Professional Documents

Culture Documents

Mds Rheinzink-Artcolor Skygrey 04 2018 de en

Mds Rheinzink-Artcolor Skygrey 04 2018 de en

Uploaded by

carlosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mds Rheinzink-Artcolor Skygrey 04 2018 de en

Mds Rheinzink-Artcolor Skygrey 04 2018 de en

Uploaded by

carlosCopyright:

Available Formats

Information Information

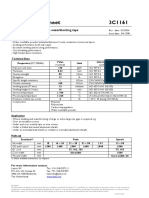

Trade name: RHEINZINK-artCOLOR® skygrey

Chemical composition

Zinc Zn 99.995 % (Z1 as per DIN EN 1179)

Copper Cu: 0.1 - 0.18 %

Titanium Ti: 0.07 - 0.12 %

Aluminium Al: max. 0.015 %

Surface

Top face

- Surface treatment Top face with protective conversion layer

- Function temporary surface protection for transport and processing

- Hue (as reference) RAL 7037

(All color values represent approximate colors in the state at delivery. Color deviations may occur

within the phosphating process.)

Bottom face

- Surface treatment Bottom face with protective conversion layer

- Marking The material is marked with a continuous stamp showing the product name, batch number and date

of production.

- Function Temporary surface protection for transport and processing

Mechanical-technical properties

0.2% proof stress (Rp0.2) min. 110 N/mm²

Tensile strength (Rm) min. 150 N/mm²

Breaking elongation (A50) min. 40 %

Vickers hardness (HV3) min. 45

Folding test no cracks at edge of fold

Bending back after folding test no crack when bending back

Fold tensile force test D min. 0.7 1)

Erichsen cupping min. 8.0 mm

Permanent elongation in creep (Rp0.1) max. 0.1 %

Longitudinal curvature max. 1.0 mm/m

Flatness max. 1.5 mm wave height

Physical and chemical properties

Melting point / Melting range 420 °C

Boiling point / Boiling range 906 °C

Recrystallisation limit > 300 °C

Density at 20 °C 7.2 g/cm³

Elasticity modulus ≥ 80.000 N/mm²

Lateral expansion coefficient 22·10-6 K-1

Horizontal expansion coefficient 17·10-6 K-1

Thickness expansion coefficient 49.5·10-6 K-1

Thermal conductivity 110 W/m·K

Specific heat capacity 398 J/kg/K

Electrical conductivity 17 m/Ω·mm²

Edition: April 2018 Page 1 of 3

Viscosity dynamic at 500 ° C: 0.0030 mPa · s

Certification

Quality management certified according to ISO 9001

Environmental management certified according to ISO 14001

Energy management certified according to ISO 50001

Monitoring external monitoring - 4x/year, sampling at plant2)

1) Bending by 180°, then bending back top end of sample by 90°, followed by a tensile test;

D = (tensile strength of folding sample)/( tensile strength of material)

2) Testing of mechanical-technical properties and chemical composition. Neutral sampling by TÜV Rheinland Group

Identification

RHEINZINK-artCOLOR skygrey Titanzink/Titanium zinc/Zinc-titane EN 988 RHEINZINK® Datteln Made in Germany

RHEINZINK-artCOLOR skygrey Rückseite/back side/verso - [Coil-Nr./Coil-no./Bobine-no. –Dicke/thickness/épaisseur]

®

Types of sheets – RHEINZINK-artCOLOR skygrey / item number 80…..

Application manual sheet metal work for buildings/ roof and façade systems /Roof drainage

Max. width 1000 mm

Standard thicknesses / Standard lengths acc. to RHEINZINK delivery programme for semi-finished products

Packaging supplied on deposit-refund pallets

Protective foil available

®

Types of coils – RHEINZINK-artCOLOR skygrey / item number 80…..

