Professional Documents

Culture Documents

Use Low-Grade Waste Steam To Power Absorption Chillers: Reduce Demand Charges

Use Low-Grade Waste Steam To Power Absorption Chillers: Reduce Demand Charges

Uploaded by

dalton2004Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Use Low-Grade Waste Steam To Power Absorption Chillers: Reduce Demand Charges

Use Low-Grade Waste Steam To Power Absorption Chillers: Reduce Demand Charges

Uploaded by

dalton2004Copyright:

Available Formats

Steam Motors Compressed Air

Use Low-Grade Waste Steam to Power

Absorption Chillers

Reduce Demand Absorption chillers use heat, instead of mechanical energy, to provide cooling. The

Charges mechanical vapor compressor is replaced by a thermal compressor (see figure) that

consists of an absorber, a generator, a pump, and a throttling device. The refrigerant vapor

Absorption chillers can from the evaporator is absorbed by a solution mixture in the absorber. This solution is

reshape facility thermal then pumped to the generator where the refrigerant is revaporized using a waste steam

and electric load profiles heat source. The refrigerant-depleted solution is then returned to the absorber via a

by shifting cooling from an throttling device. The two most common refrigerant/absorbent mixtures used in

electric to a thermal load. If absorption chillers are water/lithium bromide and ammonia/water.

you are served by an electric

utility with a ratcheted demand

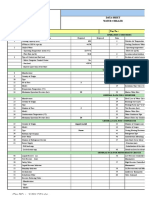

charge, you may be able to Comparison of Mechanical and Thermal Vapor Compression Systems*

reduce demand charges

throughout the year by

reducing your summer peak Waste Heat from Process

or Low-Pressure Steam

loads.

Refrigerant

Vapor to High Pressure Refrigerant

Utility Incentives Condenser

Generator Vapor to

Condenser

Some gas utilities offer

reduced rates during the

Electric/

summer. In some areas, Engine- Pump Thermal Throttle

electric utilities provide Driven Vapor Compression Valve

Compressor

rebates or incentives to

replace mechanical chillers Low Pressure

with steam absorption units. Refrigerant Refrigerant

Vapor from Absorber Vapor from

Evaporator Evaporator

Mechanical

Vapor Compression Rejected Heat

* The evaporator and the condenser, required for both systems, are not shown in the figure.

Compared to mechanical chillers, absorption chillers have a low coefficient of

Adapted from an Energy TIPS performance (COP = chiller load/heat input). Nonetheless, they can substantially

fact sheet that was originally reduce operating costs because they are energized by low-grade waste heat, while

published by the Industrial vapor compression chillers must be motor- or engine-driven.

Energy Extension Service of

Georgia Tech. For additional Low-pressure, steam-driven absorption chillers are available in capacities ranging

information on steam system from 100 to 1,500 tons. Absorption chillers come in two commercially available

efficiency measures, contact the designs: single-effect and double-effect. Single-effect machines provide a thermal

OIT Clearinghouse at COP of 0.7 and require about 18 pounds of 15-psig steam per ton-hour of cooling.

(800) 862-2086. Double-effect machines are about 40 percent more efficient, but require a higher

grade of thermal input, using about 10 pounds of 100- to 150-psig steam per

ton-hour.

OFFICE OF INDUSTRIAL TECHNOLOGIES

ENERGY EFFICIENCY AND RENEWABLE ENERGY • U.S. DEPARTMENT OF

Example

In a plant where low-pressure steam is currently being exhausted to the atmosphere, a

mechanical chiller with a COP of 4.0 is used 4,000 hours per year to produce an average

of 300 tons of refrigeration. The cost of electricity at the plant is $0.05 per kilowatt-hour.

An absorption unit requiring 5,400 lbs/hr of 15-psig steam could replace the mechanical

chiller, providing annual electrical cost savings of:

Annual = 300 tons x (12,000 Btu/ton / 4.0) x 4,000 hrs/year x $0.05/kWh x kWh/3,413 Btu

Savings = $52,740 BestPractices is part of the Office of

Industrial Technologies’ (OIT’s) Industries

of the Future strategy, which helps the

Suggested Actions country’s most energy-intensive

industries improve their competitiveness.

