Professional Documents

Culture Documents

SECTION 13 RAILINGS Table A13.2-1 Design PDF

SECTION 13 RAILINGS Table A13.2-1 Design PDF

Uploaded by

abdulazeez88Copyright:

Available Formats

You might also like

- Mos Prf111Document7 pagesMos Prf111Nadim527No ratings yet

- HOBBS (1957) - An Investigation Into The Stress Distribution in Pile Caps With Some Notes On DesignDocument34 pagesHOBBS (1957) - An Investigation Into The Stress Distribution in Pile Caps With Some Notes On DesignVítor FreitasNo ratings yet

- 1-Concrete-Filled Aluminum Circular Hollow Section Column TestsDocument9 pages1-Concrete-Filled Aluminum Circular Hollow Section Column TestsHendrik TaupanNo ratings yet

- Sample Packing List - Steel StructureDocument1 pageSample Packing List - Steel Structureabdulazeez88100% (1)

- Belt Selection CalculationDocument29 pagesBelt Selection CalculationElwathig BakhietNo ratings yet

- CE 331C Route SurveyingDocument5 pagesCE 331C Route SurveyingZanne RoseNo ratings yet

- CESMM3 Vs 4 - RepairedDocument5 pagesCESMM3 Vs 4 - RepairedDilan De SilvaNo ratings yet

- Ask The Engineer Proper Bedding For PVC Pressure PipeDocument5 pagesAsk The Engineer Proper Bedding For PVC Pressure PipeUnibellNo ratings yet

- Design For NSF by Harry PoulosDocument7 pagesDesign For NSF by Harry PoulosSantosoNo ratings yet

- KDS 11 70 20 Rockfall and Debris Prevention Facility Design StandardsDocument15 pagesKDS 11 70 20 Rockfall and Debris Prevention Facility Design StandardsSH Big ShimNo ratings yet

- Q1 - Testing, Design, and Field Implementation of GFRP RC Soft-Eyes For Tunnel ConstructionDocument17 pagesQ1 - Testing, Design, and Field Implementation of GFRP RC Soft-Eyes For Tunnel ConstructionJhoshep SaavedraNo ratings yet

- 3583.PLAXIS - 2D - CEV22.01 - Tutorial - 05 - Excavation of An NATM TunnelDocument14 pages3583.PLAXIS - 2D - CEV22.01 - Tutorial - 05 - Excavation of An NATM TunnelPhalgun MoturuNo ratings yet

- 100000Document76 pages100000Dandu ManNo ratings yet

- Budhu Soil Mechanics Foundations 3rd TXTBKDocument1 pageBudhu Soil Mechanics Foundations 3rd TXTBKNadeem AbbasiNo ratings yet

- Models For Punching Shear Capacity in Concrete SlabsDocument166 pagesModels For Punching Shear Capacity in Concrete SlabsZoran BonicNo ratings yet

- FP McCann Precast Concrete Headwalls InstallationDocument4 pagesFP McCann Precast Concrete Headwalls InstallationgemotorresNo ratings yet

- SPREW Part 3 of 3 PDFDocument122 pagesSPREW Part 3 of 3 PDFhz135874No ratings yet

- Chapter 6A PPT (Compatibility Mode)Document47 pagesChapter 6A PPT (Compatibility Mode)Elhussain HassanNo ratings yet

- 1 Input Data: WWW - Hilti.usDocument6 pages1 Input Data: WWW - Hilti.usamanpreet_ahujaNo ratings yet

- Lateral Load PileDocument21 pagesLateral Load PileCarlos FilipusNo ratings yet

- Punching Shear - ExercisesDocument8 pagesPunching Shear - ExercisesSufian AbusninaNo ratings yet

- Formwork Design N Scheme Preparation Salsette 27 PDFDocument62 pagesFormwork Design N Scheme Preparation Salsette 27 PDFnarsimhhaNo ratings yet

- Uplift Capacity of Piles in Two Layered SoilDocument7 pagesUplift Capacity of Piles in Two Layered SoilIAEME PublicationNo ratings yet

- PILES SUBJECTED TO LATERAL SOIL MOVEMENTS Poulos 1997 PDFDocument10 pagesPILES SUBJECTED TO LATERAL SOIL MOVEMENTS Poulos 1997 PDFAgapito ScogliamiglioNo ratings yet

- Simplified Analysis of Continuous BeamsDocument7 pagesSimplified Analysis of Continuous BeamsAmirNo ratings yet

- Comparison Study of Pile Foundation Using Eurocode 7 and Working Stress Design ApproachDocument7 pagesComparison Study of Pile Foundation Using Eurocode 7 and Working Stress Design ApproachIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Pile Foundation: Reason For Piles Types of Piles Capacity Prediction Methods Load TestsDocument29 pagesPile Foundation: Reason For Piles Types of Piles Capacity Prediction Methods Load TestsJohneal MatiasNo ratings yet

