Professional Documents

Culture Documents

Specification Janet Fugino

Specification Janet Fugino

Uploaded by

Meeko MasangcapCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Yangon Thanlyin Bridge 4Document50 pagesYangon Thanlyin Bridge 4ကိုနေဝင်း100% (4)

- Fastener Tightening Specifications: Application Specification Metric EnglishDocument4 pagesFastener Tightening Specifications: Application Specification Metric EnglishSebastiánLeonardoGuerreroVilchesNo ratings yet

- 1.8 Anchor Systems Indd 2009Document80 pages1.8 Anchor Systems Indd 2009ihpeter100% (1)

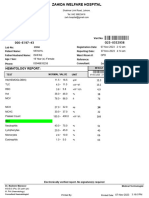

- Hematology Report:: MRN: Visit NoDocument1 pageHematology Report:: MRN: Visit Nojuniadsheikh6No ratings yet

- Avago HLCP j100, HDSP 48xxDocument7 pagesAvago HLCP j100, HDSP 48xxvelizarkoNo ratings yet

- Table MGMTDocument1 pageTable MGMTعلی احمد نعیمNo ratings yet

- Log RegDocument32 pagesLog RegSIDDHARTH KUMARNo ratings yet

- Electrical Measurements and Measuring Instruments - J. B. Gupta PDFDocument265 pagesElectrical Measurements and Measuring Instruments - J. B. Gupta PDFAnony SNo ratings yet

- Topic 5: Darkroom Conditions For Radiographic Facilities: X-Ray Facility TipsDocument3 pagesTopic 5: Darkroom Conditions For Radiographic Facilities: X-Ray Facility TipsAmrina RosyadaNo ratings yet

- LNG Easy Pvt. LTD: Pioneers of Small Scale LNG Distribution Through Virtual PipelineDocument49 pagesLNG Easy Pvt. LTD: Pioneers of Small Scale LNG Distribution Through Virtual PipelineAMIRNo ratings yet

- Tejashwini Internship ReportDocument35 pagesTejashwini Internship ReportBro FistoNo ratings yet

- SRF PresentationDocument28 pagesSRF PresentationSajeev KumarNo ratings yet

- Percussion Laser DrillingDocument1 pagePercussion Laser DrillingBefzzNo ratings yet

- Audi s6 2007 5.2l ManualDocument374 pagesAudi s6 2007 5.2l ManualMisael EspañaNo ratings yet

- ColaTeric BE 16Document2 pagesColaTeric BE 16mndmattNo ratings yet

- Group 4 Physics1Document50 pagesGroup 4 Physics1cloud kumoishNo ratings yet

- 193 Series - Hammond ChokeDocument2 pages193 Series - Hammond ChokeMario RossiNo ratings yet

- Soft Computing Module IDocument161 pagesSoft Computing Module INatarajanSubramanyamNo ratings yet

- Brown Et Al. 2009 Tribolium A Model For Developmental and Pest BiologyDocument9 pagesBrown Et Al. 2009 Tribolium A Model For Developmental and Pest BiologyAneel Nizar AliNo ratings yet

- Chemistry Practical Procedure Systematic Analysis of Salt STD: Xi & XiiDocument9 pagesChemistry Practical Procedure Systematic Analysis of Salt STD: Xi & XiivarshiniNo ratings yet

- MPD and MPK Series Midi Io Details 02Document3 pagesMPD and MPK Series Midi Io Details 02Jorge David Monroy PerezNo ratings yet

- AB 14 para Tranzystorow DarlingtonaDocument23 pagesAB 14 para Tranzystorow DarlingtonavengalamahenderNo ratings yet

- ObjectivesDocument7 pagesObjectivesPeeka booNo ratings yet

- Uae CompanyDocument22 pagesUae Companykaushal kumarNo ratings yet

- Construction Method (PICC)Document2 pagesConstruction Method (PICC)rheymar diwaNo ratings yet