BestPractices brings together the best-

Determine the cost-effectiveness of displacing a portion of your cooling load with available and emerging technologies

a waste steam absorption chiller by taking the following steps: and practices to help companies begin

improving energy efficiency, environmental

• Conduct a plant survey to identify sources and availability of waste steam. performance, and productivity right now.

• Determine cooling load requirements and the cost of meeting those requirements BestPractices focuses on plant systems,

with existing mechanical chillers or new installations. where significant efficiency improvements

and savings can be achieved. Industry

• Obtain installed cost quotes for a waste steam absorption chiller. gains easy access to near-term and

long-term solutions for improving the

• Conduct a life cycle cost analysis to determine if the waste steam absorption chiller performance of motor, steam, compressed

meets your company’s cost-effectiveness criteria. air, and process heating systems. In

addition, the Industrial Assessment Centers

provide comprehensive industrial energy

evaluations to small and medium-size

manufacturers.

F OR A DDITIONAL I NFORMATION ,

P LEASE C ONTACT:

Theo Johnson

About DOE’s Office of Industrial Technologies Office of Industrial Technologies

Phone: (202) 586-6937

The Office of Industrial Technologies (OIT), through partnerships with industry, Fax: (202) 586-6507

government, and non-governmental organizations, develops and delivers advanced Theodore.Johnson@hq.doe.gov

energy efficiency, renewable energy, and pollution prevention technologies for www.oit.doe.gov/bestpractices

industrial applications. OIT is part of the U.S. Department of Energy’s Office of

Energy Efficiency and Renewable Energy. OIT Clearinghouse

OIT encourages industry-wide efforts to boost resource productivity through a Phone: (800) 862-2086

Fax: (360) 586-8303

strategy called Industries of the Future (IOF). IOF focuses on the following nine clearinghouse@ee.doe.gov

energy- and resource-intensive industries:

• Agriculture • Forest Products • Mining Please send any comments,

• Aluminum • Glass • Petroleum questions, or suggestions to

• Chemicals • Metal Casting • Steel webmaster.oit@ee.doe.gov

OIT and its BestPractices program offer a wide variety of resources to industrial

Visit our home page at

partners that cover motor, steam, compressed air, and process heating systems. www.oit.doe.gov

For example, BestPractices software can help you decide whether to replace or

rewind motors (MotorMaster+), assess the efficiency of pumping systems (PSAT),

or determine optimal insulation thickness for pipes and pressure vessels (3E Plus). Office of Industrial Technologies

Energy Efficiency

Training is available to help you or your staff learn how to use these software and Renewable Energy

programs and learn more about industrial systems. Workshops are held around the U.S. Department of Energy

country on topics such as “Capturing the Value of Steam Efficiency,” “Fundamentals Washington, DC 20585-0121

and Advanced Management of Compressed Air Systems,” and “Motor System

Management.” Available technical publications range from case studies and tip

sheets to sourcebooks and market assessments. The Energy Matters newsletter, for

example, provides timely articles and information on comprehensive energy systems

for industry. You can access these resources and more by visiting the BestPractices DOE/GO-102001-1277

Web site at www.oit.doe.gov/bestpractices or by contacting the OIT Clearinghouse at May 2001

800-862-2086 or via email at clearinghouse@ee.doe.gov. Steam Tip Sheet #14

You might also like

- Operations and Maintenance Preventive Maintenance ChecklistsDocument35 pagesOperations and Maintenance Preventive Maintenance Checklistssooriya_82100% (14)

- Essentials of Steam Turbine Design and Analysis: Back To BasicsDocument9 pagesEssentials of Steam Turbine Design and Analysis: Back To BasicsJohn AnthoniNo ratings yet

- Gea Wiegand MVRDocument24 pagesGea Wiegand MVRPrashant Bahirgonde100% (2)