- Gabion Walls Presentation FijiDocument38 pagesGabion Walls Presentation FijiHuy ChungNo ratings yet

- Chapt 5 Shear Strength in Soil Upload PDFDocument38 pagesChapt 5 Shear Strength in Soil Upload PDFabdirahmanNo ratings yet

- Validation-Triaxial Test With Hardening Soil Model (2015)Document4 pagesValidation-Triaxial Test With Hardening Soil Model (2015)Geeta JiraliNo ratings yet

- CapwapDocument2 pagesCapwapjilofeNo ratings yet

- Prestress Concrete DPDocument20 pagesPrestress Concrete DPdanielNo ratings yet

- Design and Performance of A 15m Deep Excavation For A Wagon TipplerDocument5 pagesDesign and Performance of A 15m Deep Excavation For A Wagon TipplerlingamkumarNo ratings yet

- Pile DebondingDocument4 pagesPile DebondingjtjtfghNo ratings yet

- Stability of Steel Framed Structures: Ir. Prof. Dr. Jeffrey ChiangDocument30 pagesStability of Steel Framed Structures: Ir. Prof. Dr. Jeffrey Chiangsam19961No ratings yet

- Lindquist Secant Pile Shoring Developments in Design and Construction DFI2011Document8 pagesLindquist Secant Pile Shoring Developments in Design and Construction DFI2011santanu mukherjeeNo ratings yet

- Design of Piles: Rosalem, Glyra BDocument41 pagesDesign of Piles: Rosalem, Glyra BGlyra RosalemNo ratings yet

- Ce 382 Chapter 8 Seepage 1442 RDocument110 pagesCe 382 Chapter 8 Seepage 1442 RBhavesh ChudasamaNo ratings yet

- Piled Raft FoundationsDocument96 pagesPiled Raft FoundationsMahmoud FaroukNo ratings yet

- Cyclic Simple Shear Test PrintDocument4 pagesCyclic Simple Shear Test PrintAlher HeraNo ratings yet

- Lateral Earth Pressure in Expansive Clay SoilsDocument14 pagesLateral Earth Pressure in Expansive Clay SoilsSamad Arabi100% (1)

- Uplift Capacity of Axially Loaded Piles in Clays: Vishwas N. Khatri and Jyant KumarDocument6 pagesUplift Capacity of Axially Loaded Piles in Clays: Vishwas N. Khatri and Jyant KumarrkNo ratings yet

- Prensa Digital Triaxial-MATESTDocument42 pagesPrensa Digital Triaxial-MATESTAlvaro G. MCNo ratings yet

- Case Histories On The Use of Helical Piles For Retrofitting and New ConstructionDocument6 pagesCase Histories On The Use of Helical Piles For Retrofitting and New ConstructionLeonardo SanchezNo ratings yet

- Design Example Reinforced Strip FoundationDocument6 pagesDesign Example Reinforced Strip FoundationFrans-Shixova ShipopyeniNo ratings yet

- Modern Fastening Systems in Tunnel ConstructionDocument12 pagesModern Fastening Systems in Tunnel ConstructionfreezefreezeNo ratings yet

- Rock Socket Piles at Coventry Point, Market Way, CoventryDocument16 pagesRock Socket Piles at Coventry Point, Market Way, Coventrynagas440% (1)

- Measurement and Prediction of Construction Vibration Affecting Sensitive LaboratoriesDocument7 pagesMeasurement and Prediction of Construction Vibration Affecting Sensitive Laboratoriesfandy sipataNo ratings yet

- Aggregates FMDocument5 pagesAggregates FMabualamalNo ratings yet

- Terzaghi and PeckDocument7 pagesTerzaghi and PeckRaja Hendra Solihin RambeNo ratings yet

- Mangan D (2018) - The Role of Proof Rolling in Pavement ConstructionDocument10 pagesMangan D (2018) - The Role of Proof Rolling in Pavement Constructionkentong.leeNo ratings yet

- The Influence of Plugging On DriveabilityDocument12 pagesThe Influence of Plugging On DriveabilityDedy DharmawansyahNo ratings yet

- A Comparison of Dynamic and Static Load Tests On Reinforced Concrete Driven Pile-2004 - 02Document7 pagesA Comparison of Dynamic and Static Load Tests On Reinforced Concrete Driven Pile-2004 - 02Hoo Yen HowNo ratings yet

- Chen 2008Document10 pagesChen 2008RivaiNo ratings yet

- Chapter 3 Bearing Capacity PDFDocument11 pagesChapter 3 Bearing Capacity PDFIan SeguritanNo ratings yet

- Slope Design & Construction PracticeDocument153 pagesSlope Design & Construction PracticeKAI CHUAN CHUNo ratings yet

- Pullout Capacity of Model Piles in Sand PDFDocument6 pagesPullout Capacity of Model Piles in Sand PDFJaymin PatilNo ratings yet

- Conplast WL XtraDocument2 pagesConplast WL Xtrapankajsingh100% (1)

