Professional Documents

Culture Documents

Bolt Torque Sequence PDF

Bolt Torque Sequence PDF

Uploaded by

milOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bolt Torque Sequence PDF

Bolt Torque Sequence PDF

Uploaded by

milCopyright:

Available Formats

Automotive Racing Products Tel: (805) 339-2200

1863 Eastman Avenue Fax: (805) 650-0742

Ventura, CA 93003 www.arp-bolts.com

INSTALLATION METHOD FOR HEAD STUD KITS

Part Number: 247-4206 Application: Cummins 3.9L (4BT) Diesel

Note: This kit requires modification to the rocker arm pedestal to accommodate a shorter rocker arm

pedestal head stud included in this kit (see illustration A on reverse side). These changes were

designed to bring our 12pt nut and washer combination down to the same installed height as the

factory head bolt due to clearance issues with the valve cover. We have also included secondary 8mm

rocker arm pedestal (hold down) bolts that were previously not available.

1. Always verify the part number for your application with the part number on the side of box and the

part number on the instruction sheet. This will help ensure you have the correct installation

procedure for your specific application before installing any components.

2. To ensure proper thread engagement and accurate torque readings, clean ALL threads in the block and the

threads in the cylinder head that secure the rocker arm pedestal to the head. Chase if necessary with ARP

Thread Chaser(s), part numbers 912-0008 (M12 x 1.75) and 912-0001 (M8 x 1.25).

3. Clean and inspect all hardware prior to installation. Look for obvious defects or shipping damages, plus

proper fit, length and dimension (see illustration B on reverse side).

4. If the cylinder head studs protrude into a water jacket, lubricate the block threads of the studs with ARP

THREAD SEALER.

5. Screw studs into the block “HAND TIGHT ONLY”. NOTE: LOCTITE MAY BE USED IF PERMANENT

MOUNTING OF THE STUD IS PREFERRED.

6. Install the cylinder head and check for binding or misalignment.

7. Install the pushrods.

8. Install the rocker arms and the rocker arm pedestals onto the cylinder head as an assembly according to

OEM procedures. Make sure the dowel on the bottom of each pedestal is aligned properly with the

alignment holes in the cylinder head and the pedestals are sitting down flush on the head with the valve lash

adjusters completely backed off.

9. Lubricate the stud threads, nuts and washers with ARP ULTRA-TORQUE FASTENER ASSEMBLY

LUBRICANT. ARP recommends using the ARP ULTRA-TORQUE FASTENER ASSEMBLY

LUBRICANT that is provided with each kit as opposed to motor oil. This is due to higher friction on

the studs as well as inconsistencies in the clamping force of the fasteners when motor oil (or low

quality lubricant) is used. Also apply ARP Ultra-Torque Assembly Lubricant to the threads on the

secondary 8mm rocker arm pedestal (hold down) bolts.

10. Install the washers and the 12pt nuts onto the cylinder head studs and tighten them hand tight.

11. Install the secondary 8mm rocker arm pedestal (hold down) bolts into the cylinder head. Tighten the bolts

hand tight. Note: The secondary 8mm rocker arm pedestal (hold down) bolts must be installed in

place before tightening the head studs to properly align the tips of the rocker arms with the valve

stems.

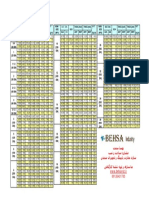

PRELOAD (TORQUE) RECOMMENDATIONS

12. Following the manufacturers recommended torque sequence tighten the nuts in three equal steps

to the specifications listed below with ARP ULTRA-TORQUE FASTENER ASSEMBLY LUBRICANT.

M12 studs 125 ft lbs M8 bolts 25 ft lbs

Note: ARP Ultra-Torque Fastener Assembly Lubricant has been specifically designed to reduce tension

preload scatter and eliminate the need to cycle high performance engine fasteners before final installation.

ARP Ultra-Torque far surpasses all requirements offered by previous ARP lubricants in terms of fastener

preload repeatability and performance lubricating properties. For more information on ARP Ultra-Torque visit

our website at www.arp-bolts.com or call 1 800-826-3045.

