Professional Documents

Culture Documents

Design Calculations From Engineering Assessment: 165 219 8.10 10.35 Owner Contact Diamondwrap® Contact

Design Calculations From Engineering Assessment: 165 219 8.10 10.35 Owner Contact Diamondwrap® Contact

Uploaded by

Manikandan MCopyright:

Available Formats

You might also like

- Lifting Beam CalculationDocument2 pagesLifting Beam Calculationராபர்ட் ஆன்றோ ரெனி100% (4)

- BooksDocument1 pageBookswahNo ratings yet

- CRMS ItpDocument2 pagesCRMS Itparockiyathass100% (1)

- Material Safety Data Sheet: Product Name: RFB Line - RFB-EC RFB-SE RFB-SA1 RFB-SADocument4 pagesMaterial Safety Data Sheet: Product Name: RFB Line - RFB-EC RFB-SE RFB-SA1 RFB-SAAlfonso GarcíaNo ratings yet

- P8 TELEDYNE CORMONweight - Loss - Coupons - Coupon - Holders - Cmec003Document4 pagesP8 TELEDYNE CORMONweight - Loss - Coupons - Coupon - Holders - Cmec003Shruti SrinivasNo ratings yet

- Icorr Certification Scheme: Icorr Training Courses (Itc)Document5 pagesIcorr Certification Scheme: Icorr Training Courses (Itc)sheikbbaNo ratings yet

- FE Mechanical Exam Computer Based Test CoverageDocument4 pagesFE Mechanical Exam Computer Based Test Coverageaoeusnthid0% (3)

- Technical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoDocument27 pagesTechnical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoIdung ChristopherNo ratings yet

- BergerMasterFile PDFDocument74 pagesBergerMasterFile PDFSumanta RoyNo ratings yet

- RTR Piping SecsDocument5 pagesRTR Piping SecsEngFaisal AlraiNo ratings yet

- PDF Api 570 Awareness Coursepdf DDDocument23 pagesPDF Api 570 Awareness Coursepdf DDkareemNo ratings yet

- Bab 4 Pipe Manufacturing & WeldingDocument29 pagesBab 4 Pipe Manufacturing & WeldingrWin doNo ratings yet

- Butt WrapFiberglassJointManual Pages 37 41Document5 pagesButt WrapFiberglassJointManual Pages 37 41anon_913434021No ratings yet

- Assessing Mechanical Damage Using Multiple Data Sets in Ili: Abel Lopes Market Development Manager EH 14 November 2012Document39 pagesAssessing Mechanical Damage Using Multiple Data Sets in Ili: Abel Lopes Market Development Manager EH 14 November 2012abhi_luvme03100% (1)

- ASME L&D B31.8 Natural Gas Pipelines GuideDocument12 pagesASME L&D B31.8 Natural Gas Pipelines GuideCalin NeagoieNo ratings yet

- Catalogo Nickel Alloys - Techalloy PDFDocument12 pagesCatalogo Nickel Alloys - Techalloy PDFCebrac ItatibaNo ratings yet

- Agenda Item: 650-2024: Coating Prior To Hydrostatic TestingDocument4 pagesAgenda Item: 650-2024: Coating Prior To Hydrostatic Testinggigiphi1No ratings yet

- Introduction To CorrosionDocument8 pagesIntroduction To Corrosion이선엽No ratings yet

- Meccoct18 12573Document9 pagesMeccoct18 12573Malik Ansar HayatNo ratings yet

- BGAS Grade1 Exam-1 To 5Document7 pagesBGAS Grade1 Exam-1 To 5Shamim AlamNo ratings yet

- Lamination ProcedureDocument5 pagesLamination Proceduretrueman44No ratings yet

- 72957d3bb1659d7c77dbf6b6c550abeeDocument41 pages72957d3bb1659d7c77dbf6b6c550abeerasheedillikkalNo ratings yet

- Internal NCR Log For Satellite 30aug18Document4 pagesInternal NCR Log For Satellite 30aug18GA JonNo ratings yet

- Some Grades of Carbon Steel and 0.5mo SteelsDocument27 pagesSome Grades of Carbon Steel and 0.5mo SteelsNidharshan Selvaraj RNo ratings yet

- BS 7910:2013 in Brief: International Journal of Pressure Vessels and Piping July 2018Document12 pagesBS 7910:2013 in Brief: International Journal of Pressure Vessels and Piping July 2018Arnab DebNo ratings yet

- 01 Saip 38Document14 pages01 Saip 38Arjun RawatNo ratings yet

- Brochure NuovagiungasDocument165 pagesBrochure NuovagiungasAbel Lopez JoachinNo ratings yet

- Paint Slip Coefficient PDFDocument28 pagesPaint Slip Coefficient PDFRk Sabarinathan100% (1)

- Condenser Cladding InfoDocument37 pagesCondenser Cladding Infoabhishe_reenaNo ratings yet