- Operating Manual Parts List: 1500VMC (FANUC 0iMD)Document261 pagesOperating Manual Parts List: 1500VMC (FANUC 0iMD)apodsh100% (1)

- HP 245 G6 Notebook PC: Maintenance and Service GuideDocument106 pagesHP 245 G6 Notebook PC: Maintenance and Service GuideStevenson QuinteroNo ratings yet

- Kami Export - Text Purpose & Author ToneDocument8 pagesKami Export - Text Purpose & Author ToneIcha SawaliNo ratings yet

- Cold Agglutinin DiseaseDocument4 pagesCold Agglutinin Diseasenavneet21usNo ratings yet

- JNTUH R09 Percentage & Credits Calculator-1Document16 pagesJNTUH R09 Percentage & Credits Calculator-1msg2dpNo ratings yet

Specification Janet Fugino

Specification Janet Fugino

Uploaded by

Meeko MasangcapCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specification Janet Fugino

Specification Janet Fugino

Uploaded by

Meeko MasangcapCopyright:

Available Formats

GENERAL SPECIFICATONS

Project : PROPOSED THREE STOREY RESIDENCE

Location : DAAN PARI, ORION BATAAN

Owner : MS. JANET PERNITO FUJINO

Prepared by:

Joseph Lideson D. Mallari

Architect

PRC Reg. Number : 0024396

TIN Number : 256-640-452

PTR Number : 2686340

Issued on : January 22, 2019

Issued at : City of San Fernando, Pampanga

Conformed by:

_____________________________

MS. JANET PERNITO FUJINO

JOSEPH LIDESON D. MALLARI

ARCHITECTPRC NO: 0024396GLOBE CP NO: 09759071260 1

Owner

GENERAL TECHINICAL SPECIFICATIONS

I. GENERAL REQUIREMENTS

1.0 GENERAL PARAGRAPHS

1.1GENERAL INTENTION

It is declared and acknowledges intentions and meaning to provide the “Proposed Two Storey Four

Bedroom Residence” to be located at Blk 60, Lot 30, Kristo Rey Navy, CapazTarlaccomplete as

indicated in the scope of work and ready for use. Design and construction shall be based on

Philippine standards, including the latest edition of the National Building Codes.

1.2 GENERAL DESCRIPTION OF WORK

The work includes the following:

1.2.1 The Contractor shall have site investigation and inspection of the area in order to familiarize

him the extent, condition, and nature of the work involved.

1.3 OFF-SITE WORKS

1.3.1 Utilities- extend all utilities to within properly line of project.

1.4 ON SITE WORKS

1.4.1 Demolition

1.5 FINISH GRADING

1.5.1 Grade site to confirm to existing adjacent grade and provide positive drainage away from the

building.

1.6 DRAINAGE

As required for surface drainage, underground drainage to be constructed as determined by Civil

Engineer/ Architect/ Sanitary Engineer.

2.0 SCHEDULE OF FINISHES

2.1 SITE DEVELOPMENT AREA

Driveway, Walkways, Service Area – Plain Cement Finish

Landscapes – (By Owner)

Fences – (By Owner)

2.2 BUILDING AREAS

2.2.1 FLOOR AREAS

Garage – Slab on fill with plain cement finish.

Porch & Lanai – plain cement finish.

Living, Dining & Kitchen – Mariwasa tiles (or approved equal).

Toilet, Kitchen, Under Counter, Laundry Counter – unglazed tiles (or approved equal).

Kitchen Counter – Glazed tiles (or approved equal).

Bedrooms – Glazed tiles (or approved equal).

Hallway/Stairs – Plain Cement Finish, for wood steps use 2” x 10” wood pranks (owner’s copy).

2.2.2 CEILING FINISHES

Bedrooms, Family room. Living, Dining, Kitchen, & Garage – Plain skin coat finish and painted. For

bedrooms use 6mm thick fiber cement on metal furring, painted.

Toilet, Maid’s room, Service Area, & Exterior – Use 4.7mm thick fiber cement on metal furring,

painted.