5/1/14

You might also like

- BTS Training Dms 100 System Maintenance andDocument6 pagesBTS Training Dms 100 System Maintenance andMuharrem RexhepiNo ratings yet

- BS-400 Service Manual (v1.1)Document365 pagesBS-400 Service Manual (v1.1)DE67% (3)

- ITwin TechnologyDocument20 pagesITwin TechnologymanasNo ratings yet

- Syntec InfoDocument14 pagesSyntec InfoGeorgi HelyanNo ratings yet

- Elwood Parts and Service ManualDocument75 pagesElwood Parts and Service Manualdindin6666No ratings yet

- CS 5200 SC01 Ope PRC 253007 - A - C2Document78 pagesCS 5200 SC01 Ope PRC 253007 - A - C2chancele nguepdjopNo ratings yet

- Manual Torque WrenchDocument2 pagesManual Torque WrenchVipul ShahNo ratings yet

- Suggested Methods and Guidelines For Torquing and Bolting Flange JointsDocument4 pagesSuggested Methods and Guidelines For Torquing and Bolting Flange JointsVivekananth AshokanNo ratings yet

- Lip Seal InstallationDocument11 pagesLip Seal InstallationMachineryengNo ratings yet

- LOCK O RING Flanges and PlugsDocument6 pagesLOCK O RING Flanges and PlugsochableNo ratings yet

- Failure of A Riser Transition Assembly On A Primary ReformerDocument10 pagesFailure of A Riser Transition Assembly On A Primary ReformerAbhimanyu PalNo ratings yet

- Thread o Ring FittingsDocument4 pagesThread o Ring FittingsLê Đức ThiệnNo ratings yet

- Chapter 1 Oil Seal IntroductionDocument0 pagesChapter 1 Oil Seal IntroductionZMCONTROLNo ratings yet

- Specification For GasketsDocument8 pagesSpecification For GasketsMehdi NouriNo ratings yet

- R5000 IomDocument26 pagesR5000 Iomfuminori0% (1)

- Trav L Cutter ManualDocument46 pagesTrav L Cutter ManualullwnNo ratings yet

- Pig Sig IVDocument7 pagesPig Sig IVsebas_vNo ratings yet

- Special Instruction Heat ExchangerDocument26 pagesSpecial Instruction Heat ExchangerDhiyo MulyadiNo ratings yet

- Field Hydrotest Manual UndergroundDocument8 pagesField Hydrotest Manual UndergroundPhuoc PhuNo ratings yet

- PCC-1-2010 Bolt Torque by FLG SizeDocument1 pagePCC-1-2010 Bolt Torque by FLG SizeemaanazeemNo ratings yet

- Hydraulics CurriculumDocument8 pagesHydraulics CurriculumChris ChrisNo ratings yet

- Flowtop-726 & 738 & 740Document32 pagesFlowtop-726 & 738 & 740sonalpanchal7No ratings yet

- Jotamastic 87: Technical Data Sheet Application GuideDocument10 pagesJotamastic 87: Technical Data Sheet Application GuideMina RemonNo ratings yet

- E25NAFLON Expansion BellowsDocument22 pagesE25NAFLON Expansion BellowsRezza Octova GochirNo ratings yet

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickNo ratings yet

- Nuflo Turbine Meter Manual PDFDocument16 pagesNuflo Turbine Meter Manual PDFfatsfinderNo ratings yet

- Stub Onin ConnectionsDocument4 pagesStub Onin ConnectionsMehman NasibovNo ratings yet

- Rupture Disk - Application and InspectionDocument33 pagesRupture Disk - Application and InspectionLudi D. LunarNo ratings yet

- Bleed Ring - ANSI Class 150-2500 (In)Document2 pagesBleed Ring - ANSI Class 150-2500 (In)ulfatNo ratings yet

- 350q-5 Operation ManualDocument97 pages350q-5 Operation ManualCesar Mora100% (2)