- Stray Current CorrosionDocument21 pagesStray Current CorrosionPaolo Mogollon AcostaNo ratings yet

- Chart For Factor B of CSDocument8 pagesChart For Factor B of CSnguyenvanphu1977No ratings yet

- The Design of Products To Be Hot-Dip Galvanized After FabricationDocument25 pagesThe Design of Products To Be Hot-Dip Galvanized After FabricationHANEENNo ratings yet

- 3lpe Coating: Typical PropertiesDocument1 page3lpe Coating: Typical PropertiesKingsley BaptistaNo ratings yet

- Case Study-R12 12Document81 pagesCase Study-R12 12ranjitpandeyNo ratings yet

- Strengthening Mechanisms: MSE3 Page 2Document17 pagesStrengthening Mechanisms: MSE3 Page 2Christian CarestiaNo ratings yet

- Basf Masterflow 980 TdsDocument4 pagesBasf Masterflow 980 TdsVijayaraghavan Srinivasamurthi100% (1)

- Piping CBT Latest Notes 27 Feb 2024Document26 pagesPiping CBT Latest Notes 27 Feb 2024AMALENDU PAUL100% (1)

- Structural Steel: Steel Shape Profile Cross Section Chemical Composition Standards I-Beams Second Moments of AreaDocument10 pagesStructural Steel: Steel Shape Profile Cross Section Chemical Composition Standards I-Beams Second Moments of AreaAnonymous nABFA4lNo ratings yet

- Weld Weave WidthDocument4 pagesWeld Weave Widthapply19842371No ratings yet

- Pipe Wrap OverviewDocument26 pagesPipe Wrap OverviewAmando FuentesNo ratings yet

- Aws SpecificationDocument4 pagesAws Specificationnike_y2kNo ratings yet

- 8 Impact Multi-Port RO Pressure Vessels in Seawater ReverseDocument6 pages8 Impact Multi-Port RO Pressure Vessels in Seawater ReverseAlfonso José García Laguna100% (1)

- Kaowool Paper 1260Document2 pagesKaowool Paper 1260praveentienNo ratings yet

- FRP TanksDocument1 pageFRP TanksMakrand SakpalNo ratings yet

- Corrosion Under Insulation - Out of Sight Out of MindDocument4 pagesCorrosion Under Insulation - Out of Sight Out of Mindengr_ahmednassarNo ratings yet

- Norsok M-001 - Materials Selection GuidanceDocument29 pagesNorsok M-001 - Materials Selection GuidanceWalid LabidiNo ratings yet

- RTR Pipe Line Install & Repair ProcedureDocument4 pagesRTR Pipe Line Install & Repair ProcedureMadhan KannanNo ratings yet

- Refinery InspectionDocument44 pagesRefinery InspectiongamadiyaNo ratings yet

- FBE Coating PDFDocument12 pagesFBE Coating PDFthadikkaran100% (1)

- Materials System SpecificationDocument5 pagesMaterials System SpecificationJeck MaquitedNo ratings yet

- Friction Stir Welding 2Document20 pagesFriction Stir Welding 2Deepak Mohapatra100% (1)

- 9.under Ground PipingDocument13 pages9.under Ground PipingAMAL VISHNUNo ratings yet

- Abs Group of Saudi ArabiaDocument24 pagesAbs Group of Saudi ArabiaMq SharozNo ratings yet

- Case Study - 7: Numerical in API 510 CodeDocument4 pagesCase Study - 7: Numerical in API 510 CodeVishal BailurNo ratings yet

- OH Corrosion Control From SuezDocument5 pagesOH Corrosion Control From SuezNS Murthy100% (1)

- Corrosion General Theory: and Be Broken Down by ItDocument1 pageCorrosion General Theory: and Be Broken Down by Itget5rajesh100% (1)

- Firelite 124Document1 pageFirelite 124pamelataboadalozanoNo ratings yet

- CLSCC LiteratureDocument62 pagesCLSCC LiteratureNakarin PotidokmaiNo ratings yet

- Satip H 002 11Document10 pagesSatip H 002 11Rauf ChaudharyNo ratings yet

- Keyfix E - TDS Epoxy Resin For DowelsDocument4 pagesKeyfix E - TDS Epoxy Resin For Dowelsjude tallyNo ratings yet

- AL-SE3510 Servo Type CNC Turret Punching Machine ALLES Offersheet 20210722Document9 pagesAL-SE3510 Servo Type CNC Turret Punching Machine ALLES Offersheet 20210722mehrdadgeminiNo ratings yet

- The GravityDocument1 pageThe GravityManikandan MNo ratings yet

- Nace Time TableDocument1 pageNace Time TableManikandan MNo ratings yet

- Compressor JacketingDocument1 pageCompressor JacketingManikandan MNo ratings yet