JOSEPH LIDESON D. MALLARI

ARCHITECTPRC NO: 0024396GLOBE CP NO: 09759071260 2

2.2.3 WALL FINISHES

a. Interior walls – CHB cement plaster finish painted;

Bedrooms – plain paints finish

Living, Dining, & Kitchen – plain paint finishes

Toilets – Glazed tiles (or approved equal)

Others – Plain cement finish

b. Exteriors walls – CHB cement plaster finish with grooves and patter, painted (or approved

equal).

c. Others – Wall and Columns, plain cement painted.

2.2.4 ROOFING

a. Pre-Painted Roofing – shall be “LONG SPAN ROOF (or approved equal)”

II. SITE WORK

1.0 EARTHWORKS

1.1All excavation shall be unclassified and includes clay, silt, sand, gravel, hard span loose stone in

masses and any other materials of any character found within the excavation area.

1.2 Use Hometreksoil poisoning products by Pro-active termite protection

1.3 Any proofing (by owner’s option).

2.0 EXTERIOR SANITARY SEWER

NELTEX to MOLDEX product PVC pipes shall be free from pinpoint holes and any other imperfection that

may cause leakage joint shall be applied with NELTEX/ MOLDEX PVC Sealant. Heavy duty drainage and

sewer shall be provided with “O” ring type.

3.0 WATER SERVICE SYSTEM

Provide MOLDEX PRR Cold water system pipe for toilets, shower lines, & all other water lines that are

indicated in plans.

4.0 STORM DRAINAGE SYSTEM

Drainage piping was required to be 150mmØ and 200mmØ PVC pipes as per indication on plans.

5.0 REMOVAL AND DISPOSAL

Conduct site investigation. Remove all materials which are not part of the finish product of the project.

III. CONCRETE

1.0 CAST-IN-PLACE CONCRETE

1.1 Structural systems, unless otherwise as per Structural Engineer’s Recommendation and

Specification indicated in plans, shall govern.

1.2 FOOTINGS - Concrete Foundation shall be as per Structural Designer Details, FC= 3000 psi.

1.3 Slabs on Fill- 5’’ thick, concrete slab on grade FC= 2500 psi.

1.4 Reinforcing - ASTM A615, #4 bars and smaller Grade 40 UNO, #5 bars and larger Grade 60.

Grade 40 for all bars requiring welding as per structural design computation and recommendations.

1.5 Wall Framing- Poured in place reinforced concrete columns, beams and slabs.

1.6 Roof Framing - Poured in place reinforced concrete at typical flat roof, RC Roof beams, steel frames

at slopped metal roofs.

2.0 STRENGTH REQUIREMENTS

Concrete on the various classes, if not indicated in the drawings and as specified under other sections,

shall be proportioned and mixed for the following strength;

MIXTURE Proportion Cement in Bag Sand Gravel

CLASS 40 kg. 50kg. (in m 3 ) (in m 3 )

Class AA 1 : 1½ : 3 12.0 9.5 0.50 1.0

Class A 1:2:4 9.0 7.0 0.50 1.0

Class B 1 : 2½ : 5 7.5 6.0 0.50 1.0

Class C 1:3:6 6.0 5.0 0.50 1.0

JOSEPH LIDESON D. MALLARI

ARCHITECTPRC NO: 0024396GLOBE CP NO: 09759071260 3

3.0 CONCRETE USAGE

Concrete of the various classes shall be used as follows:

3.1 Class “AA” Concrete - for pre- cast concrete items, suspended slabs, beams, columns footings, stairs,

lintels, and for all reinforced workout otherwise indicated or specified.

3.2 Class “A” Concrete - for slab on grade and tie beams and for such concrete work as indicated or

specified and walls above grade.