Application manual sheet metal work for buildings/ roof and façade systems /Roof drainage

Max. width 1000 mm

Standard thicknesses / Standard coil weight acc. to RHEINZINK delivery programme

Inner diameter of coil coil weight 500 kg - 508 mm*

coil weight < 500 kg - 400 mm*

Packaging supplied on deposit-refund pallets

available with paperboard sleeve on request

Protective foil available

* Other measurements available on request

Measurement tolerances for standard dimensions

Sheet and coil thickness ± 0.020 mm

Sheet and coil width + 2/-0 mm

Sheet length + 2/-0 mm

Processing

Storage dry and ventilated

Transport only in closed vehicles

Marking soft pencil or pen

Forming / Folding bending radius at least 1.75 mm (usually 2 mm), for thicknesses exceeding 1.0 mm at least 1.75 x t

Processing temperature heat if temperature of metal < 10 °C

Soft soldering use abrasive procedure to remove coating on top and bottom face

overlap of material ≥ 10 mm ≤ 15 mm

joint clearance ≤ 0.5 mm

brazing solder (leadfree solder SnZn 801 or L-Pb 40 Sn 60 (Sb), low in antimony)

Edition: April 2018 Page 2 of 3

soldering fluid Protinflux 1082

working temperature approx. 250 °C

soldering iron (shaped copper bit) > 350 g

Adhesive bonding Bitumen cold-bonding compound e.g. Enkolit®, applied over entire surface with a grooved spreader,

provide joint plate or UDS connector at sheet joints.

PU adhesive, e.g. RHEINZINK gutter adhesive, Weicon 302, SikaBond

Protective foil The foil is a self-adhesive protective plastic film that is applied at the factory and is exposed during

installation to UV radiation and temperature variations. If this exposure continues for a long time, the

properties of the film may change and cause adhesive residues on the metal surface. To avoid these

changes, we recommend removing the film immediately after the installation process.

Risk of corrosion / Resistance

Oxidising acid Roof coverings with unprotected bitumen or certain plastics may cause corrosive

effects through the runoff of acid (low pH value).

Precautionary measure: coat with non-porous paint over entire surface, e.g. ENKE Multi Protect.

Mortar / Lime dust Avoid contact with wet mortar (high alkaline pH values)

Precautionary measure: coat over entire surface.

Hot water corrosion Avoid stagnant water collecting under sheeting.

Please follow design recommendations, e.g. minimum roof pitch, jointing techniques, etc.,

use appropriate structured underlay, allow for thermal expansion of material.

Perspiration permanent marking of surface by perspiration may occur with heavy or lengthy exposure.

Recommendation: Wear gloves when handling and processing material.

Foliage Marking of surface by tannic acid may occur with heavy or lengthy exposure to foliage.

Wood preservative No harmful effects with standard salt- or oil-based products. Surface discolouration may be seen but

does not shorten the service life.

Wood Substances contained in wood such as tannic acid, resins or stains may cause surface discolouration

but this does not shorten the service life.

Metals Do not install copper over zinc (discolouration possible).

Can be combined with aluminium, stainless steel, galvanized steel and lead.

Slate No known harmful effects.

Marine climate When using the RHEINZINK-artCOLOR skygrey surface in areas subject to a marine climate, white

deposits may develop on the surface due to the salt in the atmosphere. These natural

deposits integrate into the surface colour and this will not affect the function or expected service life

of the material when used on facades, roofs or other cladded building components.

Exhaust fumes (fuel oil/gas) Oil-fired heating systems may cause marking of surface by combustion residues (sulphur/ /ferrous

additives).

No harmful effects generally seen with gas-fired systems.

Bird droppings Permanent marking will occur.

Clinker / chemical cleaning agents Corrosive effect caused by low pH-values.

Uric acid Permanent marking of surface will occur (white discolouration).

Note:

In case of contaminations on the material surfaces caused by external or environmental influences please refer to the RHEINZINK cleaning

recommendations.

In accordance with this recommendation, RHEINZINK cannot guarantee that the visual appearance will be as good as new.

Edition: April 2018 Page 3 of 3

You might also like

- CASINO by Nicholas PileggiDocument238 pagesCASINO by Nicholas PileggiPutipufNo ratings yet

- IATA EASA Cross-Reference List User Manual Ed 1Document37 pagesIATA EASA Cross-Reference List User Manual Ed 1Андрей Лубяницкий50% (2)

- MDS RHEINZINK-prePATINA Blue-Grey 11 - 2015 - DE - enDocument4 pagesMDS RHEINZINK-prePATINA Blue-Grey 11 - 2015 - DE - enPetre Cristian AlexandruNo ratings yet

- Technical Characteristics and Reference Standards: Zintek® in The Building IndustryDocument2 pagesTechnical Characteristics and Reference Standards: Zintek® in The Building Industryapi-112807037No ratings yet