- Equivalent Length TableDocument6 pagesEquivalent Length TableManikandan MNo ratings yet

- Format of Letter To Be Obtained From Customer For Activation of Dormant AccountDocument1 pageFormat of Letter To Be Obtained From Customer For Activation of Dormant AccountManikandan MNo ratings yet

- CBTDocument6 pagesCBTManikandan MNo ratings yet

- Salary Increase Letter Template 2018Document1 pageSalary Increase Letter Template 2018Manikandan MNo ratings yet

- Custom Incentives: Tank Insulation CalculatorDocument4 pagesCustom Incentives: Tank Insulation CalculatorManikandan MNo ratings yet

- CBTDocument6 pagesCBTManikandan MNo ratings yet

- QC ReportDocument12 pagesQC ReportManikandan MNo ratings yet

- Onsite Rfi 07.08.2019Document1 pageOnsite Rfi 07.08.2019Manikandan MNo ratings yet

- RI/QG/INC/INS/544: Request For InspectionDocument8 pagesRI/QG/INC/INS/544: Request For InspectionManikandan MNo ratings yet

- Insulation Engineering Co.: Field Maintenance SPIR Services Long Term Call-Off ContractDocument12 pagesInsulation Engineering Co.: Field Maintenance SPIR Services Long Term Call-Off ContractManikandan MNo ratings yet

- Request For Inspection: 000000classification: InternalDocument1 pageRequest For Inspection: 000000classification: InternalManikandan MNo ratings yet

- Refractory Installation Quality Control - Inspection and Testing Monolithic Refractory Linings and MaterialsDocument6 pagesRefractory Installation Quality Control - Inspection and Testing Monolithic Refractory Linings and MaterialsManikandan M100% (1)

- Area Equipment Tag Number WO#: B19 B19 B94 B94Document3 pagesArea Equipment Tag Number WO#: B19 B19 B94 B94Manikandan MNo ratings yet

- Request For InspectionDocument4 pagesRequest For InspectionManikandan MNo ratings yet

- Refractory Installation Quality Control - Inspection and Testing Monolithic Refractory Linings and MaterialsDocument6 pagesRefractory Installation Quality Control - Inspection and Testing Monolithic Refractory Linings and MaterialsManikandan M100% (1)

- Painting Inspection Training Brochure 2019-Rev.0Document3 pagesPainting Inspection Training Brochure 2019-Rev.0Manikandan MNo ratings yet

- Request For Inspection: 000000classification: InternalDocument1 pageRequest For Inspection: 000000classification: InternalManikandan MNo ratings yet

- Request For Inspection: Ineco Qatargas Name Signature DateDocument2 pagesRequest For Inspection: Ineco Qatargas Name Signature DateManikandan MNo ratings yet

- Request For Inspection: (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5)Document2 pagesRequest For Inspection: (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5)Manikandan MNo ratings yet

- Request For Inspection: (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P6) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5)Document1 pageRequest For Inspection: (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P6) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5)Manikandan MNo ratings yet

- Request For Inspection: Classification: InternalDocument1 pageRequest For Inspection: Classification: InternalManikandan MNo ratings yet

- Request For Inspection: (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5)Document1 pageRequest For Inspection: (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5)Manikandan MNo ratings yet

- Request For Inspection: Classification: InternalDocument4 pagesRequest For Inspection: Classification: InternalManikandan MNo ratings yet

- Coulomb's Law & Electric FieldDocument24 pagesCoulomb's Law & Electric FieldJohn RivasNo ratings yet

- Me 2351Document20 pagesMe 2351Saravanan MathiNo ratings yet

- p1200 Lecture21Document21 pagesp1200 Lecture21Crow NachorNo ratings yet

- TensionDocument9 pagesTensionnicosanquilero2No ratings yet

- Rahman 2016 (Basear)Document5 pagesRahman 2016 (Basear)annekarolinemp041193No ratings yet

- Physics 9Document14 pagesPhysics 9kissesNo ratings yet

- Continuous Surface Cap Model For Geomaterial Modeling - A New Ls-Dyna Material TypeDocument16 pagesContinuous Surface Cap Model For Geomaterial Modeling - A New Ls-Dyna Material TypeeastinentNo ratings yet

- 7 Star Academy of Science and Arts FaisalabadDocument5 pages7 Star Academy of Science and Arts FaisalabadHassan AliNo ratings yet

- Scheme: TUTORIAL 1: (Answer: 40.77kg)Document5 pagesScheme: TUTORIAL 1: (Answer: 40.77kg)Mohd AideelNo ratings yet

- IEEE Tutorial Sag Tension CalculationDocument33 pagesIEEE Tutorial Sag Tension CalculationvthiyagainNo ratings yet

- 1st Take Chem Lec MPMDocument5 pages1st Take Chem Lec MPMArabella Dela CruzNo ratings yet