3.3 Class “B” Concrete - for all concrete not reinforce except as otherwise indicated or specified.

3.4 Class “C” concrete- for path walks and other as specified.

4.0 PROPORTIONING, MEASUREMENT AMD MIXING

Concrete mixes except otherwise indicated shall be designed by the contractor. The proportion shall be

changed whenever necessary to maintain the workability, strength, and standard of quality for the

concrete covered by these specifications and to meet the varying weight shall be performed under the

supervision of the construction architect/Engineer.

IV. MASONRY

1.0 CONCRETE MASONARY UNIT WORK

1.1 5” and 4” CHB, 450psi, for walls as indicated. For all exterior walls and for walls required to have

pipes, use 5” thick 450psi.

V. METALS

1.0 MISCELLANEOUS METALS STEEL GATE

1.1 Use 1 ½ GI pipe, 1”x1”, 3/4” x ½”, ½” x ½”, 1/4” x ¾” thick flat bars for decorative bars for framing

and accent frames. Provide rust proofing before final painting coats. (by option)

2.0 STRUCTURAL STEEL WORKS

2.1 Steel frame for main rafters, purling and framing as per structural specifications, details and sizes

fabricated by reputable fabricator.

a. Structural carbon steel for welded or bolted work shall conform to ASTM A36.

b. Structural tubing bolted or welded work shall conform to ASTM A500 or A501.

c. Other steel metal frame as agreed upon as per approved manufacturing specs.

VI. WOOD AND PLASTIC

1.0 CARPENTRY AND JOINERY

Lumbers shall be approved of quality, free from big loose knots and any other imperfections that may

affect its appearance and may impair its strength and durability. Use Kiln dried wood requirements.

2.0 The following kinds of lumber shall be used:

2.1 Apitong (or approved equal)- for all wood nails and studs

2.2 Tanguille KD (or approved equal)- for all cabinet frame

2.3 Guijo (or approved equal)- for all wood jambs and trellis

VII. MOISTURE CONTROL

1.0 ELASTOMERIC WATER PROOFING

Canopies/ Balconies, 2nd floor comfort room and roof deck where indicated shall be provided with

waterproofing. Us elastomeric waterproofing (or approved equal).

2.0 CAULKING AND SEALING

2.1Primer shall be clear based from chlorinated rubber and applied prior to application of sealant.

JOSEPH LIDESON D. MALLARI

ARCHITECTPRC NO: 0024396GLOBE CP NO: 09759071260 4

2.2 Caulking compound for joints in wood, concrete and masonry shall be acrylic elastomeric or one to

two component silicon rubbers.

2.3 Caulking or sealing compound for perimeter sealing for windows and door frames shall be single or

two component silicon or two component polysulfide types.

2.4 Backstop shall be rubber, or closed cell neoprene, butyl, polyurethane, vinyl or polyethylene foams

free from oil or other staining elements. Oakum or other types of absorptive materials shall not be

used as backstops.

2.5 Color caulking compound shall be white, gray or aluminum.

3.0 LONG SPAN PRE-PAINTED AND INSULATED

Long-span pre-painted roofing by APO Steel Products “twin ribs type (or approved equal)” shall be used

in roofing materials #26, on metal purlins, other accessories like GI gutter, ridge roll, flushing be #24.

Details and connection on steel metal framings shall be based on plans and details design by Structural

Engineer or as per manufacturer specs.

VIII. DOORS, WINDOWS AND GLASS

1.0 WOOD DOORS

1.1 Tanguile panel door (or approved equal) - shall be plain paint finish.

1.2 Door jambs shall be Guijo or Yakal (or approved equal) paint finish.

2.0 GLASS AND GLAZING

2.1 ¼” fog glass and glazing (or approved equal).

3.0 PVC DOORS,WINDOWS AND FRAMES

4.0 BUILDERS’ HARDWARE

4.1 “YALE (or approved equal)” door locksets, for interior and exterior doors.

4.2 “STANLEY (or approved equal) stainless butt hinges, 3 ½”x 3 ½”, loose pin types, 3 pieces for flush

type door and 4 set for exterior and panel doors.

