacta Re BiomasDocument4 pagesDidacta Re BiomasAntonNo ratings yet

- Refrigeration UnitDocument6 pagesRefrigeration UnitNur Amira JasminNo ratings yet

- ME495 Lab - Plate Heat Exchanger - Expt Number 5Document5 pagesME495 Lab - Plate Heat Exchanger - Expt Number 5Kammy LaiNo ratings yet

- Process Dynamics and Control Experiment 5 Heat Exchanger Process Control Lab ReportDocument25 pagesProcess Dynamics and Control Experiment 5 Heat Exchanger Process Control Lab Reportfareez aqmalNo ratings yet

- ME-495 Laboratory Exercise Number 3 ME Dept, SDSU - KassegneDocument6 pagesME-495 Laboratory Exercise Number 3 ME Dept, SDSU - KassegneJasmine_lai00No ratings yet

- PC1Document11 pagesPC1Allen Low100% (1)

- Thermodynamics Lap 11 FinalDocument8 pagesThermodynamics Lap 11 Finalaquib14125No ratings yet

- Espinel-Blanco 2020 J. Phys. Conf. Ser. 1708 012010Document8 pagesEspinel-Blanco 2020 J. Phys. Conf. Ser. 1708 012010Pooja ChughNo ratings yet

- Packed Column Distillation ProcessDocument8 pagesPacked Column Distillation ProcessKhairin RenNo ratings yet

- Boiler Turbine Technical ReportDocument31 pagesBoiler Turbine Technical ReportBryan TanNo ratings yet

- Thermo ManualDocument24 pagesThermo ManualRajakhalidNo ratings yet

- Refrigeration Test Ring.Document12 pagesRefrigeration Test Ring.பிரேம் ஆனந்த்No ratings yet

- Lab ManualDocument20 pagesLab ManualNadira NadieyraNo ratings yet

- EXP 2B-Packed Column Distillation-Jan 2015Document5 pagesEXP 2B-Packed Column Distillation-Jan 2015Siti KhalidaNo ratings yet

- Refrigeration Laboratory UnitDocument8 pagesRefrigeration Laboratory Unitkhalijahjamal50% (2)

- FAMIX Manual #1711+1713Document27 pagesFAMIX Manual #1711+1713JerickNo ratings yet

- Industrial RefrigerationDocument5 pagesIndustrial RefrigerationApet GriffinNo ratings yet

- Full Report Refrigeration UnitDocument24 pagesFull Report Refrigeration UnitNabil Imran0% (1)

- Control Philosophy - UpdatedDocument13 pagesControl Philosophy - UpdatedAlvin SmithNo ratings yet

- ME-495 Laboratory Exercise - Number 5 Me Dept, Sdsu - KassegneDocument5 pagesME-495 Laboratory Exercise - Number 5 Me Dept, Sdsu - Kassegnesagarchawla13No ratings yet

- Group 1A - Lab Report Combine PDFDocument87 pagesGroup 1A - Lab Report Combine PDFHanifatur AffiqNo ratings yet

- BojlerDocument32 pagesBojlerzoxetfNo ratings yet

- Exp 1 Cooling TowerDocument7 pagesExp 1 Cooling TowerhahaNo ratings yet

- Single Effect Evaporator 2Document22 pagesSingle Effect Evaporator 2Shailesh Lohare100% (1)

- CPB30004 Process Dynamics and Control Experiment 5: Heat Exchanger Process Control Lab ReportDocument24 pagesCPB30004 Process Dynamics and Control Experiment 5: Heat Exchanger Process Control Lab ReportSiti Hajar Mohamed100% (1)

- Single Effect Evaporator2Document12 pagesSingle Effect Evaporator2prashant_cool_4_uNo ratings yet

- Vapor Compression Refrigeration CycleDocument9 pagesVapor Compression Refrigeration CycleNisha KuttanNo ratings yet

- 120-50 Ultrasonic Cement AnalyzerDocument7 pages120-50 Ultrasonic Cement AnalyzerJadeja GirirajsinhNo ratings yet

- M - Electric Heater PIROBLOC EngDocument11 pagesM - Electric Heater PIROBLOC EngpikethNo ratings yet

- NAME 178 - ThermodynamicsLab SheetDocument48 pagesNAME 178 - ThermodynamicsLab SheetMahadi HasanNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Cfb40503 Lab ManualDocument21 pagesCfb40503 Lab ManualAziemah AulanNo ratings yet

- PBL Report FullDocument12 pagesPBL Report FullAziemah AulanNo ratings yet

- Particle Size Distribution (PSD) Objectives: CFB20504 Food Process Engineering Laboratory 1: Mechanical ReductionDocument5 pagesParticle Size Distribution (PSD) Objectives: CFB20504 Food Process Engineering Laboratory 1: Mechanical ReductionAziemah AulanNo ratings yet