- Lesson 2-1 Structural Responses in Flexible PavementsDocument32 pagesLesson 2-1 Structural Responses in Flexible PavementsTiffany NeubigNo ratings yet

- Chap2 PDFDocument9 pagesChap2 PDFAbduŕ RehmanNo ratings yet

- Wind Load Calculation For RoofDocument21 pagesWind Load Calculation For RoofSameera Lakmal100% (1)

- Rep HS ModelDocument127 pagesRep HS ModelJakub ŚwidurskiNo ratings yet

- 1st Semester WorksheetsDocument42 pages1st Semester WorksheetsMang friesNo ratings yet

- The Scholar's Academy: Long QuestionsDocument4 pagesThe Scholar's Academy: Long Questionspaggal janNo ratings yet

- Gerald Holton, F. James Rutherford, Fletcher G. Watson - Project Physics - Test Booklet 1 - Concepts of Motion PDFDocument36 pagesGerald Holton, F. James Rutherford, Fletcher G. Watson - Project Physics - Test Booklet 1 - Concepts of Motion PDFVikasNo ratings yet

- Physics I ProblemsDocument1 pagePhysics I ProblemsbosschellenNo ratings yet

- Wind Tunnel LabDocument11 pagesWind Tunnel LabshmomenyNo ratings yet

- Free Fall Sample Problem With SolutionDocument8 pagesFree Fall Sample Problem With Solutionmark jason perezNo ratings yet

- INS Error Propagation (IEEE Format)Document11 pagesINS Error Propagation (IEEE Format)SenthilKumarSNo ratings yet

- Shell Momentum Balances and Velocity Distribution in Laminar FlowDocument18 pagesShell Momentum Balances and Velocity Distribution in Laminar FlowRose Dane Escobedo DiestaNo ratings yet

- ThicknessDocument53 pagesThicknessRajul MuraliNo ratings yet

- Mec 518Document2 pagesMec 518Banu SajjaNo ratings yet

- Coupled Pendulum PDFDocument7 pagesCoupled Pendulum PDFBarneyNo ratings yet

- Question Paper Code:: Reg. No.Document4 pagesQuestion Paper Code:: Reg. No.Ameer Hakeem Primus100% (1)

- Ae2251 - Aerodynamics - IDocument3 pagesAe2251 - Aerodynamics - IMinu.j.jNo ratings yet

Design Calculations From Engineering Assessment: 165 219 8.10 10.35 Owner Contact Diamondwrap® Contact

Design Calculations From Engineering Assessment: 165 219 8.10 10.35 Owner Contact Diamondwrap® Contact

Uploaded by

Manikandan MOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Calculations From Engineering Assessment: 165 219 8.10 10.35 Owner Contact Diamondwrap® Contact

Design Calculations From Engineering Assessment: 165 219 8.10 10.35 Owner Contact Diamondwrap® Contact

Uploaded by

Manikandan MCopyright:

Available Formats

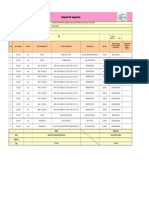

Case# ORCME03DEC18b

Description: 22K A-1016-8" -1C3AS3-N

08/08/2019

Design Calculations From Engineering Assessment

Owner Contact DiamondWrap® Contact

Q Atar GAS Citadel Middle East Minimum Yield Strength - 165 Mpa

Hanley Thomas Pipe Diameter - 219 mm

Store 16, Building 26 Operating Pressure - 8.10 bar

Mussfah, Abu Dhabi Design Pressure - 10.35 bar

Q atar United Arab Emirates Operating Temperature - 60 C

97156488264 Design Temperature - 90.0 C

hthomas@cittech.com Original Wall Thickness - 3.760 mm

Remaining Wall Thickness - 0.000 mm

% wall loss - 100%

Defects: I nternal corrosion

Calculations have taken into consideration all information provided on the Engineering Assessment, are the property of Citadel Technologies, and are

subject to Citadel Technologies' Terms and Conditions. The following calculations only apply to Citadel Technologies' products and may only be used for

the purposes desginated by Citadel Technologies.

0.939 -mm

(P*D)/2= 113.3588603

s*ts= 0

(P*D)/2-s*ts= 113.3588603

1/(ec*Ec)= 0.00828

Design repair thickness (trepair)= 0.939 mm

Tensile Modulus for the composite laminate in the circumferential direction (E c): 20,122 -Mpa

External Pipe Diameter: D

Internal Pressure: P

SMYS (Specified Minimum Yield Strength): s

Minimum remaining wall thickness of the pipe: ts

Allowable circumferential strain (%): e0.6

c

Ply thickness of the composite repair material (inch): tlayer = 0.3937 mm

trepair

n= = 4 layers L over = 51 -mm

tlayer AA cloth

Standard epoxy Minimum length of repair: 101 -mm

Material Recommendation:

(1) DW-0804S-16LM-SB (8-inch DiamondWrap® Standard 4-Ply 16 linear m. Spiral Special Build kit)

(4) CMF-1-C (C-sized Standard CMF putty)

Installation Instructions:

Use the CMF putty to smooth any sharp geometries and/or fill in severe corrosion pits.