- Equivalent Length of A Reducer - Google SearchDocument3 pagesEquivalent Length of A Reducer - Google SearchzoksiNo ratings yet

- Torque Value DelmonDocument8 pagesTorque Value DelmonKhalid HaiderNo ratings yet

- Properties of Ss410Document5 pagesProperties of Ss410gregkilatonNo ratings yet

- 【Sinopulse Catalog (Hose and Fittings) 】Document49 pages【Sinopulse Catalog (Hose and Fittings) 】joseNo ratings yet

- Deaerators BrochureDocument4 pagesDeaerators BrochurefahimshkNo ratings yet

- Howto-Recommended Guidelines For Testing of Heat ExchangersDocument1 pageHowto-Recommended Guidelines For Testing of Heat ExchangersSam_1_No ratings yet

- Heat Exchanger InspectionDocument9 pagesHeat Exchanger Inspectionpstechnical_43312697No ratings yet

- Transformer-WPS OfficeDocument19 pagesTransformer-WPS OfficeVinaya kumar BGNo ratings yet

- ESP Is The Static PressureDocument7 pagesESP Is The Static PressureArlene DeiparineNo ratings yet

- Angular Tightening: K. LindbladDocument5 pagesAngular Tightening: K. LindbladKonrad LindbladNo ratings yet

- Clock Spring Pipe Repair System PDFDocument2 pagesClock Spring Pipe Repair System PDFNeo_1982No ratings yet

- Uk-Standard Asme Bladder AccumulatorDocument3 pagesUk-Standard Asme Bladder AccumulatorRamin SoadNo ratings yet

- Installation, Operation & Maintenance Manual: Hisaka Works, LTDDocument48 pagesInstallation, Operation & Maintenance Manual: Hisaka Works, LTDmadodandembeNo ratings yet

- API RP 687-2001 (2015) Ut BabbitpdfDocument1 pageAPI RP 687-2001 (2015) Ut BabbitpdfudomNo ratings yet

- Spiral Wound GasketsDocument3 pagesSpiral Wound GasketsHarish GundaNo ratings yet

- JHF 610-Xgat-Mm (2006 Ac)Document1 pageJHF 610-Xgat-Mm (2006 Ac)Arya Bayu WibisonoNo ratings yet

- Corrosion Data GuideDocument8 pagesCorrosion Data GuideLê Tuấn Asia ValvesNo ratings yet

- RF Return Line FilterDocument8 pagesRF Return Line Filterboobalan_shriNo ratings yet

- Pipe Size Table: 1/2 (15 DN) 3/4 (20 DN) 1 (25 DN)Document1 pagePipe Size Table: 1/2 (15 DN) 3/4 (20 DN) 1 (25 DN)Hadi KoraniNo ratings yet

- Tai PresentationDocument43 pagesTai PresentationusamafalakNo ratings yet

- Wavistrong Supplemental Installation InstructionsDocument13 pagesWavistrong Supplemental Installation Instructionsmg4myNo ratings yet

- How Do Plant Pipe Strain Problems Affect My Pumping SystemsDocument5 pagesHow Do Plant Pipe Strain Problems Affect My Pumping SystemsKarimAboelmkaremNo ratings yet

- Steel Pipe Leak Repair ClampDocument1 pageSteel Pipe Leak Repair Clampjohn3791No ratings yet

- Gate ValveDocument27 pagesGate ValveYogesh Kumar Bhatnagar0% (1)

- Document Title: Technical Proposal For 6500cbm LNG Storage TankDocument4 pagesDocument Title: Technical Proposal For 6500cbm LNG Storage Tankroni_arsyahNo ratings yet

- Tube Removal Catalog Web ELLIOTDocument24 pagesTube Removal Catalog Web ELLIOTJose Luis RattiaNo ratings yet

- Swagelok High Pressure FittingsDocument8 pagesSwagelok High Pressure FittingsSyahirul AlimNo ratings yet

- 3DX SchematicDocument4 pages3DX Schematicab59510% (1)