- Lab Manual Gas Pressure Process ControlDocument10 pagesLab Manual Gas Pressure Process ControlAziemah AulanNo ratings yet

- Lecturer's Name: Section/ Group/ Name: Date:: Lab Report: CLD 20502 Basic Engineering WorkshopDocument1 pageLecturer's Name: Section/ Group/ Name: Date:: Lab Report: CLD 20502 Basic Engineering WorkshopAziemah AulanNo ratings yet

- Assignment Fluid (Soalan)Document1 pageAssignment Fluid (Soalan)Aziemah AulanNo ratings yet

- Department of Mechanical Engineering: Mech412: Machine Design II Second Semester, 2020-2021Document3 pagesDepartment of Mechanical Engineering: Mech412: Machine Design II Second Semester, 2020-2021mhd slmnNo ratings yet

- Robert 5Document440 pagesRobert 5로헬No ratings yet

- Ebill 13072638909Document6 pagesEbill 13072638909marliaNo ratings yet

- Prism4 SuccinctlyDocument111 pagesPrism4 SuccinctlyHorácio GasparNo ratings yet

- 113 - Power SteeringDocument109 pages113 - Power SteeringGedas GvildysNo ratings yet

- Common Lesson Plan 3 - Kelly SibrianDocument4 pagesCommon Lesson Plan 3 - Kelly Sibrianapi-510450123No ratings yet

- Invotech Scroll - YM - YF - RefrigerationDocument31 pagesInvotech Scroll - YM - YF - RefrigerationDiego Elías SuazoNo ratings yet

- Capacitive MicrophoneDocument17 pagesCapacitive MicrophoneGeethakshayaNo ratings yet

- Case Study Class 12 Physics ImportantDocument5 pagesCase Study Class 12 Physics Importantdivanshu2006yadavNo ratings yet

- Heavy Engineering Corporation Project ReportDocument28 pagesHeavy Engineering Corporation Project ReportAshish jhaNo ratings yet

- Binary ClassificationMetrics CheathsheetDocument7 pagesBinary ClassificationMetrics CheathsheetPedro PereiraNo ratings yet

- Brs20304 Final ThesisDocument34 pagesBrs20304 Final ThesisjaiNo ratings yet

- Technical Data Sheet: NIR-OnlineDocument10 pagesTechnical Data Sheet: NIR-OnlineMiguelNo ratings yet

- Recruitment For The Post of Office AttendantDocument2 pagesRecruitment For The Post of Office AttendantrajnagpNo ratings yet

- Solutions To Revision Exercise 14: (Ho Soo Thong & Khor Nyak Hiong's Panpac Additional Mathematics)Document6 pagesSolutions To Revision Exercise 14: (Ho Soo Thong & Khor Nyak Hiong's Panpac Additional Mathematics)Lim Kew ChongNo ratings yet

- Evidence Giving AdviceDocument3 pagesEvidence Giving AdviceJessica Morales0% (1)

- Synthesis PaperDocument17 pagesSynthesis Paperapi-511635668No ratings yet

- 630 KVA Distribution TransformerDocument4 pages630 KVA Distribution TransformerusmanaliNo ratings yet

- D5032408 Setting Up and Using Transportable Cutting and Shaping Machines in The Workplace - LFX - Dec19Document12 pagesD5032408 Setting Up and Using Transportable Cutting and Shaping Machines in The Workplace - LFX - Dec19Himanshu MishraNo ratings yet

- A REPORT OF SIX-WPS OfficeDocument10 pagesA REPORT OF SIX-WPS OfficeAjay KNo ratings yet

- Excavadora 270 CLC John Deere 1719Document524 pagesExcavadora 270 CLC John Deere 1719Angel Rodriguez100% (1)

- Walter Fales - Historical FactsDocument11 pagesWalter Fales - Historical FactsCésarNo ratings yet

- Aaron Kipngeno - 1061200425-Trade ProjectDocument21 pagesAaron Kipngeno - 1061200425-Trade ProjectEvansNo ratings yet

- Welcome: PB6200/ PB6100 Digital Projector User's ManualDocument41 pagesWelcome: PB6200/ PB6100 Digital Projector User's ManualnitrossNo ratings yet

- Edmonton Event Growth and Attraction StrategyDocument22 pagesEdmonton Event Growth and Attraction StrategyEmily Mertz100% (2)

- MOS Manual W-20 With ReadingsDocument71 pagesMOS Manual W-20 With ReadingsMuhammad AmmarNo ratings yet

- 832 2461 1 PBDocument13 pages832 2461 1 PBSuraya NatashaNo ratings yet