Apply spiral kit as true spiral. The fabric should maintain 50% overlap of the fabric width while spiraling. Each pass supplies a 2 ply repair, make 2

pass(es) for a full 4 ply repair.

This repair is designed to contain the following defects:

• Wall loss of 100%.

• Through wall defect with a diameter of 7.5 mm.

Note: A 10 year warranty can be offered for this year repair under the above conditions.. Repair must be installed by a trained and certified installer to be

compliant with ASME PCC2 Article 4.1. Citadel Technologies' products are not designed to stop crack propagation. Proper surface preparation is required

to ensure adequate bond strength to the substrate.

Project? (Yes/No): Reviewed by: Date:

Revision log:

Calc rev # 2017.12.030

Wrap calculations have taken into consideration all information provided on the Engineering Assessment and are subject to Clock Spring' Terms and Conditions.

The following calculations apply only to Clock Spring' products.

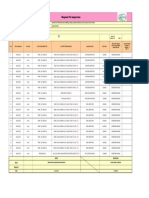

Case #: ORCME03DEC18b

Description: 22K -1016-8" -1C3S3-N

Diamond Wrap® Contact Owner Conctact

Citadel Middle East Company Q ATAR GAS

Hanley Thomas Name

Store 16, Building 26 Address

Mussfah, Abu Dhabi City, State

United Arab Emirates Country Q ATAR

97156488264 Phone

hthomas@cittech.com Email

= User Input

= Material Properties

Desired Pressure 10.35 bar

Material

Maximum Temp. 90°C Used: AA

Enter cloth types: AA, BA, CA, CB, or

Temp. Derating Factor: ƒ T 0.6 HY

Number of

Service Factor: ƒ 0.333 Plies = 4

Enter number of plies until pressure

Poisson's Ratio: ν 0.092 rating is satisfied.

Modulus: E ac 20,122 Mpa

Epoxy type Standard

Repair Thickness: t min 1.57 mm OD of Pipe, D 219.08 mm

Diameter of Defect, d 7.5 mm Nominal Pipe Wall, t 3.760 mm

Composite Modulus in

Shear Modulus: G 936 Mpa Axial Direction E a 20,122 Mpa

2

Toughness Parameter, γ 88 N-m/m Lap Shear Strength , τ 6.89 Mpa

Allowable Axial Strain in

Composite ε a 0.00280

ASME PCC2 Equation (13):

P= 12.8 Bar

Equation (17): 2.5 Dt / 2 = 51 mm

Eae atrepair

L over = 51 mm = 13 mm

t

This repair requires 4 plies of material and should extend a minimum of

50.74 mm from the defect on all sides.

You might also like

- Lifting Beam CalculationDocument2 pagesLifting Beam Calculationராபர்ட் ஆன்றோ ரெனி100% (4)

- BooksDocument1 pageBookswahNo ratings yet

- CRMS ItpDocument2 pagesCRMS Itparockiyathass100% (1)

- Material Safety Data Sheet: Product Name: RFB Line - RFB-EC RFB-SE RFB-SA1 RFB-SADocument4 pagesMaterial Safety Data Sheet: Product Name: RFB Line - RFB-EC RFB-SE RFB-SA1 RFB-SAAlfonso GarcíaNo ratings yet

- P8 TELEDYNE CORMONweight - Loss - Coupons - Coupon - Holders - Cmec003Document4 pagesP8 TELEDYNE CORMONweight - Loss - Coupons - Coupon - Holders - Cmec003Shruti SrinivasNo ratings yet

- Icorr Certification Scheme: Icorr Training Courses (Itc)Document5 pagesIcorr Certification Scheme: Icorr Training Courses (Itc)sheikbbaNo ratings yet

- FE Mechanical Exam Computer Based Test CoverageDocument4 pagesFE Mechanical Exam Computer Based Test Coverageaoeusnthid0% (3)

- Technical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoDocument27 pagesTechnical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoIdung ChristopherNo ratings yet

- BergerMasterFile PDFDocument74 pagesBergerMasterFile PDFSumanta RoyNo ratings yet

- RTR Piping SecsDocument5 pagesRTR Piping SecsEngFaisal AlraiNo ratings yet

- PDF Api 570 Awareness Coursepdf DDDocument23 pagesPDF Api 570 Awareness Coursepdf DDkareemNo ratings yet

- Bab 4 Pipe Manufacturing & WeldingDocument29 pagesBab 4 Pipe Manufacturing & WeldingrWin doNo ratings yet

- Butt WrapFiberglassJointManual Pages 37 41Document5 pagesButt WrapFiberglassJointManual Pages 37 41anon_913434021No ratings yet