- Economizer PDFDocument14 pagesEconomizer PDFdalton2004No ratings yet

- KK180 US 55chemicalDocument2 pagesKK180 US 55chemicaldalton2004No ratings yet

- Chiller Data SheetDocument4 pagesChiller Data SheetChotiwan Rattanasatien100% (1)

- Waste AbsorptionDocument2 pagesWaste AbsorptionSandeep SinghNo ratings yet

- Steam14 Chillers PDFDocument2 pagesSteam14 Chillers PDFwaheedNo ratings yet

- Replace Pressure-Reducing Valves With Backpressure TurbogeneratorsDocument2 pagesReplace Pressure-Reducing Valves With Backpressure TurbogeneratorsEmerson RwkNo ratings yet

- Thermally Activated Absorption Chillers PDFDocument2 pagesThermally Activated Absorption Chillers PDFdalton2004No ratings yet

- Steam Absorption ChillerDocument3 pagesSteam Absorption ChillerAbd AbdulNo ratings yet

- Use Vapor Recompression To Recover Low-Pressure Waste Steam: Conduct A Pinch AnalysisDocument2 pagesUse Vapor Recompression To Recover Low-Pressure Waste Steam: Conduct A Pinch Analysisedgardiaz5519No ratings yet

- Converting Waste Heat To Useful Energy in Heating, Ventilating and Air-Conditioning SystemsDocument4 pagesConverting Waste Heat To Useful Energy in Heating, Ventilating and Air-Conditioning SystemskdpmansiNo ratings yet

- UioijoDocument28 pagesUioijoParchuri PraveenNo ratings yet

- ASHRAE Absorption ChillerDocument7 pagesASHRAE Absorption ChillerMinh TranNo ratings yet

- Advanced Technology Combined CyclesDocument20 pagesAdvanced Technology Combined CyclestermicalcceNo ratings yet

- 2004 09 Building For The Future - Driving Absorption Chillers Using Heat Recovery - RyanDocument7 pages2004 09 Building For The Future - Driving Absorption Chillers Using Heat Recovery - RyanmeomeportabNo ratings yet

- Evaporation For Instant Coffee Plants Tcm11 54061Document1 pageEvaporation For Instant Coffee Plants Tcm11 54061Hung DoNo ratings yet

- BS 5204 Energy Efficiency and Renewable Energy in BuildingsDocument39 pagesBS 5204 Energy Efficiency and Renewable Energy in BuildingsMohamedNo ratings yet

- Vol5 (1) 2014 P71 80Document10 pagesVol5 (1) 2014 P71 80KishoreNo ratings yet

- Steam Turbinea NalysisDocument10 pagesSteam Turbinea NalysiswasayNo ratings yet

- Boiler Performance ImproveDocument5 pagesBoiler Performance Improvehwang2No ratings yet

- Federal Technology Alert: Refrigerant SubcoolingDocument24 pagesFederal Technology Alert: Refrigerant SubcoolingVeera ManiNo ratings yet

- JT EffectDocument6 pagesJT EffectToge GedeNo ratings yet

- HVAC: Natural Gas Chillers: What Are The Options?Document5 pagesHVAC: Natural Gas Chillers: What Are The Options?Anton WorkNo ratings yet

- The Three Es of Geothermal Heat Pump SystemsDocument4 pagesThe Three Es of Geothermal Heat Pump SystemsRakshithKumarNo ratings yet

- Absorption ChillersDocument4 pagesAbsorption ChillerscharlievirayNo ratings yet

- 160.67-PR1 - Advances in Steam Cooling ASHRAEDocument4 pages160.67-PR1 - Advances in Steam Cooling ASHRAEGustavo Oliveira SilvaNo ratings yet

- Adsorption Chiller Brochures BryairDocument28 pagesAdsorption Chiller Brochures BryairHua Hidari YangNo ratings yet

- Steam16 Cycling LossesDocument2 pagesSteam16 Cycling LossesShahid AliNo ratings yet