4.3 Steel pre-fabricated hinges for steel frame gate. (By Option).

4.4 Dead bolt lockset gate. (By Option).

5.0 STEEL GATE (By Option)

5.1Provide 2”x4” tubular gate frame and ¼” x 1” decorative flat bars and 5/8” square bar framing bars and

#18 GI sheet. Provide pre-fabricated bearing hinges.

IX. FINISHES

1.0 PLASTERING

All interior and exterior walls shall be cement plastered, except as indicated.

2.0 FIELD PAINTING

2.1 Two (2) top coats finish of water based paints for concrete and masonry surfaces. Before any

painting is done, all cracks, nail holes and other imperfections shall be carefully applied with putty,

properly evened and sanded and allowed to dry thoroughly before painting.

2.2 All exterior wood work shall be applied to two coats of enamel paints of semi-gloss.

2.3 Apply metal rust proofing and metal surfaces prior to painting of polyurethane paint coats (2 coats).

2.4 A color scheme for the general painting works shall be provided by the civil Engineer/ Architect prior

to application sample of this color and paints shall be approved by the Architect/ Civil Engineer.

2.5 Interior Walls- masonry textured and plain paint semi-gloss finish (acrylic solvent type), as per

location schedule.

2.6 Interior Ceiling- semi-gloss (alkyd type) painting finish for ceiling.

2.7 Exterior Wall- paint finishes semi-gloss as per location schedule.

3.0 CERAMIC TILE WORK

600mm x 600mm glazed and unglazed tiles for toilets and shower walls and floorings. (or approved

equal)

JOSEPH LIDESON D. MALLARI

ARCHITECTPRC NO: 0024396GLOBE CP NO: 09759071260 5

X. SPECIALTIES

1.0 TOILET AND BATH ACCESSORIES (By Owner)

XI. MECHANICAL

1.0 PLUMBING SYSTEMS

1.1 Leakage. Joints shall be applied with sealant recommended by the manufacturer.

1.2 All PVC pipes shall be of Crown Products Pipe brand (or approved equal) standard PVC pipes

schedule 40. They shall be set squarely and perpendicularly to the walls of the building all joints shall

be carefully done to ensure water tightness. All water supply line of each group of fixtures shall equip

with individual gate valves.

1.3 Storm drainage system shall be PVC pipes and carefully sealed at joints with PVC adhesive as per

plan.

1.4 Floor drain – 4”x4” stainless steel or bronze.

1.5 Faucet/ Hose bib- by great volume as per indicated in plans.

1.6 Sanitary sewage lines shall be conveyed to the drainage line, sizes and locations as shown on

plans.

1.7 Drainage Pipes- 100mmØ lines shall be PVC Crown Products Pipes (or approved equal). All lines

above 100mmØ PVC shall be concrete drain pipes or 150mmØ or 200mmØ special drainage pipes

as per plan design by Sanitary Design.

2.0 AIR CONDITION SYSTEM AND VENTILATING SYSTEM (By Owner)

3.0 FIRE PROTECTION SYSTEM

3.1 Fire protection system conforming to the requirements of the national fire protection association and

local authorities.

3.2 Provide fire extinguisher as per area required. (By Owner)

XII. ELECTRICAL SYSTEM AND WORKS

1.0 ELECTRICAL WIRING AND FIXTURES

1.1 Concealed Underground Pipes - PVC schedule 40 (rigid) by NELTEX/ MOLDEX product pipes as

shown on the plans.

1.2 Pipes in ceiling and walls - PVC flex-conduits and ducts manufactured by NELTEX/MOLDEX

products pipes.

1.3 Wires and Cables- shall be 98% conductivity and 1% below or above the size called or

manufactured be PHILFLEX or approved equal.

1.4 Circuit Breaker - shall be NEMA standard molded case manufactured by KOTEN Electrical products

or approved equal.