- FE Fixed Band StripDocument5 pagesFE Fixed Band StripStevenNo ratings yet

- 2023 - Potini - Rigorous Lower and Upper Bounds For The Generalised FailureDocument7 pages2023 - Potini - Rigorous Lower and Upper Bounds For The Generalised FailureValerioNo ratings yet

- Allowable Load of Main Components of ScaffoldDocument10 pagesAllowable Load of Main Components of Scaffoldteguh widayatNo ratings yet

- Festoon Cable SystemDocument17 pagesFestoon Cable SystemKwanhee HanNo ratings yet

- Lecture 9: Quarter-Wave-Transformer Matching.: R JZ L Z Z Z JR LDocument13 pagesLecture 9: Quarter-Wave-Transformer Matching.: R JZ L Z Z Z JR LRuth EnormeNo ratings yet

- Ex Slab BridgeDocument32 pagesEx Slab BridgeKhadafi Dwi AnugrahNo ratings yet

- Grade 1 Maths WorksheetDocument3 pagesGrade 1 Maths Worksheetabdulazeez88No ratings yet

- Merint-Railing System & AccessoriesDocument20 pagesMerint-Railing System & Accessoriesabdulazeez88No ratings yet

- Hilti - Anchor Design - Jan 5, 2020Document15 pagesHilti - Anchor Design - Jan 5, 2020abdulazeez88No ratings yet

- GMI CatalogDocument37 pagesGMI Catalogabdulazeez88No ratings yet

- Hotel & Branded Apartments - TDDocument16 pagesHotel & Branded Apartments - TDabdulazeez88No ratings yet

- General - Overview - Finland Pavilion - Expo 2020Document14 pagesGeneral - Overview - Finland Pavilion - Expo 2020abdulazeez88100% (2)

- 3D View of Staad ProDocument1 page3D View of Staad Proabdulazeez88No ratings yet

- Bolt and Baseplate CalcDocument3 pagesBolt and Baseplate Calcabdulazeez88No ratings yet

- Electrical Load ScheduleDocument3 pagesElectrical Load Scheduleabdulazeez88No ratings yet

- +1.650 M. BOT of TrenchDocument1 page+1.650 M. BOT of Trenchabdulazeez88No ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'abdulazeez88No ratings yet

- Crane Material ListDocument2 pagesCrane Material Listabdulazeez88No ratings yet

- Shailesh Final ThesisDocument70 pagesShailesh Final Thesisabdulazeez88No ratings yet

- Frame Structure ElevationDocument1 pageFrame Structure Elevationabdulazeez88No ratings yet

- Aircraft Wood GluingDocument3 pagesAircraft Wood Gluingabdulazeez88No ratings yet

- Eee CompaniesDocument4 pagesEee Companiesabdulazeez88No ratings yet

- 921e Cargador Frontal CaterpillarDocument8 pages921e Cargador Frontal CaterpillarElvis Eberth Huanca MachacaNo ratings yet

- South Dakota v. Miller, No. 27198 (S.D. Dec. 7, 2016)Document35 pagesSouth Dakota v. Miller, No. 27198 (S.D. Dec. 7, 2016)RHTNo ratings yet

- New York City MTA Subway MapDocument1 pageNew York City MTA Subway Mapsorin_us10No ratings yet

- Still - MXDocument8 pagesStill - MXtomy112No ratings yet

- AutoTrack MasterDocument480 pagesAutoTrack MasterCEGUS CATALINNo ratings yet

- Pavement Design ManualDocument295 pagesPavement Design ManualkonstantanolNo ratings yet

- A Seminar Report-1Document21 pagesA Seminar Report-1Rameez BedekarNo ratings yet

- About Quantum TrimbleDocument68 pagesAbout Quantum TrimbleantonNo ratings yet

- Council Minutes 3 October 2019 1Document63 pagesCouncil Minutes 3 October 2019 1markNo ratings yet

- Project Proposal 1Document47 pagesProject Proposal 1Bikash sharrf100% (3)

- Executive Summary Site and Project JustificationDocument25 pagesExecutive Summary Site and Project JustificationVANESSA DELA TORRENo ratings yet

- FormDocument8 pagesFormDipesh GuptaNo ratings yet

- LC Gate TvuDocument7 pagesLC Gate Tvuranjitbhuyan87No ratings yet

- 1 - Introduction To Geometric Design (With Ghanaian Considerations)Document36 pages1 - Introduction To Geometric Design (With Ghanaian Considerations)Kwasi Agyeman-Boakye100% (1)

- RECYFIX TRAFFIC GUGIBLOC 300 Tipe 010 - E600Document2 pagesRECYFIX TRAFFIC GUGIBLOC 300 Tipe 010 - E600Dadang KurniaNo ratings yet

- DO - 011 - S2006 Hot Poured SealantDocument7 pagesDO - 011 - S2006 Hot Poured SealantCarol SantosNo ratings yet