- WarrenDocument28 pagesWarrennolispe6No ratings yet

- CCO New Moppet A4 Sales Sheet 100418Document2 pagesCCO New Moppet A4 Sales Sheet 100418Puja Ningrat WibowoNo ratings yet

- ChecklistDocument2 pagesChecklistdassayevNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Motor B411 Turbo MitsubishiDocument1 pageMotor B411 Turbo MitsubishiCarlos Alberto Lau SosaNo ratings yet

- Agilent 34970A Data Acquisition / Switch Unit User ManualDocument221 pagesAgilent 34970A Data Acquisition / Switch Unit User ManualJonathan OlsonNo ratings yet

- Vehicle Inspection ManualDocument9 pagesVehicle Inspection ManualAsad KhanNo ratings yet

- Linux Boot ProcessesDocument7 pagesLinux Boot ProcessesRiyas MohamedNo ratings yet

- Cams 4h-3p ManualDocument44 pagesCams 4h-3p ManualJELMUNTNo ratings yet

- Codigos y Partes de CoronaDocument56 pagesCodigos y Partes de CoronaAntony Moreno0% (1)

- Pm880 Datasheet EnglishDocument4 pagesPm880 Datasheet EnglishNicola MargarelliNo ratings yet

- Big Buck Bunny Animation MovieDocument2 pagesBig Buck Bunny Animation Moviedarebusi1No ratings yet

- PRODUCTS: DH67BL, DH67CF, DH67CL, DH67GD, DH67VR (Standard Bios)Document8 pagesPRODUCTS: DH67BL, DH67CF, DH67CL, DH67GD, DH67VR (Standard Bios)Carlos CarrascoNo ratings yet

- MRD 4400 Receiver Decoder v19Document3 pagesMRD 4400 Receiver Decoder v19Hama AieaNo ratings yet

- PDMS - Command SyntaxDocument3 pagesPDMS - Command SyntaxLANKAPALLISURINo ratings yet

- HSD150MX15 BDocument30 pagesHSD150MX15 BarjaylzoNo ratings yet

- TC-HEMAXA Service Manual BC-3000PLUS PDFDocument191 pagesTC-HEMAXA Service Manual BC-3000PLUS PDFEsam PhlipeNo ratings yet

- Panasonic LCD Projector PT-AE2000 Service ManualDocument81 pagesPanasonic LCD Projector PT-AE2000 Service ManualJuanch01972100% (1)

- GPR Brochure 1Document6 pagesGPR Brochure 1Venkata MayurNo ratings yet

- Performance Evaluation of Server Virtualization in Data CenterDocument12 pagesPerformance Evaluation of Server Virtualization in Data CenterAhmed Bahig MohamedNo ratings yet

- PROPOSED Isales and Inventory Monitoring SystemDocument27 pagesPROPOSED Isales and Inventory Monitoring SystemDMNo ratings yet

- Acer Cu TSU56K Al1722Document59 pagesAcer Cu TSU56K Al1722flo2410No ratings yet

- Device Eligibility and Deductible Schedule For Mobile InsuranceDocument17 pagesDevice Eligibility and Deductible Schedule For Mobile InsuranceYejezkel ContrerasNo ratings yet

- Unix Previous Question PapersDocument8 pagesUnix Previous Question Papersapi-3849895No ratings yet

- 1100S Camera Broch RevADocument4 pages1100S Camera Broch RevAanon_242998136No ratings yet

- Datacool Installation Operation Maintenance ManualDocument20 pagesDatacool Installation Operation Maintenance Manualgabo andresNo ratings yet

- CH 01 SFAFASDFDocument20 pagesCH 01 SFAFASDFAngelo VillanuevaNo ratings yet

- SCM Group 05Document21 pagesSCM Group 05si ranNo ratings yet

- CDM 330CDocument8 pagesCDM 330CTonia GlennNo ratings yet

- Lesson 5 - Assemble ComputerDocument30 pagesLesson 5 - Assemble ComputerPaulo CelisNo ratings yet

- Datasheet 593356 (98-8970) enDocument12 pagesDatasheet 593356 (98-8970) enLuis Ramirez CNo ratings yet