- Recuperación de Calor de Sistemas de Refrigeración ASHRAEDocument8 pagesRecuperación de Calor de Sistemas de Refrigeración ASHRAEDiegoAlvarezHuguezNo ratings yet

- Modeling Heat Recovery Plants in Hourly Analysis Program (HAP) v4.90 by CarrierDocument8 pagesModeling Heat Recovery Plants in Hourly Analysis Program (HAP) v4.90 by CarrierrobinssonNo ratings yet

- Power Production From A Moderate - Temperature Geothermal ResourceDocument8 pagesPower Production From A Moderate - Temperature Geothermal ResourceSanjoy BasakNo ratings yet

- EER Comparison HITEMA Chillers: Free Cooling MW Hours OperationDocument5 pagesEER Comparison HITEMA Chillers: Free Cooling MW Hours Operationm4xiNo ratings yet

- 41-266.0 Icebreaker - CondensateRecoveryDocument1 page41-266.0 Icebreaker - CondensateRecoverybkarakoseNo ratings yet

- Co-Generation: Handout On Cogeneration by AAKDocument5 pagesCo-Generation: Handout On Cogeneration by AAKMuhammad Omar AzadNo ratings yet

- An Introduction To Gas Turbines & Microturbines For DE ApplicationsDocument30 pagesAn Introduction To Gas Turbines & Microturbines For DE Applications1111AABBTT100% (1)

- Improved Energy Efficiency of Air Cooled ChillersDocument4 pagesImproved Energy Efficiency of Air Cooled ChillersKhozema GoodluckNo ratings yet

- Absorption Chillers Articulo ComplementoDocument2 pagesAbsorption Chillers Articulo ComplementoHelena GissNo ratings yet

- How To Know If Cogeneration Is The Right Choice For YouDocument4 pagesHow To Know If Cogeneration Is The Right Choice For YouRicardo BecNo ratings yet

- GCM 14Document8 pagesGCM 14Soe ThuNo ratings yet

- Co GenerationDocument47 pagesCo GenerationDeshdeepak Sharma D DNo ratings yet

- Steam Tip Sheet #18Document2 pagesSteam Tip Sheet #18Muhammad NaeemNo ratings yet

- Case Study: Exergy Accounting of A Vapor Power PlantDocument1 pageCase Study: Exergy Accounting of A Vapor Power Plantali jabarNo ratings yet

- An Analysis of The Performance of An Ejector RefriDocument6 pagesAn Analysis of The Performance of An Ejector RefriHalvor JohnsenNo ratings yet

- Steam Tip Sheet #13Document2 pagesSteam Tip Sheet #13Muhammad NaeemNo ratings yet

- IsoTherming® Hydroprocessing TechnologyDocument4 pagesIsoTherming® Hydroprocessing Technologyromi moriNo ratings yet

- Performance Increase of Steam Turbine Condensers by CFD AnalysisDocument10 pagesPerformance Increase of Steam Turbine Condensers by CFD AnalysisAbdullah RobbaniNo ratings yet

- Cleaver Brooks - Design Considerations For Small Scale HRSGsDocument16 pagesCleaver Brooks - Design Considerations For Small Scale HRSGsLiu YangtzeNo ratings yet

- Envirofresh QuietDocument16 pagesEnvirofresh QuietAmer GaladNo ratings yet

- ASHRAE - Series Series Counterflow For Central Chilled Water PlantsDocument7 pagesASHRAE - Series Series Counterflow For Central Chilled Water PlantsAntonio LebrunNo ratings yet

- A Case Study On Thermodynamic Analysis of Cogeneration Power Plant (IRJET-V2I9163)Document5 pagesA Case Study On Thermodynamic Analysis of Cogeneration Power Plant (IRJET-V2I9163)luis hyungNo ratings yet

- Steam11 Waste SteamDocument2 pagesSteam11 Waste SteamGaurav UpaNo ratings yet

- Comparison of Various Heat Pump Assisted Distillation ConfigurationsDocument13 pagesComparison of Various Heat Pump Assisted Distillation ConfigurationsRohan PrajapatiNo ratings yet