1.5 Switches - (by KOTEN 230v or approved equal)

1.6 Convenience Outlet - (T-slot 15A, 230V by KOTEN or approved equal)

1.7 Plate - (by KOTEN type and color to be approved by the Civil Engineer/Owner or approved equal)

1.8 Boxes - shall be PVC schedule 40 NELTEX/MOLDEX products.

2.0 POWER SYSTEM

2.1 Entire electrical installation shall comply with the latest National Building Code, National Electrical

Code and requirements of all authorities having jurisdiction.

2.2 A local available operating system shall be provided from an exterior pad munt transformer. (serving

voltage shall be confirmed with local utility)

3.0 LIGHTINGS

3.1 All lighting fixtures shall approve by Underwriters Laboratories, supplies by Firefly, KOTEN or

approved equal.

3.2 Facade and Exterior areas shall be illuminated with decorative walls up lighting or down lighting.

3.3 Service space shall be illuminated with fluorescent or pin lights lighting fixtures.

JOSEPH LIDESON D. MALLARI

ARCHITECTPRC NO: 0024396GLOBE CP NO: 09759071260 6

4.0 CONVENIENCE OUTLETS

4.1 All spaces, shall have a receptacles placed to accommodate furnishing.

4.2 Exterior wall receptacles shall be connected to a separate circuit with cover and weather proof.

4.3 Duplex receptacles shall 220V, (110V shall be as per local Electric Company) existing regulated

supply.

4.4 Air Con, Vent, and Exhaust outlet shall be provided as per design capacity.

5.0 TELEPHONE SYSTEM

5.1 Provide terminal cabinets, outlet boxes, plaster rings, pull wires and conduits for service and

distribution by Local Telephone Authority.

6.0 TELEVISON CABLE SYSTEM

6.1 Provide system for distribution of TV outlet boxes.

7.0 ELECTRICAL WIRING FIXTURES

7.1 Rigid solid metal conduit for service entrance.

7.2 Crown products pipes concealed PVC for wiring installation in concrete and masonry walls and flexi

pipe wooden partitions and ceiling.

7.3 KOTEN flushed duplex type for convenience outlets.

7.4 Flushed type wall switches and plates.

7.5 KOTEN Plate type and color shall be properly set as approved by the Architect.

7.6 All electrical fixtures location shall be properly installed and located at the side with proper height

allocation.

7.7 Provide conduit and wiring for motor outlet, TV and antenna, telephone outlet and intercom.

7.8 Circuit Breaker - shall be NEMA standard molded case manufactured by KOTEN Electrical products

or approved equal.

7.9 Wires and Cables - shall be 98% conductivity and 1% below or above the size called or

manufactured be PHILFLEX or approved equal.

7.10 Wires and Cables - shall be 98% conductivity and 1% below or above the size called or

manufactured be PHILFLEX or approved equal.

7.11 Panel boards and Circuit Breakers shall be NEMA standard molded case manufactured be GE or

WESTINGHOUSE (or approved equal). All protective devices shall meet NEMA and UL

Specification.

7.12 Parabolic Louvers fixtures and Optical Reflector lighting fixtures with fluorescent lamps.

Signed and sealed by:

Joseph Lideson D. Mallari

Architect

PRC Reg. Number : 0024396 PTR Number : 2686340on January 22, 2019

TIN Number : 256-640-452 @ City of San Fernando, Pampanga

JOSEPH LIDESON D. MALLARI

ARCHITECTPRC NO: 0024396GLOBE CP NO: 09759071260 7

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Yangon Thanlyin Bridge 4Document50 pagesYangon Thanlyin Bridge 4ကိုနေဝင်း100% (4)

- Fastener Tightening Specifications: Application Specification Metric EnglishDocument4 pagesFastener Tightening Specifications: Application Specification Metric EnglishSebastiánLeonardoGuerreroVilchesNo ratings yet

- 1.8 Anchor Systems Indd 2009Document80 pages1.8 Anchor Systems Indd 2009ihpeter100% (1)