- Civil - Intelligent Transportation SystemsDocument1 pageCivil - Intelligent Transportation SystemsRocky BhaiNo ratings yet

- California DMV CDL Skills TestsDocument5 pagesCalifornia DMV CDL Skills TestsLOUNo ratings yet

- Binder 5Document20 pagesBinder 5Anonymous 2yVesLNo ratings yet

- Public Transportation DirectionsDocument2 pagesPublic Transportation DirectionsIliana SanmartinNo ratings yet

- Engineering Department Sop HandbookDocument254 pagesEngineering Department Sop Handbookshankar kharat100% (1)

- Components of Ts I.Document15 pagesComponents of Ts I.Tariq HasanNo ratings yet

- Compendium OF Correction Slips To Codes & Manuals Pertaining To Engg. DepttDocument22 pagesCompendium OF Correction Slips To Codes & Manuals Pertaining To Engg. DepttvijaysinhjagtapNo ratings yet

- Iloilo City Regulation Ordinance 2004-268Document9 pagesIloilo City Regulation Ordinance 2004-268Iloilo City CouncilNo ratings yet

- 02 - Gideon-Boie - The Activist Commons and How It Changes The CityDocument13 pages02 - Gideon-Boie - The Activist Commons and How It Changes The CitySimon BoulezNo ratings yet

- Toll Road Project - Specifications Section 9 - PavementsDocument32 pagesToll Road Project - Specifications Section 9 - PavementsadhystiraNo ratings yet

SECTION 13 RAILINGS Table A13.2-1 Design PDF

SECTION 13 RAILINGS Table A13.2-1 Design PDF

Uploaded by

abdulazeez88Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SECTION 13 RAILINGS Table A13.2-1 Design PDF

SECTION 13 RAILINGS Table A13.2-1 Design PDF

Uploaded by

abdulazeez88Copyright:

Available Formats

www.bantui.

com

SECTION 13: RAILINGS 13-17

where:

Ri = resistance of the rail (kips)

Yi = distance from bridge deck to the ith rail (ft)

All forces shall be applied to the longitudinal rail Eq. A13.2-1 has been found to give reasonable

elements. The distribution of longitudinal loads to posts predictions of effective railing height requirements to

shall be consistent with the continuity of rail elements. prevent rollover.

Distribution of transverse loads shall be consistent with the If the design load located at He falls between rail

assumed failure mechanism of the railing system. elements, it should be distributed proportionally to rail

elements above and below such that Y ≥ He.

As an example of the significance of the data in

Table A13.2-1, the length of 4.0 ft for Lt and LL is the

length of significant contact between the vehicle and

railing that has been observed in films of crash tests. The

length of 3.5 ft for TL-4 is the rear-axle tire diameter of the

truck. The length of 8.0 ft for TL-5 and TL-6 is the length

of the tractor rear tandem axles: two 3.5-ft diameter tires,

plus 1.0 ft between them.

Fv, the weight of the vehicle lying on top of the bridge

rail, is distributed over the length of the vehicle in contact

with the rail, Lv.

For concrete railings, Eq. A13.2-1 results in a

theoretically-required height, H, of 34.0 in. for Test Level

TL-4. However, a height of 32.0 in., shown in

Table A13.2-1, was considered to be acceptable because

many railings of that height have been built and appear to

be performing acceptably.

The minimum height, H, listed for TL-1, TL-2, and

TL-3 is based on the minimum railings height used in the

past. The minimum effective height, He, for TL-1 is an

estimate based on the limited information available for this

test level.

The minimum height, H, of 42.0 in., shown in

Table A13.2-1, for TL-5 is based on the height used for

successfully crash-tested concrete barrier engaging only

the tires of the truck. For post and beam metal bridge

railings, it may be prudent to increase the height by

12.0 in. so as to engage the bed of the truck.

The minimum height, H, shown in Table A13.2-1, for

TL-6 is the height required to engage the side of the tank

as determined by crash test.

Table A13.2-1—Design Forces for Traffic Railings

Railing Test Levels

Design Forces and Designations TL-1 TL-2 TL-3 TL-4 TL-5 TL-6

Ft Transverse (kips) 13.5 27.0 54.0 54.0 124.0 175.0

FL Longitudinal (kips) 4.5 9.0 18.0 18.0 41.0 58.0

Fv Vertical (kips) Down 4.5 4.5 4.5 18.0 80.0 80.0

Lt and LL (ft) 4.0 4.0 4.0 3.5 8.0 8.0

Lv (ft) 18.0 18.0 18.0 18.0 40.0 40.0

He (min) (in.) 18.0 20.0 24.0 32.0 42.0 56.0

Minimum H Height of Rail (in.) 27.0 27.0 27.0 32.0 42.0 90.0

© 2010 by the American Association of State Highway and Transportation Officials.