- Assessing Mechanical Damage Using Multiple Data Sets in Ili: Abel Lopes Market Development Manager EH 14 November 2012Document39 pagesAssessing Mechanical Damage Using Multiple Data Sets in Ili: Abel Lopes Market Development Manager EH 14 November 2012abhi_luvme03100% (1)

- ASME L&D B31.8 Natural Gas Pipelines GuideDocument12 pagesASME L&D B31.8 Natural Gas Pipelines GuideCalin NeagoieNo ratings yet

- Catalogo Nickel Alloys - Techalloy PDFDocument12 pagesCatalogo Nickel Alloys - Techalloy PDFCebrac ItatibaNo ratings yet

- Agenda Item: 650-2024: Coating Prior To Hydrostatic TestingDocument4 pagesAgenda Item: 650-2024: Coating Prior To Hydrostatic Testinggigiphi1No ratings yet

- Introduction To CorrosionDocument8 pagesIntroduction To Corrosion이선엽No ratings yet

- Meccoct18 12573Document9 pagesMeccoct18 12573Malik Ansar HayatNo ratings yet

- BGAS Grade1 Exam-1 To 5Document7 pagesBGAS Grade1 Exam-1 To 5Shamim AlamNo ratings yet

- Lamination ProcedureDocument5 pagesLamination Proceduretrueman44No ratings yet

- 72957d3bb1659d7c77dbf6b6c550abeeDocument41 pages72957d3bb1659d7c77dbf6b6c550abeerasheedillikkalNo ratings yet

- Internal NCR Log For Satellite 30aug18Document4 pagesInternal NCR Log For Satellite 30aug18GA JonNo ratings yet

- Some Grades of Carbon Steel and 0.5mo SteelsDocument27 pagesSome Grades of Carbon Steel and 0.5mo SteelsNidharshan Selvaraj RNo ratings yet

- BS 7910:2013 in Brief: International Journal of Pressure Vessels and Piping July 2018Document12 pagesBS 7910:2013 in Brief: International Journal of Pressure Vessels and Piping July 2018Arnab DebNo ratings yet

- 01 Saip 38Document14 pages01 Saip 38Arjun RawatNo ratings yet

- Brochure NuovagiungasDocument165 pagesBrochure NuovagiungasAbel Lopez JoachinNo ratings yet

- Paint Slip Coefficient PDFDocument28 pagesPaint Slip Coefficient PDFRk Sabarinathan100% (1)

- Condenser Cladding InfoDocument37 pagesCondenser Cladding Infoabhishe_reenaNo ratings yet

- Stray Current CorrosionDocument21 pagesStray Current CorrosionPaolo Mogollon AcostaNo ratings yet

- Chart For Factor B of CSDocument8 pagesChart For Factor B of CSnguyenvanphu1977No ratings yet

- The Design of Products To Be Hot-Dip Galvanized After FabricationDocument25 pagesThe Design of Products To Be Hot-Dip Galvanized After FabricationHANEENNo ratings yet

- 3lpe Coating: Typical PropertiesDocument1 page3lpe Coating: Typical PropertiesKingsley BaptistaNo ratings yet

- Case Study-R12 12Document81 pagesCase Study-R12 12ranjitpandeyNo ratings yet

- Strengthening Mechanisms: MSE3 Page 2Document17 pagesStrengthening Mechanisms: MSE3 Page 2Christian CarestiaNo ratings yet

- Basf Masterflow 980 TdsDocument4 pagesBasf Masterflow 980 TdsVijayaraghavan Srinivasamurthi100% (1)

- Piping CBT Latest Notes 27 Feb 2024Document26 pagesPiping CBT Latest Notes 27 Feb 2024AMALENDU PAUL100% (1)

- Structural Steel: Steel Shape Profile Cross Section Chemical Composition Standards I-Beams Second Moments of AreaDocument10 pagesStructural Steel: Steel Shape Profile Cross Section Chemical Composition Standards I-Beams Second Moments of AreaAnonymous nABFA4lNo ratings yet

- Weld Weave WidthDocument4 pagesWeld Weave Widthapply19842371No ratings yet

- Pipe Wrap OverviewDocument26 pagesPipe Wrap OverviewAmando FuentesNo ratings yet

- Aws SpecificationDocument4 pagesAws Specificationnike_y2kNo ratings yet

- 8 Impact Multi-Port RO Pressure Vessels in Seawater ReverseDocument6 pages8 Impact Multi-Port RO Pressure Vessels in Seawater ReverseAlfonso José García Laguna100% (1)

- Kaowool Paper 1260Document2 pagesKaowool Paper 1260praveentienNo ratings yet

- FRP TanksDocument1 pageFRP TanksMakrand SakpalNo ratings yet

- Corrosion Under Insulation - Out of Sight Out of MindDocument4 pagesCorrosion Under Insulation - Out of Sight Out of Mindengr_ahmednassarNo ratings yet