- Hematology Report:: MRN: Visit NoDocument1 pageHematology Report:: MRN: Visit Nojuniadsheikh6No ratings yet

- Avago HLCP j100, HDSP 48xxDocument7 pagesAvago HLCP j100, HDSP 48xxvelizarkoNo ratings yet

- Table MGMTDocument1 pageTable MGMTعلی احمد نعیمNo ratings yet

- Log RegDocument32 pagesLog RegSIDDHARTH KUMARNo ratings yet

- Electrical Measurements and Measuring Instruments - J. B. Gupta PDFDocument265 pagesElectrical Measurements and Measuring Instruments - J. B. Gupta PDFAnony SNo ratings yet

- Topic 5: Darkroom Conditions For Radiographic Facilities: X-Ray Facility TipsDocument3 pagesTopic 5: Darkroom Conditions For Radiographic Facilities: X-Ray Facility TipsAmrina RosyadaNo ratings yet

- LNG Easy Pvt. LTD: Pioneers of Small Scale LNG Distribution Through Virtual PipelineDocument49 pagesLNG Easy Pvt. LTD: Pioneers of Small Scale LNG Distribution Through Virtual PipelineAMIRNo ratings yet

- Tejashwini Internship ReportDocument35 pagesTejashwini Internship ReportBro FistoNo ratings yet

- SRF PresentationDocument28 pagesSRF PresentationSajeev KumarNo ratings yet

- Percussion Laser DrillingDocument1 pagePercussion Laser DrillingBefzzNo ratings yet

- Audi s6 2007 5.2l ManualDocument374 pagesAudi s6 2007 5.2l ManualMisael EspañaNo ratings yet

- ColaTeric BE 16Document2 pagesColaTeric BE 16mndmattNo ratings yet

- Group 4 Physics1Document50 pagesGroup 4 Physics1cloud kumoishNo ratings yet

- 193 Series - Hammond ChokeDocument2 pages193 Series - Hammond ChokeMario RossiNo ratings yet

- Soft Computing Module IDocument161 pagesSoft Computing Module INatarajanSubramanyamNo ratings yet

- Brown Et Al. 2009 Tribolium A Model For Developmental and Pest BiologyDocument9 pagesBrown Et Al. 2009 Tribolium A Model For Developmental and Pest BiologyAneel Nizar AliNo ratings yet

- Chemistry Practical Procedure Systematic Analysis of Salt STD: Xi & XiiDocument9 pagesChemistry Practical Procedure Systematic Analysis of Salt STD: Xi & XiivarshiniNo ratings yet

- MPD and MPK Series Midi Io Details 02Document3 pagesMPD and MPK Series Midi Io Details 02Jorge David Monroy PerezNo ratings yet

- AB 14 para Tranzystorow DarlingtonaDocument23 pagesAB 14 para Tranzystorow DarlingtonavengalamahenderNo ratings yet

- ObjectivesDocument7 pagesObjectivesPeeka booNo ratings yet

- Uae CompanyDocument22 pagesUae Companykaushal kumarNo ratings yet

- Construction Method (PICC)Document2 pagesConstruction Method (PICC)rheymar diwaNo ratings yet

- Operating Manual Parts List: 1500VMC (FANUC 0iMD)Document261 pagesOperating Manual Parts List: 1500VMC (FANUC 0iMD)apodsh100% (1)

- HP 245 G6 Notebook PC: Maintenance and Service GuideDocument106 pagesHP 245 G6 Notebook PC: Maintenance and Service GuideStevenson QuinteroNo ratings yet

- Kami Export - Text Purpose & Author ToneDocument8 pagesKami Export - Text Purpose & Author ToneIcha SawaliNo ratings yet

- Cold Agglutinin DiseaseDocument4 pagesCold Agglutinin Diseasenavneet21usNo ratings yet

- JNTUH R09 Percentage & Credits Calculator-1Document16 pagesJNTUH R09 Percentage & Credits Calculator-1msg2dpNo ratings yet