- Cogeneration PDFDocument19 pagesCogeneration PDFMandeep Singh100% (1)

- Cogeneration Power Plant SystemDocument14 pagesCogeneration Power Plant SystemRizelle VinaraoNo ratings yet

- Topic: - Power Cogeneration Plant: Term Paper OF Project ManagementDocument13 pagesTopic: - Power Cogeneration Plant: Term Paper OF Project ManagementankuaaaNo ratings yet

- DEVAGYA GANDHI OF CLASS 3-B Air Conditioning PPT FROM NATIONAL BUILDING CODE OF INDIADocument44 pagesDEVAGYA GANDHI OF CLASS 3-B Air Conditioning PPT FROM NATIONAL BUILDING CODE OF INDIADevagya GandhiNo ratings yet

- Exhaust Base Vam Tonnage CalculationDocument9 pagesExhaust Base Vam Tonnage CalculationMagical RiyaNo ratings yet

- Thermal Analysis of Waste Heat Recovery Unit Using The Exhaust Gas Emitted From Internal Combustion EngineDocument6 pagesThermal Analysis of Waste Heat Recovery Unit Using The Exhaust Gas Emitted From Internal Combustion EngineAmal RajNo ratings yet

- Dry Wet Cooling Systems and Flue Gas System ENEXIODocument55 pagesDry Wet Cooling Systems and Flue Gas System ENEXIOAmir AbbaszadehNo ratings yet

- Ice PlantDocument25 pagesIce PlantAbenliciousNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Mec in Carbon SteelDocument7 pagesMec in Carbon Steeldalton2004No ratings yet

- PH Control: P2 FactsDocument4 pagesPH Control: P2 Factsdalton2004No ratings yet

- Chemical Resistance ChartDocument32 pagesChemical Resistance Chartdalton2004No ratings yet

- The Unique Doubble Function Physical Water Conditioner.: Hard Water, Lime Scale Deposits and Corrosion PreventionDocument1 pageThe Unique Doubble Function Physical Water Conditioner.: Hard Water, Lime Scale Deposits and Corrosion Preventiondalton2004No ratings yet

- Thermally Activated Absorption Chillers PDFDocument2 pagesThermally Activated Absorption Chillers PDFdalton2004No ratings yet

- GT W03 Small Absorption Chillers PDFDocument2 pagesGT W03 Small Absorption Chillers PDFdalton2004No ratings yet

- KK260 US 40chemicalDocument2 pagesKK260 US 40chemicaldalton2004No ratings yet

- Norit Selection EDocument1 pageNorit Selection Edalton2004No ratings yet

- Faravar Palayesh Information CenterDocument4 pagesFaravar Palayesh Information Centerdalton2004No ratings yet

- ChemicalDocument2 pagesChemicaldalton2004No ratings yet

- Kleen: Koch Additive Z Membrane CleanerDocument2 pagesKleen: Koch Additive Z Membrane Cleanerdalton2004No ratings yet

- Faravar Palayesh Information CenterDocument5 pagesFaravar Palayesh Information Centerdalton2004No ratings yet

- ChemicalDocument2 pagesChemicaldalton2004No ratings yet

- Corrosion Rate Conversion: Ma CM MM Year Mpy GM Day Ma CM MM Year Mpy GM DayDocument1 pageCorrosion Rate Conversion: Ma CM MM Year Mpy GM Day Ma CM MM Year Mpy GM Daydalton2004No ratings yet

- Kleen: Koch 221 Membrane CleanerDocument2 pagesKleen: Koch 221 Membrane Cleanerdalton2004No ratings yet

- KKL07 US 275chemicalDocument2 pagesKKL07 US 275chemicaldalton2004No ratings yet

- Kleen: Koch 150 Membrane CleanerDocument2 pagesKleen: Koch 150 Membrane Cleanerdalton2004No ratings yet

- Treat: Koch 275 AntiscalantDocument2 pagesTreat: Koch 275 Antiscalantdalton2004No ratings yet