- Rubber Mastic and Sealant Tapes PDFDocument18 pagesRubber Mastic and Sealant Tapes PDFNikhil MathewNo ratings yet

- Fireproof ROOF Panels Technical InformationDocument4 pagesFireproof ROOF Panels Technical InformationMarko MiticNo ratings yet

- Waterproofing - SikaBit - T-245 - MGMY-Product - Data - SheetDocument3 pagesWaterproofing - SikaBit - T-245 - MGMY-Product - Data - SheetCC Cost AdvisoryNo ratings yet

- Estimation Cost For W32 & W29Document10 pagesEstimation Cost For W32 & W29SENG ZHeng CHIEWNo ratings yet

- Automotive: Technical Data SheetDocument2 pagesAutomotive: Technical Data Sheetvaibhav dhandeNo ratings yet

- Sikasil 728 SLDocument5 pagesSikasil 728 SLJesusFloresRodriguezNo ratings yet

- Jotatemp 1000 CeramicDocument5 pagesJotatemp 1000 CeramicBiju_PottayilNo ratings yet

- Rilsan Fine Powders Physical PropertiesDocument2 pagesRilsan Fine Powders Physical Propertiesธนาชัย เต็งจิรธนาภาNo ratings yet

- Automotive: Technical Data SheetDocument2 pagesAutomotive: Technical Data SheetCarlos Santos100% (1)

- Sikaplan WP 1100-15hlDocument4 pagesSikaplan WP 1100-15hlpaulaNo ratings yet

- Fiberglass Reinforced Polyester Enclosures: Enclosure ProgramDocument6 pagesFiberglass Reinforced Polyester Enclosures: Enclosure ProgramVBANo ratings yet

- Sikaplan®-18 DDocument4 pagesSikaplan®-18 DMUTHUNo ratings yet

- Sikalastic - 8800Document4 pagesSikalastic - 8800Michael A FarinNo ratings yet

- SpecificationsDocument3 pagesSpecificationsRahma HafezNo ratings yet

- NWP Rockwool Filled Roof Panel TDSDocument2 pagesNWP Rockwool Filled Roof Panel TDSRawaa Al-EdreesiNo ratings yet

- Sikaflex ProDocument4 pagesSikaflex ProAmr Adel HameedNo ratings yet

- Sikashield p24 s3mmDocument4 pagesSikashield p24 s3mmariefNo ratings yet

- Thyssenkrupp Materials (UK) LTD Stainless Steel 1.4878: Material Data SheetDocument3 pagesThyssenkrupp Materials (UK) LTD Stainless Steel 1.4878: Material Data SheetShariq KhanNo ratings yet

- Solvalitt ALU - TDS.eng PDFDocument5 pagesSolvalitt ALU - TDS.eng PDFsaiful anwarNo ratings yet

- Sika Kimia SDN BHD - Pds - Sikabit t130 Mgmy - SgmyDocument3 pagesSika Kimia SDN BHD - Pds - Sikabit t130 Mgmy - Sgmymultifocus sb100% (1)

- 1.4845 EnglDocument3 pages1.4845 EnglpdmsNo ratings yet

- Sikaflex®-11 FC+: Product Data SheetDocument5 pagesSikaflex®-11 FC+: Product Data SheetYousef HalasehNo ratings yet

- 2-Part PUR Tough-Elastic Coloured Seal Coat: Product DescriptionDocument7 pages2-Part PUR Tough-Elastic Coloured Seal Coat: Product Descriptionbeck.26No ratings yet

- Esd Jotun PaintDocument3 pagesEsd Jotun PaintMohd Ridzuan Abdul AzizNo ratings yet

- PDS Stopaq Insulwrap FR V1 enDocument1 pagePDS Stopaq Insulwrap FR V1 enAndyNo ratings yet

- 2-Part PUR Highly Elastic, Crack-Bridging Coating: Product DescriptionDocument7 pages2-Part PUR Highly Elastic, Crack-Bridging Coating: Product Descriptionbeck.26No ratings yet

- Ceramite T: Bauxite and Silicon Carbide Based Trowellable RefractoryDocument2 pagesCeramite T: Bauxite and Silicon Carbide Based Trowellable RefractorySHRINIVASAN GTKNo ratings yet

- Bakelite PF 31Document3 pagesBakelite PF 31dioguitomsolhaNo ratings yet

- Pittclad 316S PDS 7.13.21Document4 pagesPittclad 316S PDS 7.13.21MassimoPartipiloNo ratings yet