All rights reserved. Duplication is a violation of applicable law.

www.bantui.com

13-18 AASHTO LRFD BRIDGE DESIGN SPECIFICATIONS

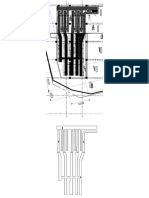

Figure A13.2-1 shows the design forces from

Table A13.2-1 applied to a beam and post railing. This is

for illustrative purposes only. The forces and distribution

lengths shown apply to any type of railing.

Figure A13.2-1—Metal Bridge Railing Design Forces,

Vertical Location, and Horizontal Distribution Length

A13.3—DESIGN PROCEDURE FOR RAILING

TEST SPECIMENS

A13.3.1—Concrete Railings CA13.3.1

Yield line analysis and strength design for reinforced The yield line analysis shown in Figures CA13.3.1-1 and

concrete and prestressed concrete barriers or parapets may CA13.3.1-2 includes only the ultimate flexural capacity of the

be used. concrete component. Stirrups or ties should be provided to

The nominal railing resistance to transverse load, Rw, resist the shear and/or diagonal tension forces.

may be determined using a yield line approach as: The ultimate flexural resistance, Ms, of the bridge deck

or slab should be determined in recognition that the deck is

• For impacts within a wall segment: also resisting a tensile force, caused by the component of the

impact forces, Ft.

⎛ 2 ⎞⎛ M c Lc 2 ⎞

Rw = ⎜ ⎟⎜ 8 M b + 8 M w + ⎟ In this analysis it is assumed that the yield line failure

⎝ 2 Lc − Lt ⎠ ⎝ H ⎠ pattern occurs within the parapet only and does not extend

(A13.3.1-1) into the deck. This means that the deck must have sufficient

resistance to force the yield line failure pattern to remain

The critical wall length over which the yield line within the parapet. If the failure pattern extends into the deck,

mechanism occurs, Lc, shall be taken as: the equations for resistance of the parapet are not valid.

The analysis is also based on the assumption that

2 sufficient longitudinal length of parapet exists to result in the

Lt ⎛ L ⎞ 8H ( M b + M w )

Lc = + ⎜ t⎟+ (A13.3.1-2) yield line failure pattern shown. For short lengths of parapet,

2 ⎝ 2⎠ Mc a single yield line may form along the juncture of the parapet

and deck. Such a failure pattern is permissible, and the

• For impacts at end of wall or at joint: resistance of the parapet should be computed using an

appropriate analysis.

⎛ 2 ⎞⎛ M c Lc 2 ⎞ This analysis is based on the assumption that the

Rw = ⎜ ⎟ ⎜ Mb + Mw + ⎟

⎝ 2 Lc − Lt ⎠ ⎝ H ⎠ negative and positive wall resisting moments are equal and

that the negative and positive beam resisting moments are

(A13.3.1-3)

equal.

The measurement of system resistance of a concrete

⎛ M + Mw ⎞

2

Lt ⎛L ⎞ railing is Rw, which is compared to the loads in Table A13.2-1

Lc = + ⎜ t ⎟ +H⎜ b ⎟ to determine structural adequacy. The flexure resistances, Mb,

2 ⎝ ⎠

2 ⎝ Mc ⎠

Mw, and Mc, are related to the system resistance Rw through

(A13.3.1-4) the yield line analysis embodied in Eqs. A13.3.1-1 and

A13.3.1-2. In the terminology of these Specifications, Rw is

where:

the “nominal resistance” because it is compared to the

“nominal load” given in Table A13.2-1.

Ft = transverse force specified in Table A13.2-1

Where the width of the concrete railing varies along the

assumed to be acting at top of a concrete wall

height, Mc used in Eqs. A13.3.1-1 through A13.3.1-4 for

(kips)

wall resistance should be taken as the average of its value

along the height of the railing.

© 2010 by the American Association of State Highway and Transportation Officials.

All rights reserved. Duplication is a violation of applicable law.

You might also like

- Mos Prf111Document7 pagesMos Prf111Nadim527No ratings yet

- HOBBS (1957) - An Investigation Into The Stress Distribution in Pile Caps With Some Notes On DesignDocument34 pagesHOBBS (1957) - An Investigation Into The Stress Distribution in Pile Caps With Some Notes On DesignVítor FreitasNo ratings yet

- 1-Concrete-Filled Aluminum Circular Hollow Section Column TestsDocument9 pages1-Concrete-Filled Aluminum Circular Hollow Section Column TestsHendrik TaupanNo ratings yet

- Sample Packing List - Steel StructureDocument1 pageSample Packing List - Steel Structureabdulazeez88100% (1)

- Belt Selection CalculationDocument29 pagesBelt Selection CalculationElwathig BakhietNo ratings yet

- CE 331C Route SurveyingDocument5 pagesCE 331C Route SurveyingZanne RoseNo ratings yet

- CESMM3 Vs 4 - RepairedDocument5 pagesCESMM3 Vs 4 - RepairedDilan De SilvaNo ratings yet

- Ask The Engineer Proper Bedding For PVC Pressure PipeDocument5 pagesAsk The Engineer Proper Bedding For PVC Pressure PipeUnibellNo ratings yet