- Norsok M-001 - Materials Selection GuidanceDocument29 pagesNorsok M-001 - Materials Selection GuidanceWalid LabidiNo ratings yet

- RTR Pipe Line Install & Repair ProcedureDocument4 pagesRTR Pipe Line Install & Repair ProcedureMadhan KannanNo ratings yet

- Refinery InspectionDocument44 pagesRefinery InspectiongamadiyaNo ratings yet

- FBE Coating PDFDocument12 pagesFBE Coating PDFthadikkaran100% (1)

- Materials System SpecificationDocument5 pagesMaterials System SpecificationJeck MaquitedNo ratings yet

- Friction Stir Welding 2Document20 pagesFriction Stir Welding 2Deepak Mohapatra100% (1)

- 9.under Ground PipingDocument13 pages9.under Ground PipingAMAL VISHNUNo ratings yet

- Abs Group of Saudi ArabiaDocument24 pagesAbs Group of Saudi ArabiaMq SharozNo ratings yet

- Case Study - 7: Numerical in API 510 CodeDocument4 pagesCase Study - 7: Numerical in API 510 CodeVishal BailurNo ratings yet

- OH Corrosion Control From SuezDocument5 pagesOH Corrosion Control From SuezNS Murthy100% (1)

- Corrosion General Theory: and Be Broken Down by ItDocument1 pageCorrosion General Theory: and Be Broken Down by Itget5rajesh100% (1)

- Firelite 124Document1 pageFirelite 124pamelataboadalozanoNo ratings yet

- CLSCC LiteratureDocument62 pagesCLSCC LiteratureNakarin PotidokmaiNo ratings yet

- Satip H 002 11Document10 pagesSatip H 002 11Rauf ChaudharyNo ratings yet

- Keyfix E - TDS Epoxy Resin For DowelsDocument4 pagesKeyfix E - TDS Epoxy Resin For Dowelsjude tallyNo ratings yet

- AL-SE3510 Servo Type CNC Turret Punching Machine ALLES Offersheet 20210722Document9 pagesAL-SE3510 Servo Type CNC Turret Punching Machine ALLES Offersheet 20210722mehrdadgeminiNo ratings yet

- The GravityDocument1 pageThe GravityManikandan MNo ratings yet

- Nace Time TableDocument1 pageNace Time TableManikandan MNo ratings yet

- Compressor JacketingDocument1 pageCompressor JacketingManikandan MNo ratings yet

- Equivalent Length TableDocument6 pagesEquivalent Length TableManikandan MNo ratings yet

- Format of Letter To Be Obtained From Customer For Activation of Dormant AccountDocument1 pageFormat of Letter To Be Obtained From Customer For Activation of Dormant AccountManikandan MNo ratings yet

- CBTDocument6 pagesCBTManikandan MNo ratings yet

- Salary Increase Letter Template 2018Document1 pageSalary Increase Letter Template 2018Manikandan MNo ratings yet

- Custom Incentives: Tank Insulation CalculatorDocument4 pagesCustom Incentives: Tank Insulation CalculatorManikandan MNo ratings yet

- CBTDocument6 pagesCBTManikandan MNo ratings yet

- QC ReportDocument12 pagesQC ReportManikandan MNo ratings yet

- Onsite Rfi 07.08.2019Document1 pageOnsite Rfi 07.08.2019Manikandan MNo ratings yet

- RI/QG/INC/INS/544: Request For InspectionDocument8 pagesRI/QG/INC/INS/544: Request For InspectionManikandan MNo ratings yet

- Insulation Engineering Co.: Field Maintenance SPIR Services Long Term Call-Off ContractDocument12 pagesInsulation Engineering Co.: Field Maintenance SPIR Services Long Term Call-Off ContractManikandan MNo ratings yet

- Request For Inspection: 000000classification: InternalDocument1 pageRequest For Inspection: 000000classification: InternalManikandan MNo ratings yet

- Refractory Installation Quality Control - Inspection and Testing Monolithic Refractory Linings and MaterialsDocument6 pagesRefractory Installation Quality Control - Inspection and Testing Monolithic Refractory Linings and MaterialsManikandan M100% (1)

- Area Equipment Tag Number WO#: B19 B19 B94 B94Document3 pagesArea Equipment Tag Number WO#: B19 B19 B94 B94Manikandan MNo ratings yet

- Request For InspectionDocument4 pagesRequest For InspectionManikandan MNo ratings yet

- Refractory Installation Quality Control - Inspection and Testing Monolithic Refractory Linings and MaterialsDocument6 pagesRefractory Installation Quality Control - Inspection and Testing Monolithic Refractory Linings and MaterialsManikandan M100% (1)

- Painting Inspection Training Brochure 2019-Rev.0Document3 pagesPainting Inspection Training Brochure 2019-Rev.0Manikandan MNo ratings yet