- 1.4878 Eng PDFDocument3 pages1.4878 Eng PDFRoberto_PrrNo ratings yet

- Sikahyflex®-140 Construction: Product Data SheetDocument4 pagesSikahyflex®-140 Construction: Product Data SheetNicholas WashingtonNo ratings yet

- Water Swallable TapeDocument1 pageWater Swallable TapeSanthosh V RaajendiranNo ratings yet

- Sikasil 670 Fire - Pds enDocument4 pagesSikasil 670 Fire - Pds enTRI MINTO WIDODONo ratings yet

- Product Data Sheet UP GM 203Document1 pageProduct Data Sheet UP GM 203Ravindra ErabattiNo ratings yet

- 772 Oracal8300Document2 pages772 Oracal8300bobby_flaviuNo ratings yet

- Powder Type FDocument3 pagesPowder Type Fferdlh9No ratings yet

- Renolit Alkorplan 00414 15mm + Lacquer enDocument2 pagesRenolit Alkorplan 00414 15mm + Lacquer enIngénieur CivilNo ratings yet

- Sika Nigeria - Sikadur 42 MP Slow v1Document7 pagesSika Nigeria - Sikadur 42 MP Slow v1willy iremNo ratings yet

- Lexan Polycarbonate 9030 Technical Properties Data SheetDocument6 pagesLexan Polycarbonate 9030 Technical Properties Data Sheetenki95823100% (1)

- Butyl Tapes, Mastic Tapes, Adhesives & SealantsDocument35 pagesButyl Tapes, Mastic Tapes, Adhesives & SealantsNikhil MathewNo ratings yet

- Sika Bituseal T-140 SGDocument3 pagesSika Bituseal T-140 SGjet toledoNo ratings yet

- Electric Tape P029eDocument8 pagesElectric Tape P029esakthivelNo ratings yet

- Tds Az Eci 3000 SeriesDocument11 pagesTds Az Eci 3000 SeriesIgor_uhuNo ratings yet

- Sika Bituseal T-130 SG PdsDocument4 pagesSika Bituseal T-130 SG Pdsmr_hendihalimNo ratings yet

- VALMEX MEHATOP N - 2018 08 - Samples PDFDocument6 pagesVALMEX MEHATOP N - 2018 08 - Samples PDFRamakrishnan SitaramanNo ratings yet

- Teranap 431 TP 4m (En)Document2 pagesTeranap 431 TP 4m (En)Franco Saenz SolisNo ratings yet

- Coextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataDocument2 pagesCoextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataJan GawełNo ratings yet

- Matrox U110 TDS PDFDocument1 pageMatrox U110 TDS PDFrajanarenderNo ratings yet

- Sikafloor Multiflexpb-52uvDocument4 pagesSikafloor Multiflexpb-52uvakajsiNo ratings yet

- Building ProtectionDocument16 pagesBuilding ProtectionSildan Import-ExportNo ratings yet

- Tilara Polyplast EcatalogueDocument16 pagesTilara Polyplast EcatalogueRohit ChudasamaNo ratings yet

- Heradesign® Style: WW-EN 13168-L3-W2-T2-S3-P2-CS (10-Y) 20-TR5-Cl3Document4 pagesHeradesign® Style: WW-EN 13168-L3-W2-T2-S3-P2-CS (10-Y) 20-TR5-Cl3Chester FengNo ratings yet

- KXNEDocument2 pagesKXNEJan GawełNo ratings yet

- TechPlasty - PA6G - Cast Polyamide 6 - 2019-08-07Document3 pagesTechPlasty - PA6G - Cast Polyamide 6 - 2019-08-07rajesh kothariNo ratings yet

- Sika AnchorFix 3+ - PDSDocument4 pagesSika AnchorFix 3+ - PDSAnonymous jbvNLNANLINo ratings yet

- Wall Sandwich PanelsDocument4 pagesWall Sandwich PanelsSiniora AkoumNo ratings yet

- Courage Makumire CV (Zimp)Document3 pagesCourage Makumire CV (Zimp)Courage MakumireNo ratings yet

- PDF PMP Exam Quick Reference GuideDocument8 pagesPDF PMP Exam Quick Reference GuideNantha KumarNo ratings yet