- Design For NSF by Harry PoulosDocument7 pagesDesign For NSF by Harry PoulosSantosoNo ratings yet

- KDS 11 70 20 Rockfall and Debris Prevention Facility Design StandardsDocument15 pagesKDS 11 70 20 Rockfall and Debris Prevention Facility Design StandardsSH Big ShimNo ratings yet

- Q1 - Testing, Design, and Field Implementation of GFRP RC Soft-Eyes For Tunnel ConstructionDocument17 pagesQ1 - Testing, Design, and Field Implementation of GFRP RC Soft-Eyes For Tunnel ConstructionJhoshep SaavedraNo ratings yet

- 3583.PLAXIS - 2D - CEV22.01 - Tutorial - 05 - Excavation of An NATM TunnelDocument14 pages3583.PLAXIS - 2D - CEV22.01 - Tutorial - 05 - Excavation of An NATM TunnelPhalgun MoturuNo ratings yet

- 100000Document76 pages100000Dandu ManNo ratings yet

- Budhu Soil Mechanics Foundations 3rd TXTBKDocument1 pageBudhu Soil Mechanics Foundations 3rd TXTBKNadeem AbbasiNo ratings yet

- Models For Punching Shear Capacity in Concrete SlabsDocument166 pagesModels For Punching Shear Capacity in Concrete SlabsZoran BonicNo ratings yet

- FP McCann Precast Concrete Headwalls InstallationDocument4 pagesFP McCann Precast Concrete Headwalls InstallationgemotorresNo ratings yet

- SPREW Part 3 of 3 PDFDocument122 pagesSPREW Part 3 of 3 PDFhz135874No ratings yet

- Chapter 6A PPT (Compatibility Mode)Document47 pagesChapter 6A PPT (Compatibility Mode)Elhussain HassanNo ratings yet

- 1 Input Data: WWW - Hilti.usDocument6 pages1 Input Data: WWW - Hilti.usamanpreet_ahujaNo ratings yet

- Lateral Load PileDocument21 pagesLateral Load PileCarlos FilipusNo ratings yet

- Punching Shear - ExercisesDocument8 pagesPunching Shear - ExercisesSufian AbusninaNo ratings yet

- Formwork Design N Scheme Preparation Salsette 27 PDFDocument62 pagesFormwork Design N Scheme Preparation Salsette 27 PDFnarsimhhaNo ratings yet

- Uplift Capacity of Piles in Two Layered SoilDocument7 pagesUplift Capacity of Piles in Two Layered SoilIAEME PublicationNo ratings yet

- PILES SUBJECTED TO LATERAL SOIL MOVEMENTS Poulos 1997 PDFDocument10 pagesPILES SUBJECTED TO LATERAL SOIL MOVEMENTS Poulos 1997 PDFAgapito ScogliamiglioNo ratings yet

- Simplified Analysis of Continuous BeamsDocument7 pagesSimplified Analysis of Continuous BeamsAmirNo ratings yet

- Comparison Study of Pile Foundation Using Eurocode 7 and Working Stress Design ApproachDocument7 pagesComparison Study of Pile Foundation Using Eurocode 7 and Working Stress Design ApproachIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Pile Foundation: Reason For Piles Types of Piles Capacity Prediction Methods Load TestsDocument29 pagesPile Foundation: Reason For Piles Types of Piles Capacity Prediction Methods Load TestsJohneal MatiasNo ratings yet

- Gabion Walls Presentation FijiDocument38 pagesGabion Walls Presentation FijiHuy ChungNo ratings yet

- Chapt 5 Shear Strength in Soil Upload PDFDocument38 pagesChapt 5 Shear Strength in Soil Upload PDFabdirahmanNo ratings yet

- Validation-Triaxial Test With Hardening Soil Model (2015)Document4 pagesValidation-Triaxial Test With Hardening Soil Model (2015)Geeta JiraliNo ratings yet

- CapwapDocument2 pagesCapwapjilofeNo ratings yet

- Prestress Concrete DPDocument20 pagesPrestress Concrete DPdanielNo ratings yet

- Design and Performance of A 15m Deep Excavation For A Wagon TipplerDocument5 pagesDesign and Performance of A 15m Deep Excavation For A Wagon TipplerlingamkumarNo ratings yet

- Pile DebondingDocument4 pagesPile DebondingjtjtfghNo ratings yet

- Stability of Steel Framed Structures: Ir. Prof. Dr. Jeffrey ChiangDocument30 pagesStability of Steel Framed Structures: Ir. Prof. Dr. Jeffrey Chiangsam19961No ratings yet

- Lindquist Secant Pile Shoring Developments in Design and Construction DFI2011Document8 pagesLindquist Secant Pile Shoring Developments in Design and Construction DFI2011santanu mukherjeeNo ratings yet