- Request For Inspection: 000000classification: InternalDocument1 pageRequest For Inspection: 000000classification: InternalManikandan MNo ratings yet

- Request For Inspection: Ineco Qatargas Name Signature DateDocument2 pagesRequest For Inspection: Ineco Qatargas Name Signature DateManikandan MNo ratings yet

- Request For Inspection: (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5)Document2 pagesRequest For Inspection: (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5)Manikandan MNo ratings yet

- Request For Inspection: (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P6) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5)Document1 pageRequest For Inspection: (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P6) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5)Manikandan MNo ratings yet

- Request For Inspection: Classification: InternalDocument1 pageRequest For Inspection: Classification: InternalManikandan MNo ratings yet

- Request For Inspection: (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5)Document1 pageRequest For Inspection: (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5) (P5)Manikandan MNo ratings yet

- Request For Inspection: Classification: InternalDocument4 pagesRequest For Inspection: Classification: InternalManikandan MNo ratings yet

- Coulomb's Law & Electric FieldDocument24 pagesCoulomb's Law & Electric FieldJohn RivasNo ratings yet

- Me 2351Document20 pagesMe 2351Saravanan MathiNo ratings yet

- p1200 Lecture21Document21 pagesp1200 Lecture21Crow NachorNo ratings yet

- TensionDocument9 pagesTensionnicosanquilero2No ratings yet

- Rahman 2016 (Basear)Document5 pagesRahman 2016 (Basear)annekarolinemp041193No ratings yet

- Physics 9Document14 pagesPhysics 9kissesNo ratings yet

- Continuous Surface Cap Model For Geomaterial Modeling - A New Ls-Dyna Material TypeDocument16 pagesContinuous Surface Cap Model For Geomaterial Modeling - A New Ls-Dyna Material TypeeastinentNo ratings yet

- 7 Star Academy of Science and Arts FaisalabadDocument5 pages7 Star Academy of Science and Arts FaisalabadHassan AliNo ratings yet

- Scheme: TUTORIAL 1: (Answer: 40.77kg)Document5 pagesScheme: TUTORIAL 1: (Answer: 40.77kg)Mohd AideelNo ratings yet

- IEEE Tutorial Sag Tension CalculationDocument33 pagesIEEE Tutorial Sag Tension CalculationvthiyagainNo ratings yet

- 1st Take Chem Lec MPMDocument5 pages1st Take Chem Lec MPMArabella Dela CruzNo ratings yet

- Lesson 2-1 Structural Responses in Flexible PavementsDocument32 pagesLesson 2-1 Structural Responses in Flexible PavementsTiffany NeubigNo ratings yet

- Chap2 PDFDocument9 pagesChap2 PDFAbduŕ RehmanNo ratings yet

- Wind Load Calculation For RoofDocument21 pagesWind Load Calculation For RoofSameera Lakmal100% (1)

- Rep HS ModelDocument127 pagesRep HS ModelJakub ŚwidurskiNo ratings yet

- 1st Semester WorksheetsDocument42 pages1st Semester WorksheetsMang friesNo ratings yet

- The Scholar's Academy: Long QuestionsDocument4 pagesThe Scholar's Academy: Long Questionspaggal janNo ratings yet

- Gerald Holton, F. James Rutherford, Fletcher G. Watson - Project Physics - Test Booklet 1 - Concepts of Motion PDFDocument36 pagesGerald Holton, F. James Rutherford, Fletcher G. Watson - Project Physics - Test Booklet 1 - Concepts of Motion PDFVikasNo ratings yet

- Physics I ProblemsDocument1 pagePhysics I ProblemsbosschellenNo ratings yet

- Wind Tunnel LabDocument11 pagesWind Tunnel LabshmomenyNo ratings yet

- Free Fall Sample Problem With SolutionDocument8 pagesFree Fall Sample Problem With Solutionmark jason perezNo ratings yet

- INS Error Propagation (IEEE Format)Document11 pagesINS Error Propagation (IEEE Format)SenthilKumarSNo ratings yet

- Shell Momentum Balances and Velocity Distribution in Laminar FlowDocument18 pagesShell Momentum Balances and Velocity Distribution in Laminar FlowRose Dane Escobedo DiestaNo ratings yet

- ThicknessDocument53 pagesThicknessRajul MuraliNo ratings yet

- Mec 518Document2 pagesMec 518Banu SajjaNo ratings yet

- Coupled Pendulum PDFDocument7 pagesCoupled Pendulum PDFBarneyNo ratings yet

- Question Paper Code:: Reg. No.Document4 pagesQuestion Paper Code:: Reg. No.Ameer Hakeem Primus100% (1)

- Ae2251 - Aerodynamics - IDocument3 pagesAe2251 - Aerodynamics - IMinu.j.jNo ratings yet