- Listening and Note-Taking Week 01Document6 pagesListening and Note-Taking Week 01AlvinPennNo ratings yet

- Gastroenterología y Hepatología: Use of Electrosurgical Units in The Endoscopic Resection of Gastrointestinal TumorsDocument12 pagesGastroenterología y Hepatología: Use of Electrosurgical Units in The Endoscopic Resection of Gastrointestinal TumorsJesús MaríñezNo ratings yet

- Group Medical Insurance - 2020-21Document2 pagesGroup Medical Insurance - 2020-21Vilaz VijiNo ratings yet

- Chronic Suppurative Otitis MediaDocument37 pagesChronic Suppurative Otitis Media43 Mohamed RazikNo ratings yet

- The Cattell-Horn-Carroll Theory of Cognitive AbilitiesDocument13 pagesThe Cattell-Horn-Carroll Theory of Cognitive Abilitiessergio_poblete_ortegaNo ratings yet

- Vaskulitisi Malih Krvnih Sudova Bubrega: Etiopatogeneza, Dijagnostika I LečenjeDocument5 pagesVaskulitisi Malih Krvnih Sudova Bubrega: Etiopatogeneza, Dijagnostika I LečenjedjpaanNo ratings yet

- Machine Spindle Noses: 6 Bison - Bial S. ADocument2 pagesMachine Spindle Noses: 6 Bison - Bial S. AshanehatfieldNo ratings yet

- VR8304 Intermittent Pilot Combination Gas Control: ApplicationDocument8 pagesVR8304 Intermittent Pilot Combination Gas Control: ApplicationGregorio Mata MartínezNo ratings yet

- Hardtimes Analysis PDFDocument30 pagesHardtimes Analysis PDFV LkvNo ratings yet

- Steam TurbineDocument16 pagesSteam TurbineVinayakNo ratings yet

- The Importance of Mineral Elements For Humans, Domestic Animals and Plants: A ReviewDocument3 pagesThe Importance of Mineral Elements For Humans, Domestic Animals and Plants: A ReviewMaricel Canlas MacatoNo ratings yet

- OligohydramniosDocument20 pagesOligohydramniosjudssalangsangNo ratings yet

- Brief Background and OverviewDocument2 pagesBrief Background and OverviewCamille MarieNo ratings yet

- Holy Family Academy of Gma, Inc.: Diocese of Imus Catholic Educational System, Inc. (DICESDocument2 pagesHoly Family Academy of Gma, Inc.: Diocese of Imus Catholic Educational System, Inc. (DICESellieneh21No ratings yet

- BTS Power ManagementDocument21 pagesBTS Power ManagementSam FicherNo ratings yet

- Solid State MCQ & CsaDocument10 pagesSolid State MCQ & Csashivansh upadhyay100% (1)

- GeoseaDocument9 pagesGeoseaArthur WakashimasuNo ratings yet

- Jurnal SdaDocument7 pagesJurnal SdaPeten AmtiranNo ratings yet

- NOMAC - Red Stone - Briding Program - Rev 03Document53 pagesNOMAC - Red Stone - Briding Program - Rev 03tlhalefangmogoengtermNo ratings yet

- Sri Chaitanya IIT Academy, India: Grand Test-5Document31 pagesSri Chaitanya IIT Academy, India: Grand Test-5ashrithNo ratings yet

- Semi-Detailed Lesson Plan: Teacher: Blessie Jean A. YbañezDocument3 pagesSemi-Detailed Lesson Plan: Teacher: Blessie Jean A. YbañezJENNIFER YBAÑEZNo ratings yet

- Jaipur Rajasthan, India. 16bar1081 Simran DeoDocument25 pagesJaipur Rajasthan, India. 16bar1081 Simran Deosimran deo100% (1)

- UGCNETDEC AdmitCardDocument1 pageUGCNETDEC AdmitCardAkshay RajNo ratings yet

- Non-Destructive Electrical Test Methods For Evaluating High-Voltage Stator InsulationDocument9 pagesNon-Destructive Electrical Test Methods For Evaluating High-Voltage Stator InsulationHendi AfriyanNo ratings yet

- CS2106 Lec1 IntroDocument97 pagesCS2106 Lec1 IntroweitsangNo ratings yet

- Kristian M. Dinapo: ObjectiveDocument2 pagesKristian M. Dinapo: ObjectiveX.oFlawlesso.XNo ratings yet