- Design of Piles: Rosalem, Glyra BDocument41 pagesDesign of Piles: Rosalem, Glyra BGlyra RosalemNo ratings yet

- Ce 382 Chapter 8 Seepage 1442 RDocument110 pagesCe 382 Chapter 8 Seepage 1442 RBhavesh ChudasamaNo ratings yet

- Piled Raft FoundationsDocument96 pagesPiled Raft FoundationsMahmoud FaroukNo ratings yet

- Cyclic Simple Shear Test PrintDocument4 pagesCyclic Simple Shear Test PrintAlher HeraNo ratings yet

- Lateral Earth Pressure in Expansive Clay SoilsDocument14 pagesLateral Earth Pressure in Expansive Clay SoilsSamad Arabi100% (1)

- Uplift Capacity of Axially Loaded Piles in Clays: Vishwas N. Khatri and Jyant KumarDocument6 pagesUplift Capacity of Axially Loaded Piles in Clays: Vishwas N. Khatri and Jyant KumarrkNo ratings yet

- Prensa Digital Triaxial-MATESTDocument42 pagesPrensa Digital Triaxial-MATESTAlvaro G. MCNo ratings yet

- Case Histories On The Use of Helical Piles For Retrofitting and New ConstructionDocument6 pagesCase Histories On The Use of Helical Piles For Retrofitting and New ConstructionLeonardo SanchezNo ratings yet

- Design Example Reinforced Strip FoundationDocument6 pagesDesign Example Reinforced Strip FoundationFrans-Shixova ShipopyeniNo ratings yet

- Modern Fastening Systems in Tunnel ConstructionDocument12 pagesModern Fastening Systems in Tunnel ConstructionfreezefreezeNo ratings yet

- Rock Socket Piles at Coventry Point, Market Way, CoventryDocument16 pagesRock Socket Piles at Coventry Point, Market Way, Coventrynagas440% (1)

- Measurement and Prediction of Construction Vibration Affecting Sensitive LaboratoriesDocument7 pagesMeasurement and Prediction of Construction Vibration Affecting Sensitive Laboratoriesfandy sipataNo ratings yet

- Aggregates FMDocument5 pagesAggregates FMabualamalNo ratings yet

- Terzaghi and PeckDocument7 pagesTerzaghi and PeckRaja Hendra Solihin RambeNo ratings yet

- Mangan D (2018) - The Role of Proof Rolling in Pavement ConstructionDocument10 pagesMangan D (2018) - The Role of Proof Rolling in Pavement Constructionkentong.leeNo ratings yet

- The Influence of Plugging On DriveabilityDocument12 pagesThe Influence of Plugging On DriveabilityDedy DharmawansyahNo ratings yet

- A Comparison of Dynamic and Static Load Tests On Reinforced Concrete Driven Pile-2004 - 02Document7 pagesA Comparison of Dynamic and Static Load Tests On Reinforced Concrete Driven Pile-2004 - 02Hoo Yen HowNo ratings yet

- Chen 2008Document10 pagesChen 2008RivaiNo ratings yet

- Chapter 3 Bearing Capacity PDFDocument11 pagesChapter 3 Bearing Capacity PDFIan SeguritanNo ratings yet

- Slope Design & Construction PracticeDocument153 pagesSlope Design & Construction PracticeKAI CHUAN CHUNo ratings yet

- Pullout Capacity of Model Piles in Sand PDFDocument6 pagesPullout Capacity of Model Piles in Sand PDFJaymin PatilNo ratings yet

- Conplast WL XtraDocument2 pagesConplast WL Xtrapankajsingh100% (1)

- FE Fixed Band StripDocument5 pagesFE Fixed Band StripStevenNo ratings yet

- 2023 - Potini - Rigorous Lower and Upper Bounds For The Generalised FailureDocument7 pages2023 - Potini - Rigorous Lower and Upper Bounds For The Generalised FailureValerioNo ratings yet

- Allowable Load of Main Components of ScaffoldDocument10 pagesAllowable Load of Main Components of Scaffoldteguh widayatNo ratings yet

- Festoon Cable SystemDocument17 pagesFestoon Cable SystemKwanhee HanNo ratings yet

- Lecture 9: Quarter-Wave-Transformer Matching.: R JZ L Z Z Z JR LDocument13 pagesLecture 9: Quarter-Wave-Transformer Matching.: R JZ L Z Z Z JR LRuth EnormeNo ratings yet

- Ex Slab BridgeDocument32 pagesEx Slab BridgeKhadafi Dwi AnugrahNo ratings yet

- Grade 1 Maths WorksheetDocument3 pagesGrade 1 Maths Worksheetabdulazeez88No ratings yet

- Merint-Railing System & AccessoriesDocument20 pagesMerint-Railing System & Accessoriesabdulazeez88No ratings yet

- Hilti - Anchor Design - Jan 5, 2020Document15 pagesHilti - Anchor Design - Jan 5, 2020abdulazeez88No ratings yet