- Chiller SE XRAF3612A 17-24Document2 pagesChiller SE XRAF3612A 17-24Mauricio RiscoNo ratings yet

- Maintenance Cost Calculator - ASHRAE 1983 Study BasisDocument3 pagesMaintenance Cost Calculator - ASHRAE 1983 Study BasisADESHINANo ratings yet

- Project (Repaired) Mulugeta and YalewDocument83 pagesProject (Repaired) Mulugeta and YalewSolomon Girma100% (3)

- 18 TR-ChillerDocument2 pages18 TR-ChillerAbdul Rauf KhanNo ratings yet

- II 3 Technical Data - HVACDocument206 pagesII 3 Technical Data - HVACAnh Vân Trần100% (1)

- 3.1 Mechanical - Operational - Chemical Survey ConceptDocument14 pages3.1 Mechanical - Operational - Chemical Survey ConceptdavidmacanaNo ratings yet

- York Recovery ChillerDocument4 pagesYork Recovery ChillerBen MusimaneNo ratings yet

- Accop 2007Document35 pagesAccop 2007roypunNo ratings yet

- Carel 030220426Document72 pagesCarel 030220426mikiimiNo ratings yet

- Trnsys 2004 PDFDocument32 pagesTrnsys 2004 PDFKhuleedShaikhNo ratings yet

- Section - 15985 Temperature Control Specifiers GuideDocument6 pagesSection - 15985 Temperature Control Specifiers GuideAntonio LebrunNo ratings yet

- Systemair Syscroll 140Document76 pagesSystemair Syscroll 140Назар СвиридNo ratings yet

- Clivet ManualDocument50 pagesClivet ManualPrestoneK75% (4)

- Ys Screw Chiller Carte TehnicaDocument68 pagesYs Screw Chiller Carte TehnicaMonnu Banta100% (3)

- Aermec VMF E5 Installation Manual EngDocument52 pagesAermec VMF E5 Installation Manual EngArmen TarkhanyanNo ratings yet

- Installing Seismic Restraints For Mechanical EquipmentDocument158 pagesInstalling Seismic Restraints For Mechanical EquipmentinitbashNo ratings yet

- Utility Management Plan PDFDocument4 pagesUtility Management Plan PDFMuhammad Ammar AkbarNo ratings yet

- P 271 B - Doc 2 - Part D - Sec - HVAC - BOQ Priced Rev.001 Subcontractor WorksDocument55 pagesP 271 B - Doc 2 - Part D - Sec - HVAC - BOQ Priced Rev.001 Subcontractor WorksAdmire MuvunzwiNo ratings yet

- Chiller Testing Procedure Rev 3 PDFDocument11 pagesChiller Testing Procedure Rev 3 PDFOanh NguyenNo ratings yet

- Ewaq140g SsDocument5 pagesEwaq140g SsTofan VasileNo ratings yet

- APCN-S Series Air Cooled Packaged Chillers: Range 50 TR To 435 TR (176 KW To 1529 KW)Document47 pagesAPCN-S Series Air Cooled Packaged Chillers: Range 50 TR To 435 TR (176 KW To 1529 KW)Ahmad Salah100% (1)

- Frigel Water Chiller PDFDocument4 pagesFrigel Water Chiller PDFoptogan50% (2)

- County of Alameda Qualified Contractor ListDocument6 pagesCounty of Alameda Qualified Contractor ListZak KNi9thNo ratings yet

- Blue Star Ltd.Document69 pagesBlue Star Ltd.AB JaatNo ratings yet

- Hysys UB 2021Document134 pagesHysys UB 2021Harits Eka FebriyantoNo ratings yet

- Trane Air Cooled Scroll Chillers Installation Operation MaintenanceDocument276 pagesTrane Air Cooled Scroll Chillers Installation Operation MaintenanceBay Mưa100% (1)

- 0407 What's Up With Cooling TowersDocument9 pages0407 What's Up With Cooling Towersenlightened1718No ratings yet