- GMI CatalogDocument37 pagesGMI Catalogabdulazeez88No ratings yet

- Hotel & Branded Apartments - TDDocument16 pagesHotel & Branded Apartments - TDabdulazeez88No ratings yet

- General - Overview - Finland Pavilion - Expo 2020Document14 pagesGeneral - Overview - Finland Pavilion - Expo 2020abdulazeez88100% (2)

- 3D View of Staad ProDocument1 page3D View of Staad Proabdulazeez88No ratings yet

- Bolt and Baseplate CalcDocument3 pagesBolt and Baseplate Calcabdulazeez88No ratings yet

- Electrical Load ScheduleDocument3 pagesElectrical Load Scheduleabdulazeez88No ratings yet

- +1.650 M. BOT of TrenchDocument1 page+1.650 M. BOT of Trenchabdulazeez88No ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'abdulazeez88No ratings yet

- Crane Material ListDocument2 pagesCrane Material Listabdulazeez88No ratings yet

- Shailesh Final ThesisDocument70 pagesShailesh Final Thesisabdulazeez88No ratings yet

- Frame Structure ElevationDocument1 pageFrame Structure Elevationabdulazeez88No ratings yet

- Aircraft Wood GluingDocument3 pagesAircraft Wood Gluingabdulazeez88No ratings yet

- Eee CompaniesDocument4 pagesEee Companiesabdulazeez88No ratings yet

- 921e Cargador Frontal CaterpillarDocument8 pages921e Cargador Frontal CaterpillarElvis Eberth Huanca MachacaNo ratings yet

- South Dakota v. Miller, No. 27198 (S.D. Dec. 7, 2016)Document35 pagesSouth Dakota v. Miller, No. 27198 (S.D. Dec. 7, 2016)RHTNo ratings yet

- New York City MTA Subway MapDocument1 pageNew York City MTA Subway Mapsorin_us10No ratings yet

- Still - MXDocument8 pagesStill - MXtomy112No ratings yet

- AutoTrack MasterDocument480 pagesAutoTrack MasterCEGUS CATALINNo ratings yet

- Pavement Design ManualDocument295 pagesPavement Design ManualkonstantanolNo ratings yet

- A Seminar Report-1Document21 pagesA Seminar Report-1Rameez BedekarNo ratings yet

- About Quantum TrimbleDocument68 pagesAbout Quantum TrimbleantonNo ratings yet

- Council Minutes 3 October 2019 1Document63 pagesCouncil Minutes 3 October 2019 1markNo ratings yet

- Project Proposal 1Document47 pagesProject Proposal 1Bikash sharrf100% (3)

- Executive Summary Site and Project JustificationDocument25 pagesExecutive Summary Site and Project JustificationVANESSA DELA TORRENo ratings yet

- FormDocument8 pagesFormDipesh GuptaNo ratings yet

- LC Gate TvuDocument7 pagesLC Gate Tvuranjitbhuyan87No ratings yet

- 1 - Introduction To Geometric Design (With Ghanaian Considerations)Document36 pages1 - Introduction To Geometric Design (With Ghanaian Considerations)Kwasi Agyeman-Boakye100% (1)

- RECYFIX TRAFFIC GUGIBLOC 300 Tipe 010 - E600Document2 pagesRECYFIX TRAFFIC GUGIBLOC 300 Tipe 010 - E600Dadang KurniaNo ratings yet

- DO - 011 - S2006 Hot Poured SealantDocument7 pagesDO - 011 - S2006 Hot Poured SealantCarol SantosNo ratings yet

- Civil - Intelligent Transportation SystemsDocument1 pageCivil - Intelligent Transportation SystemsRocky BhaiNo ratings yet

- California DMV CDL Skills TestsDocument5 pagesCalifornia DMV CDL Skills TestsLOUNo ratings yet

- Binder 5Document20 pagesBinder 5Anonymous 2yVesLNo ratings yet

- Public Transportation DirectionsDocument2 pagesPublic Transportation DirectionsIliana SanmartinNo ratings yet

- Engineering Department Sop HandbookDocument254 pagesEngineering Department Sop Handbookshankar kharat100% (1)

- Components of Ts I.Document15 pagesComponents of Ts I.Tariq HasanNo ratings yet

- Compendium OF Correction Slips To Codes & Manuals Pertaining To Engg. DepttDocument22 pagesCompendium OF Correction Slips To Codes & Manuals Pertaining To Engg. DepttvijaysinhjagtapNo ratings yet

- Iloilo City Regulation Ordinance 2004-268Document9 pagesIloilo City Regulation Ordinance 2004-268Iloilo City CouncilNo ratings yet

- 02 - Gideon-Boie - The Activist Commons and How It Changes The CityDocument13 pages02 - Gideon-Boie - The Activist Commons and How It Changes The CitySimon BoulezNo ratings yet

- Toll Road Project - Specifications Section 9 - PavementsDocument32 pagesToll Road Project - Specifications Section 9 - PavementsadhystiraNo ratings yet